Professional Documents

Culture Documents

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Uploaded by

Son NguyenCopyright:

Available Formats

You might also like

- Maestro EDGE (Feb, 2017)Document144 pagesMaestro EDGE (Feb, 2017)Kishonkumar Kishon100% (1)

- Godin String GaugesDocument2 pagesGodin String GaugeswplaisNo ratings yet

- NAS1834Document2 pagesNAS1834Ray DutchmanNo ratings yet

- NAS1835Document3 pagesNAS1835Ray DutchmanNo ratings yet

- Insert, Molded In, Threaded, Self-Locking, Nonself Locking, Sandwich PanelDocument3 pagesInsert, Molded In, Threaded, Self-Locking, Nonself Locking, Sandwich PanelAZIZNo ratings yet

- Eng CD TXR54 LDocument3 pagesEng CD TXR54 LZorbanfrNo ratings yet

- NA2159Document2 pagesNA2159Bogdan RusuNo ratings yet

- Wall Thickness: Piping SpecificationDocument2 pagesWall Thickness: Piping SpecificationLynn AlgerNo ratings yet

- Piping Class Spec. - 1c23pe (Lurgi)Document5 pagesPiping Class Spec. - 1c23pe (Lurgi)otezgidenNo ratings yet

- Hot Insulation Supports ENCI E16 FOR N:Na Mimed Storage TanksDocument3 pagesHot Insulation Supports ENCI E16 FOR N:Na Mimed Storage TankssahilNo ratings yet

- Piping Class Spec. - 3c5pe (Lurgi) PDFDocument9 pagesPiping Class Spec. - 3c5pe (Lurgi) PDFotezgidenNo ratings yet

- Piping Class Spec. - 1C16 (Lurgi)Document9 pagesPiping Class Spec. - 1C16 (Lurgi)otezgidenNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Piping Class Spec. - 1c9pe (Lurgi)Document8 pagesPiping Class Spec. - 1c9pe (Lurgi)otezgidenNo ratings yet

- RC 1Document2 pagesRC 1Anony MousNo ratings yet

- Isometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)Document2 pagesIsometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)leizel dacuNo ratings yet

- RCP PDFDocument2 pagesRCP PDFalfred jamNo ratings yet

- Piping Class Spec. - 1c28pe (Lurgi)Document8 pagesPiping Class Spec. - 1c28pe (Lurgi)otezgidenNo ratings yet

- Homac T&B Multi-LugsDocument3 pagesHomac T&B Multi-LugsallfloridaNo ratings yet

- Piping Class Spec. - 1c16pe (Lurgi)Document10 pagesPiping Class Spec. - 1c16pe (Lurgi)otezgidenNo ratings yet

- Piping Class Spec. - 1C23 (Lurgi)Document5 pagesPiping Class Spec. - 1C23 (Lurgi)otezgidenNo ratings yet

- Piping Class Spec. - 3c24pe (Lurgi)Document9 pagesPiping Class Spec. - 3c24pe (Lurgi)otezgidenNo ratings yet

- 5/8-18 UNF-2A: Sheet 1 of 1Document1 page5/8-18 UNF-2A: Sheet 1 of 1seanNo ratings yet

- PL 0201719 0 0000 307 MOP 1001 - Rev.1Document1 pagePL 0201719 0 0000 307 MOP 1001 - Rev.1Alejandro CastroNo ratings yet

- 59 e 02Document46 pages59 e 02Natarajan RavisankarNo ratings yet

- Rocking Steam Engines Vapeur MoteurDocument6 pagesRocking Steam Engines Vapeur MoteurSteve LebgNo ratings yet

- 28 X 44,5 (TYP.) : Mark Piece InformationDocument3 pages28 X 44,5 (TYP.) : Mark Piece InformationProorocu MikyNo ratings yet

- Piping Class Spec. - 1C9 (Lurgi)Document8 pagesPiping Class Spec. - 1C9 (Lurgi)otezgidenNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

- Io PanelDocument26 pagesIo PanelakramNo ratings yet

- Camy Plants: Final Dimension ReportDocument7 pagesCamy Plants: Final Dimension Reportnarendra vermaNo ratings yet

