Professional Documents

Culture Documents

How To Bring Existing Ammonia Plants Up-to-Date: Svend Erik Nielsen

How To Bring Existing Ammonia Plants Up-to-Date: Svend Erik Nielsen

Uploaded by

Alfonso BlancoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Bring Existing Ammonia Plants Up-to-Date: Svend Erik Nielsen

How To Bring Existing Ammonia Plants Up-to-Date: Svend Erik Nielsen

Uploaded by

Alfonso BlancoCopyright:

Available Formats

How to Bring Existing Ammonia

Plants Up-to-Date

Many existing ammonia plants located in areas with high feedstock prices are facing difficulties in today’s

more and more competitive market. In order to survive the competition from new plants coming up in areas

with low gas cost, existing plant owners can revamp their plants to reduce the energy consumption and/or

increase the plant capacity. Capacity revamps often offer a lower cost option to meet increased demand.

This paper will highlight a preferred approach to a revamp project and list a number of revamp features

available for bringing existing ammonia plants up-to-date. Following this a number of revamp projects cur-

rently under implementation will be described. Finally, a novel revamp option, the proprietary and patented

Haldor Topsøe Exchange Reformer (HTER), and the benefits by installing the same will be presented. The

HTER can be applied in existing plants, or may be included in the design of new plants. It offers, when in-

stalled in parallel with an existing reforming unit, the potential for increasing the capacity by up to 25% or

more depending upon specific plant configuration.

Svend Erik Nielsen

Haldor Topsøe A/S, Lyngby, Denmark

Peter Vang Christensen

Haldor Topsøe A/S, Lyngby, Denmark

Introduction with a lower investment compared to erect-

ing new facilities. Furthermore, local infra-

The increasing demand for ammonia and fertil- structure is available and can be utilised.

isers is widely discussed and well documented. The

world population is constantly growing and the fertil- If the plant owner consider revamping an existing

iser consumption increases by 2-3% every year. plant it is our experience that the best way to structure a

The increasing demands can in principle be satis- revamp project is to divide the project into a study

fied by a number of actions such as: phase followed by an engineering and implementation

phase provided that the scheme identified in the study is

• Construct new production facilities at loca- attractive to the plant owner.

tions where natural gas is cheap, and trans- The target of the study phase is to establish the

port the products to the consumers. most attractive revamp scheme in accordance with the

• Revamp existing production facilities for objective of the project together with a cost estimate for

increased capacity as required in order to the implementation of the project. Thus, the main pur-

satisfy the increased demand locally. This pose of the study is to establish a solid basis for the

additional capacity can often be achieved

AMMONIA TECHNICAL MANUAL 168 2004

plant owner to evaluate the attractiveness of the revamp by installing new internals or by adding

project at a minimum cost. new converter(s)

Which specific revamp features to consider in the • Changing make-up gas addition point by

study phase of the revamp project will have to be using a make-up drying unit or alterna-

evaluated on a case to case basis depending on the ob- tively an ammonia washing unit

jective and the specific conditions prevailing. Below are • Introduction of purge gas recovery unit

listed a number of the current revamp features which • Modification/replacement of rotating ma-

can be considered when establishing the best possible chinery to add more capacity or to reduce

revamp scheme: energy consumption

• Upgrading of feed purification and desul- The most often used features are introduction of

phurization section prereformer, installation of additional ammonia con-

• Installation of feed gas saturator verter capacity, new reformer tubes and reduction of

• Upgrading of mixed feed preheater and in- S/C ratio. However, the choice beween the above op-

let header system to increase reformer inlet tions must of course be made during the study phase on

temperature the basis of a careful analysis of the specific situation,

• Reduction of the steam to carbon ratio in keeping in mind that an attractive revamp concept will

the reformer, taking advantage of new be characterised by:

high-activity reforming catalysts

• Change of reformer catalyst tubes with • Low investment cost per additional ton of

thinner wall tubes made from new, ammonia product

stronger alloys • Low operating costs

• Introduction of combustion air preheat • Short implementation time

• Installation of adiabatic prereformer • Minimum interference with the existing in-

• Installation of a “heated prereformer”, a stallation

heat exchange reformer heated by either

flue gas or by process gas The above approach to a revamp project has been

• Installation of an add-on convection re- applied in connection with a number of revamp projects

forming unit (e.g. the Topsøe HTCR de- currently under implementation for a plant owner in In-

sign) with associated waste heat recovery dia. In the following we will list the selected revamp

in parallel with the existing reformer options and describe one of the revamp features to be

• Installation of a primary reformer with as- implemented in more detail. Following this we will

sociated waste heat recovery in parallel demonstrate that the list of available revamp options is

with the existing reformer constantly being extended by the development of new

• Introduction of new high-activity shift technology features. In this respect a novel and attrac-

catalysts and re-configuration of shift sec- tive revamp feature which is of particular interest when

tion by e.g. introduction of a LT shift the reforming capacity of an existing plant is a bottle-

guard reactor neck will be presented.

