Professional Documents

Culture Documents

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Uploaded by

Sureesh VRCopyright:

Available Formats

You might also like

- ABB Project ReportDocument58 pagesABB Project ReportRitu Goyal71% (7)

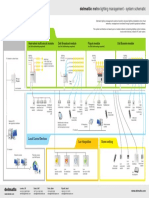

- Delmatic Lighting Management Schematic PDFDocument1 pageDelmatic Lighting Management Schematic PDFSureesh VR0% (1)

- EuValue - ABB India Ltd.Document6 pagesEuValue - ABB India Ltd.Chanchal BiswasNo ratings yet

- Transformer Life CycleDocument53 pagesTransformer Life CycleTaher El NoamanNo ratings yet

- Case Study On Abb India LTDDocument4 pagesCase Study On Abb India LTDPriyesh LunagariaNo ratings yet

- Corporate Profile: ABB Group and ItalyDocument5 pagesCorporate Profile: ABB Group and ItalyBalongNo ratings yet

- ABB Electric - Propulsion SYSTEMS 2.4.2 PDFDocument117 pagesABB Electric - Propulsion SYSTEMS 2.4.2 PDFCrazyRound01No ratings yet

- ABB Excitation and Synchronization A Short Introduction ABBDocument71 pagesABB Excitation and Synchronization A Short Introduction ABBMoucha JustdoitNo ratings yet

- ABB India Limited, Industrial TrainingDocument18 pagesABB India Limited, Industrial TrainingPiyush chaudhari100% (1)

- Clean Development Mechanism Project Design Document Form (CDM-PDD) Version 03 - in Effect As Of: 28 July 2006Document44 pagesClean Development Mechanism Project Design Document Form (CDM-PDD) Version 03 - in Effect As Of: 28 July 2006smh1678No ratings yet

- ABB Integrated Report 2023Document112 pagesABB Integrated Report 2023nikhil.uk010No ratings yet

- ABB Review 2-2015 - 72dpiDocument76 pagesABB Review 2-2015 - 72dpiasnawisulong mohdNo ratings yet

- ABB Review 3 - 2008Document80 pagesABB Review 3 - 2008Cuong NguyenNo ratings yet

- Abb 2017Document236 pagesAbb 2017Hardik BudhirajaNo ratings yet

- ABB Capability Guide - LRDocument60 pagesABB Capability Guide - LRtobyNo ratings yet

- ABB SR Transformers-121031Document76 pagesABB SR Transformers-121031Tran Xuan TruongNo ratings yet

- Abb Feb07Document92 pagesAbb Feb07Long HoàngNo ratings yet

- Transformer Efficiency An Opportunity For SustainabilityDocument55 pagesTransformer Efficiency An Opportunity For SustainabilitydevNo ratings yet

- Group Strategy Update Presentation-2019Document72 pagesGroup Strategy Update Presentation-2019KitNo ratings yet

- Service Brochure Rail - EN - RevB - WebDocument8 pagesService Brochure Rail - EN - RevB - WebFaeezAbdålaNo ratings yet

- 01 ABB Industries LVS ProfileDocument9 pages01 ABB Industries LVS Profilehabibi1328No ratings yet

- Waaree CorporateDocument54 pagesWaaree Corporatevivek daptareNo ratings yet

- General Catalogue InglesDocument18 pagesGeneral Catalogue InglesSaravanan BNo ratings yet

- Solar PV Manufacturing Scenario in India: Dr. J. N. RoyDocument23 pagesSolar PV Manufacturing Scenario in India: Dr. J. N. RoysnairmNo ratings yet

- ABB EPC - General Presentation - March 15 EPC Plants For The Oil&Gas IndustryDocument45 pagesABB EPC - General Presentation - March 15 EPC Plants For The Oil&Gas IndustryAnonymous Vbv8SHv0bNo ratings yet

- Contact 1/14: ServiceDocument24 pagesContact 1/14: ServiceCONTACTABBNo ratings yet

- Cat Hybrid Inv Blue EssDocument38 pagesCat Hybrid Inv Blue EssFausto Javier Llerena RengelNo ratings yet

- ManualDocument64 pagesManualPruthvi KrishnaNo ratings yet

- Company Profile ABB - Final FIle PDFDocument28 pagesCompany Profile ABB - Final FIle PDFAliyyus Sya'niNo ratings yet

- ABB India Introduction - Power and Productivity For A Better WorldDocument30 pagesABB India Introduction - Power and Productivity For A Better Worldidmail99No ratings yet

- (AHU) Clivet AHU and Modular Air Handling UnitDocument27 pages(AHU) Clivet AHU and Modular Air Handling UnitDoniNo ratings yet

- ABB SR Transformers-121031 PDFDocument76 pagesABB SR Transformers-121031 PDFvundavilliravindraNo ratings yet

- Catalogo Movilidad enDocument52 pagesCatalogo Movilidad enjambojeefNo ratings yet

- Abb HistoryDocument7 pagesAbb HistoryKushagra MathurNo ratings yet

- Abb SP 4-04Document68 pagesAbb SP 4-04arindam banerjeeNo ratings yet

- Presentación TEDAGUA 2016 08 ENG V.Red STDDocument56 pagesPresentación TEDAGUA 2016 08 ENG V.Red STDTurinto MarjonoNo ratings yet

- Operator'S Manual: Read and Save This ManualDocument112 pagesOperator'S Manual: Read and Save This Manualphucdc095041No ratings yet

- Edge Industrial Gateway 2021 Local View LeafletDocument3 pagesEdge Industrial Gateway 2021 Local View LeafletAmr Ahmed ZeyadaNo ratings yet

- ABB UPS Catalog WebDocument80 pagesABB UPS Catalog WebAceel FitchNo ratings yet

- ABBNG Profile 2009Document13 pagesABBNG Profile 2009bjinx26No ratings yet

- ScilabDocument31 pagesScilabsheshadrirampurNo ratings yet

- It SlidesDocument31 pagesIt SlidesShri KumaranNo ratings yet

- ABB UPS CatalogueDocument80 pagesABB UPS CatalogueFamilia Chiroque CNo ratings yet

- ABB UPS Product Catalog enDocument76 pagesABB UPS Product Catalog enmohsen AlimohammadiNo ratings yet

- Polycab Solar Catalogue 2023-24Document10 pagesPolycab Solar Catalogue 2023-24Arete Electro powerNo ratings yet

- 3000kva Transformer DimensionDocument20 pages3000kva Transformer DimensionPopoola O. AdedotunNo ratings yet

- Abb Distributor Sheets Combined (Rev4 March13)Document183 pagesAbb Distributor Sheets Combined (Rev4 March13)IngenieriaNo ratings yet

- Products and Services For Wind Turbines Lowres PDFDocument32 pagesProducts and Services For Wind Turbines Lowres PDFJonathan RangelNo ratings yet

- Waaree Corporate PPT - V3Document53 pagesWaaree Corporate PPT - V3Bhushan MalsheNo ratings yet

- LuenenDocument21 pagesLuenenstarengineer3473No ratings yet

- 06 en Saving by Incorporation of Eff Lighting Systems MangaloreDocument37 pages06 en Saving by Incorporation of Eff Lighting Systems MangaloremohdshadabNo ratings yet

