Professional Documents

Culture Documents

Weld 3

Weld 3

Uploaded by

canettijCopyright:

Available Formats

You might also like

- Spreadsheet For Single Span Cast in Place Concrete Bridge DesignDocument16 pagesSpreadsheet For Single Span Cast in Place Concrete Bridge DesignAli Akbar100% (1)

- Seafastening Design CalculationsDocument82 pagesSeafastening Design CalculationsInhake AutechreNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- The Mechanics of Soils ATKINSONDocument292 pagesThe Mechanics of Soils ATKINSONFebrianto Ch89% (27)

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Design of Beams: DataDocument3 pagesDesign of Beams: DataSharath SharathNo ratings yet

- VIII Unit DOS IIDocument37 pagesVIII Unit DOS IIImaad UddinNo ratings yet

- 2ND ExampleDocument12 pages2ND ExamplesamehNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Design of Strip Footing (Raft) For PM Room1Document3 pagesDesign of Strip Footing (Raft) For PM Room1Nagesh ChitariNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabrukesh104No ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- A. Design of Flanged Beam SectionDocument7 pagesA. Design of Flanged Beam SectionWilson PatyalNo ratings yet

- StaicaseDocument4 pagesStaicaseAlex MachariaNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- Design and Detailing of Steel in Combined FootingsDocument34 pagesDesign and Detailing of Steel in Combined FootingsgundulpNo ratings yet

- Slide Share BDocument42 pagesSlide Share BShakeel WaseemNo ratings yet

- 1 - SPLICE-WPB 700X300X204.5 - DraftDocument7 pages1 - SPLICE-WPB 700X300X204.5 - DraftAvishek DeyNo ratings yet

- 20 M SpanDocument20 pages20 M SpanEr KanwarPal SinghNo ratings yet

- Design CalculationDocument23 pagesDesign CalculationKathir VelNo ratings yet

- Beam LSMDocument6 pagesBeam LSMARVIND SINGH RAWATNo ratings yet

- Design of Water TankDocument30 pagesDesign of Water TankDeepthi ReddyNo ratings yet

- Lecture Three - Welded ConnectionsDocument30 pagesLecture Three - Welded ConnectionsAhmedNo ratings yet

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- GI$. Note That Since: O P E AE PL AL AEDocument6 pagesGI$. Note That Since: O P E AE PL AL AESuraj KumarNo ratings yet

- Over Head ResevoirDocument8 pagesOver Head ResevoirPoulomi BiswasNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- DPT Numericals For Production EngineeringDocument8 pagesDPT Numericals For Production Engineeringprithvi shettyNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabrukesh104No ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Design of SlabsDocument10 pagesDesign of SlabsMaheshreddyNo ratings yet

- 15epme011 Strength of MaterialsDocument50 pages15epme011 Strength of MaterialsgsanthoshskNo ratings yet

- Design OfSteel Structures-IDocument50 pagesDesign OfSteel Structures-IBhagyshri SiddheNo ratings yet

- Chapter - 3 - Torsion - Class ExamplesDocument14 pagesChapter - 3 - Torsion - Class ExamplesCandice MdakaNo ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

- Intze Tank 1 Moin 25-1-23Document17 pagesIntze Tank 1 Moin 25-1-23MOIN UDDINNo ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Slab DesignDocument6 pagesSlab DesignmadhuNo ratings yet

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Reinf - conc.Beams-Design Torsional&Axially LoadedDocument1 pageReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaNo ratings yet

- CCCCCCDocument2 pagesCCCCCCmirzakamranbaig.mkNo ratings yet

- Design Data: Design of Floor SlabDocument1 pageDesign Data: Design of Floor SlabDrafters EngineeringNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- Designed By: Submitted ToDocument46 pagesDesigned By: Submitted To106 MOMENUL ISLAM KHAN 17No ratings yet

- 2 Way Slab Menuka FinalDocument1 page2 Way Slab Menuka Finalabhisek adhikariNo ratings yet

- Lifting LugDocument17 pagesLifting LugJoosung HanNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhaneNo ratings yet

- Torsion Design For BeamDocument4 pagesTorsion Design For BeamtkofaiNo ratings yet

- UNIT 11unit 2 FrontDocument5 pagesUNIT 11unit 2 FronticonicshashankNo ratings yet