• Modification of shift reactor outlet system

to reduce pressure drop

• Upgrade of CO2 removal unit to boost ca- Revamp Projects Currently under

pacity or reduce energy consumption by Implementation

introducing improved packing materials

and/or by adding additional flash stages In India, for a significant period of time, gas short-

• Modifications/additions of coils in the re- age has presented significant restrictions to the ammo-

former waste heat section nia producers. Many plants changed their feedstock

• Replacement/addition of heat exchangers from natural gas to naphtha and some plants have even

to handle revised operating conditions been designed for mixed feed operation. These days,

• Addition of more ammonia synthesis ca- LNG is becoming available in India. In view of this,

pacity by modifying the existing converter many plant owners consider revamping their plants to

be able to operate on LNG and at the same time to re-

2004 169 AMMONIA TECHNICAL MANUAL

duce the specific energy consumption to the lowest pos- • Introduction of LT shift guard

sible level, with reasonable investment cost. • New outlet systems from HT, LT shifts

One of the major fertiliser producers in India, and methanator in Kellogg designed plants

IFFCO (Indian Farmers and Fertilisers Cooperative) has • Revamp of the oldest CO2 removal units to

decided to revamp all their ammonia plants to be able to two stage Giammarco Vetrocoke/aMDEA

meet the future Indian fertiliser scenario and is cur- with two-stage flash

rently implementing energy saving revamp projects in • Introduction of make-up gas chilling

their 5 ammonia plants. The five plants are: • Retrofit of synthesis gas compressor train

• New make-up gas point along with ammo-

• Kalol, natural gas-based plant started up in nia wash unit in Kellogg designed plants

1975 designed by Kellogg • Introduction of radial flow S-50 converter

• Phulpur I, naphtha-based plant started up and new waste heat boiler

in 1980 designed by Kellogg

• Aonla I, natural gas-based plant started up The achievable energy savings by implementing the

in 1988 designed by Topsøe revamp schemes in the five ammonia plants vary be-

• Aonla II, mixed feed-based plant started up tween 0.3 – 0.9 Gcal/MT NH3 (1.3 – 3.9 MMBtu/ST

in 1996 designed by Topsøe NH3). Considering that the introduction of the S-50

• Phulpur II, naphtha-based plant started up converter is the revamp feature that accounts for the

in 1997 designed by Topsøe highest contribution to the overall energy savings, this

feature will be described in more detail in the follow-

The revamp schemes that will be implemented in ing.

each of the five ammonia plants was developed during

the study phase of the project where various alternative

features were considered before arriving at the most at- S-50 Converter – M.W. Kellogg Plants

tractive schemes. Considering that the plants are of dif-

ferent designs and of very different vintage the revamp In Kellogg plants, the ammonia synthesis loop con-

features that were evaluated during the study phase was tains an existing ammonia converter unit with

carefully considered in each specific case. built-in feed/effluent exchanger. From the existing

As part of the study work a cost estimate was de- converter, the exit gas is sent direct to the new S-50

veloped in order to provide the plant owner with a solid

converter at a temperature of approx. 325° (617°F).

basis for deciding if implementing the schemes would

be an attractive investment.

After the S-50 converter a new MP steam boiler is

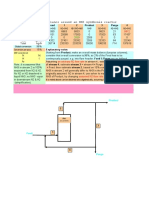

A number of revamp features that will be imple- introduced. See Fig 1.

mented in the five ammonia plants are listed below (not As the inlet temperature to the S-50 converter

all features will be implemented in all of the plants): is lower than the required inlet temperature to the

catalyst bed, an S-50 converter with a lower heat

• Final desulphurisation section to handle exchanger is applied in the Kellogg plants.

the new feedstock

• New coils in cold end of reformer waste

heat section

AMMONIA TECHNICAL MANUAL 170 2004

Purge

Gas

BFW

Preheater

New MP CW NH (l) NH (l) NH (l)

Steam Boiler 3 3 3

Ammonia

Product

Figure 1: Lay-out of Synthesis Loop in M.W. Kellogg-designed Plant with S-50 Converter

The S-50 converter consists of a full closure pres- passed the shell side of the heat exchanger, and the

sure vessel and a converter basket. The converter basket mixed gas stream passes to the top of the converter

consists of a catalyst bed and a feed/effluent heat ex- through the transfer pipe located in the centre of the

changer (lower heat exchanger). See Fig 2 for details. catalyst bed. The amount of cold shot gas determines

