Professional Documents

Culture Documents

24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwright0 ratings0% found this document useful (0 votes)

29 views1 pageThis document provides instructions and specifications for mounting a C27 or C32 engine with a TH48-E70 transmission. It includes:

- Dimensions for isolator mount placement on the transmission cradle when using a C27 (451.1mm from flywheel housing) or C32 (472.7mm) engine.

- A notice about properly aligning the engine and transmission centerlines.

- Recommendations for OEMs to perform a power train component system mounting analysis to identify a compatible mounting arrangement.

Original Description:

Original Title

24_PDFsam_REHS2891-04 TH48 E70 Mechanical A&I Guide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides instructions and specifications for mounting a C27 or C32 engine with a TH48-E70 transmission. It includes:

- Dimensions for isolator mount placement on the transmission cradle when using a C27 (451.1mm from flywheel housing) or C32 (472.7mm) engine.

- A notice about properly aligning the engine and transmission centerlines.

- Recommendations for OEMs to perform a power train component system mounting analysis to identify a compatible mounting arrangement.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

29 views1 page24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

24 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwrightThis document provides instructions and specifications for mounting a C27 or C32 engine with a TH48-E70 transmission. It includes:

- Dimensions for isolator mount placement on the transmission cradle when using a C27 (451.1mm from flywheel housing) or C32 (472.7mm) engine.

- A notice about properly aligning the engine and transmission centerlines.

- Recommendations for OEMs to perform a power train component system mounting analysis to identify a compatible mounting arrangement.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

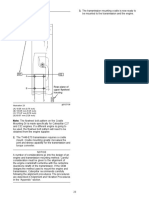

g03134076

Illustration 24

Left side view of a C27 and TH48-E70

(E) For C27 dimension is 451.1 mm (93) Isolator mount (96) Rear of flywheel housing (plane 01

(17.76 inch), and C32 is 472.7 mm (94) Isolator mount in Illustration 23)

(18.61 inch) (95) Front engine mount (97) Transmission long cradle structure

4. After the cradle has been mounted to the engine

and the transmission, the transmission to flywheel NOTICE

housing bolts will need to be checked again for In the design of an engine and transmission mounting

the proper torque. method, careful consideration must be given to the

alignment of the engine crankshaft centerline with the

5. The engine and transmission system is now centerline (backbone shaft) of the transmission. As

ready to be mounted into the vehicle. Refer to the the OEM designs their own method of mounting the

Transmission and Mounting Dimensions under engine and transmission, Caterpillar recommends

the “Appendix” section for the information on carefully following the alignment procedures that are

dimensions and mounting hole patterns. described in Alignment and Vibration Procedures that

is under the “Appendix” section.

6. The recommended placement for isolator mounts

(93) and (94) are shown in Illustration 24.

Isolator mount (94) should be placed 451.1 mm Mounting the Engine and Transmission

(17.76 inch) from the rear of flywheel housing (96)

when mounting the transmission to a Caterpillar Original Equipment Manufactures (OEMs) must

C27 engine. The dimension is 472.7 mm consider the following variables when mounting the

(18.61 inch) for Caterpillar C32 engines. Refer engine and the transmission: static loads, torque,

to “Bending Moments” through “Determination dynamic “g” loads, resonant frequencies, frame

of Flywheel Housing Bending Moment” for stiffness, and the mounts fatigue limits. Caterpillar

information on other engines. recommends that OEMs perform a power train

component system mounting analysis. Most of the

7. After the engine and transmission have been major suppliers of engine and transmission mounts

mounted into the OEM vehicle system, the have computer programs that can run a power train

flywheel housing bolts need checked again for mounting system analysis. The analysis will identify

proper torque setting. a compatible mounting arrangement with stiffness

and frequencies that do not over or under load each

power train system mount.