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- Built Up Column - ChannelDocument18 pagesBuilt Up Column - ChannelSambhav PoddarNo ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- Pre-Stressed Concrete MSCE 514: Problem Set 2Document8 pagesPre-Stressed Concrete MSCE 514: Problem Set 2Andrea Mae Sanchez0% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Cantilever Welds Subject To Both Bending and ShearDocument1 pageCantilever Welds Subject To Both Bending and ShearcanettijNo ratings yet

- Siemens Integrator Milltronics BW500 and BW500L DatasheetDocument5 pagesSiemens Integrator Milltronics BW500 and BW500L DatasheetcanettijNo ratings yet

- Calculati Ons Based On Unit ValuesDocument1 pageCalculati Ons Based On Unit ValuescanettijNo ratings yet

- Weld Throat Area Unit Area Location of COG X y I - (Unit) J - (Unit)Document1 pageWeld Throat Area Unit Area Location of COG X y I - (Unit) J - (Unit)canettijNo ratings yet

- Stainless Steel: General Information ApplicationsDocument11 pagesStainless Steel: General Information ApplicationscanettijNo ratings yet

- 2008 - 8 - DIN Threaded FittingsDocument10 pages2008 - 8 - DIN Threaded FittingscanettijNo ratings yet

- BD-ISO 5459 Technical Drawing - Geometrical TolerancesDocument26 pagesBD-ISO 5459 Technical Drawing - Geometrical Tolerancescanettij100% (1)

- Steelway StandardsDocument20 pagesSteelway StandardscanettijNo ratings yet

- 2008 - 9 - Sandvik Coupling LDocument6 pages2008 - 9 - Sandvik Coupling LcanettijNo ratings yet

- 2008 - 4 - ANSI FlangesDocument12 pages2008 - 4 - ANSI FlangescanettijNo ratings yet

- 2008 - 6 - ISO BW FittingsDocument12 pages2008 - 6 - ISO BW FittingscanettijNo ratings yet

- 2008 - 2 - Tube & PipeDocument7 pages2008 - 2 - Tube & PipecanettijNo ratings yet

- Design ProcewssDocument10 pagesDesign ProcewsscanettijNo ratings yet

- Artikulli 12Document10 pagesArtikulli 12jenniferNo ratings yet

- 620-1025 Rules For Compression-Ring Regions Exceeding 2 Inches Thickness - Rev 0Document2 pages620-1025 Rules For Compression-Ring Regions Exceeding 2 Inches Thickness - Rev 0Bilal ZahidNo ratings yet

- EarthquakeAnalysisOfRC BuildingsDocument67 pagesEarthquakeAnalysisOfRC BuildingsKaran ThakurNo ratings yet

- The Analysis of Earth Pressure On Retaining Wall Based On ABAQUSDocument4 pagesThe Analysis of Earth Pressure On Retaining Wall Based On ABAQUSroloheNo ratings yet

- Ductile Damage For MetalsDocument17 pagesDuctile Damage For MetalsVinita VermaNo ratings yet

- Pete 322 - Drilling Engineering - Ii Chapter 6 - Casing DesignDocument39 pagesPete 322 - Drilling Engineering - Ii Chapter 6 - Casing DesignTuran Amiraslanli100% (1)

- Zsteel Design Practice Problems With Ans KeyDocument4 pagesZsteel Design Practice Problems With Ans Keyjj012586No ratings yet

- BookDocument620 pagesBookpiv0ter_betterNo ratings yet

- Effects of An Earthquake PDFDocument11 pagesEffects of An Earthquake PDFverben siegaNo ratings yet

- Lab Manual DBT 210 PDFDocument19 pagesLab Manual DBT 210 PDFBELAL ALSUBARINo ratings yet

- Lab Manual (ME 3802)Document22 pagesLab Manual (ME 3802)Pranto ShuvoNo ratings yet

- Pengaruh Getaran Tanah Akibat Peledakaan Terhadap Kemantapan Lereng Tambang Air Laya Selatan PT Bukit Asam (Persero) TBKDocument9 pagesPengaruh Getaran Tanah Akibat Peledakaan Terhadap Kemantapan Lereng Tambang Air Laya Selatan PT Bukit Asam (Persero) TBKRafael GultomNo ratings yet

- DMRC DBR Chennai PDFDocument25 pagesDMRC DBR Chennai PDFTarun Kant Goyal100% (1)