The main part of the gas is introduced into the con- the inlet temperature to the catalyst bed.

verter through the main inlet in the top of the converter At the top of the converter the gas passes to the

(A) and passes downwards through the outer annulus inlet panels of the catalyst bed. It passes the catalyst

between the basket and the pressure shell, keeping the bed in radial inward direction and flows to the annulus

latter cooled. It passes to the shell side of the feed- between the bed and the central transfer pipe.

effluent exchanger, where it is heated to reaction tem- The effluent from the catalyst bed passes the tube

perature by heat exchange with the converter effluent side of the heat exchanger, thereby heating the feed gas

leaving the catalyst bed. to the reaction temperature, and flows to the converter

The remaining part of the gas, the cold shot gas, is outlet (C).

introduced through the inlet in the bottom of the con-

verter (B). It mixes with the main inlet gas having

2004 171 AMMONIA TECHNICAL MANUAL

fore the gas enters the S-50 converter at approx. 370°C

(698°F). See Fig 3 for details.

S-200 S-50

Converter Converter

Purge Gas

NH3 (l)

Preheater

BFW CW

Boiler NH3 (l) NH3 (l)

Product

Ammonia

Make-up Gas

Figure 3: Lay-out of Synthesis Loop in a Topsøe-

designed Plant with S-50 Converter

In the Topsøe designed plants, the S-50 converter is

designed as a hot wall radial flow converter (further de-

tails on the hot wall design are provided in [1]). The

converter lay-out is shown in Fig 4.

In this case, the S-50 converter has no lower heat

exchanger and the optimum inlet temperature to the

ammonia converter is achieved by cooling the effluent

from the first ammonia converter in the intermediate

HP steam boiler. The inlet temperature to the S-50 con-

verter is controlled by means of a by-pass around the

HP steam boiler.

The actual energy saving achieved by installing an

S-50 converter depends upon the lay-out of the synthe-

sis loop, but varies in the IFFCO cases between 0.15 –

0.30 Gcal/MT NH3 (0.65 – 1.30 MMBtu/ST). With the

high feedstock cost in India, this gives very attractive

payback times ranging from 1.5 – 3 years.

The revamp projects in IFFCO’s five ammonia

plants are implemented in a phased manner, and all the

revamp options will be installed from now and up to

3rd quarter 2005.

As stated previously the main objective in the re-

vamp projects for IFFCO has been to reduce the spe-

Figure 2: S-50 Converter with Lower Heat Ex- cific energy consumption, and the revamp options

changer evaluated in this connection has therefore been with the

target to meet this objective.

S-50 Converter – Topsøe Plants

The ammonia synthesis loop in the Topsøe-

designed plants contains an existing converter without a

built-in feed/effluent exchanger. From the existing con-

verter, the exit gas is sent to a new HP steam boiler be-

AMMONIA TECHNICAL MANUAL 172 2004

However, very often the plant owner has the main

objective to increase the capacity of the plant. In this

connection it will be relevant to evaluate how to in-

crease the capacity of the existing reforming section in

the most attractive way. In the following a new revamp

feature addressing this issue will be presented.

Revamp by Installation of HTER

When significant capacity increase is desired, the

traditional revamp options may be insufficient

because bottlenecks in existing equipment, espe-

cially in the reforming section, restrict a possible in-

crease in production capacity. In such cases the pre-

ferred solution was the introduction of a prereformer [2]

to reduce the load on the primary reformer. In other

cases it has been necessary to construct a new primary

reformer in parallel to the existing one. In addition to

these options, Topsøe offers a new revamp option – in-

stallation of a newly developed proprietary and pat-

ented Haldor Topsøe Exchange Reformer (HTER) in

parallel with the existing reformer. This revamp feature

caters for significant capacity increase, and may repre-

sent an attractive solution especially in cases where the

existing reformer or the steam generation system is a

bottleneck.

This new revamp option will be described in the

following. The basis will be a typical ammonia plant

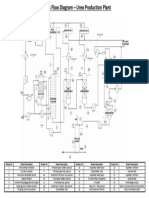

with a lay-out as illustrated in Fig 5.

Figure 4: Hot Wall Radial Flow S-50 Converter

2004 173 AMMONIA TECHNICAL MANUAL

Desulphurization Reforming Shift

Natural Gas

Process Air

Flue Gas

Purge Gas

CO2- CO2

Removal

Ammonia Process

Product Condensate

Ammonia Synthesis Methanation

Figure 5: Typical Lay-out of an Ammonia Plant

The HTER is a newly developed proprietary heat HTER concept for revamps of hydrogen plants may be

exchange reformer design, which offers a compact and found in [3].

cost-effective increase of the reforming capacity when The installation of a HTER in parallel with the

installed in parallel with an existing steam reformer reforming section in a typical ammonia plant is illus-

(SMR). A description of the trated in Fig 6.