- Solar Inverters and Inverter Solutions For Power Generation Brochure 3AXD50000039235 RevD EN 2019Document48 pagesSolar Inverters and Inverter Solutions For Power Generation Brochure 3AXD50000039235 RevD EN 2019Krishna PrasathNo ratings yet

- Reliance EnergyDocument19 pagesReliance EnergyProbodh Mallick0% (1)

- ABB Review 3-2017 - 72dpiDocument102 pagesABB Review 3-2017 - 72dpiYashveer TakooryNo ratings yet

- ABB Industrial Sensor Ss PRESENTATIONSDocument12 pagesABB Industrial Sensor Ss PRESENTATIONSAli KhanNo ratings yet

- Presentacion ABBDocument128 pagesPresentacion ABBnapster260% (1)

- Mr. Sandeep GIZDocument20 pagesMr. Sandeep GIZTamonash JanaNo ratings yet

- ABB Review 2 2010 72dpiDocument96 pagesABB Review 2 2010 72dpiAlbert WangNo ratings yet

- Knowledge and Power: Lessons from ADB Energy ProjectsFrom EverandKnowledge and Power: Lessons from ADB Energy ProjectsNo ratings yet

- Improving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsFrom EverandImproving Energy Efficiency and Reducing Emissions through Intelligent Railway Station BuildingsNo ratings yet

- Intelliquad Multi-Criteria Fire Sensor Frequently Asked QuestionsDocument2 pagesIntelliquad Multi-Criteria Fire Sensor Frequently Asked QuestionsSureesh VRNo ratings yet

- PART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFDocument20 pagesPART 2 - WORK REQUIREMENTS Rev 4a - May Date and Revised Schedule Dates PDFSureesh VRNo ratings yet

- Schedule of VRF Condensing/Outdoor UnitsDocument1 pageSchedule of VRF Condensing/Outdoor UnitsSureesh VRNo ratings yet

- ACON IndoorDocument1 pageACON IndoorSureesh VRNo ratings yet

- Guidelines For Preparation of Theses/ Dissertations/ Reports FOR B.Tech and M.Tech StudentsDocument19 pagesGuidelines For Preparation of Theses/ Dissertations/ Reports FOR B.Tech and M.Tech StudentsSureesh VRNo ratings yet

- Thearmal Camera SystemDocument2 pagesThearmal Camera SystemSureesh VRNo ratings yet

- Street Lighting CalculationDocument19 pagesStreet Lighting CalculationSureesh VRNo ratings yet

- Dewa Lightning Protection PDFDocument1 pageDewa Lightning Protection PDFSureesh VRNo ratings yet

- Dewa Earthing PDFDocument1 pageDewa Earthing PDFSureesh VRNo ratings yet

- Sequence of OperationDocument1 pageSequence of OperationSureesh VRNo ratings yet

- Delmatic Lighting Management SchematicDocument1 pageDelmatic Lighting Management SchematicSureesh VRNo ratings yet

- CC1608 - Fire Systems Design GuideDocument20 pagesCC1608 - Fire Systems Design GuidePhạm Thanh Sơn0% (1)

- Project: Responding To Society With SatireDocument3 pagesProject: Responding To Society With SatireSarah SmithNo ratings yet

- 81170-1D SPDocument48 pages81170-1D SPOthman ElhamriNo ratings yet

- Surfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneDocument77 pagesSurfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneSaurabhSharmaNo ratings yet

- Needham's 5 Phase Constructive ModelDocument5 pagesNeedham's 5 Phase Constructive ModelNg Kim Kee100% (1)

- Vacancies in The Department of Transport, Energy and Public WorksDocument13 pagesVacancies in The Department of Transport, Energy and Public WorksramonkefaNo ratings yet

- Techno-Economic Analysis of A Hybrid Solar Thermal-PV Power PlantDocument16 pagesTechno-Economic Analysis of A Hybrid Solar Thermal-PV Power PlantDr Nandan Kumar NavinNo ratings yet

- Midterm Exam 2 Sched (BS Prog) Apr 5-10Document5 pagesMidterm Exam 2 Sched (BS Prog) Apr 5-10Manelli Faten BuenaventuraNo ratings yet

- Simulation and Performances of Main Processes For Waste and Biomass GasificationDocument10 pagesSimulation and Performances of Main Processes For Waste and Biomass GasificationMario WhoeverNo ratings yet

- The Evolution of Remote Work Navigating The Future of Flexible EmploymentDocument2 pagesThe Evolution of Remote Work Navigating The Future of Flexible EmploymentAntoine MNo ratings yet

- David Lowe Thesis PDFDocument201 pagesDavid Lowe Thesis PDFKRISHNA VAMSHINo ratings yet

- 2008 62494-1 Exposure IndexDocument25 pages2008 62494-1 Exposure IndexGeorgiana Kokona100% (1)

- 74995bos60536 SSMDocument36 pages74995bos60536 SSMVipul SharmaNo ratings yet

- Table Reservation Task Sheet 1.1 (Assignment 1.1)Document3 pagesTable Reservation Task Sheet 1.1 (Assignment 1.1)gene roy hernandezNo ratings yet

- UBT by Dustin Dean PDFDocument55 pagesUBT by Dustin Dean PDFMohamed G. Ebrahim100% (1)

- Mini Project Report PaperDocument9 pagesMini Project Report PaperatikpNo ratings yet

- Semi Anual SM Semana 5Document58 pagesSemi Anual SM Semana 5Jose LuisNo ratings yet

- Leveling Survey: Student Name: Group: Instructor Name: SectionDocument9 pagesLeveling Survey: Student Name: Group: Instructor Name: SectionHussein Bou SalehNo ratings yet

- Specific Criteria For Calibration Laboratories in Mechanical Discipline: MASS (Weights)Document24 pagesSpecific Criteria For Calibration Laboratories in Mechanical Discipline: MASS (Weights)kumarNo ratings yet

- Analytical Method For Cleaning Validation of Levothyroxine Sodium inDocument9 pagesAnalytical Method For Cleaning Validation of Levothyroxine Sodium inDidarulNo ratings yet

- Korean Grammar Beginner PDFDocument20 pagesKorean Grammar Beginner PDFAurorah100% (1)

- PS 22 23 24Document95 pagesPS 22 23 24gaurav gargNo ratings yet

- KT-01 03.09Document8 pagesKT-01 03.09GaneshNo ratings yet

- Interpretation of Quantum Mechanics. A View of Our Universe: Ingvar LindgrenDocument8 pagesInterpretation of Quantum Mechanics. A View of Our Universe: Ingvar LindgrenSrramNo ratings yet

- Source Credibility PDFDocument1 pageSource Credibility PDFRasha ElbannaNo ratings yet

- Are We Ready For ELcentroDocument55 pagesAre We Ready For ELcentroSaikat KabirajNo ratings yet

- Difference Between Philosophy and PsychologyDocument2 pagesDifference Between Philosophy and PsychologyPrecious ChagomelanaNo ratings yet

- Line Electrical: PropertiesDocument13 pagesLine Electrical: Propertiesj_andrade_arceNo ratings yet

- Chapter 2 2013Document63 pagesChapter 2 2013Enes YavuzNo ratings yet

- Separation - Level 6 - QuestionsDocument5 pagesSeparation - Level 6 - QuestionsShahnaz AhmedNo ratings yet

- De Davi Hei PhysigDocument39 pagesDe Davi Hei PhysigAshutosh PradhanNo ratings yet

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Uploaded by

Sureesh VROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Transformers & Transformer Services: Overview of Products and Services For University of Illinois ECE 431

Uploaded by

Sureesh VRCopyright:

Available Formats

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformers & Transformer Remanufacturing and Engineering Services

Transformers & Transformer Services

Overview of products and services for

University of Illinois ECE 431

© ABB Inc. 2015

A global leader in power and automation technologies

Leading market positions in main businesses

~145,000

$ 42 billion

In revenue

employees (2013)

Present Formed

in in

+100 1988

countries merger of Swiss (BBC, 1891)

and Swedish (ASEA, 1883)

engineering companies

© ABB Group

March 21, 2015 | Slide 2

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 1 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Power and productivity for a better world

ABB’s vision

As one of the world’s leading engineering companies, we

help our customers to use electrical power efficiently, to

increase industrial productivity and to lower environmental

impact in a sustainable way.