- Geneva Drive DrawingsDocument7 pagesGeneva Drive Drawingsapi-553158328No ratings yet

- Piping Class Spec. - 3C24 (Lurgi) PDFDocument9 pagesPiping Class Spec. - 3C24 (Lurgi) PDFotezgidenNo ratings yet

- G-4201 Volvo Penta Quan TrọngDocument2 pagesG-4201 Volvo Penta Quan TrọngleejoNo ratings yet

- 12.5-310-100 High Mast Lighting SystemDocument1 page12.5-310-100 High Mast Lighting SystemrituNo ratings yet

- GeneralDocument39 pagesGeneralDeerendra KaranthNo ratings yet

- Piping Class Spec. - 1C19 (Lurgi)Document9 pagesPiping Class Spec. - 1C19 (Lurgi)otezgidenNo ratings yet

- Extinguishing Control Unit A6V10061857 HQ enDocument38 pagesExtinguishing Control Unit A6V10061857 HQ enscribdkhatn0% (1)

- Butterfly Valves - 250 Psi: SIZE 2" - 8"Document2 pagesButterfly Valves - 250 Psi: SIZE 2" - 8"thilina lakhithaNo ratings yet

- Red Is Etch For Assembly: Bend Line See Bend Table & Table AboveDocument1 pageRed Is Etch For Assembly: Bend Line See Bend Table & Table AboveGurdeep Singh. 2209No ratings yet

- B1 PDFDocument1 pageB1 PDFSuman RoyNo ratings yet

- Online Weighing Scale Canopy TrussDocument1 pageOnline Weighing Scale Canopy TrussyogeshNo ratings yet

- NAS1836Document3 pagesNAS1836Ray DutchmanNo ratings yet

- MGPS DetailsDocument3 pagesMGPS DetailsjarekNo ratings yet

- G A DrawingDocument1 pageG A DrawingghillialexNo ratings yet

- E36 Test PanelDocument12 pagesE36 Test PanelGanesa MurthyNo ratings yet

- Terasaki Mapadecurvaedimensoes PDFDocument2 pagesTerasaki Mapadecurvaedimensoes PDFthyagoenerg100% (1)

- ColumnreportDocument3 pagesColumnreportOsama MamdouhNo ratings yet

- Shed Work Details: S.No Building Fabrication Bom Material Description QTYDocument7 pagesShed Work Details: S.No Building Fabrication Bom Material Description QTYBala SundharamNo ratings yet

- Workshop Customer #Id Email Order #Id: Alcoa Diesel 02.14.0760Document1 pageWorkshop Customer #Id Email Order #Id: Alcoa Diesel 02.14.0760carlos sousaNo ratings yet

- 4 KL TankDocument2 pages4 KL TankSantosh Reddy KesavaNo ratings yet

- Land Cruiser 40 Series: Year Model Features Winches Part NoDocument3 pagesLand Cruiser 40 Series: Year Model Features Winches Part NoAli GillaniNo ratings yet

- Tank Specification Sheet PDFDocument1 pageTank Specification Sheet PDFRaj Bahadur YadavNo ratings yet

- Fairchild Fasteners Europe: Saint Cosme OperationsDocument1 pageFairchild Fasteners Europe: Saint Cosme OperationsstaedtlerpNo ratings yet

- CalcsDocument7 pagesCalcskukadiya127_48673372No ratings yet

- Ref.: Gil/cms/g3/0591 Date: 31/03/2011Document2 pagesRef.: Gil/cms/g3/0591 Date: 31/03/2011prati121No ratings yet

- LMEL Opration and Maint of 90 T BOILERDocument249 pagesLMEL Opration and Maint of 90 T BOILERPratik TyagiNo ratings yet

- NPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20Document132 pagesNPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20MuhammadNurrahmanNo ratings yet

- BW and PathwayDocument1 pageBW and PathwaySHUBHAM SINGHNo ratings yet

- American Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883From EverandAmerican Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883Rating: 3 out of 5 stars3/5 (1)