Secondary HTER

Reformer

Process

Steam

Desulp.

Natural

Gas

Process Air

Figure 6: Revamp of an Ammonia Plant by installation of HTER in Parallel with SMR

AMMONIA TECHNICAL MANUAL 174 2004

The HTER is installed in parallel with the SMR and change to the reforming reaction in the HTER, be-

fed independently with desulphurized feed mixed with fore it passes to waste heat recovery and further proc-

steam. This allows for individual adjustment of the essing.

feedstocks, e.g. the steam to carbon ratio, to obtain a The operating conditions before and after revamp

desired conversion. The outlet gas from the existing by installation of a HTER in an ammonia plant are

secondary reformer is transferred to the HTER and summarised in Table 1 and compared with the installa-

mixed internally with the product gas from the catalyst tion of a prereformer and a fired

bed installed in the HTER. The mixed gas is then sup- heater.

plying heat by heat ex

Before After After

Revamp Revamp Revamp

Prereformer HTER

NH3 Production, MTPD 1,500 1,650 1,650

(STPD) (1,654) (1,819) (1,819)

SMR Duty, Gcal/h 78.5 71.2 72.9

(MMBtu/h) (311.5) (282.5) (289.3)

NG Consumption for Feed and Fuel, 57,786 61,683 59,532

Nm3/h (MMSCFD) (2.15) (2.30) (2.21)

HP Steam Prod. (110 kg/cm2g, 510°C), MT/h 283 284 267

(ST/h) (312) (313) (294)

Steam Export (44 kg/cm2g, 390°C), MT/h 91 66 33

(ST/h) (100) (73) (36)

Outlet Temperature SMR, °C 820 816 801

(°F) (1,508) (1,501) (1,474)

Relative Flow through Reformer 1.00 1.10 0.99

Table 1: Operating Conditions Before and After Revamp by Installation of Prereformer or HTER

The operating conditions are unchanged for the normally used for steam production. Furthermore, due

SMR after the revamp with respect to steam to carbon to the parallel operation, the pressure drop across the

ratio. Since the duty of the reformer is slightly reduced, reforming unit is minimised.

the amount of waste heat available from the flue gas is In most cases, the steam production lost in the proc-

reduced. This in combination with the fact that the natu- ess unit after the revamp can be substituted by steam

ral gas preheat duty along with the process air preheat production in already existing installations, e.g. by util-

duty is increased more or less proportionally to the ca- ising idle capacity in auxiliary boilers. In other cases,

pacity increase, gives certain modified operating condi- especially in cases with very large capacity increase, it

tions in the existing flue gas waste heat section and the may be necessary to install additional steam generating

revised operating conditions have been taken into ac- capacity. In both situations, additional steam production

count. can often be made with cheaper fuel than the fuel nor-

Compared to a revamp including a prereformer, the mally used in the tubular reformer.

inclusion of a HTER offers certain benefits.

Using the HTER, which operates in parallel to the

existing primary reformer, both the load on the combus-

tion side as well as the process side of the primary re-

former are reduced. The overall effect is seen directly

on the steam production, since the HTER utilises part of

the waste heat available after the secondary reformer

2004 175 AMMONIA TECHNICAL MANUAL

A HTER has been in successful industrial operation References

in combination with an ATR in a synthesis gas generat-

ing plant at SASOL in South Africa for more than 16 1. Dybkjær, I., “Advances in Ammonia Con-

months. The operating conditions in this installation, verter Design and Catalyst Loading”, pre-

which has a capacity corresponding to more than sented at the NITROGEN ’97 Conference,

100,000 Nm3/h (3.7 MMSCFD) of hydrogen, are more Geneva, Switzerland, Feb. 9-11, 1997

severe than what would be expected in a revamp of an 2. Nielsen S.E., Dybkjær I., ”Use of Adia-

ammonia plant as described above. batic Prereforming in Ammonia Plants”,

It should be emphasized that the HTER installed in Ammonia Plant Safety & Related Facili-

SASOL was also as a revamp project in an existing ties, Vol. 37, AIChE, New York (1997)

plant, i.e. the tie-in of the HTER in an existing plant has 3. Winter Madsen, S., Dybkjær I., ”Novel

already been successfully demonstrated. Revamp Solutions for Increased Hydrogen

Regarding the economical attractiveness of install- Demand”, presented at the 8th Europeran

ing a HTER in an ammonia plant a cost comparison re- Technology Conference, London, U.K.,

veals that the expected investment cost for the HTER Nov. 17-19, 2003

concept in most cases will be a very attractive alterna-

tive compared to the cost related to the installation of a

prereformer with a fired heater for the same capacity

increase.