© ABB Group

March 21, 2015 | Slide 3

How ABB is organized

Five global divisions

© ABB Group

March 21, 2015 | Slide 4

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 2 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Power and automation are all around us

You will find ABB technology…

orbiting the earth and working

beneath it,

crossing oceans and on the sea bed,

in the fields that grow our crops and

packing the food we eat,

on the trains we ride and in the

facilities that process our water,

in the plants that generate our power

and in our homes, offices and

factories

© ABB Group

March 21, 2015 | Slide 5

Tackling society’s challenges on path to low-carbon era

Helping customers do more using less

Rise in electricity demand by 2035 ABB power and automation

(under current policies) solutions are:

Source: IEA, World Energy Outlook 2013

In thousand Terawatt-hours (TWh)

Meeting rising demand for electricity

40

Increasing energy efficiency and reducing

CO2 emissions

35 Improving productivity to raise

competitiveness of businesses

30 and utilities

25 +92

20 %

15

10

0

2011 2035

Electricity demand is calculated as the total gross electricity

generated less own use in the production of electricity and

transmission, and distribution losses.

© ABB Group

March 21, 2015 | Slide 6

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 3 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Improving capacity, reliability and efficiency in the grid

A pioneer in smart technologies

Texas

Improving efficiency of Jinping-Sunan

wholesale electricity

Delivering 7,200MW

market and reducing

of hydropower over

transmission congestion

2,000 km with

minimal losses

Karnataka

Improving reliability

in grid serving state

(pop. 53 million)

© ABB Group

March 21, 2015 | Slide 7

Renewable energy

Key growth driver for both power and automation

© ABB Group

March 21, 2015 | Slide 8

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 4 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Boosting productivity and energy efficiency

Example: Stora Enso, world’s biggest paper maker

Skoghall mill, Sweden:

No. 1 maker of board for drink cartons

Two-year revamp boosted productivity and cut CO2 by 170,000

tons/year

ABB provided key control systems:

For boiler, collecting and analyzing data on pressure, flow,

temperature, etc. from thousands of instruments

For total control over power supply with real-time data

© ABB Group

March 21, 2015 | Slide 9

Leading power system’s biggest-ever transformation

Smarter, greener grid for more efficiency and reliability

Merging power and automation technologies makes electricity

network more reliable, flexible, secure and efficient. Smart grid

benefits include:

Lower power consumption

Greater use of renewable energy

ABB’s broad offering in both power and automation

technologies positions it uniquely to support this evolution

Transformation of grid to take place over several decades

© ABB Group

March 21, 2015 | Slide 10

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 5 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Software across industries and across the Group

Enhancing operations and raising business performance

Embedded software

Office

From protection logic in our relays to interactive

functionality in our measurement devices and

Remote robot controllers, embedded software is a key

control

center

component of many ABB products and systems

Software systems

Local

control

center Used to control and coordinate operational

processes across industry sectors, from

Plant floor

chemical plants to power grids

Enterprise software

Boosted by recent acquisitions, this category

Power enables ABB to bridge the divide between

grid

operational data and business intelligence,

delivering actionable information

© ABB Group

March 21, 2015 | Slide 11

Services across the entire value chain

Creating measurable performance improvements

Value-creating partnerships

Co-develop solutions

Advanced services Strategic partnerships

Process improvement Value-based offerings

Lifecycle management Productivity and energy

Responsive service efficiency solutions

Software services

Installation & Consulting

Evolution programs

commissioning

Optimization solutions

Break & fix

Remote solutions

Technical support

Spare parts

Training

© ABB Group

March 21, 2015 | Slide 12

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 6 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Shaping the world we know today through innovation

Pioneering technology since 1883

© ABB Group

March 21, 2015 | Slide 13

Innovation is key to ABB’s competitive advantage

Leadership built on consistent R&D investment

More than $1.5 billion invested annually in R&D

8,000 scientists and engineers

Collaboration with 70 universities

© ABB Group

March 21, 2015 | Slide 14

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 7 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Developing sustainability of products and operations

Lowering environmental impact and costs

Sustainable products Sustainable operations

Focus on resource and energy Cuts targeted in use of energy, raw

efficiency of equipment over life cycle materials, hazardous substances

Helping customers do more with less

© ABB Group

March 21, 2015 | Slide 15

People make the difference

The best want to work in a first-class environment

ABB is one of the world’s most global companies

A culture of openness, flexibility and inclusiveness helps to

attract top performers

ABB strives for excellence in personal development,

operational execution, health and safety, business ethics

A Group-wide staff development program aims to bring a

culture of leadership to every level of the organization

© ABB Group

March 21, 2015 | Slide 16

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 8 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Committed to the highest standards of business ethics

Integrity as bedrock of ABB’s global culture

“At ABB performance is measured not only by

the results achieved, but also how these

results were achieved. This is why our

stakeholders can rely on the fact that our

services, operations and daily business are

based on ethical behavior.”

CEO Ulrich Spiesshofer in ABB’s Code of Conduct

Code of Conduct defines relationships with all stakeholders

Employees acknowledge Code of Conduct and take compulsory

training courses

Zero tolerance toward violations

Several reporting options in place for employees to report

suspected violations; each report thoroughly investigated

© ABB Group

March 21, 2015 | Slide 17

A successful business and a reliable partner

Strong financial position is competitive advantage

Revenue (US$ million) by quarter

and annual operational EBITDA margin

50000 20%

18%

40000 16% 13 –19%

14% operational EBITDA

30000 12% margin corridor targeted

10% for period 2011-2015

20000 8%

6% Q4

10000 4% Q3

2% Q2

0 0% Q1

2010 2011 2012 2013

© ABB Group

March 21, 2015 | Slide 18

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 9 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

More than $14 bln invested for growth since 2008

Main acquisitions and capital investment 2012/2013

New plants and expansions

Main acquisitions

and investments 2012 2013

Newave, Thomas & Betts, APS, Dynamotive, Newron

Tropos, RGM, Bob White Systems, Power One, EL-BI,

Electrix / L.E. Jarvis Alstom Ring Motors, Los

Gatos Research

© ABB Group

March 21, 2015 | Slide 19

Well-balanced business and geographic portfolio

Capturing growth opportunities, wherever they arise

Orders by division Share of employees

% of total orders 2013 (non-consolidated) 2013 (approximate)

25% Power products

14% Power systems

23% Discrete automation and motion

19% Low voltage products

19% Process automation

Orders by region

% of total orders 2013

34% Europe

27% Asia

45% Emerging markets

29% Americas 55% Mature markets

10% Middle East and Africa

© ABB Group

March 21, 2015 | Slide 20

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 10 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Innovation, passion and diversity are hallmarks of ABB

“As a global leader in power and

automation technologies, ABB is

continuously pioneering reliable, cleaner

and more efficient energy and automation

solutions, helping its customers increase

the productivity of their industrial and

infrastructure operations.”

