Professional Documents

Culture Documents

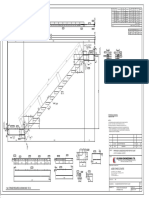

Pipe Support2of 5

Pipe Support2of 5

Uploaded by

Anonymous fLgaidVBhzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Support2of 5

Pipe Support2of 5

Uploaded by

Anonymous fLgaidVBhzCopyright:

Available Formats

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 05 Issue: 04 | Apr-2018 www.irjet.net p-ISSN: 2395-0072

Spacing of supports, pedestal (d) Rim stress

L 5.00 m

Angle of bedding Fr=Fh/4 = 85/4 = 21.25 ksc

β 120 deg

LONGITUDINAL STRESS

Weight calculation (pipe with water in it)

Maximum permissible longitudinal stress

Weight of inlining = π*(0.6+0.012)*0.012*2200 F’ = fy *0.6*efficiency of circumferential joint =

2500*0.6*0.8

= 50.758 kg/m

F’ = 1200 ksc

Weight of the pipe shell =

π*(0.6+2*0.012+0.006)*0.006*7850 Total actual longitudinal stress, F’ = saddle stress +bending

stress +rim stress

= 93.22 kg/m

= fI + fb + fr

Weight of gunniting =

π*(0.6+2*(0.012+0.006)+0.012)*0.012*220) = 470.949+88.53+21.25

= 53.744 kg/m F’ = 580.7

Weight of water running in the pipe = ksc < 1200 SAFE

π*0.6^2/4*1000

CIRCUMFERENTIAL STRESS

= 280.743 kg/m

Total load due to the pipe and water in it = Maximum permissible circumferential stress

50.758+93.22+53.744+282.743 F”= Fy* 6*efficiency of longitudinal joint

= 480.5 kg/m = 2500*0.6*0.9

F” = 1350 ksc

(a) Maximum value of localized stress in pipe ( saddle

stress) Total circumferential stress, F” = saddle stress +hoop

stress= fI + fh

FI = K * p/ * log(r/t) = 470.949+85

Where, F” = 555.9 ksc <1350 SAFE

k a factor obtained from expression (0.02-0.00012(β-90)) Hence, c/c distance between the supports, (i.e, pedestal),

Β angle of support 5m is sufficient for angle of support being 120 deg.

K = 0.0164

P saddle reaction including 10% for continuity DESIGN OF SUPPORT STRUCTURE, PEDESTAL ‘P’

= 2642.60 kg

Grade of concrete M20

Shell thickness = 6 mm

Grade of steel Fe 500

R radius of pipe, (D/2) = 300 mm

mp

Permissible stress in compression, bending, σcbc

Fl = 470.949 ksc = 7 N/

(b)Bending stress mp

Permissible stress in compression, direct, σcc

= 5 N/

Fb = bending moment / modulus of shell plate Permissible tensile stress in steel

Where, bending moment, M = W /8 = 230 N/

= 480.465*5^2/8 Design constants

= 1501.5 kg-m

m = 280/(3 σcbc) = 13.3333

Sectional n π* *t =(22/7)*300^2*6/1000

k = m σcbc / (m σcbc)= 0.2887

= 1696 cm^4 j = 1- k/3 = 0.9038

fb =1501.5*100/1696 Q = ½ kj σcbc = 0.9132

= 88.53ksc

= = 27 deg

(c)Hoop stress Hoop force in pipeline,σt = PD/2

= 51 KN

Fh = P*d/2/t 1.7*(60/2)(0.6) = 85 ksc

Longitudinal force in the pipeline = 0.303* σt

= 15.45 KN

Vertical component = 7.01 KN

© 2018, IRJET | Impact Factor value: 6.171 | ISO 9001:2008 Certified Journal | Page 1913

You might also like

- Wind Load On Cable TraysDocument10 pagesWind Load On Cable TraysAaron EasleyNo ratings yet

- Blight - 1968 - A Note On Field Vane Testing of Silty SoilsDocument8 pagesBlight - 1968 - A Note On Field Vane Testing of Silty SoilsDavid WhiteNo ratings yet

- Circular Motion ProblemDocument32 pagesCircular Motion ProblemAnjani SinghNo ratings yet

- Design of Steel ColumnDocument7 pagesDesign of Steel ColumnKim Javier EstaNo ratings yet

- Urban DrainageDocument26 pagesUrban Drainagesatria11No ratings yet

- Apf Cal Pipe Bridge Rev 2Document36 pagesApf Cal Pipe Bridge Rev 2Edwin RachmanudinNo ratings yet