Conclusions

• In order to arrive at the most attractive re-

vamp scheme it is of paramount impor-

tance that the scheme is optimised based

on the objective and the specific conditions

prevailing.

• As demonstrated with the IFFCO revamps,

various attractive possibilities exist for re-

vamping ammonia plants to save energy or

to increase capacity.

• The novel revamp feature, the Haldor Top-

søe Exchange Reformer (HTER), is an at-

tractive alternative for increasing the ca-

pacity of the reforming section in an

ammonia plant.

AMMONIA TECHNICAL MANUAL 176 2004

You might also like

- Ullmann S Encyclopedia of Industrial Chemistry - 2011 - Appl - Ammonia 2 Production ProcessesDocument88 pagesUllmann S Encyclopedia of Industrial Chemistry - 2011 - Appl - Ammonia 2 Production ProcessesJulius SuhermanNo ratings yet

- Engine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01Document5 pagesEngine Brochure Industrial-3406c Dita-2000 Rpm-328 Kw-dm0346-01maekel abdul HakimNo ratings yet

- Caterpillar Traxcavator Service Manual CT S 955ltx64jDocument14 pagesCaterpillar Traxcavator Service Manual CT S 955ltx64jJesus DiazNo ratings yet

- Advanced Gas-Heated Reformer: P. W. FarneilDocument9 pagesAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoNo ratings yet

- Egeberg 2010 - Hydrotreating in The Production ofDocument13 pagesEgeberg 2010 - Hydrotreating in The Production ofNadia RizanedewiNo ratings yet

- Ammonia Synthesis Loops Variables Investigated by Steady-State SimulationDocument14 pagesAmmonia Synthesis Loops Variables Investigated by Steady-State Simulationpolonium2310No ratings yet

- 50 Olefin ReductionDocument2 pages50 Olefin ReductiondimkuhNo ratings yet

- Advanced Gas-Heated Reformer: P. W. FarneilDocument9 pagesAdvanced Gas-Heated Reformer: P. W. FarneilAlfonso BlancoNo ratings yet

- Dokumen - Tips - Case 580sle Loader Backhoe Service Repair ManualDocument25 pagesDokumen - Tips - Case 580sle Loader Backhoe Service Repair ManualMourad Wanen0% (2)

- Mitsubishi 4G6 and 4G6 EW Engine Factory Workshop Repair ManualDocument137 pagesMitsubishi 4G6 and 4G6 EW Engine Factory Workshop Repair ManualMozes Simataa100% (1)

- KRES TechnologyDocument10 pagesKRES TechnologyabubakarNo ratings yet

- 014 PDFDocument12 pages014 PDFGrootNo ratings yet

- Pushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert RingerDocument6 pagesPushing The Limits - Breakthrough in Pre-Reformer Design: Ingo Hanke and Norbert Ringervaratharajan g rNo ratings yet

- Brochure Kboost V1 1sep2022Document5 pagesBrochure Kboost V1 1sep2022parsiti unnes100% (1)

- Comparative Evaluation of Cryogenic Air SeparationDocument21 pagesComparative Evaluation of Cryogenic Air SeparationmuratNo ratings yet

- 263 269 JMTR Oct16Document7 pages263 269 JMTR Oct16Taniadi SuriaNo ratings yet

- Haldor Topsoe Hter First ExperiencesDocument8 pagesHaldor Topsoe Hter First ExperiencesGeorge Van BommelNo ratings yet

- CO Capture and Storage: Options and Challenges For The Cement IndustryDocument49 pagesCO Capture and Storage: Options and Challenges For The Cement IndustryMohamedRaahimNo ratings yet

- AmmoniaDocument33 pagesAmmoniaWilly ChandraNo ratings yet

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Document20 pagesProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-324ainmnrhNo ratings yet

- Recovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-NassarDocument8 pagesRecovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-Nassarvaratharajan g rNo ratings yet

- Kinetic Simulation of Ammonia Synthesis CatalysisDocument11 pagesKinetic Simulation of Ammonia Synthesis CatalysisLE HIENNo ratings yet

- Named Equipment List: Item Name Description Type QTY RemarksDocument8 pagesNamed Equipment List: Item Name Description Type QTY RemarksAnonymous kbPP3CCcNo ratings yet