CEO Ulrich Spiesshofer

© ABB Group

March 21, 2015 | Slide 21

A global leader in power and automation technologies

Leading market positions in main businesses

145,000 employees in about 100

countries

$42 billion in revenue (2013)

Formed in 1988 merger of Swiss and

Swedish engineering companies

Acquired Westinghouse (& GE large

power) transformers in 1989

Predecessors founded in 1883 and 1891

(Westinghouse & GE in the 1880’s)

Publicly owned company with head

office in Switzerland

Region Headquarters in Raleigh, NC

More than 30,000 employees working in

the United States, Canada, and Mexico

© ABB Inc. 2015 - Slide 22

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 11 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB North America Footprint

Fort Nelson

Fort McMurray

Fort St John

Grande Prairie

Fox Creek Bonnyville

Edmonton

Edson

Rocky Mtn House Stettler

Eckville Red Deer

Calgary

Winnipeg

Vancouver

Jonquière

Saanichton Thunder Bay

Quebec City Saint Jean

Tacoma St Laurent Saint Claire

Sudbury Montreal Varennes

NAM REGION Hager City Iberville

Pointe Claire

Lachine

St Remi Saint John

Dorval Bromont

Combined Locations Scarborough

Stratford

Whitby

Brampton

New Berlin Burlington

Auburn Hills Stratford

Westland Mercer

Chicago Wickliffe Windsor

Boulder Cleveland Natrona Hts

Westerville Danbury

Pittsburgh Hackettstown

Napa Aurora Mt Pleasant/Greensburg North Brunswick

St Louis Warminster

Lewisburg Richmond

Santa Clara Mountain View Jefferson City South Boston

San Jose Sunnyvale Bland Hickory

Pinetops

Albuquerque Bartlesville Rogersville Marion • Cary

Claremore Nashville Crossville

Portland Asheville • Raleigh

Camarillo Westville Clarksville Huntersville

Carson Phoenix Athens,TN

Fort Smith Alamo Atlanta Kings Mountain

San Diego Memphis Clio

Byhalia Florence

Charleston

Greenville

Zaragoza Midland Belton

Houston Athens,GA

Sugarland

Pleasanton Ozark Gadsden Ormond Beach

Jonesboro Birmingham Lake Mary

South Haven

Gainesville

Prairieville Coral Springs

Columbus

Monterrey New Orleans Miramar

Crystal Springs

San Luis Potosí Vega Baja

Guanajuato

Jalisco Mexico City

Veracruz

© ABB Inc.

March 21, 2015 | Slide 23

Transformers

One stop shop supplier

History

125+ yr business

> 20 companies

Facts

Sales in 110 countries

Orders & Rev: 6 BUSD

55 locations in 23 countries

16 500 employees

Range: 10 kVA to 1600 MVA

Global management team:

8 nationalities

Homepage:

www.abb.com /transformers

© ABB Inc. 2015 - Slide 24

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 12 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

World Map ABB Transformer Factories 2015

Sweden – Ludvika

Norway – Steinkjer

Sweden – Pitea

Norway – Drammen

Finland – Vaasa

Ireland – Waterford Russia – Khotkovo

Canada – Edmonton Germany – Brilon Sweden – Mjolby

Canada – Quebec City Germany – Bad Honnef Sweden – Figeholm

Germany – Roigheim Poland – Lodz

Canada – Varennes

Germany – Halle

USA – South Boston Italy– Legnano

China– Hefei

USA – Bland Switzerland – Geneve Italy– Monselice

USA - Jefferson City Spain – Bilbao South Korea – Chonan-si

Turkey– Istanbu China– Chongquing

Spain – Zaragosa

USA – St Louis Switzerland – Zurich

USA – Alamo

Spain – Cordoba

USA – Crystal Springs China– Shanghai

Egypt – 10th of Ramadan China– Zhongshan

Saudi Arabia – Riyadh

Vietnam – Hanoi

India – Baroda

Thailand – Bangkok

Singapore – Singapore

Tanzania – Arusha

Columbia – Pereira

Peru – Lima Australia – Darra

Brazil – Guarulhos

South Africa – Pretoria

South Africa – Booysens

Brazil – Blumenau

Australia – Perth

South Africa – Cape Town

• 54 Factories in 28 Countries New Zealand – New Plymouth

© ABB Inc. 2015 - Slide 25

• Sales to 130 Countries

Transformers are all around us in different segments

You will find ABB transformers…

in buildings and in airports we use when

traveling,

crossing oceans and on the sea bed,

in substations that power our industrial

areas,

on the trains we ride and in the facilities

that process our water,

in windmills, solar fields, urban areas and

households.

© ABB Inc. 2015 - Slide 26

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 13 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformers are all around us in different applications

Wherever you are, transformers are near by

1 6

Traction and Dry type distribution

distribution transformers

transformers 7 8

2 6 7

Distribution Subsea

transformers transformers

3 8

Power and 5 10 Dry type distribution

distribution 3 transformers

transformers

9

4 9

Power transformers Power and

4 distribution

transformers

5 10

Low sound emitting Power transformers

transformers

1 2

© ABB Inc. 2015 - Slide 27

ABB Transformers

Technologies

Rated voltage

Power Transformers

161 kV Small Power Transformers

72.5 kV Dry Type

CORE TYPE

Liquid filled

36 kV

distribution

SHELL TYPE

10 MVA 40 MVA 63 MVA Rated power

Four common technology platforms guaranteeing highest quality

© ABB Inc. 2015 - Slide 28

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 14 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformers

Complete portfolio – product offering

What ever you need

from our broad

Generator step-up, Network

portfolio ->

ABB is your “one-stop

Large Medium Coupling, Shell, Shunt Reactors,

shop” supplier Small Power Phase-Shifting & HVDC, etc.

Large Medium 1ph, 3ph, Mineral, Silicon, Midel,

Small BioTemp®, Pole, Pad, Ground,

Distribution Sub-Sea, Cooling, etc.

Cast Coil, Open Wound,

Dry Type RESIBLOC®, Vacuum Pressure

Distribution Impregnated, VP

Encapsulated, etc.

AC Furnace, DC Furnaces, DC

Industrial & Electrolysis Process (Al, Cl), AC

Special series Reactors, etc.