- BY Annoy Kumar Ghosh B.Tech NIT, Durgapur: EarthquakeDocument25 pagesBY Annoy Kumar Ghosh B.Tech NIT, Durgapur: EarthquakeARIJIT DASNo ratings yet

- Rigid 1Document1 pageRigid 1Arjun Chitradurga RamachandraRaoNo ratings yet

- Chapter 2Document40 pagesChapter 2IntanLeeyanaNo ratings yet

- Drilled Cast-In-Place Pile Design Based On ACI 318-05Document3 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-05Sabrina ImloulNo ratings yet

- Sensitivity Analysis of Clock Spring Repair To Hydrogen Gas-Effect On Burst PressureDocument28 pagesSensitivity Analysis of Clock Spring Repair To Hydrogen Gas-Effect On Burst Pressuregerry_ndutzNo ratings yet

- Evaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsDocument23 pagesEvaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsSudip ShresthaNo ratings yet

- Bearing Capacity of Shallow FoundationDocument124 pagesBearing Capacity of Shallow FoundationSHAN NUHRIO50% (4)

- 1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsDocument5 pages1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsBejil ShresthaNo ratings yet

- Comprehensive Rock Engineering LNJTNDocument18 pagesComprehensive Rock Engineering LNJTNargaNo ratings yet

- Module 3. Mechanical TestingDocument13 pagesModule 3. Mechanical TestingPearl Alexandra FabitoNo ratings yet

- Beam Deflection 2bDocument2 pagesBeam Deflection 2bKrisia MartinezNo ratings yet

- 05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysisDocument11 pages05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysislingamkumarNo ratings yet

- Nonlinear Seismic Behaviour of Concrete Arch BridgesDocument61 pagesNonlinear Seismic Behaviour of Concrete Arch BridgesJoseAngelFernandezOrtegaNo ratings yet

- Pipeline Lowering Analysis at Limited SpaceDocument2 pagesPipeline Lowering Analysis at Limited SpaceArvin PutrantoNo ratings yet

- Analysis&Design of Truss For Indoor StadiumDocument40 pagesAnalysis&Design of Truss For Indoor StadiumD.V.Srinivasa Rao100% (2)

Weld 3

Weld 3

Uploaded by

canettijOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld 3

Weld 3

Uploaded by

canettijCopyright:

Available Formats

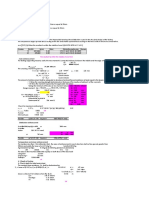

P= 30000 Newtons

d= 100mm

b= 75mm

y = 50mm

Design Stress p w = 220 N/mm 2 (Electrode E35 steel S275) Design Strength

Moment = M = 30000*60=18.10 5 Nmm

Simple Method as BS 5950 clause 6.8.7.2 Direction Method as BS 5950 clause 6.8.7.3

Unit Weld Area = A u = 2(d+b) =2(100+75) =350mm 2 Length of Weld of unit thickness = L = 2(d+b) =2(100+75) =350mm

Unit Moment of Inertia = I u Moment of Inertia / mm throat thickness = I u / mm

= d 2(3b+d) / 6 = 100 2 (3.75 +100) / 6 =5,42.105 mm4 = d 2(3b+d) / 6 = 100 2 (3.75 +100) / 6 =5,42.105 mm 4 / mm

τ r = Sqrt(τ s2 + τ b2) F r = Resultant force per unit length of weld.

F s = Shear force per unit length of weld.

τ s = P / A u = 30000/350 = 85,71 N/mm 2 F b = Bending force per unit length of weld.

τ b = M.y / I u = 18.105 . 50 / 5,42.105 = 166,05 N/mm 2

τ r = Sqrt(85,71 2 + 166.052) =186,86 N/mm2 F r = Sqrt(F s2 + F b2)

τ r / p w = 186,86 / 220 = 0,85 = Throat Thickness..... F s = P / L = 30000/350 = 85,71 N per mm length of weld

F b = M.y / I u

( Throat thickness for τ<SUBR< sub> = 220 N/mm2 )

= 18.105 . 50 / 5,42.105 = 166,05 N per mm length of weld

Leg Length = Throat thickness *1,414 = 1,2mm use 3mm weld thickness

F r = Sqrt(85,71 2 + 166.052) =186,86 N per mm length of weld.