- New KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard StraitDocument12 pagesNew KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard Straitvaratharajan g rNo ratings yet

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Document28 pagesAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNo ratings yet

- Ammonia Synthesis EquilibriumDocument28 pagesAmmonia Synthesis EquilibriumRaga BimaNo ratings yet

- Questions and Answers For Primary ReformerDocument3 pagesQuestions and Answers For Primary ReformerMaged HegabNo ratings yet

- 50 Year History of The Aiche Ammonia Safety Symposium: Gerald P. WilliamsDocument9 pages50 Year History of The Aiche Ammonia Safety Symposium: Gerald P. Williamsvaratharajan g rNo ratings yet

- BREF LargeVolInorgChemicals Vdez06Document446 pagesBREF LargeVolInorgChemicals Vdez06Luís Miguel Castro100% (2)

- Reactor Project Ammonia SynthesisDocument21 pagesReactor Project Ammonia SynthesisEmerson Oliveira100% (1)

- Plant Layout PDFDocument19 pagesPlant Layout PDFazzatul amiraNo ratings yet

- POWER Magazine - May 2023-1Document43 pagesPOWER Magazine - May 2023-1MarcialgonzalezpNo ratings yet

- UhdeDocument9 pagesUhdeibkhiNo ratings yet

- "New Reforming Concepts For Large Scale NH Plants": Paper AbstractDocument17 pages"New Reforming Concepts For Large Scale NH Plants": Paper AbstractAlfonso Blanco100% (1)

- Steamreforming Typesofreformerdesign 130924133238 Phpapp02Document59 pagesSteamreforming Typesofreformerdesign 130924133238 Phpapp02Mary Scott100% (1)

- Methanol Catalyst Poisons - A Literature Study (CCS)Document19 pagesMethanol Catalyst Poisons - A Literature Study (CCS)ahsan888No ratings yet

- 2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2Document15 pages2008 Morikawa TEC IFA ACES21 Advanced Urea Production Technology - 2MubasharNo ratings yet

- BASF R5-12 Data SheetDocument1 pageBASF R5-12 Data SheetAmir RahbariNo ratings yet

- 08 Foil Supported CatalystsDocument24 pages08 Foil Supported CatalystsKvspavan KumarNo ratings yet

- Shift Conversion OperationDocument26 pagesShift Conversion OperationMuhammad JunaidNo ratings yet

- Topsoe Prereforming CatalystDocument13 pagesTopsoe Prereforming CatalystReza RhiNo ratings yet

- 4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev ClaesDocument8 pages4000 MTPD Ammonia Plant Based On Proven Technology: Joachim Rüther, John Larsen, Dennis Lippmann, Detlev Claesvaratharajan g rNo ratings yet

- Ammonia Synthesis Material Balence CalulDocument1 pageAmmonia Synthesis Material Balence CalulDhruv RanaNo ratings yet

- Ud He TechnologyDocument16 pagesUd He TechnologyBejavada Suresh100% (1)

- Collie Urea Project Air Quality Report FinalDocument184 pagesCollie Urea Project Air Quality Report FinalSayal GuptaNo ratings yet

- Customized aMDEA Process For Acid Gas RemovalDocument11 pagesCustomized aMDEA Process For Acid Gas RemovalArjun BabuNo ratings yet

- Reactor Kinetics of Urea Formation: November 2015Document21 pagesReactor Kinetics of Urea Formation: November 2015Javiera MellaNo ratings yet

- Air Separation Unit Atmospheric AirDocument2 pagesAir Separation Unit Atmospheric Airv.satyanarayana EthaNo ratings yet

- Basaroof ReactionDocument14 pagesBasaroof ReactiontreyzzztylerNo ratings yet

- Toxicological Review of TCEDocument1,200 pagesToxicological Review of TCEJanja TothNo ratings yet

- Ammonia and UreaDocument33 pagesAmmonia and UreaPRAJWAL RASTOGINo ratings yet

- 2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICDocument35 pages2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICHummel Johnson0% (1)

- Driving Expander TechnologyDocument24 pagesDriving Expander TechnologysajadranjbaranNo ratings yet

- 3-Energy Efficiency Gains in Indian Ammonia Plants Retrospects and ProspectsDocument14 pages3-Energy Efficiency Gains in Indian Ammonia Plants Retrospects and ProspectsMuhammad Naeem100% (1)

- Vdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Document31 pagesVdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Shabir MansuriNo ratings yet

- Indian Fertilizer IndustryDocument4 pagesIndian Fertilizer Industrypriyankakohli88No ratings yet

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocument33 pagesAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNo ratings yet