IEEE/ANSI & IEC standards

© ABB Inc. 2015 - Slide 29

Transformer components

Insulation and components for transformers

Pressboard Protection & Preservation Systems

Winding and Active Kits Renewal Parts

Transformer Bushings Insulation Materials

Tap Changers Hollow Composite Insulators

Diagnostic & Control Systems Distribution components

In-house technology

© ABB Inc. 2015 - Slide 30

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 15 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Energy efficient and green solutions for a better world

Technology trends reflecting environmental needs

EcoDry family – dry type transformers

Highest efficiency dry type transformer for industrial and utility

applications reducing no load loss by 2/3 and load loss by 1/3

The green liquid filled distribution transformer program

Energy efficient products and solutions for lower CO2 emissions

The amorphous metal distribution transformer is one concept of the

green program

Natural and Synthetic Esters

Natural ester-based dielectric fluids

Biodegradable insulating fluid made out of seeds

A complete and sustainable solution for both distribution and power

transformers associating environmental friendliness (high

biodegradability), safety (superior fire resistance), and efficiency (high

overload capacity)

Ultra low sound emitting transformers

20-25 decibles dB(A) below conventional noise specifications

dB(A) reduction without use of sound panels or sound enclosures

© ABB Inc. 2015 - Slide 31

Transformers for special applications

Experience well beyond standard power transformer

applications

Generator Step up Arc furnaces

Excitation Rectifiers

Substation T&D Boosters

Phase Shifter Marine

HVDC converters Offshore distribution

Reactors Traction

Step down Variable speed drives

Solar energy Windmills

© ABB Inc. 2015 - Slide 32

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 16 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Transformers

Factories in North America

Edmonton

St. Louis Quebec

Varennes

Bland

South

Jefferson City Boston

Alamo

(Athens)

Crystal

Springs

© ABB Inc. 2015 - Slide 33

ABB Power Transformers - North America

Transformers Product Scope Top Rated (MVA)

System kV

LPT

275 kV

345 kV

Varennes

MPT

St. Louis

172 kV

SPT

72.5 kV South Boston

Crystal Springs

36 kV

DTR

3Ф, Top Rating

6.25 MVA 63 MVA 150 MVA 300

200MVA

MVA

© ABB Inc. 2015 - Slide 34

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 17 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers - North America

Varennes, Quebec, Canada

Built in 1971 by ASEA

260,000 square feet

300+ employees

Plant's average ANNUAL production

capacity: 20,000 MVA

Production capacity:

Ratings from 200 to 1200 MVA

Rated Voltage up to 800 kV

BIL max: 2400 kV

Shunt reactors of 5 to 300 MVAr

Independent test lab, connected by

rail, one mile away.

Quality/Certificates: ISO 9001, ISO

14001

Current lead time: 15 months EXW

© ABB Inc. 2015 - Slide 35

ABB Power Transformers - North America

Varennes, Quebec, Canada

ABB IREQ HV

Varennes Laboratory

© ABB Inc. 2015 - Slide 36

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 18 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers - North America

Varennes, Quebec, Canada

ABB Varennes builds the largest, most sophisticated

power transformers in North America

1200 MVA, 735 kV

© ABB Inc. 2015 - Slide 37

ABB Power Transformers - North America

Varennes, Quebec, Canada

© ABB Inc. 2015 - Slide 38

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 19 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers - North America

St. Louis, Missouri, USA

10 minutes from Lambert International Airport, located

in industrial area, between airport & downtown

ABB hotel agreements near airport & downtown ($70-

100/night)

Built in 1950’s by Moloney Electric

Westinghouse purchased 1975 as a repair facility

Upgraded in 1985 for new transformer production

Recent investments: over $1M USD test floor upgrade

in 2013

Over 300,000 square feet

All new transformers produced to TrafoStar technology

Waste elimination through TPS – Transformer

Production System

Daily management GEMBA walks insures early issue

identification and resolution

4Q quality quadrant approach

Sigma cards document process control & quality

Certifications:

ISO 9001

ISO 14001

© ABB Inc. 2015 - Slide 39

ABB Power Transformers - North America

St. Louis, Missouri, USA

Capacity:

Total output >12,000 MVA per year

Average MVA >170 MVA per transformer

Produces about 60-75 units per year

230+ employees: First shift full, partial 2nd shift,

skeleton 3rd shift

Non-union facility, very flexible workforce

Average tenure 21 years

Thorough interview & training process with continuous

refresher courses for all employees

Dielectric test capability up to 345 kV, 1300 kV BIL

Full thermal test capability through 500 MVA

Mobile AC test system based in St. Louis allows full

PD testing for transformers through 765kV

200 ton crane with 70’ lift, 150 ton crane with 45’ lift

Service and Repair Center for US, Canada and

Mexico; dedicated/separate repair area

© ABB Inc. 2015 - Slide 40

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 20 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers - North America

St. Louis, Missouri, USA

ABB Focused Factory for Technically Challenging

Medium Power Transformers (>63 MVA, up to 500

MVA for autotransformers)

Customer focused sales organization, covering all

transformers sold into North America

Thorough technical and commercial specification

review

All quotations fully designed with a production capable

design (4 designers focused on St. Louis units)

Engineering Staff:

5 electrical designers

13 mechanical designers

2 controls engineers

Engineers participate in KCC training every 2-3 years

Current Lead Time: 6-8 months ARO EXW

© ABB Inc. 2015 - Slide 41

ABB Power Transformers - North America

St. Louis, Missouri, USA

Capability

Center of Excellence for development, design and

technical assessment of new power transformers

Specializes in technically challenging medium

power transformers

Repair and Assessment Center of Excellence

TRES “owns” and maintains an archive of original

technical & manufacturing information for:

Westinghouse (US & Canada)

GE (Pittsfield Large Power & Canadian GE)

Kuhlman

Moloney Electric

ABB; including Asea, BBC, EB National

Industri, Strömberg and others

representing 70-80% of US installed base of

power transformers

© ABB Inc. 2015 - Slide 42

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 21 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Movies should be screened in the

grey area as featured here, size

proportion 4:3. No titles should be

used.

ABB St. Louis featured on Fox Business Network

© ABB Inc. 2015 - Slide 43

https://www.youtube.com/watch?v=HaK8vLSyphY

ABB Power Transformers - North America

SPT – Crystal Springs, MS and South Boston, VA

South Boston, Virginia Crystal Springs, Mississippi (Since 1953)

2006 greenfield expansion for MPT Line Substation Transformers 1 and 3 Phase

up to 161kV and 63 MVA Oil-Filled Instrument Transformers (HV)

Network Transformers (DTR) Field Services

Unit Substation Transformers 179,000 square feet / 16 acres

3 phase Padmount Transformers 25,600 sq ft used for Oil-filled Instrument

Substation Transformers 1 and 3 Phase transformer production

Field Services ISO 9001 Registered (UL)

>100,000 sq ft IUE-CWA Local 83799 (Since 1974)

ISO 9001 Registered (UL)

Non-union

© ABB Inc. 2015 - Slide 44

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 22 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers - North America

South Boston, Virginia, USA

Factory Facts (Line 1)

Built in 1968

Area: >400,000 sq. ft.

Employees: 450+

Maximum MVA capability: 20 MVA

Maximum voltage & BIL capability: 69

kV, 350 BIL

2006 expansion for MPT Line – up to

161kV and 63 MVA – increased size

to >510,000 sq. ft.

Scope of Supply

Liquid Filled small power transformers,

including substation, secondary unit

substation, network, and padmounted.