For this case for the welds under greatest loading the type of loading is traverse loading. The

Note : If a leg length h= 1,2mm is used in the equations in relevant part of the "Table of bracket weld

bending stress is in line with horizontal element and the shear stress is in line with vertical member.

subject to direct and bending stresses" above a value of τ b = 198 N/mm and a value of τ s = 100

N/mm2 results with a resultant stress of Sqrt (τ b2 + τ s2) = 222N/mm2..Which is in general agreement The angle of the resulting specific load to the horizontal element

with the above result = arctan(85,71/166,5)= 27,5o.

This is an angle with the weld throat θ = 45o + 27,5o = 72,5o

Referring to weld capacities table below.Weld Capacities K is calculated at 1,36 for this resultant

direction of forces.

PT = a.K.pwfor a E35 Weld electrode used with S275 steel

pw = 220 N/mm2 and therefore PT = a*300N/mm2..

A 3mm weld (a = 2,1mm) therefore will therefore have a design capacity of 630 N/mm run and will

easily be able to support the load of 186,86 N per mm run

You might also like

- Spreadsheet For Single Span Cast in Place Concrete Bridge DesignDocument16 pagesSpreadsheet For Single Span Cast in Place Concrete Bridge DesignAli Akbar100% (1)

- Seafastening Design CalculationsDocument82 pagesSeafastening Design CalculationsInhake AutechreNo ratings yet

- Design of Cantilever BeamDocument23 pagesDesign of Cantilever Beamjs kalyana rama85% (13)

- The Mechanics of Soils ATKINSONDocument292 pagesThe Mechanics of Soils ATKINSONFebrianto Ch89% (27)

- Design of Embeded Plate (INDIAN STANDARD)Document3 pagesDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- Design of Beams: DataDocument3 pagesDesign of Beams: DataSharath SharathNo ratings yet

- VIII Unit DOS IIDocument37 pagesVIII Unit DOS IIImaad UddinNo ratings yet

- 2ND ExampleDocument12 pages2ND ExamplesamehNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Design of Strip Footing (Raft) For PM Room1Document3 pagesDesign of Strip Footing (Raft) For PM Room1Nagesh ChitariNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabrukesh104No ratings yet

- Manyam Dr.s HouseDocument33 pagesManyam Dr.s HouseDurga Rama Swamy KalvakolanuNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- A. Design of Flanged Beam SectionDocument7 pagesA. Design of Flanged Beam SectionWilson PatyalNo ratings yet

- StaicaseDocument4 pagesStaicaseAlex MachariaNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- Design and Detailing of Steel in Combined FootingsDocument34 pagesDesign and Detailing of Steel in Combined FootingsgundulpNo ratings yet

- Slide Share BDocument42 pagesSlide Share BShakeel WaseemNo ratings yet

- 1 - SPLICE-WPB 700X300X204.5 - DraftDocument7 pages1 - SPLICE-WPB 700X300X204.5 - DraftAvishek DeyNo ratings yet

- 20 M SpanDocument20 pages20 M SpanEr KanwarPal SinghNo ratings yet

- Design CalculationDocument23 pagesDesign CalculationKathir VelNo ratings yet

- Beam LSMDocument6 pagesBeam LSMARVIND SINGH RAWATNo ratings yet

- Design of Water TankDocument30 pagesDesign of Water TankDeepthi ReddyNo ratings yet

- Lecture Three - Welded ConnectionsDocument30 pagesLecture Three - Welded ConnectionsAhmedNo ratings yet

- Unit 3 32,33,34,35Document3 pagesUnit 3 32,33,34,35Deepanshu VermaNo ratings yet

- GI$. Note That Since: O P E AE PL AL AEDocument6 pagesGI$. Note That Since: O P E AE PL AL AESuraj KumarNo ratings yet

- Over Head ResevoirDocument8 pagesOver Head ResevoirPoulomi BiswasNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- DPT Numericals For Production EngineeringDocument8 pagesDPT Numericals For Production Engineeringprithvi shettyNo ratings yet

- Two Way SlabDocument2 pagesTwo Way Slabrukesh104No ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Design of SlabsDocument10 pagesDesign of SlabsMaheshreddyNo ratings yet

- 15epme011 Strength of MaterialsDocument50 pages15epme011 Strength of MaterialsgsanthoshskNo ratings yet

- Design OfSteel Structures-IDocument50 pagesDesign OfSteel Structures-IBhagyshri SiddheNo ratings yet

- Chapter - 3 - Torsion - Class ExamplesDocument14 pagesChapter - 3 - Torsion - Class ExamplesCandice MdakaNo ratings yet