24

You might also like

- INA Repair Manual GearBOX VW-02J 210x297 en Black PDFDocument32 pagesINA Repair Manual GearBOX VW-02J 210x297 en Black PDFEmilioGastón50% (2)

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocument246 pagesADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- Shop Manual s225lc V 1 PDFDocument670 pagesShop Manual s225lc V 1 PDFEdgar Martinez Carmona67% (6)

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- OM 654 - Launch of A NewDocument8 pagesOM 654 - Launch of A Newkammy4love9888100% (3)

- Voith Retarder 115 E 147 Pag PDFDocument147 pagesVoith Retarder 115 E 147 Pag PDFDardan Husi100% (2)

- Cummins ISB 5.9 Exhaust Manifold InstallationDocument16 pagesCummins ISB 5.9 Exhaust Manifold Installationmds9185No ratings yet

- 1394 Drive Conversion BSJDocument152 pages1394 Drive Conversion BSJangelpadronaNo ratings yet

- QSK60 Mounting SystemDocument24 pagesQSK60 Mounting SystemagvassNo ratings yet

- Agn232 ADocument6 pagesAgn232 AariwibowoNo ratings yet

- Alignment InstructionsDocument19 pagesAlignment Instructionskrishnaprasad_rajaseNo ratings yet

- 25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- PowerplantDocument14 pagesPowerplantOSCARDELTA100% (2)

- Cpu-95evs Ii 9-14Document14 pagesCpu-95evs Ii 9-14Jeshua RiveraNo ratings yet

- Caso Estudio Alineamiento de EjesDocument8 pagesCaso Estudio Alineamiento de EjesBacoNo ratings yet

- Sid97 3eDocument39 pagesSid97 3eJonatan BernalNo ratings yet

- A Methodology To Analyze Aircraft EngineDocument10 pagesA Methodology To Analyze Aircraft Engineanmol6237No ratings yet

- MTG Des OverhungDocument12 pagesMTG Des OverhungPaunescu CostinNo ratings yet

- TCM Sid97-3fDocument28 pagesTCM Sid97-3fPaula Pulido MartínezNo ratings yet

- W Defa3763Document22 pagesW Defa3763Jerish JohnNo ratings yet

- Influence of Elastic Foundation Structures On The Rotor Dynamics PDFDocument8 pagesInfluence of Elastic Foundation Structures On The Rotor Dynamics PDFyonex215317No ratings yet

- Specifications Standards For Shafts Alignment PDFDocument18 pagesSpecifications Standards For Shafts Alignment PDFDelfinshNo ratings yet

- AGN 235 - Generating Set Assembly - Torsional Vibration AnalysisDocument10 pagesAGN 235 - Generating Set Assembly - Torsional Vibration AnalysisariwibowoNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Transfer Box, Axle Drive and Shafts E70.: Aftersales Training - Product InformationDocument22 pagesTransfer Box, Axle Drive and Shafts E70.: Aftersales Training - Product InformationYau Shien LiangNo ratings yet

- 5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Increasing Availability Through Advanced Gearless Drive TechnologyDocument12 pagesIncreasing Availability Through Advanced Gearless Drive TechnologyJaime Magno Gutierrez RamirezNo ratings yet

- Transsmission Driveline AdaptationDocument16 pagesTranssmission Driveline Adaptationamin chaabenNo ratings yet

- 23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 3 - Gas A&I G3500 Mounting and AlignmentDocument40 pages3 - Gas A&I G3500 Mounting and AlignmentosamaNo ratings yet

- The Integrated Balancer Shaft System of The New BMW Four-Cylinder Diesel EngineDocument6 pagesThe Integrated Balancer Shaft System of The New BMW Four-Cylinder Diesel EngineZhihai DengNo ratings yet

- Park, Brake ProvisionDocument7 pagesPark, Brake Provisionamin chaabenNo ratings yet

- RBE Series Motors Brochure en-US 2003Document44 pagesRBE Series Motors Brochure en-US 2003derribo78No ratings yet

- Sachs 1Document45 pagesSachs 1caf28035No ratings yet

- RBE (H) Series Motors: Data PublicationDocument44 pagesRBE (H) Series Motors: Data PublicationKOMATSU SHOVELNo ratings yet

- Transmission Removal & Installation - Metro & Firefly (Canadian)Document2 pagesTransmission Removal & Installation - Metro & Firefly (Canadian)Jose PichinteNo ratings yet