© ABB Inc. 2015 - Slide 45

ABB Power Transformers

Cordoba, Spain

Founded in 1930, taken over by Westinghouse in 1970

(plant enlargement, technology transfer/license)

First 525 kV unit built in 1980

Taken over by ABB and further upgraded in 1990

Plant capacity: 15,000 MVA (shell form + core form)

Capability through 525 kV, 1800 kV BIL, 1200 MVA

Employees: 300+

ABB Global Center of Excellence for Shell Form

Transformers

Certifications: ISO 9001, ISO 14001

Product range:

Core form (> 200 MVA)

Shell form (large GSU, autos, fast deployable

transformers, POLYTRANSFORMERS

Current lead time EXW:

Shell-form: 12 months ARO

Core-form: 14 months ARO

© ABB Inc. 2015 - Slide 46

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 23 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Shell Transformers – Cordoba, Spain

Highlights / Main Features

ABB Shell covers all transformer applications

especially in the large power range up to 1200MVA

and very high voltages, providing a compact and

robust alternative.

Some important features are:

State of the art design tools and manufacturing

processes.

High efficiency with low losses and controlled hot

spots to increase life expectancy.

Compact design to meet transportation limits.

Exceptional natural mechanical robustness for

short circuit events and transport accelerations,

making them uniquely suited for high-current

industrial applications requiring excellent through-

fault performance.

Flexibility to electrically and mechanically match

existing units to meet dimensional, connection

arrangements and impedance requirements.

Simple retrofit and repair process.

© ABB Inc. 2015 - Slide 47

ABB Shell Transformers

Highlights Main Applications

The main applications are:

Generator step up transformers: Nuclear power

plants and other generating stations.

Substation autotransformers: Interconnection

between high voltage transmission lines.

Multi-voltage transformers: Spares,

contingency planning and asset management.

Polytransformers: Multi-voltage

autotransformer planned to substitute within

an existing fleet a wide number of substation

transformers.

Universal GSU’s: To replace different units

in several power plants, even with different

power outputs, generator voltages or

physical arrangements.

Industrial Transformers: Uniquely suited for

high-power/current industrial applications

requiring excellent mechanical stability.

Replacement of existing units: Matching

dimensions and characteristics.

© ABB Inc. 2015 - Slide 48

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 24 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Shell Transformers

Large GSU’s

1100MVA 3ph GSU 345kV at QC1 Exelon NPP (USA)

© ABB Inc. 2015 - Slide 49

ABB Power Transformers

Bad Honnef, Germany

Built in 1906 as August Lepper GmbH;

purchased by Asea in 1965; ABB since 1988

300+ employees

German Headquarters of Transformer

Business (Bad Honnef, Halle and Brilon)

TrafoStar Development Group Headquarters

Home of KCC (Transformer Knowledge

Communication Center)

ABB Focused Factory for Phase Shifting

Transformers and Industrial Transformers

Over 320,000 square feet

About 75 units per year

Up to 500 kV

300 ton crane

Certifications: ISO 9001, ISO 14001, KTA

Current leadtime for PST: 15 months ARO

EXW

© ABB Inc. 2015 - Slide 50

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 25 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Power Transformers

Ludvika, Sweden

Built in 1900 as Elektriska AB Magnet

Purchased by Asea in 1916, ABB from

1988

Over 300,000 square feet

500+ employees

ABB Focus Factory for Large power

transformers, 800 kV, HVDC, reactors

About 80 units per year

Up to 800 kV, (delivered one 765 kV to

USA in 1978)

400 ton crane

Certifications:

ISO 9001, ISO 14001

Current leadtime: 15 months EXW

for Shunt Reactors

© ABB Inc. 2015 - Slide 51

ABB Power Transformers

Lodz, Poland

• Production of Power Transformers since

1925, Elta purchased by ABB in 1991

• Over 350,000 square feet

• 900+ employees

• ABB Focus Factory - Medium Power

Transformers, <250MVA, up to 345kV

• About 60 units per year

• Distribution Transformers

• Insulation Kit Centre for southern Europe

• 250 ton Lifting Capacity

• Certifications:

• ISO 9001

• ISO 14001

• Lead Time: 9 months EXW

© ABB Inc. 2015 - Slide 52

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 26 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

ABB Dry-type Transformers

Bland, VA

Applications

Secondary Unit Substation

Transformers

Exciter transformers

Sub-transmission

Insulation System Technologies

VPI, Cast Coil, Resibloc®

© ABB Inc. 2015 - Slide 53

ABB Power Transformers - North America

Transformers Product Scope Top Rated (MVA)

ABB South Boston

Westinghouse

St. Louis Varennes

Westinghouse Asea

& Crystal Springs

Kuhlman

10 63 300 1200

S. Boston Small Power

C. Springs Small Power

St. Louis Medium Power

St. Louis Repairs

Varennes Large Power

Cordoba – Shell Form

Ludvika, Sweden

(&Varennes, Canada) Shunt Reactors (5 to 300 MVAr)

ABB Off-Shore Power Production can be optimized according to workload

All core-form plants use common technology (TrafoStar)

© ABB Inc. 2015 - Slide 54

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 27 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Craig L. Stiegemeier, ABB Transformer Remanufacturing & Engineering Services

Transformer knowledge enrichment

Power transformer basics

© ABB Inc. 2015

TRES North America - Slide 55

Power Transformers – some general comments

first transformer 1885, well developed technology today

simple working principle - unchanged since then

large, heavy and expensive component in the power system – optimization

the larger a unit the less cost per unit power

total cost is factory cost plus cost of losses over life time

highest cleanness mandatory during production

© ABB Group

March 21, 2015 | Slide 56

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 28 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer principle I

flux

( main flux U2

m)

~ U1

U2 ~

I0

U ~

1 = = m =

no-load condition

Current causes a magnetic field (EMF)

EMF I w

Time varying magnetic flux induces voltage in coil (induction law)

d d

U w U

dt dt

© ABB Group

March 21, 2015 | Slide 57

Transformer principle II

I2

U2

~ U1

I1

U ~ 2 U2 2 1

(stray flux

1

load condition w1 I1 w2 I 2

I2 sc

U2=0

~ U1

I1 sc 2 0

U ~

1

w1 I1 w2 I 2

© ABB Group

March 21, 2015 | Slide 58

short-circuit condition

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 29 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer equivalent circuit

magnetic circuit based -equivalent

i1 L i2

im1 im2

u1 u2

L1 L2

practically used T-equivalent circuit

i1 R1 L1 L2 R2 i2

im

u1 u2

uh

Lm RFe

© ABB Group

March 21, 2015 | Slide 59

Transformer main components

Core grain oriented silicon steel

Winding copper

Insulation paper, pressboard, oil

Leads paper insulated cables / bars

Tank steel

Bushings component

Tap changer component

50…60% of total factory cost is material!

