Professional Documents

Culture Documents

Measuring With Calipers: Tech Tips: Elevator Industry Tools

Measuring With Calipers: Tech Tips: Elevator Industry Tools

Uploaded by

Jorge Prado DiazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Measuring With Calipers: Tech Tips: Elevator Industry Tools

Measuring With Calipers: Tech Tips: Elevator Industry Tools

Uploaded by

Jorge Prado DiazCopyright:

Available Formats

TechMeasuRIng

Tips: ElevatorWITh calIpeRs

Industry Tools

Caliper Usage

Rope Diameter sheave surface) due to abrasion, or to

Measuring Devices help in ascertaining the overall condition of

the hoist rope itself.

Various rope diameter measuring devices

are available that feature either digital or Many criteria are used to determine when

analog displays. Though Brugg offers no one should replace a suspension, governor or

recommendation as to which type one compensation rope (for the North American

should employ, it does strongly recommend elevator industry these are detailed in A

a procedure to accurately and consistently 17.1/CSA B44 guidelines). Certainly one of

measure hoist rope diameters. the more important guidelines concerns the

amount of diameter reduction evident in a

The Right Way (#1) rope. ASME guidelines state that hoist

Versus The Wrong Way (#2) ropes should be replaced if they meet the

specified diameter reduction — even if no

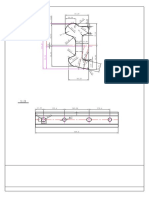

Figure #1 details the correct way To crown or valley breaks are detected.

use calipers to measure rope diameter. For suspension and compensation rope

one should ALWAYS measure rope size replacement criteria one should consult

proceeding from crown to crown (or peak to section 8.11.2.1.3.— as it includes

peak) on the strands, and NOT as shown in guildelines on the equal distribution of

Image #2, from valley to valley.

1

broken wires; unequal distribution of

broken wires; if four or five wires, side

Why It Is Important by side, are broken across the crown of

To Do The Job Right. any strand; the existence of unfavorable

Less than attentive measurement conditions such as fretting corrosion

technique used in measuring rope diameter (red dust or rouge), etc. ; if there is more

can render this data of little use in verifying than one valley break per rope lay.

0.3125 in rope diameter reduction. And listing

data incorrectly can make it difficult for

NOTE: For more specific information

review ASME 17.6 “Standard for Elevator

professionals (especially inspectors) to Suspension, Compensation and

formulate opinions on topics such as crown Governor Systems”.

0.3125 in wear (Note: crown wires are those wires

actually making contact with the sheave

groove surface — valley wires are those

located within the valleys of adjacent

strands and do not make contact with the

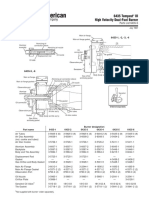

TABLE 8.11.2.1.3 (cc)(3)

2

Rope Diameter Max. Reduced Diameter* Rope Diameter Max. Reduced Diameter*

in.•mm in.• decimal in.•mm in.•mm in.•decimal in.•mm

0.3014 in 8.0 mm 9/32 • 0.313 • 7.50 5/8 • 16.0 37/64 • 0.578 • 15.00

3/8 • 9.5 11/32 • 0.344 • 8.91 11/16 • 17.5 41/64 • 0.641 • 16.41

10.0 mm 9.38 mm 18.0 mm 16.88 mm

0.3014 in 7/16 • 11.0 13/32 • 0.406 • 10.31 3/4 • 19.0 45/64 • 0.703 • 17.81

12.0 mm 11.25 mm 20.0 mm 18.75 mm

1/2 • 12.7 15/32 • 0.469 • 11.91 22.0 mm 20.63 mm

13.0 mm 12.19 mm 1 • 25.4 15/16 • 0.938 • 23.81

14.0 mm 13.13 mm * Under normal wear conditions

Brugg Lifting_0413

the discard number is 6.25% below nomimal.

9/16 • 14.3 17/32 • 0.531 • 13.41

15.5 mm 14.53 mm

Brugg Lifting • Rome, GA USA • 866.542.7844 • www.bruggrope.com • Brugg Lifting • Birr CH • +41 56 464 42 42 • www.brugglifting.com

54

Brugg Lifting • Dubai UAE • +97 14 813 78 13 • www.brugglifting.com • Brugg Lifting • P.R. CHINA • +86 512 6299 0779 • www.bruggrope.com.cn

You might also like

- Geometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsFrom EverandGeometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsRating: 5 out of 5 stars5/5 (2)

- The Measurement of Local Axial Strains in Triaxial Tests Using LVDTsDocument5 pagesThe Measurement of Local Axial Strains in Triaxial Tests Using LVDTsPinak RayNo ratings yet