- KKKH3353 - Structural Steel Design - Joints 2Document26 pagesKKKH3353 - Structural Steel Design - Joints 2Zeyad Tareq Al SaroriNo ratings yet

- Intze Tank 1 Moin 25-1-23Document17 pagesIntze Tank 1 Moin 25-1-23MOIN UDDINNo ratings yet

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- Slab DesignDocument6 pagesSlab DesignmadhuNo ratings yet

- Column Reinforcement Design: Uex UeyDocument15 pagesColumn Reinforcement Design: Uex Ueyswargadwari consultancyNo ratings yet

- Reinf - conc.Beams-Design Torsional&Axially LoadedDocument1 pageReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaNo ratings yet

- CCCCCCDocument2 pagesCCCCCCmirzakamranbaig.mkNo ratings yet

- Design Data: Design of Floor SlabDocument1 pageDesign Data: Design of Floor SlabDrafters EngineeringNo ratings yet

- Escaltor Cantilever Beam: Load CalculationDocument6 pagesEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANo ratings yet

- Designed By: Submitted ToDocument46 pagesDesigned By: Submitted To106 MOMENUL ISLAM KHAN 17No ratings yet

- 2 Way Slab Menuka FinalDocument1 page2 Way Slab Menuka Finalabhisek adhikariNo ratings yet

- Lifting LugDocument17 pagesLifting LugJoosung HanNo ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- The Resultant Is Within The Middle of One Third: ComputedDocument1 pageThe Resultant Is Within The Middle of One Third: Computedtewele brhaneNo ratings yet

- Torsion Design For BeamDocument4 pagesTorsion Design For BeamtkofaiNo ratings yet

- UNIT 11unit 2 FrontDocument5 pagesUNIT 11unit 2 FronticonicshashankNo ratings yet

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- Built Up Column - ChannelDocument18 pagesBuilt Up Column - ChannelSambhav PoddarNo ratings yet

- Built Up Section Design SheetDocument12 pagesBuilt Up Section Design SheetBikal BastakotiNo ratings yet

- Pre-Stressed Concrete MSCE 514: Problem Set 2Document8 pagesPre-Stressed Concrete MSCE 514: Problem Set 2Andrea Mae Sanchez0% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Cantilever Welds Subject To Both Bending and ShearDocument1 pageCantilever Welds Subject To Both Bending and ShearcanettijNo ratings yet

- Siemens Integrator Milltronics BW500 and BW500L DatasheetDocument5 pagesSiemens Integrator Milltronics BW500 and BW500L DatasheetcanettijNo ratings yet

- Calculati Ons Based On Unit ValuesDocument1 pageCalculati Ons Based On Unit ValuescanettijNo ratings yet

- Weld Throat Area Unit Area Location of COG X y I - (Unit) J - (Unit)Document1 pageWeld Throat Area Unit Area Location of COG X y I - (Unit) J - (Unit)canettijNo ratings yet

- Stainless Steel: General Information ApplicationsDocument11 pagesStainless Steel: General Information ApplicationscanettijNo ratings yet

- 2008 - 8 - DIN Threaded FittingsDocument10 pages2008 - 8 - DIN Threaded FittingscanettijNo ratings yet

- BD-ISO 5459 Technical Drawing - Geometrical TolerancesDocument26 pagesBD-ISO 5459 Technical Drawing - Geometrical Tolerancescanettij100% (1)

- Steelway StandardsDocument20 pagesSteelway StandardscanettijNo ratings yet

- 2008 - 9 - Sandvik Coupling LDocument6 pages2008 - 9 - Sandvik Coupling LcanettijNo ratings yet

- 2008 - 4 - ANSI FlangesDocument12 pages2008 - 4 - ANSI FlangescanettijNo ratings yet

- 2008 - 6 - ISO BW FittingsDocument12 pages2008 - 6 - ISO BW FittingscanettijNo ratings yet

- 2008 - 2 - Tube & PipeDocument7 pages2008 - 2 - Tube & PipecanettijNo ratings yet

- Design ProcewssDocument10 pagesDesign ProcewsscanettijNo ratings yet

- Artikulli 12Document10 pagesArtikulli 12jenniferNo ratings yet

- 620-1025 Rules For Compression-Ring Regions Exceeding 2 Inches Thickness - Rev 0Document2 pages620-1025 Rules For Compression-Ring Regions Exceeding 2 Inches Thickness - Rev 0Bilal ZahidNo ratings yet