- Steer by Wire System Development Using ADocument8 pagesSteer by Wire System Development Using AMikyNo ratings yet

- Installation Manual: Model T430A Engine BrakesDocument11 pagesInstallation Manual: Model T430A Engine Brakesjaved samaaNo ratings yet

- 700Series5to10Ton ManDocument20 pages700Series5to10Ton ManStiven PeñaNo ratings yet

- Influence of Elastic Foundation Structures On The Rotor DynamicsDocument8 pagesInfluence of Elastic Foundation Structures On The Rotor DynamicsVodanh Tieutot100% (1)

- A Particle Swarm Optimization Tool For Decoupling Automotive Powertrain Torque Roll AxisDocument8 pagesA Particle Swarm Optimization Tool For Decoupling Automotive Powertrain Torque Roll AxisDavid NeihgukNo ratings yet

- Unimotor Manual v2bDocument119 pagesUnimotor Manual v2bFranCanavNo ratings yet

- SSP 266 28l Tdi Engine With Common Rail InjectionDocument56 pagesSSP 266 28l Tdi Engine With Common Rail InjectionNhuong Hoang DinhNo ratings yet

- 2 Product Description and Overview of Types: General InformationDocument14 pages2 Product Description and Overview of Types: General InformationErich ThomasNo ratings yet

- Gas Engines Application and Installation Guide: Engine Selection Ambient ConsiderationsDocument21 pagesGas Engines Application and Installation Guide: Engine Selection Ambient ConsiderationsMauro DiazNo ratings yet

- Installation Instructions: Warning: WarningDocument30 pagesInstallation Instructions: Warning: WarningwcuevasmNo ratings yet

- QSK MCRS Mounting SystemDocument10 pagesQSK MCRS Mounting SystemaldhanyNo ratings yet

- DTS 04 UkDocument12 pagesDTS 04 UkhepcomotionNo ratings yet

- Paper - Payload Dropping and Tilt Rotor Mechanism For Unmanned Aerial Vehicle (1) - 1-6 - RemovedDocument2 pagesPaper - Payload Dropping and Tilt Rotor Mechanism For Unmanned Aerial Vehicle (1) - 1-6 - Removeddrmahadev.1961No ratings yet

- Automax Actuators & Accessories English PDFDocument18 pagesAutomax Actuators & Accessories English PDFSt. Labuhan MaringgaiNo ratings yet

- Penjadwalan Pemeliharaan Komponen Kritis Pada Sistem Hidrolik Dan Engine Unit Excavator Di Departemen Tambang Pt. Semen PadangDocument11 pagesPenjadwalan Pemeliharaan Komponen Kritis Pada Sistem Hidrolik Dan Engine Unit Excavator Di Departemen Tambang Pt. Semen PadangmayaNo ratings yet

- 15419Document29 pages15419tushar11singhNo ratings yet

- 23netp 0107Document7 pages23netp 0107Abdelmajid AittalebNo ratings yet

- MR Num4-EnDocument14 pagesMR Num4-EnaminardakaniNo ratings yet

- 06 - Tf6ve We 0431Document582 pages06 - Tf6ve We 0431jrrodrigueza2No ratings yet

- 48 PumpDrive SelectionGuide 1Document52 pages48 PumpDrive SelectionGuide 1rgopikrishna313No ratings yet

- Presentacion de CargadoresDocument103 pagesPresentacion de CargadoresCristian NeiraNo ratings yet

- Selector Hub AssemblyDocument36 pagesSelector Hub AssemblyfilipCARbovaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- 41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuideDocument1 page45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuidetvwrightNo ratings yet

- 44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page23 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page11 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 96 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page96 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page5 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page9 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 6 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page6 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 8 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page8 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Special Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionsDocument1 pageSpecial Instruction: Mechanical Application and Installation Guide For TH48-E70 Petroleum TransmissionstvwrightNo ratings yet

- 3 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page3 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page4 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 97 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page97 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 95 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page95 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 98 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page98 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- 93 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90Document1 page93 - PDFsam - REHS2892-08 Electrical A&I Guide For Frac Xmissions TH48-E70, TH55-E70 & TH55-E90tvwrightNo ratings yet