- April 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument25 pagesApril 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeToni Garrote FerreroNo ratings yet

- 2395 CH 15Document19 pages2395 CH 15abdülkadir cebeciNo ratings yet

- Pile StirrupDocument1 pagePile Stirrupbuffyto5377No ratings yet

- SHEAR WALL REBAR Autosaved ExcelDocument10 pagesSHEAR WALL REBAR Autosaved ExcelSohagNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Gorhar-Khairatunda: Subject: Estimation of VUP at KM 1+330 DataDocument17 pagesGorhar-Khairatunda: Subject: Estimation of VUP at KM 1+330 Datanandu523No ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- FW PDFDocument61 pagesFW PDFAhmed KhattabNo ratings yet

- RCC14 Crack Width PDFDocument1 pageRCC14 Crack Width PDFmdelacua2No ratings yet

- Title: Document/Drawing Approval/Comment Transmital ProjectDocument2 pagesTitle: Document/Drawing Approval/Comment Transmital ProjectPritom AhmedNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- IS 3370 Part 2 - 2009-Readable PDFDocument14 pagesIS 3370 Part 2 - 2009-Readable PDFpradip ghodeswarNo ratings yet

- Connection Design:: SB NB Ub Yb Mo MB MFDocument1 pageConnection Design:: SB NB Ub Yb Mo MB MFSuman NakarmiNo ratings yet

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- Phase-2 Voided SlabDocument16 pagesPhase-2 Voided SlabKetan DhameliyaNo ratings yet

- B. Super Impose Load Due To WaterDocument2 pagesB. Super Impose Load Due To WaterMohanSharmaNo ratings yet

- Suitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationDocument4 pagesSuitability of Fixed Base and Pinned Base PEB Structure With Pile FoundationKarthik SgNo ratings yet

- ACI-Beam LedgeDocument7 pagesACI-Beam Ledgeja'far baderNo ratings yet

- BERKHEDA PUMP HOUSE FINAL-ModelDocument1 pageBERKHEDA PUMP HOUSE FINAL-ModelvishalNo ratings yet

- EqualAngle PDFDocument2 pagesEqualAngle PDFGalih PutraNo ratings yet

- Aanalysis of Pad&Chimney Foundation - MDY+9M With 50% LoadDocument24 pagesAanalysis of Pad&Chimney Foundation - MDY+9M With 50% LoadHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Crack WidthDocument6 pagesCrack Widthnitin400No ratings yet

- Crack WidthDocument1 pageCrack WidthD SRINIVASNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- Design of Rectangular Footing Col Edge 3Document28 pagesDesign of Rectangular Footing Col Edge 3Shaikh Muhammad AteeqNo ratings yet

- Free Head Vs Fixed Head Laterally Loaded PileDocument3 pagesFree Head Vs Fixed Head Laterally Loaded PileFiras AndanawarihNo ratings yet

- Design Doc. - Rt. WallDocument16 pagesDesign Doc. - Rt. WallAnindit MajumderNo ratings yet

- Calculation - Loading PlatformDocument6 pagesCalculation - Loading PlatformDaniel SarmientoNo ratings yet

- Square PileDocument2 pagesSquare Piledepi_rachman100% (1)

- Calculation of Steel PlateDocument2 pagesCalculation of Steel PlateChan Kin CheungNo ratings yet

- Grating1 2Document17 pagesGrating1 2Dhanraj VasanthNo ratings yet

- Gantry Tower (1TA) Foundation at Rupsi (13!03!19)Document1 pageGantry Tower (1TA) Foundation at Rupsi (13!03!19)Zahid Hasan ZituNo ratings yet

- Pipe Support - Type 3Document17 pagesPipe Support - Type 3Angelique SutantoNo ratings yet

- Project Area Sub Area Plant/Unit Code Se-Spml (JV) RevDocument13 pagesProject Area Sub Area Plant/Unit Code Se-Spml (JV) RevBanwari Lal GuptaNo ratings yet

- Dimensional Solutions Mat3DDocument69 pagesDimensional Solutions Mat3DTimothy HancockNo ratings yet

- 24711-SE-A4-006 - PUMP FOUNDATIONDocument4 pages24711-SE-A4-006 - PUMP FOUNDATIONJohn BuntalesNo ratings yet

- Data Sheet Ko Drum 43-401Document14 pagesData Sheet Ko Drum 43-401sokrat sebti100% (1)