- PTFE-Coated Anodized Aluminum Alloy 6061 With Icephobic PropertiesDocument6 pagesPTFE-Coated Anodized Aluminum Alloy 6061 With Icephobic PropertiesSon NguyenNo ratings yet

- Anod 7075-T6Document7 pagesAnod 7075-T6Son NguyenNo ratings yet

- History of Thermal Barrier Coatings For Gas Turbine Engines: Emphasizing NASA's Role From 1942 To 1990Document29 pagesHistory of Thermal Barrier Coatings For Gas Turbine Engines: Emphasizing NASA's Role From 1942 To 1990Son NguyenNo ratings yet

- Mil A 63576aDocument13 pagesMil A 63576aSon NguyenNo ratings yet

- NAS1832 Thru NAS1836, Inserts: Genuine Aircraft Hardware CoDocument3 pagesNAS1832 Thru NAS1836, Inserts: Genuine Aircraft Hardware CoSon NguyenNo ratings yet

- Preprints202002 0023 v1Document25 pagesPreprints202002 0023 v1Son NguyenNo ratings yet

- Fundamentals of Composites Manufacturing: Materials, Methods and Applications, 2 Edition DesignDocument43 pagesFundamentals of Composites Manufacturing: Materials, Methods and Applications, 2 Edition DesignSon NguyenNo ratings yet

- Surface RoughnessDocument79 pagesSurface RoughnessSon NguyenNo ratings yet

- (Vanbanphapluat - Co) tcvn4178-1985Document5 pages(Vanbanphapluat - Co) tcvn4178-1985Son NguyenNo ratings yet

- Surface Roughness 3Document26 pagesSurface Roughness 3Son NguyenNo ratings yet

- Solucionario Vinnakota Capitulo 8 PDFDocument50 pagesSolucionario Vinnakota Capitulo 8 PDFjupabuvi75% (4)

- Update Terbaru PFD FixDocument1 pageUpdate Terbaru PFD FixaulianwNo ratings yet

- EN7938 8 11 17 - OF5 - FahrbarDocument4 pagesEN7938 8 11 17 - OF5 - FahrbarPrasantaKumarMallikaNo ratings yet

- Flowserve, Rotary Valve & Actuation CatalogueDocument27 pagesFlowserve, Rotary Valve & Actuation CatalogueJunaidi Santoso100% (1)

- ASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesDocument3 pagesASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesFrancisco Marin BortoluzziNo ratings yet

- Microbiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaDocument8 pagesMicrobiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaInternational Network For Natural SciencesNo ratings yet

- Samsung Evaporator Technical Details Aug 17 PDFDocument9 pagesSamsung Evaporator Technical Details Aug 17 PDFkumarNo ratings yet

- Captive Air Commercial Kitchen Exhaust Vent ManualDocument31 pagesCaptive Air Commercial Kitchen Exhaust Vent ManualGiann CarlosNo ratings yet

- Soldering Equipment: How To Solder - Soldering TutorialDocument7 pagesSoldering Equipment: How To Solder - Soldering TutorialAnonymous f6goFflg3TNo ratings yet

- AirCon Brochure 2013Document12 pagesAirCon Brochure 2013Alex BaicuNo ratings yet

- Project On Partial Replacement of Cement With Marble PowderDocument8 pagesProject On Partial Replacement of Cement With Marble PowderYu Paing HanNo ratings yet

- Technical Training ManualDocument40 pagesTechnical Training ManualAkashdeep100% (1)

- DPWH Matl Min Test ReqDocument51 pagesDPWH Matl Min Test ReqEnterone Alvaro Rico100% (2)

- Deka Batteries PDFDocument6 pagesDeka Batteries PDFLuis Alonso Osorio MolinaNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- (N) HXH Fe180 E90Document3 pages(N) HXH Fe180 E90djordje tekicNo ratings yet

- CableDocument2 pagesCableJuan David Yepez MonterosNo ratings yet

- Final PPT LITRACONDocument15 pagesFinal PPT LITRACONRAmyaNo ratings yet

- Magnetic Nanoparticles ReviewDocument61 pagesMagnetic Nanoparticles ReviewramikNo ratings yet