- Solving The Mysteries of The Fin Pass: ProducingresultsDocument3 pagesSolving The Mysteries of The Fin Pass: ProducingresultswahyoesoemantriNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Astm E11-13Document9 pagesAstm E11-13OmarMageedNo ratings yet

- D N.D. Fopaune: Merlt BarglanDocument5 pagesD N.D. Fopaune: Merlt Barglanhari krishnaNo ratings yet

- 8 hintsDocument16 pages8 hintspepetonventuraNo ratings yet

- Qualification of Phased ArraysDocument55 pagesQualification of Phased Arrayssolrac4371No ratings yet

- Wire Rope InspectionDocument5 pagesWire Rope InspectionJan Weinans100% (1)

- Astm A 388.aDocument8 pagesAstm A 388.aGlauber MartinsNo ratings yet

- 1910 - Handy Adhesion PDFDocument3 pages1910 - Handy Adhesion PDFMohamed NouzerNo ratings yet

- Astm D 6926 Marshall Specimen Prepration PDFDocument6 pagesAstm D 6926 Marshall Specimen Prepration PDFrajeshji_000100% (1)

- Bar Bending Schedule For Column - Detailed Practical GuideDocument5 pagesBar Bending Schedule For Column - Detailed Practical GuidewweretNo ratings yet

- Wireline StretchDocument2 pagesWireline StretchLuisNo ratings yet

- Vibrating Wire Load Cells: Model SeriesDocument2 pagesVibrating Wire Load Cells: Model Seriesacls5005No ratings yet

- How To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointsDocument2 pagesHow To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointskaloordenisNo ratings yet

- Elcometer 124 Thickness Gauge Product Data SheetDocument2 pagesElcometer 124 Thickness Gauge Product Data SheetMohamedNo ratings yet

- Data Sheet: Elcometer 124 Thickness GaugeDocument3 pagesData Sheet: Elcometer 124 Thickness GaugeMohamed NouzerNo ratings yet

- WellIntegrity RBL+combinedDocument4 pagesWellIntegrity RBL+combinedJulio BaratçabalNo ratings yet

- Crane Rail SelectionDocument3 pagesCrane Rail SelectionnoxleekNo ratings yet

- Displacement Transducers and Accuracy Classification Per ASTM E2309Document4 pagesDisplacement Transducers and Accuracy Classification Per ASTM E2309Ximena SilvaNo ratings yet

- D%D RATIODocument2 pagesD%D RATIOaswinsarensnass25No ratings yet

- NASA Workmanship Ref-CRIMPINGDocument27 pagesNASA Workmanship Ref-CRIMPINGkpal525No ratings yet

- V-Belt Drives 0905Document3 pagesV-Belt Drives 0905FV AllanNo ratings yet

- Za Izabenost Na JaznicaDocument10 pagesZa Izabenost Na JaznicaDaceDropNo ratings yet

- Model Msi-121: CBR Test Apparatus - DigitalDocument2 pagesModel Msi-121: CBR Test Apparatus - Digitalahana expotech lab abeerNo ratings yet

- Overview of Artificial Lift SystemsDocument19 pagesOverview of Artificial Lift SystemsHspetrocrusosNo ratings yet

- Astm a291_a291m-2018a 减速器小齿轮、齿轮和轴用锻造碳素及合金钢Document5 pagesAstm a291_a291m-2018a 减速器小齿轮、齿轮和轴用锻造碳素及合金钢labnitzNo ratings yet

- Recommendations For Machine Design: ContentDocument20 pagesRecommendations For Machine Design: ContentEmerson FerreiraNo ratings yet

- 305-Fms Recommendation Machine Design enDocument20 pages305-Fms Recommendation Machine Design envhbernaltNo ratings yet

- Te Connectivity - Crimp Quality GuidelinesDocument1 pageTe Connectivity - Crimp Quality GuidelinesGustavo RamirezNo ratings yet

- Transducer CatalogDocument7 pagesTransducer CatalogJ. Rodrigo Rizatti Rodrigo RizattiNo ratings yet

- TSC Subsea Tool Brochures NodeScanner 0.2Document4 pagesTSC Subsea Tool Brochures NodeScanner 0.2Bimal BosmiaNo ratings yet

- Msi Belt Scale: Application GuidelinesDocument19 pagesMsi Belt Scale: Application GuidelinesJulisa LombardoNo ratings yet

- Tab 7a - Completion Running Ops Update 01022012Document16 pagesTab 7a - Completion Running Ops Update 01022012Hassan MohamedNo ratings yet

- Denim Seam Quality DefectsDocument6 pagesDenim Seam Quality Defectsapi-26494555No ratings yet

- Bearing Load Rating GuidelineDocument4 pagesBearing Load Rating GuidelineAnand kumarNo ratings yet