© ABB Group

March 21, 2015 | Slide 60

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 30 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer core - requirements

Mechanical strength

transportation forces

short circuit forces

seismic forces

Thermal demands

low losses

hot spot control

over magnetism

Low noise

Core mass for largest units > 250 tons

© ABB Group

March 21, 2015 | Slide 61

Transformer core - types

3-phase

cores

1-Phase

cores

© ABB Group

March 21, 2015 | Slide 62

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 31 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer core - material and stacking

A A

View A-A

Conventional Step lap

Loss and noise minimization

Grain oriented silicon steel

0.23…0.35 mm thick

© ABB Group

March 21, 2015 | Slide 63

Transformer core material – carries magnetic flux

The core is an unbroken path for magnetic flux

Normally reused for a repair /

A A remanufacture

View A-A

Conventional Step lap Core is cleaned and damaged

material is replaced

The core laminations are a high tech material

Iron crystals oriented to align with

flux

Insulation coating to reduce losses

from eddy currents

© ABB Group

March 21, 2015 | Slide 64

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 32 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer core - mechanics

Clamping force required to

guarantee friction force in

joints

Step blocks to keep

clamping plate straight

Core support beam to

withstand longitudinal forces

up to 5g during

transportation

© ABB Group

March 21, 2015 | Slide 65

Transformer core material improvements

Core performance is set by configuration and

material

W/lb Continuous

improvement in

core steel

quality

Reduction in

specific losses

by a factor of

five

© ABB Group

March 21, 2015 | Slide 66

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 33 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Winding arrangement

Means physical location relative to core

Operating characteristics and costs are strongly affected

Optimization task for designer

Core

Core

A B C D

© ABB Group D

March 21, 2015 | Slide 67

Winding arrangement optimization

Winding shells:

• Concentric arrangement

• Effectively equal heights

• LV often nearest core

• HV often the outer winding

• Equal current distribution

• Ensure balanced flux distribution

© ABB Group

March 21, 2015 | Slide 68

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 34 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Insulation system

Made from organic material that

degrades over time

Typically an aggregate of:

Cellulose (wood fibers)

Mineral oil

Insulation system separates:

HV winding

LV winding (s)

Regulating winding (if present)

Ground

Directs cooling oil to dissipate heat

from I2R and eddy losses

Provides support in radial and axial

dimensions to withstand short

circuit forces

© ABB Group

March 21, 2015 | Slide 69

Transformer insulation

1. winding insulation

2. winding end insulation

3. main insulation between windings

4. exit lead insulation

mainly cellulose based material

immersed in mineral oil

high dielectric, mechanical and thermal strength

© ABB Group

March 21, 2015 | Slide 70

low shrinkage during drying

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 35 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Insulation system components

Winding & active part kits

Winding cylinders are oil

impregnated to limit growth

Components are manufactured

to tight tolerances

© ABB Group

March 21, 2015 | Slide 71

Conductor material

Load losses can be reduced and short circuit performance

enhanced through the use of modern CTCs

Glue

The continuously transposed cable is an important

tool for the control of eddy current losses.

© ABB Group

March 21, 2015 | Slide 72

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 36 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Vertical winding lathes (gravity compacts the winding)

© ABB Group

March 21, 2015 | Slide 73

© ABB Group

March 21, 2015 | Slide 74

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 37 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Winding arrangement - Examples

Two windings

Yoke entry HV Four windings

HV with body taps Yoke entry HV

LV HV Double layer LV Ter LV HV HVreg Separate HV reg

Inside Tertiary

Four windings

Four windings Yoke entry HV

Centre entry HV Separate N reg

N LV HV Separate N reg Outside Tertiary

Ter N LV HV Ter

reg Inside Tertiary

reg

© ABB Group

March 21, 2015 | Slide 75

“Landing” of windings

© ABB Group

March 21, 2015 | Slide 76

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 38 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Nesting of windings

Proper technique can improve (tighten) radial

tolerances

© ABB Group

March 21, 2015 | Slide 77

Transformer Cleats & leads

© ABB Group

March 21, 2015 | Slide 78

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 39 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Cleats & Leads

mechanical withstand capability – also in short circuit case

sufficient dielectric clearance to each other and ground (tank/core)

temperature limits

© ABB Group

March 21, 2015 | Slide 79

Loss components in transformers (no-load losses)

Losses due to core flux (no-load loss)

Losses in windings to winding current and magnetic field in winding

Losses in structural metallic parts due to magnetic stray field entering

Load losses 100%

Winding: ~ 85 %

Structural parts: ~ 15%

Total losses 100%

no-load losses: 10…15 %

load losses: 85…90 %

© ABB Group

March 21, 2015 | Slide 80

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 40 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Winding losses – components and relative ratio

Winding losses 100%

ohmic: ~ 85 %

axial eddy: ~ 10%

radial eddy: ~ 5%

Radial

eddy

loss

ohmic Axial

loss eddy

loss

© ABB Group

field plot Winding arrangement losses

March 21, 2015 | Slide 81

Transformer tank

Corrosion protection system – water based paint system

Vacuum and overpressure proof

Sealing system for live time (change gaskets only when opened)

Controlled rupture in case of internal arcing (on tank cover)

Low noise (avoid tank resonances)

Equipment to be mounted on tank

1. Temperature indicators

2. Oil indicators

3. Breathers

4. Gas detection relays

5. Oil conservators

6. Control cabinets

7. Tap changers

8. Bushings

9. CoreTec (Monitoring system)

10. CoreSense (Gas sensor)

© ABB Group

March 21, 2015 | Slide 82

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 41 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Remanufacturing & Engineering Services

Transformer knowledge enrichment

Transformer failure mechanisms

© ABB Inc. 2015

Stresses Acting on Power Transformers

Understanding These Allows Development of an

Effective Transformer Maintenance Plan

Mechanical Stresses

Forces between conductors, leads and windings due to

overcurrents or fault currents caused by short circuits

and inrush currents

Thermal Stresses

Due to local overheating, overload currents and leakage

fluxes when loading above nameplate ratings;

malfunction of cooling equipment

Dielectric Stresses

Due to system overvoltages, transient impulse

conditions or internal resonance of windings

© ABB Inc. 2015 - Slide 84

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 42 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Mechanical Stresses in Power Transformers

The fault current is

governed by:

Open-circuit voltage

Source impedance

Instant of fault onset

Displacement of

current

© ABB Inc. 2015 - Slide 85

Transformer Failure Modes

Mechanical Stresses in Power Transformers

A short circuit gives rise to:

Mechanical forces

Temperature rise

The transformer must be designed so that

permanent damage does not take place

The first peak of a full short circuit current can

be 20 times higher than in normal operation

The forces on the transformer windings and

leads are typically 400 times higher than in

normal operation

Two force components on windings:

radial

axial

Electromagnetic forces tend to increase the

volume of high flux

Inner winding to reduced radius

Outer winding towards increased radius

Winding height reduction

© ABB Inc. 2015 - Slide 86

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 43 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Effect of the radial forces on windings

Fmean

Inner Outer

winding winding

Radial forces inwards Radial forces outwards

compressive stress tensile stress

© ABB Inc. 2015 - Slide 87

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Effect of the axial forces on windings

The radial

component of

the leakage

flux creates

forces in axial

direction

Axial short circuit forces accumulate towards winding mid-height

© ABB Inc. 2015 - Slide 88

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 44 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Mechanical Stresses in Power Transformers – Axial

B B Fax Fax

Axial imbalance

will create extra

axial forces

B B Fax Fax

The forces tend

to increase the

imbalance

© ABB Inc. 2015 - Slide 89

Transformer Failure Modes

Mechanical Stresses in Power Transformers - Radial

Failure mode Buckling: Failure mode Spiraling:

Characteristic failure Characteristic failure mode

mode for inner winding for inner and outer winding

© ABB Inc. 2015 - Slide 90

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 45 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Risk: Short Circuit Forces & Stresses