- Aquafine DW Series ManualDocument19 pagesAquafine DW Series Manualjorman GuzmanNo ratings yet

- Instant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEDocument33 pagesInstant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEsam.hirt196100% (50)

- SMA Connector SeriesDocument26 pagesSMA Connector SeriesCmpterRFNo ratings yet

- 10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsDocument3 pages10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsVignesh RajanNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- Polymer and Composite Failure and Durability-Exam QuestionsDocument10 pagesPolymer and Composite Failure and Durability-Exam QuestionsNatalia Ramos MontillaNo ratings yet

- Presentation MPCBDocument26 pagesPresentation MPCBapi-26219976No ratings yet

- APM Steel and Cast IronsDocument48 pagesAPM Steel and Cast Ironsvarniraj patelmetNo ratings yet

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- Alphatec 3000 Trousers Ultrasonically Welded Taped Model 302 - Pds - GBDocument2 pagesAlphatec 3000 Trousers Ultrasonically Welded Taped Model 302 - Pds - GBsrikanth reddyNo ratings yet

- Tet 213 Fibre Length - 112836Document3 pagesTet 213 Fibre Length - 112836maryamibrahimhassan437No ratings yet

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Uploaded by

Son NguyenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Insert, Molded In, CSK and Thru Clearance Hole, Sandwich Panel

Uploaded by

Son NguyenCopyright:

Available Formats

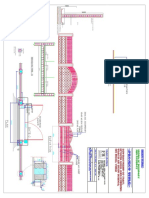

NAS 1834

SHEET 1OF 2

NAS 1834

INSERT, MOLDED IN, CSK AND THRU CLEARANCE

HOLE, SANDWICH PANEL

K

J 3 8 MIN 8

2 X .092 - .097 POTTING 2 X POTTING

& VENT HOLES & VENT SLOTS

(TYPICAL ALL STYLES)

2 X FULL R

OPTIONAL

ØD

"OPTIONAL" SLOTS

SHOWN

2X ØA

ØB .060

2X Ø A

.060 X 2 PLCS

7

L

.050

MIN 6 L

7

CSK Ø C X 99° - 101° ØB

COUNTERSINK CLEARANCE THRU CLEARANCE

HOLE STYLE HOLE STYLE

TABLE I

ØA ØD

FIRST J K L (a) INSTALLATION

+.000 ØB ØC CLEARANCE

DASH NO BASIC MIN MIN HOLE SIZE

-.010 HOLE

-06 .560 .30 .280 .139 - .145 .367 .260 .250 .561 - .566

-08 .560 .30 .332 .168 - .174 .367 .260 .250 .561 - .566

-3 .560 .30 .385 .195 - .201 .367 .260 .250 .561 - .566

-4 .685 .37 .507 .256 - .263 .467 .360 .312 .686 - .691

-5 .685 .47 .625 .315 - .322 .467 .360 .312 .686 - .691

-6 .841 .50 .750 .376 - .383 .591 .484 .375 .842 - .847

WITTEN COMPANY INC

918-272-9567

REV:- 8/25/09

NAS 1834

SHEET 2 OF 2

NAS 1834

INSERT, MOLDED IN, CSK AND THRU CLEARANCE

HOLE, SANDWICH PANEL

(a) MINIMUM LENGTH WHICH MAY BE SPECIFIED.

MATERIAL: CARBON STEEL PER ASTM-A-108, ASTM A576 OR MATERIAL COMPOSITION PER FED-STD-66.

ULTIMATE TENSILE STRENGTH , 85 KSI MINIMUM

ALUMINUM ALLOY, GRADE 2024 (UNS A92024) TEMPER T4 OR T351 PER QQ-A-225/6.

CORROSION RESISTANT STEEL, TYPE 303 (UNS S30300) PER ASTM A582.

FINISH: CARBON STEEL - CADMIUM PLATE PER SAE-AMS QQ-P-416, TYPE II, CLASS 2.

ALUMINUM ALLOY - ANODIZE PER MIL-A-8625 TYPE I, CLASS OPTIONAL.