- Strain Gage Rosettes: Selection, Application and Data ReductionDocument12 pagesStrain Gage Rosettes: Selection, Application and Data ReductionGiovani MartinsNo ratings yet

- Astm C241Document3 pagesAstm C241Ali ArsalanNo ratings yet

- Omega Dyne NH - SGDocument89 pagesOmega Dyne NH - SGChallengerPowerNo ratings yet

- PCB-RULER-12INCH Rev 2016 PDFDocument13 pagesPCB-RULER-12INCH Rev 2016 PDFgiorgioviNo ratings yet

- PVC U ConduitDocument2 pagesPVC U Conduitahmed khattabNo ratings yet

- Abrasion Resistance C944Document4 pagesAbrasion Resistance C944SAPTIONONo ratings yet

- Applications/Processing Guide: How To Use This Section The Resistive ElementDocument8 pagesApplications/Processing Guide: How To Use This Section The Resistive ElementNiyamathullahNo ratings yet

- Astm 388Document8 pagesAstm 388Joseph RefuerzoNo ratings yet

- 01052-Submission of Factory Testing PlanDocument113 pages01052-Submission of Factory Testing PlanNaveen Kumar SakalaNo ratings yet

- Common Seam Quality DefectsDocument6 pagesCommon Seam Quality Defectskernchia100% (2)

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- Lowloss Single-Mode GaAsAlGaAs WaveguidesDocument7 pagesLowloss Single-Mode GaAsAlGaAs WaveguidesMiles FernsbyNo ratings yet

- Fitting & Acc.Document595 pagesFitting & Acc.jarekNo ratings yet

- Fitting & Acc PDFDocument663 pagesFitting & Acc PDFUncorrectableNameNo ratings yet

- ASTM C181-11 TrabajabilidadDocument3 pagesASTM C181-11 TrabajabilidadRosibel YgNo ratings yet

- EW0709Document13 pagesEW0709acapNo ratings yet

- Testing: Service LineDocument2 pagesTesting: Service LineVerónicaNo ratings yet

- Astm D2255 D2255M 09Document2 pagesAstm D2255 D2255M 09Buvanesh WaranNo ratings yet

- #22basic List of Machinery and Equipment Required For Engineering Domains July 07@2021Document31 pages#22basic List of Machinery and Equipment Required For Engineering Domains July 07@2021Lijalem GebrehiwetNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- Coraza Cilindro Bajo 003-46-05Document1 pageCoraza Cilindro Bajo 003-46-05Jorge Prado DiazNo ratings yet

- 9617-1127-V K2 Nose Casting - Vented 4X Rev 0Document2 pages9617-1127-V K2 Nose Casting - Vented 4X Rev 0Jorge Prado DiazNo ratings yet

- Compromise JointsDocument2 pagesCompromise JointsJorge Prado DiazNo ratings yet

- Bomba GIW LSA 8X10 CAJA DE RODAMT 5816CDocument3 pagesBomba GIW LSA 8X10 CAJA DE RODAMT 5816CJorge Prado DiazNo ratings yet

- AREMA 2003 - EclisasDocument5 pagesAREMA 2003 - EclisasJorge Prado DiazNo ratings yet

- Codigos y EstándaresDocument2 pagesCodigos y EstándaresJorge Prado DiazNo ratings yet

- RT 800 WP: The Proven Interchangeable Insert Drilling System With Highest Cutting Performance and Economy - Now WithDocument12 pagesRT 800 WP: The Proven Interchangeable Insert Drilling System With Highest Cutting Performance and Economy - Now WithJorge Prado DiazNo ratings yet

- Eclisa 115re 4 Hole-AaDocument1 pageEclisa 115re 4 Hole-AaJorge Prado DiazNo ratings yet

- Mf-156/Astm A532-Llb: Rev Description Date Approved 2Document1 pageMf-156/Astm A532-Llb: Rev Description Date Approved 2Jorge Prado DiazNo ratings yet

- Recovery of Magnesium in A Ductile Iron Process.: AbstractDocument8 pagesRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazNo ratings yet

- Operating Manual: Thule Rigtech VSM 100 Linear Motion Shale ShakerDocument84 pagesOperating Manual: Thule Rigtech VSM 100 Linear Motion Shale ShakerJorge Prado DiazNo ratings yet

- 47143A - COPLA DOBLE BRIDA DIA.85x175MM - 19751 1Document1 page47143A - COPLA DOBLE BRIDA DIA.85x175MM - 19751 1Jorge Prado DiazNo ratings yet

- Tenova TAKRAF Apron Feeders: Optimal Solutions For Mining, Materials Handling and ProcessingDocument6 pagesTenova TAKRAF Apron Feeders: Optimal Solutions For Mining, Materials Handling and ProcessingJorge Prado DiazNo ratings yet