- Process Flow Diagram - Urea Production PlantDocument1 pageProcess Flow Diagram - Urea Production PlantDasun AttanayakeNo ratings yet

- From Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GDocument14 pagesFrom Synthesis Gas Production To Methanol Synthesi 2015 Journal of Natural GRafael DamarNo ratings yet

- Steam Methane Reforming Reaction Process Intensification by Using A ReactorDocument14 pagesSteam Methane Reforming Reaction Process Intensification by Using A ReactorserchNo ratings yet

- Increased Steam Methane Reformer ThroughputDocument5 pagesIncreased Steam Methane Reformer ThroughputAlexReituNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Chemical Process Plants - Plan For RevampsDocument6 pagesChemical Process Plants - Plan For RevampsBramJanssen76No ratings yet

- Envirocarb 207C 4X8 AND 6X12: Coconut Based Granular Activated CarbonsDocument2 pagesEnvirocarb 207C 4X8 AND 6X12: Coconut Based Granular Activated CarbonsAlfonso BlancoNo ratings yet

- Comparative Study For Adsorption of Hydrogen-Methane Mixtures On Activated Carbon and 5A Molecular SieveDocument10 pagesComparative Study For Adsorption of Hydrogen-Methane Mixtures On Activated Carbon and 5A Molecular SieveAlfonso BlancoNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- 2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetDocument4 pages2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetAlfonso BlancoNo ratings yet

- Transparent Level GaugesDocument4 pagesTransparent Level GaugesAlfonso BlancoNo ratings yet

- Magnetic Level Gauge Spec Sheet Top MountedDocument1 pageMagnetic Level Gauge Spec Sheet Top MountedAlfonso BlancoNo ratings yet

- Fundamentals of Fixed Bed Adsorption Processes Analysis of Adsorption Breakthrough and Desorption Elution CurvesDocument9 pagesFundamentals of Fixed Bed Adsorption Processes Analysis of Adsorption Breakthrough and Desorption Elution CurvesAlfonso BlancoNo ratings yet

- Digital Pressure Gauge Xp2i Psi Data Sheet UsDocument5 pagesDigital Pressure Gauge Xp2i Psi Data Sheet UsAlfonso BlancoNo ratings yet

- Gas Gauge IC With Battery Charger Control For Handheld ApplicationsDocument35 pagesGas Gauge IC With Battery Charger Control For Handheld ApplicationsAlfonso BlancoNo ratings yet

- IMPAC Infrared: ThermometersDocument2 pagesIMPAC Infrared: ThermometersAlfonso BlancoNo ratings yet

- 1130 Differential Pressure Gauge: Data SheetDocument3 pages1130 Differential Pressure Gauge: Data SheetAlfonso BlancoNo ratings yet

- Pressure Gauge: With Integral Stainless Steel DiaphragmDocument2 pagesPressure Gauge: With Integral Stainless Steel DiaphragmAlfonso BlancoNo ratings yet

- Utility Pressure Gauge: Product HighlightsDocument2 pagesUtility Pressure Gauge: Product HighlightsAlfonso BlancoNo ratings yet

- 2450 Sourcemeter Smu Instrument: DatasheetDocument14 pages2450 Sourcemeter Smu Instrument: DatasheetAlfonso BlancoNo ratings yet

- MAX4208/MAX4209 Ultra-Low Offset/Drift, Precision Instrumentation Amplifiers With REF BufferDocument17 pagesMAX4208/MAX4209 Ultra-Low Offset/Drift, Precision Instrumentation Amplifiers With REF BufferAlfonso BlancoNo ratings yet

- EC400 DatasheetDocument1 pageEC400 DatasheetAlfonso BlancoNo ratings yet

- One-Piece Instrumentation Ball Valves: 40G Series and 40 SeriesDocument29 pagesOne-Piece Instrumentation Ball Valves: 40G Series and 40 SeriesAlfonso BlancoNo ratings yet

- Pressure Transmitter Pressure Transmitter: Measuring Instruments - Strumenti Per MisurareDocument35 pagesPressure Transmitter Pressure Transmitter: Measuring Instruments - Strumenti Per MisurareAlfonso BlancoNo ratings yet

- Descriptio: FeaturesDocument8 pagesDescriptio: FeaturesAlfonso BlancoNo ratings yet

- SN54F32, SN74F32 Quadruple 2-Input Positive-Or Gates: DescriptionDocument19 pagesSN54F32, SN74F32 Quadruple 2-Input Positive-Or Gates: DescriptionAlfonso BlancoNo ratings yet

- Texas-Instruments-SN65HVD3082EDR C6912 PDFDocument27 pagesTexas-Instruments-SN65HVD3082EDR C6912 PDFAlfonso BlancoNo ratings yet