- DTU ReportDocument9 pagesDTU ReportHarsh PandeyNo ratings yet

- Electric Vehicle Designing, Modelling and SimulationDocument6 pagesElectric Vehicle Designing, Modelling and SimulationLE-225 Moulali ShaikNo ratings yet

- Yaskawa SGDM Servo User's ManualDocument416 pagesYaskawa SGDM Servo User's Manualtom corvin67% (3)

- SECTION 307-01A: Automatic Transaxle/Transmission - CVT 2005 Freestyle/Five Hundred/Montego Workshop Manual SpecificationsDocument5 pagesSECTION 307-01A: Automatic Transaxle/Transmission - CVT 2005 Freestyle/Five Hundred/Montego Workshop Manual Specificationskamaleon doradoNo ratings yet

- 769D Renr3381renr3381-02 - Sis PDFDocument12 pages769D Renr3381renr3381-02 - Sis PDFJose Miguel Salas BritoNo ratings yet

- Msar GroupDocument20 pagesMsar GroupmchathirNo ratings yet

- 06 Komatsu GD825 Final Drive & TandemDocument9 pages06 Komatsu GD825 Final Drive & TandemLucyan Ionescu100% (3)

- Sensor Systems Broch 09 MedDocument12 pagesSensor Systems Broch 09 MedscribdkhatnNo ratings yet

- Cruze Training Course April 2009Document92 pagesCruze Training Course April 2009karim_shallNo ratings yet

- TM 9-1425-2525-24P - KLu - Initial - Mandatory - Part - List - 2000 PDFDocument28 pagesTM 9-1425-2525-24P - KLu - Initial - Mandatory - Part - List - 2000 PDFWurzel1946No ratings yet

- Operator's ManualDocument110 pagesOperator's ManualAdam0% (1)

- Selecting The Right Speed Reducer For Mixers PDFDocument12 pagesSelecting The Right Speed Reducer For Mixers PDFGian Carlos Perea DiazNo ratings yet

- ViscothermDocument46 pagesViscothermJezrell JaravataNo ratings yet

- Hydraulik: Jahns-Regulatoren GMBHDocument12 pagesHydraulik: Jahns-Regulatoren GMBHLake HouseNo ratings yet

- Case Ih 7220 Test PDFDocument5 pagesCase Ih 7220 Test PDFdanutspataruNo ratings yet

- Simulation For Wind Turbine Generators-With FAST and MATLAB-Simulink ModulesDocument137 pagesSimulation For Wind Turbine Generators-With FAST and MATLAB-Simulink ModulesPRAMOD SHARMANo ratings yet

- Final Drive Transmission 9030bDocument3 pagesFinal Drive Transmission 9030bCaroline Rosa100% (1)

- Direct Drive PDFDocument12 pagesDirect Drive PDFAnonymous LBwADkNZH100% (1)

- Wtec Iii PDFDocument19 pagesWtec Iii PDFMohammed Yassine GarrebNo ratings yet

- 700Series5to10Ton ManDocument20 pages700Series5to10Ton ManStiven PeñaNo ratings yet

- Driveone Catalog English PDFDocument184 pagesDriveone Catalog English PDFangel017No ratings yet

- HSS Rotor Side Bearing Inspection InstructionsDocument6 pagesHSS Rotor Side Bearing Inspection InstructionsAdriano Cesário100% (1)

- MBSA Actros Specification FADocument4 pagesMBSA Actros Specification FAanon_509618907100% (1)

- Brochure Magirus Airport Fire EnginesDocument13 pagesBrochure Magirus Airport Fire EnginesLaurensNL0% (1)

- Al-Gazi Tractors - (Management)Document46 pagesAl-Gazi Tractors - (Management)api-19759801No ratings yet

- BMW Seria2 Gran Coupe - Ro.enDocument24 pagesBMW Seria2 Gran Coupe - Ro.enqueen.mileenaNo ratings yet

- ZJ70 4500DB Technical Spec PDFDocument44 pagesZJ70 4500DB Technical Spec PDFMaung Oo100% (1)