- XyzDocument64 pagesXyzP S HARSHITANo ratings yet

- WWW - Civildesignhelp.info VV - HTMLDocument52 pagesWWW - Civildesignhelp.info VV - HTMLconsultor9010No ratings yet

- 12m Tripod Tower - SI Report Template - Customer Tower - Exposure D SI Report 01212020 PDFDocument136 pages12m Tripod Tower - SI Report Template - Customer Tower - Exposure D SI Report 01212020 PDFChristian ReyesNo ratings yet

- A&m BSR-2011Document26 pagesA&m BSR-2011Mukesh Jangid100% (1)

- 1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandDocument79 pages1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandRianto FelissimoNo ratings yet

- Civil Manhole UGDocument1 pageCivil Manhole UGvijay104840% (1)

- Top Slab Design SheetDocument3 pagesTop Slab Design SheetersivarajNo ratings yet

- Rebar Chair Designr1Document3 pagesRebar Chair Designr1John Vincent MusngiNo ratings yet

- Annex-3 Vetogrout CG518Document2 pagesAnnex-3 Vetogrout CG518MdShahbazAhmedNo ratings yet

- Design of RCC Retaining WallDocument9 pagesDesign of RCC Retaining Wallbhagvat daveNo ratings yet

- L & T Construction: Water, Smart World & Communication ICDocument12 pagesL & T Construction: Water, Smart World & Communication ICMUTHUKKUMARAMNo ratings yet

- Calculation of Bearing Plate Dimension:: Beam SectionDocument2 pagesCalculation of Bearing Plate Dimension:: Beam Sectionk.m.ariful islamNo ratings yet

- Pile Design 38kDocument12 pagesPile Design 38kRaxKitNo ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- Design of Raft Foundation: Column Distance From A-A Name Load (KN) X (M) y (M)Document4 pagesDesign of Raft Foundation: Column Distance From A-A Name Load (KN) X (M) y (M)Anish NeupaneNo ratings yet

- Column Design2 (Final) PRINTDocument13 pagesColumn Design2 (Final) PRINTAashish MaharjanNo ratings yet

- Cross Section1Document1 pageCross Section1Anonymous fLgaidVBhzNo ratings yet

- Cross Section2Document1 pageCross Section2Anonymous fLgaidVBhzNo ratings yet

- Cross SectionDocument1 pageCross SectionAnonymous fLgaidVBhzNo ratings yet

- Cross Section3Document1 pageCross Section3Anonymous fLgaidVBhzNo ratings yet

- Step 1: Establish Material PropertiesDocument30 pagesStep 1: Establish Material PropertiesAnonymous fLgaidVBhzNo ratings yet

- Load Calculation-PLATFORM - 08-22-2023 (R0)Document57 pagesLoad Calculation-PLATFORM - 08-22-2023 (R0)Anonymous fLgaidVBhzNo ratings yet

- Architectural GA - Intake PH - Tamluk - Commented 6 4 23Document3 pagesArchitectural GA - Intake PH - Tamluk - Commented 6 4 23Anonymous fLgaidVBhzNo ratings yet

- Route Survey SORDocument67 pagesRoute Survey SORAnonymous fLgaidVBhzNo ratings yet

- Concrete Filled Steel Tube Columns Under Earthquake LoadsDocument10 pagesConcrete Filled Steel Tube Columns Under Earthquake LoadsAnonymous fLgaidVBhzNo ratings yet

- 2.ANNEXUREDocument89 pages2.ANNEXUREAnonymous fLgaidVBhzNo ratings yet

- Pipe Support4of 5Document1 pagePipe Support4of 5Anonymous fLgaidVBhzNo ratings yet

- Pipe Support3of 5Document1 pagePipe Support3of 5Anonymous fLgaidVBhzNo ratings yet

- Scale Date Checked: Reviewed: Approved: DrawnDocument1 pageScale Date Checked: Reviewed: Approved: DrawnAnonymous fLgaidVBhzNo ratings yet

- Pipe Support 1of 5Document1 pagePipe Support 1of 5Anonymous fLgaidVBhzNo ratings yet

- Substation Building Design Report PDFDocument57 pagesSubstation Building Design Report PDFAnonymous fLgaidVBhzNo ratings yet

- Design BasisDocument55 pagesDesign BasisAnonymous fLgaidVBhz100% (1)