CRES - PASSIVATE PER ASTM-A-967.

CODING: NO LETTER AFTER BASIC NUMBER INDICATES CARBON STEEL, CADMIUM PLATED.

SUFFIX A TO BASIC NUMBER INDICATES AL ALLOY ANODIZED.

SUFFIX C TO BASIC NUMBER INDICATES CRES, PASSIVATED.

FIRST DASH NUMBER INDICATES CLEARANCE HOLE SIZE SEE TABLE I.

SUFFIX K TO FIRST DASH NUMBER INDICATES COUNTERSUNK TYPE.

SECOND DASH NUMBER INDICATES LENGTH IN THOUSANDTHS.

EXAMPLE OF PART NUMBER:

NAS1834-3-500 CARBON STEEL, CADMIUM PLATED, .500 LONG WITH THRU CLEARANCE HOLE

FOR .1900 BOLT.

NAS 1834C4-500 CRES, PASSIVATED, .500 LONG, WITH THRU CLEARANCE HOLE FOR Ø .2500 BOLT

NAS 1834C4K1250 CRES, PASSIVATED, 1.250 WITH COUNTERSUNK THRU CLEARANCE HOLE

FOR Ø .2500 BOLT.

NOTES:

1. TOLERANCES UNLESS OTHERWISE SPECIFIED:

.XXX = ±.010

.XX = ±.02

2. AN ADHESIVE BACKED INSTALLATION TAB NAS 1837 (PLASTIC WITTEN 2007) SHALL

BE FURNISHED WITH EACH INSERT.

3 BURRS CAUSED BY MACHINING POTTING HOLES OR SLOTS PERMISSIBLE UNDER FLANGE.

4. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M-1982.

5. DIMENSIONS ARE IN INCHES UNLESS OTHERWISE NOTED.

6 EXTERNAL CONFIGURATION OPTIONAL IN THIS AREA FOR SHORT LENGTHS THROUGH .375.

7 STRAIGHT OR DIAMOND ANTI-ROTATIONAL KNURL. (MANUFACTURER'S OPTION)

8 POTTING AND VENT HOLES OR SLOTS. (MANUFACTURER'S OPTION)

9. ALL DIAMETERS TO BE CONCENTRIC (SAME AXIS) WITHIN .010".

10. DIMENSIONAL LIMITS APPLY AFTER PLATING.

WITTEN COMPANY INC

918-272-9567

REV:- 8/25/09

You might also like

- Maestro EDGE (Feb, 2017)Document144 pagesMaestro EDGE (Feb, 2017)Kishonkumar Kishon100% (1)

- Godin String GaugesDocument2 pagesGodin String GaugeswplaisNo ratings yet

- NAS1834Document2 pagesNAS1834Ray DutchmanNo ratings yet

- NAS1835Document3 pagesNAS1835Ray DutchmanNo ratings yet

- Insert, Molded In, Threaded, Self-Locking, Nonself Locking, Sandwich PanelDocument3 pagesInsert, Molded In, Threaded, Self-Locking, Nonself Locking, Sandwich PanelAZIZNo ratings yet

- Eng CD TXR54 LDocument3 pagesEng CD TXR54 LZorbanfrNo ratings yet

- NA2159Document2 pagesNA2159Bogdan RusuNo ratings yet

- Wall Thickness: Piping SpecificationDocument2 pagesWall Thickness: Piping SpecificationLynn AlgerNo ratings yet

- Piping Class Spec. - 1c23pe (Lurgi)Document5 pagesPiping Class Spec. - 1c23pe (Lurgi)otezgidenNo ratings yet

- Hot Insulation Supports ENCI E16 FOR N:Na Mimed Storage TanksDocument3 pagesHot Insulation Supports ENCI E16 FOR N:Na Mimed Storage TankssahilNo ratings yet

- Piping Class Spec. - 3c5pe (Lurgi) PDFDocument9 pagesPiping Class Spec. - 3c5pe (Lurgi) PDFotezgidenNo ratings yet