Through faults are often the cause of

transformer failures

Many older designs have insufficient

margin for today’s fault currents

Loose coils due to aging can cause

failures

Normal aging can cause brittle

insulation and increased failures

Even brief overloading may cause

significant aging

Oxygen in the oil can double the

aging rate

Moisture in the insulation increases

aging rate 2-5 times depending on

the amount of moisture

© ABB Inc. 2015 - Slide 91

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Two examples showing buckling of inner windings

© ABB Inc. 2015 - Slide 92

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 46 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Axial force failure modes:

Collapse of winding end support

Tilting of winding conductors

Telescoping of windings

Bending of cables between spacers

Damage of conductor insulation

© ABB Inc. 2015 - Slide 93

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Axial forces cause:

Mechanical withstand of insulation material

Risk for tilting

© ABB Inc. 2015 - Slide 94

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 47 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Mechanical Stresses in Power Transformers

Failure mode

Collapse of end support

Failure mode

Bending of cables

Failure mode

Conductor tilting

© ABB Inc. 2015 - Slide 95

Transformer Failure Modes

Short circuit failure video example

Unit Auxiliary Test Transformer Failure

Internal High Speed Film Camera Footage

© ABB Inc.

Originally taken by The General Electric Company at

Pittsfield, Massachusetts

© ABB Inc. 2015 - Slide 96

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 48 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Winding sizing – effective axial compression

Windings are designed for removal of pressboard

Disc windings – can remove “minus” keyspacers

Layer windings – adjustment done at end of windings

© ABB Group

March 21, 2015 | Slide 97

Transformer Failure Modes

Mechanical Risk: Short Circuit Forces & Stresses

Little Risk of Failure

Design Margin

Slight Risk of Failure

Design #1

Design #2

Design #3

High Risk of Failure

Design #4

HV Radial HV Axial LV Radial LV Axial LTC LTC

(Hoop) (tipping or (Buckling) (tipping or Winding Winding

crushing) crushing) Radial Axial

(Buckling) (tipping)

Figure 3. Results of the Short-Circuit Strength Design Analysis used in a Life Assessment Study

© ABB Inc. 2015 - Slide 98

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 49 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Thermal Stresses in Power Transformers

Loading is primarily limited by highest permissible temperatures in

the transformer, especially within the windings

Temperature limits are based on:

Expected lifetime

The risk for oil vaporization

Permissible temperatures are generally expressed as temperature

rises above ambient

Ambient temperature is in turn defined by current standards

24 hour ambient temperature average 30° C

Maximum ambient 40° C

In accordance to Standards:

Winding temperature rise 65° K

Top oil temperature rise 65° K

Hot spot temperature rise 80° K

© ABB Inc. 2015 - Slide 99

Transformer Failure Modes

Winding Temperature Rise and HS Calculation

Winding hot spot

Top oil rise

hot spot factor

Winding average rise

Copper over tank oil gradient

Copper over winding oil gradient

Winding Ambient Bottom oil

Temperature

© ABB Inc. 2015 - Slide 100

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 50 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Thermal Stresses in Power Transformers

Life Expectancy Based on DP and Other Factors

© ABB Inc. 2015 - Slide 101

Transformer Failure Modes

Thermal Risk: Intensive aging

© ABB Inc. 2015 - Slide 102

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 51 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Thermal Risk: Intensive aging

© ABB Inc. 2015 - Slide 103

Transformer Failure Modes

Degree of Polymerization – DP

Measures Insulating Paper Strength

Degree of polymerization is a measure of the number of

intact chains in a cellulose fiber. It provides an indication of

the ability of the transformer insulation to withstand

mechanical force (due to through-faults, etc).

Cellulose Fiber Chain

© ABB Inc. 2015 - Slide 104

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 52 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Factors affecting DP and Measurement Method

The DP of the insulation is affected by the following

conditions:

Moisture content

Acidity of the oil

Oxygen content

Temperature

The DP is measured by viscosity measurements according

an ASTM method after dissolving the paper samples in

cupriethylene diamine solvent.

Paper samples must be taken from enough different

areas in a transformer in order to get a profile of

deterioration of the cellulose

When combined with detailed design knowledge,

measurements in one area of the transformer can give

information on the condition of paper in inaccessible

areas of the windings.

© ABB Inc. 2015 - Slide 105

Transformer Failure Modes

Life Expectancy Based on DP and Other Factors

It is assumed that the DP of transformer insulation is approx. 1,000 at the start of life and approx.

200 at the end of life. This graph shows the expected life of thermally upgraded insulation

(Insuldur) under various conditions:

10000.0

Dry & Clean (Insuldur)

Acidic Oil (Insuldur)

1000.0 1% Water Content (Insuldur)

3-4% Water Content (Insuldur)

L ife E x p e c ta n c y (y e a rs )

100.0

10.0

1.0

0.1

50 60 70 80 90 100 110 120 130 140 150

Temperature [o C]

For long insulation life expectancy, it is important to keep the insulation dry, keep acidity

and oxygen concentration of oil low and provide good cooling for insulation

© ABB Inc. 2015 - Slide 106

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 53 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Moisture and loading capability – risk of bubble

formation

Loading limits based on moisture content

Hottest Spot Cellulose Overload Level

o Moisture Overload Type with 40°C

Temperature( C)

(% ) Ambient

120 3.5 Normal Loading 0%

130 2.4 Planned O/L Beyond N/P 6%

140 1.7 Long Time Emergency (1-3 mo.) 12%

180 0.8 Short-Time Emergency (½ -2hr) 40%

© ABB Group

March 21, 2015 | Slide 107

Transformer Failure Modes

Dielectric Stresses in Power Transformers

Overvoltage integrity

Overvoltages can be divided into two classes:

Continuous

Transitory

Continuous overvoltage is related to the core and its

magnetization (“normal” 50Hz or 60 Hz stresses)

Transitory overvoltage refers to intermittent stresses

placed on the insulation system, usually at much higher

levels than the power frequency stresses

© ABB Inc. 2015 - Slide 108

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 54 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Dielectric Stresses in Power Transformers

Transient Voltages

Lightning and switching impulse

surges are called “Transients”

because their duration is short.

The frequencies are much higher

than the power frequency (60 Hz

here) operation frequency.

Transient calculations are used to

find the time dependent distribution

of transient voltages, applied on the

line terminals, over the windings.

© ABB Inc. 2015 - Slide 109

Transformer Failure Modes

Dielectric Stresses in Power Transformers

Winding oscillation

Voltage

Win-

ding

Winding length

© ABB Inc. 2015 - Slide 110

Copyright © ABB Inc. 2015

All rights reserved. Any reproduction – in whole or in part – 55 March 19, 2015

is forbidden without ABB’s prior written consent.

ABB Transformers and Transformer Remanufacturing and

Engineering Services Overview for ECE 431

Transformer Failure Modes

Analysis of Bushing Failure

525 kV unit – assumed bushing failure

Simulation showed electric stress was greatest on the paper

insulation around the shield ring

Used simulation to redesign insulation barriers

FLC evaluation

CAD-model Field distribution over the barriers and

© ABB Inc. 2015 - Slide 111 HV-LV windings

Transformer Failure Modes