- (Rules To Form Interrogative Sentences) : Subject: English Language Lesson: Kind of SentencesDocument2 pages(Rules To Form Interrogative Sentences) : Subject: English Language Lesson: Kind of SentencesAnonymous fLgaidVBhzNo ratings yet

- Quotation-Tirupati GardenDocument12 pagesQuotation-Tirupati GardenAnonymous fLgaidVBhzNo ratings yet

- Design Ground Based Radar by Using Matlab Simulink: Working PaperDocument10 pagesDesign Ground Based Radar by Using Matlab Simulink: Working Paperarazoo mustafa azizNo ratings yet

- Lost Foam CastingDocument31 pagesLost Foam CastingokicirdarNo ratings yet

- Tribology International: V. Hegadekatte, S. Kurzenha User, N. Huber, O. KraftDocument12 pagesTribology International: V. Hegadekatte, S. Kurzenha User, N. Huber, O. Kraftvsraju2No ratings yet

- Impact of Mining Subsidence On Natural Gas PipelinDocument11 pagesImpact of Mining Subsidence On Natural Gas PipelinPranavNo ratings yet

- Level Switch - LS-1040, LS-1050 & LS-1055 Data SheetDocument16 pagesLevel Switch - LS-1040, LS-1050 & LS-1055 Data SheetAlfredoNo ratings yet

- 6051 DDD 5 B 285 ADocument7 pages6051 DDD 5 B 285 AYarob ZeebNo ratings yet

- Design and Assessment of Static VAR Compensator On Railways Power Grid Operation Under Normal and Contingencies ConditionsDocument6 pagesDesign and Assessment of Static VAR Compensator On Railways Power Grid Operation Under Normal and Contingencies ConditionsSUMAN ChandrashekharNo ratings yet

- Stereoisomerism BPS4Document32 pagesStereoisomerism BPS4SHIVAM AGARWALNo ratings yet

- Yukon 0904Document4 pagesYukon 0904Việt Đặng XuânNo ratings yet

- AC GeneratorDocument7 pagesAC Generatoraswardi8756No ratings yet

- Group Complete ReportDocument37 pagesGroup Complete ReportMahantheshaNo ratings yet

- Solids, Liquids and Gases Quick Assessment: State of Matter Before State of Matter AfterDocument3 pagesSolids, Liquids and Gases Quick Assessment: State of Matter Before State of Matter AfterEffNo ratings yet

- محطات الطاقةDocument22 pagesمحطات الطاقةJoe LewisNo ratings yet

- Paper Optics Linda JohanssonDocument11 pagesPaper Optics Linda JohanssonNolanNo ratings yet

- My Reaction PaperDocument2 pagesMy Reaction PaperQuindap JonalineNo ratings yet

- AU Solutions Price List 01nov2019 PDFDocument40 pagesAU Solutions Price List 01nov2019 PDFPrasenjit MaityNo ratings yet

- Binary StarDocument2 pagesBinary StarMar DieronNo ratings yet

- Power Quality in Grid Connected Renewable Energy SDocument7 pagesPower Quality in Grid Connected Renewable Energy SRamshaNo ratings yet

- ABE 321 Module 2Document52 pagesABE 321 Module 2Crispin NasamNo ratings yet

- NT 6 Contrast ScannersDocument2 pagesNT 6 Contrast ScannershiloactiveNo ratings yet

- Fisika Mekanika Teknik Mesin - Ardi Wiranata, M.EngDocument59 pagesFisika Mekanika Teknik Mesin - Ardi Wiranata, M.EngMirsalurriza MukhajjalinNo ratings yet

- Sporlan TXV PDFDocument72 pagesSporlan TXV PDFjorge castillo100% (1)

- MAE 104 - SUMMER 2015 Homework 1 Solution: Problem 1Document9 pagesMAE 104 - SUMMER 2015 Homework 1 Solution: Problem 1Giang VũNo ratings yet

- Rubber-Determination of The Degree of Silanization by Dynamic Strain SofteningDocument3 pagesRubber-Determination of The Degree of Silanization by Dynamic Strain SofteningSdferwste SrqreNo ratings yet

- CHEM 153 SyllabusDocument3 pagesCHEM 153 SyllabusGhazanfar IqbalNo ratings yet

- Chapter 14 Physics Class 10thDocument1 pageChapter 14 Physics Class 10thIjazUlHaqPathanNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Die Design For Flat Parts - The FabricatorDocument9 pagesDie Design For Flat Parts - The FabricatorSIMONENo ratings yet

- D 86-17Document29 pagesD 86-17Jenny_1985100% (1)