- Piping Class Spec. - 1C16 (Lurgi)Document9 pagesPiping Class Spec. - 1C16 (Lurgi)otezgidenNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Piping Class Spec. - 1c9pe (Lurgi)Document8 pagesPiping Class Spec. - 1c9pe (Lurgi)otezgidenNo ratings yet

- RC 1Document2 pagesRC 1Anony MousNo ratings yet

- Isometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)Document2 pagesIsometric View: SLA Product Variables Part Id Nominal Size ID OD MFG WT Mass (KG)leizel dacuNo ratings yet

- RCP PDFDocument2 pagesRCP PDFalfred jamNo ratings yet

- Piping Class Spec. - 1c28pe (Lurgi)Document8 pagesPiping Class Spec. - 1c28pe (Lurgi)otezgidenNo ratings yet

- Homac T&B Multi-LugsDocument3 pagesHomac T&B Multi-LugsallfloridaNo ratings yet

- Piping Class Spec. - 1c16pe (Lurgi)Document10 pagesPiping Class Spec. - 1c16pe (Lurgi)otezgidenNo ratings yet

- Piping Class Spec. - 1C23 (Lurgi)Document5 pagesPiping Class Spec. - 1C23 (Lurgi)otezgidenNo ratings yet

- Piping Class Spec. - 3c24pe (Lurgi)Document9 pagesPiping Class Spec. - 3c24pe (Lurgi)otezgidenNo ratings yet

- 5/8-18 UNF-2A: Sheet 1 of 1Document1 page5/8-18 UNF-2A: Sheet 1 of 1seanNo ratings yet

- PL 0201719 0 0000 307 MOP 1001 - Rev.1Document1 pagePL 0201719 0 0000 307 MOP 1001 - Rev.1Alejandro CastroNo ratings yet

- 59 e 02Document46 pages59 e 02Natarajan RavisankarNo ratings yet

- Rocking Steam Engines Vapeur MoteurDocument6 pagesRocking Steam Engines Vapeur MoteurSteve LebgNo ratings yet

- 28 X 44,5 (TYP.) : Mark Piece InformationDocument3 pages28 X 44,5 (TYP.) : Mark Piece InformationProorocu MikyNo ratings yet

- Piping Class Spec. - 1C9 (Lurgi)Document8 pagesPiping Class Spec. - 1C9 (Lurgi)otezgidenNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

- Io PanelDocument26 pagesIo PanelakramNo ratings yet

- Camy Plants: Final Dimension ReportDocument7 pagesCamy Plants: Final Dimension Reportnarendra vermaNo ratings yet

- Geneva Drive DrawingsDocument7 pagesGeneva Drive Drawingsapi-553158328No ratings yet

- Piping Class Spec. - 3C24 (Lurgi) PDFDocument9 pagesPiping Class Spec. - 3C24 (Lurgi) PDFotezgidenNo ratings yet

- G-4201 Volvo Penta Quan TrọngDocument2 pagesG-4201 Volvo Penta Quan TrọngleejoNo ratings yet

- 12.5-310-100 High Mast Lighting SystemDocument1 page12.5-310-100 High Mast Lighting SystemrituNo ratings yet

- GeneralDocument39 pagesGeneralDeerendra KaranthNo ratings yet

- Piping Class Spec. - 1C19 (Lurgi)Document9 pagesPiping Class Spec. - 1C19 (Lurgi)otezgidenNo ratings yet

- Extinguishing Control Unit A6V10061857 HQ enDocument38 pagesExtinguishing Control Unit A6V10061857 HQ enscribdkhatn0% (1)

- Butterfly Valves - 250 Psi: SIZE 2" - 8"Document2 pagesButterfly Valves - 250 Psi: SIZE 2" - 8"thilina lakhithaNo ratings yet

- Red Is Etch For Assembly: Bend Line See Bend Table & Table AboveDocument1 pageRed Is Etch For Assembly: Bend Line See Bend Table & Table AboveGurdeep Singh. 2209No ratings yet

- B1 PDFDocument1 pageB1 PDFSuman RoyNo ratings yet

- Online Weighing Scale Canopy TrussDocument1 pageOnline Weighing Scale Canopy TrussyogeshNo ratings yet