- Biomolecules: Human Telomerase RNA: Telomerase Component or More?Document15 pagesBiomolecules: Human Telomerase RNA: Telomerase Component or More?Alfonso BlancoNo ratings yet

- Autothermal Reforming Syngas 2010 Paper PDFDocument20 pagesAutothermal Reforming Syngas 2010 Paper PDFAlfonso BlancoNo ratings yet

- Head-Mount Temperature Transmitter: Abb Measurement & Analytics - Data SheetDocument20 pagesHead-Mount Temperature Transmitter: Abb Measurement & Analytics - Data SheetAlfonso BlancoNo ratings yet

- TCAHQ1 de 1Document106 pagesTCAHQ1 de 1Alfonso BlancoNo ratings yet

- Yanmar 6LPA STP2datasheetDocument2 pagesYanmar 6LPA STP2datasheetŠime StipaničevNo ratings yet

- ServiceSchedule MD22Document3 pagesServiceSchedule MD22theo_swaranNo ratings yet

- GALGALLA - Working Assignment 3 - Gas TurbineDocument5 pagesGALGALLA - Working Assignment 3 - Gas TurbineGodfrey Jr Jr.No ratings yet

- Progress KPLPDocument48 pagesProgress KPLPAssesment RTGsurabayaNo ratings yet

- Volvo Penta d13-800Document108 pagesVolvo Penta d13-800Maxim VasilevskiyNo ratings yet

- DG SetDocument19 pagesDG SetSatyajit PandaNo ratings yet

- SK200-8 Engine CRS Parts - 01Document11 pagesSK200-8 Engine CRS Parts - 01suwardjoNo ratings yet

- Fso Nabarima Q88Document8 pagesFso Nabarima Q88Manuel GuerreroNo ratings yet

- Fuel Injector of Diesel Engines - Marine StudyMarine StudyDocument7 pagesFuel Injector of Diesel Engines - Marine StudyMarine StudymhnmndrkNo ratings yet

- TAD760VE: Volvo Penta Industrial DieselDocument2 pagesTAD760VE: Volvo Penta Industrial DieselDatNo ratings yet

- 26 - Davao Gulf Lumber v. CIR, GR No. 117359Document2 pages26 - Davao Gulf Lumber v. CIR, GR No. 117359Lloyd LiwagNo ratings yet

- 3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Document2 pages3303.0002 Micropack FDS303 Multi Spectrum IR Flame Detector - Datasheet Rev 1.4Landi ManusNo ratings yet

- CM20210223 Dcdec 95cf5Document2 pagesCM20210223 Dcdec 95cf5kumarraghuNo ratings yet

- Which Cars Are Equipped With k9k 808. Engines and Weaknesses of The K9K EngineDocument19 pagesWhich Cars Are Equipped With k9k 808. Engines and Weaknesses of The K9K EngineShalla Balla100% (1)

- Module 2 TechnologyDocument20 pagesModule 2 Technologybenitez1No ratings yet

- Diagrams EuDocument54 pagesDiagrams EuJuanjo Garcia Jimenez100% (1)

- Path To Hydrogen Competitiveness - Full Study 1Document88 pagesPath To Hydrogen Competitiveness - Full Study 1Zakiah Darajat NurfajrinNo ratings yet

- My ITReport 20192Document43 pagesMy ITReport 20192Agunbiade Jewel MichaelNo ratings yet

- Yes and Arkers: Mortrace STDocument2 pagesYes and Arkers: Mortrace STgabriel_faroppaNo ratings yet

- ASTM D6079.dvfr3720 PDFDocument8 pagesASTM D6079.dvfr3720 PDFangel100% (2)

- Engine: Terminology HistoryDocument13 pagesEngine: Terminology HistoryBenjamin Konjicija100% (1)

- Engine Misfire, Runs Rough or Is UnstableDocument4 pagesEngine Misfire, Runs Rough or Is UnstableAdolfo Dario Saavedra0% (1)

- KTA50 Land-Based Drilling Power ModuleDocument4 pagesKTA50 Land-Based Drilling Power ModuleMuhammad RozzaqNo ratings yet

- Q88 Js-Cougar - Gas-Form-C-LPG - 28oct2020Document5 pagesQ88 Js-Cougar - Gas-Form-C-LPG - 28oct2020Александр ШуваловNo ratings yet

- Tp6985 - Kohler SPN Fault CodesDocument216 pagesTp6985 - Kohler SPN Fault CodesOrhan TuncelNo ratings yet

- Fundamentals of Automotive SystemsDocument85 pagesFundamentals of Automotive Systemsvedant sawantNo ratings yet