- 6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Document2 pages6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Jorge Prado DiazNo ratings yet

- Sheaves & GroovesDocument1 pageSheaves & GroovesJorge Prado Diaz100% (1)

- Customer Service AssignmentDocument2 pagesCustomer Service AssignmentJoe Kau Zi YaoNo ratings yet

- Chapter 1: Why Study Money, Banking, and Financial Markets?Document23 pagesChapter 1: Why Study Money, Banking, and Financial Markets?Nguyễn Thanh TrangNo ratings yet

- R304 0307 Env HHDocument221 pagesR304 0307 Env HHsyamsundariitmiitmNo ratings yet

- ARM130A1 - Aermacchi MB.339 Series Archived NOVDocument5 pagesARM130A1 - Aermacchi MB.339 Series Archived NOVLava R5s2019No ratings yet

- UG Bulletin2018FinalDocument39 pagesUG Bulletin2018FinalAman KumarNo ratings yet

- Poster NanosensorsDocument1 pagePoster NanosensorspvegaNo ratings yet

- Properties of Bio-Based PolyurethaneDocument200 pagesProperties of Bio-Based PolyurethaneMust BoujaataNo ratings yet

- Limba Folktale Large FileDocument606 pagesLimba Folktale Large FileAmalia BanaşNo ratings yet

- Lecture 6 - RTL SynthesisDocument72 pagesLecture 6 - RTL SynthesisantoniocljNo ratings yet

- Publishedarticle38 SeleniumreviewDocument5 pagesPublishedarticle38 SeleniumreviewOlvira EsaNo ratings yet

- Tank BlanketingDocument27 pagesTank Blanketingkhali54100% (1)

- Toro CCR3650 SnowBlowerDocument24 pagesToro CCR3650 SnowBlowerRupertPupkin74No ratings yet

- Modern Auditing Beynton Solution Manual Chapter 2Document21 pagesModern Auditing Beynton Solution Manual Chapter 2Sjifa AuliaNo ratings yet

- Transit 2006.5 (04/2006-) : New Product IntroductionDocument81 pagesTransit 2006.5 (04/2006-) : New Product Introductionmail4281No ratings yet

- Group Discussion WorksheetDocument2 pagesGroup Discussion WorksheetNE AONo ratings yet

- Hubungan Penerapan Metode Tim Dengan Rencana Asuhan Keperawatan Pasien Diruang Rawat Inap Sari Madonni 1Document9 pagesHubungan Penerapan Metode Tim Dengan Rencana Asuhan Keperawatan Pasien Diruang Rawat Inap Sari Madonni 1rogerNo ratings yet

- Factors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Document11 pagesFactors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Shai Anne Cortez100% (2)

- Taxi ServiceDocument25 pagesTaxi ServiceAmitsinh ViholNo ratings yet

- Soal Latihan Persiapan Us Bahasa InggrisDocument6 pagesSoal Latihan Persiapan Us Bahasa InggrisNurrul Hadhya ZaraNo ratings yet

- Gea32131 mv1q Borescope Adapter r3Document2 pagesGea32131 mv1q Borescope Adapter r3Maximiliano Ezequiel LopezNo ratings yet

- SimpleNursing Study GuidesDocument5 pagesSimpleNursing Study Guidessilgabernard100% (1)

- Bomba Peristáltica EspecificacionDocument1 pageBomba Peristáltica EspecificacionhugoNo ratings yet

- Halfen Cast-In Channels: ConcreteDocument92 pagesHalfen Cast-In Channels: ConcreteFernando Castillo HerreraNo ratings yet

- This Study Resource Was: Student Exploration: HomeostasisDocument6 pagesThis Study Resource Was: Student Exploration: HomeostasisHabiba Mohamed0% (1)

- Lecture 5 - Aldehydes & KetonesDocument93 pagesLecture 5 - Aldehydes & KetonesQutaiba Ibrahim100% (1)

- Urban Planning - WikipediaDocument10 pagesUrban Planning - Wikipediaعمران ساجيلNo ratings yet

- How Does Photodynamic Therapy WorkDocument13 pagesHow Does Photodynamic Therapy WorkLoredana VoiculescuNo ratings yet

- Word PartsDocument15 pagesWord PartsDr. Zakir HorizontalNo ratings yet

- Techciti: Managed ServicesDocument6 pagesTechciti: Managed ServicesTechciti TechnologiesNo ratings yet

- EC Type-Approval Certificate No. DK0199.274 Revision 2Document1 pageEC Type-Approval Certificate No. DK0199.274 Revision 2MjeriteljXNo ratings yet