- NAS1836Document3 pagesNAS1836Ray DutchmanNo ratings yet

- MGPS DetailsDocument3 pagesMGPS DetailsjarekNo ratings yet

- G A DrawingDocument1 pageG A DrawingghillialexNo ratings yet

- E36 Test PanelDocument12 pagesE36 Test PanelGanesa MurthyNo ratings yet

- Terasaki Mapadecurvaedimensoes PDFDocument2 pagesTerasaki Mapadecurvaedimensoes PDFthyagoenerg100% (1)

- ColumnreportDocument3 pagesColumnreportOsama MamdouhNo ratings yet

- Shed Work Details: S.No Building Fabrication Bom Material Description QTYDocument7 pagesShed Work Details: S.No Building Fabrication Bom Material Description QTYBala SundharamNo ratings yet

- Workshop Customer #Id Email Order #Id: Alcoa Diesel 02.14.0760Document1 pageWorkshop Customer #Id Email Order #Id: Alcoa Diesel 02.14.0760carlos sousaNo ratings yet

- 4 KL TankDocument2 pages4 KL TankSantosh Reddy KesavaNo ratings yet

- Land Cruiser 40 Series: Year Model Features Winches Part NoDocument3 pagesLand Cruiser 40 Series: Year Model Features Winches Part NoAli GillaniNo ratings yet

- Tank Specification Sheet PDFDocument1 pageTank Specification Sheet PDFRaj Bahadur YadavNo ratings yet

- Fairchild Fasteners Europe: Saint Cosme OperationsDocument1 pageFairchild Fasteners Europe: Saint Cosme OperationsstaedtlerpNo ratings yet

- CalcsDocument7 pagesCalcskukadiya127_48673372No ratings yet

- Ref.: Gil/cms/g3/0591 Date: 31/03/2011Document2 pagesRef.: Gil/cms/g3/0591 Date: 31/03/2011prati121No ratings yet

- LMEL Opration and Maint of 90 T BOILERDocument249 pagesLMEL Opration and Maint of 90 T BOILERPratik TyagiNo ratings yet

- NPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20Document132 pagesNPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20MuhammadNurrahmanNo ratings yet

- BW and PathwayDocument1 pageBW and PathwaySHUBHAM SINGHNo ratings yet

- American Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883From EverandAmerican Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883Rating: 3 out of 5 stars3/5 (1)

- PTFE-Coated Anodized Aluminum Alloy 6061 With Icephobic PropertiesDocument6 pagesPTFE-Coated Anodized Aluminum Alloy 6061 With Icephobic PropertiesSon NguyenNo ratings yet

- Anod 7075-T6Document7 pagesAnod 7075-T6Son NguyenNo ratings yet

- History of Thermal Barrier Coatings For Gas Turbine Engines: Emphasizing NASA's Role From 1942 To 1990Document29 pagesHistory of Thermal Barrier Coatings For Gas Turbine Engines: Emphasizing NASA's Role From 1942 To 1990Son NguyenNo ratings yet

- Mil A 63576aDocument13 pagesMil A 63576aSon NguyenNo ratings yet

- NAS1832 Thru NAS1836, Inserts: Genuine Aircraft Hardware CoDocument3 pagesNAS1832 Thru NAS1836, Inserts: Genuine Aircraft Hardware CoSon NguyenNo ratings yet

- Preprints202002 0023 v1Document25 pagesPreprints202002 0023 v1Son NguyenNo ratings yet

- Fundamentals of Composites Manufacturing: Materials, Methods and Applications, 2 Edition DesignDocument43 pagesFundamentals of Composites Manufacturing: Materials, Methods and Applications, 2 Edition DesignSon NguyenNo ratings yet

- Surface RoughnessDocument79 pagesSurface RoughnessSon NguyenNo ratings yet

- (Vanbanphapluat - Co) tcvn4178-1985Document5 pages(Vanbanphapluat - Co) tcvn4178-1985Son NguyenNo ratings yet

- Surface Roughness 3Document26 pagesSurface Roughness 3Son NguyenNo ratings yet

- Solucionario Vinnakota Capitulo 8 PDFDocument50 pagesSolucionario Vinnakota Capitulo 8 PDFjupabuvi75% (4)