- EarthquakeAnalysisOfRC BuildingsDocument67 pagesEarthquakeAnalysisOfRC BuildingsKaran ThakurNo ratings yet

- The Analysis of Earth Pressure On Retaining Wall Based On ABAQUSDocument4 pagesThe Analysis of Earth Pressure On Retaining Wall Based On ABAQUSroloheNo ratings yet

- Ductile Damage For MetalsDocument17 pagesDuctile Damage For MetalsVinita VermaNo ratings yet

- Pete 322 - Drilling Engineering - Ii Chapter 6 - Casing DesignDocument39 pagesPete 322 - Drilling Engineering - Ii Chapter 6 - Casing DesignTuran Amiraslanli100% (1)

- Zsteel Design Practice Problems With Ans KeyDocument4 pagesZsteel Design Practice Problems With Ans Keyjj012586No ratings yet

- BookDocument620 pagesBookpiv0ter_betterNo ratings yet

- Effects of An Earthquake PDFDocument11 pagesEffects of An Earthquake PDFverben siegaNo ratings yet

- Lab Manual DBT 210 PDFDocument19 pagesLab Manual DBT 210 PDFBELAL ALSUBARINo ratings yet

- Lab Manual (ME 3802)Document22 pagesLab Manual (ME 3802)Pranto ShuvoNo ratings yet

- Pengaruh Getaran Tanah Akibat Peledakaan Terhadap Kemantapan Lereng Tambang Air Laya Selatan PT Bukit Asam (Persero) TBKDocument9 pagesPengaruh Getaran Tanah Akibat Peledakaan Terhadap Kemantapan Lereng Tambang Air Laya Selatan PT Bukit Asam (Persero) TBKRafael GultomNo ratings yet

- DMRC DBR Chennai PDFDocument25 pagesDMRC DBR Chennai PDFTarun Kant Goyal100% (1)

- BY Annoy Kumar Ghosh B.Tech NIT, Durgapur: EarthquakeDocument25 pagesBY Annoy Kumar Ghosh B.Tech NIT, Durgapur: EarthquakeARIJIT DASNo ratings yet

- Rigid 1Document1 pageRigid 1Arjun Chitradurga RamachandraRaoNo ratings yet

- Chapter 2Document40 pagesChapter 2IntanLeeyanaNo ratings yet

- Drilled Cast-In-Place Pile Design Based On ACI 318-05Document3 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-05Sabrina ImloulNo ratings yet

- Sensitivity Analysis of Clock Spring Repair To Hydrogen Gas-Effect On Burst PressureDocument28 pagesSensitivity Analysis of Clock Spring Repair To Hydrogen Gas-Effect On Burst Pressuregerry_ndutzNo ratings yet

- Evaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsDocument23 pagesEvaluation of ACI 318 19 Provisions For Special Moment Frames and Special Structural Walls Using Data From The E Defense 10 Story TestsSudip ShresthaNo ratings yet

- Bearing Capacity of Shallow FoundationDocument124 pagesBearing Capacity of Shallow FoundationSHAN NUHRIO50% (4)

- 1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsDocument5 pages1 456:2000 Clause 25.2) Annex E of The Code With The Assumption That The Frame IsBejil ShresthaNo ratings yet

- Comprehensive Rock Engineering LNJTNDocument18 pagesComprehensive Rock Engineering LNJTNargaNo ratings yet

- Module 3. Mechanical TestingDocument13 pagesModule 3. Mechanical TestingPearl Alexandra FabitoNo ratings yet

- Beam Deflection 2bDocument2 pagesBeam Deflection 2bKrisia MartinezNo ratings yet

- 05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysisDocument11 pages05 Constructing Load Transfer QZ and TZ Curves From Pile Loading Tests For 3D FEA AnalysislingamkumarNo ratings yet

- Nonlinear Seismic Behaviour of Concrete Arch BridgesDocument61 pagesNonlinear Seismic Behaviour of Concrete Arch BridgesJoseAngelFernandezOrtegaNo ratings yet

- Pipeline Lowering Analysis at Limited SpaceDocument2 pagesPipeline Lowering Analysis at Limited SpaceArvin PutrantoNo ratings yet

- Analysis&Design of Truss For Indoor StadiumDocument40 pagesAnalysis&Design of Truss For Indoor StadiumD.V.Srinivasa Rao100% (2)