- Update Terbaru PFD FixDocument1 pageUpdate Terbaru PFD FixaulianwNo ratings yet

- EN7938 8 11 17 - OF5 - FahrbarDocument4 pagesEN7938 8 11 17 - OF5 - FahrbarPrasantaKumarMallikaNo ratings yet

- Flowserve, Rotary Valve & Actuation CatalogueDocument27 pagesFlowserve, Rotary Valve & Actuation CatalogueJunaidi Santoso100% (1)

- ASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesDocument3 pagesASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesFrancisco Marin BortoluzziNo ratings yet

- Microbiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaDocument8 pagesMicrobiological and Physicochemical Analyses of Top Soils Obtained From Four Municipal Waste Dumpsites in Benin City, NigeriaInternational Network For Natural SciencesNo ratings yet

- Samsung Evaporator Technical Details Aug 17 PDFDocument9 pagesSamsung Evaporator Technical Details Aug 17 PDFkumarNo ratings yet

- Captive Air Commercial Kitchen Exhaust Vent ManualDocument31 pagesCaptive Air Commercial Kitchen Exhaust Vent ManualGiann CarlosNo ratings yet

- Soldering Equipment: How To Solder - Soldering TutorialDocument7 pagesSoldering Equipment: How To Solder - Soldering TutorialAnonymous f6goFflg3TNo ratings yet

- AirCon Brochure 2013Document12 pagesAirCon Brochure 2013Alex BaicuNo ratings yet

- Project On Partial Replacement of Cement With Marble PowderDocument8 pagesProject On Partial Replacement of Cement With Marble PowderYu Paing HanNo ratings yet

- Technical Training ManualDocument40 pagesTechnical Training ManualAkashdeep100% (1)

- DPWH Matl Min Test ReqDocument51 pagesDPWH Matl Min Test ReqEnterone Alvaro Rico100% (2)

- Deka Batteries PDFDocument6 pagesDeka Batteries PDFLuis Alonso Osorio MolinaNo ratings yet

- Refinery TankagesDocument4 pagesRefinery Tankagesmayuresh1101100% (1)

- (N) HXH Fe180 E90Document3 pages(N) HXH Fe180 E90djordje tekicNo ratings yet

- CableDocument2 pagesCableJuan David Yepez MonterosNo ratings yet

- Final PPT LITRACONDocument15 pagesFinal PPT LITRACONRAmyaNo ratings yet

- Magnetic Nanoparticles ReviewDocument61 pagesMagnetic Nanoparticles ReviewramikNo ratings yet

- Aquafine DW Series ManualDocument19 pagesAquafine DW Series Manualjorman GuzmanNo ratings yet

- Instant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEDocument33 pagesInstant Download American Immigration A Very Short Introduction Very Short Introductions 1st Edition Ebook PDF PDF FREEsam.hirt196100% (50)

- SMA Connector SeriesDocument26 pagesSMA Connector SeriesCmpterRFNo ratings yet

- 10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsDocument3 pages10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsVignesh RajanNo ratings yet

- Phosphoric Acid Industry - Problems & SolutionsDocument18 pagesPhosphoric Acid Industry - Problems & SolutionsRiyasNo ratings yet

- Polymer and Composite Failure and Durability-Exam QuestionsDocument10 pagesPolymer and Composite Failure and Durability-Exam QuestionsNatalia Ramos MontillaNo ratings yet

- Presentation MPCBDocument26 pagesPresentation MPCBapi-26219976No ratings yet

- APM Steel and Cast IronsDocument48 pagesAPM Steel and Cast Ironsvarniraj patelmetNo ratings yet

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- Alphatec 3000 Trousers Ultrasonically Welded Taped Model 302 - Pds - GBDocument2 pagesAlphatec 3000 Trousers Ultrasonically Welded Taped Model 302 - Pds - GBsrikanth reddyNo ratings yet

- Tet 213 Fibre Length - 112836Document3 pagesTet 213 Fibre Length - 112836maryamibrahimhassan437No ratings yet