Professional Documents

Culture Documents

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Uploaded by

mandingos707Copyright:

Available Formats

You might also like

- Method of Statement For R.C.C Jacketing - Rev.0 PDFDocument5 pagesMethod of Statement For R.C.C Jacketing - Rev.0 PDFrobin7No ratings yet

- BS 6144 1990 Specification For Expansion Vessels Using An Internal Diaphragm, For Unvented Hot WDocument14 pagesBS 6144 1990 Specification For Expansion Vessels Using An Internal Diaphragm, For Unvented Hot WRamiAl-fuqahaNo ratings yet

- Safebuck Design Guideline and DNV RP F110Document8 pagesSafebuck Design Guideline and DNV RP F110Константин ДмитриевNo ratings yet

- QC10-H-049 M09 Steel Tanks-Rev6 PDFDocument14 pagesQC10-H-049 M09 Steel Tanks-Rev6 PDFMohammed HilalNo ratings yet

- Stress Analysis Using Actual Coke DrumDocument11 pagesStress Analysis Using Actual Coke Drumash1968No ratings yet

- 2002 Davis-Besse Reactor Pressure Vessel Head Degradation Knowledge Management DigestDocument24 pages2002 Davis-Besse Reactor Pressure Vessel Head Degradation Knowledge Management DigestBraedonNo ratings yet

- Mechanics of Deepwater Steel Catenary Riser: September 2011Document29 pagesMechanics of Deepwater Steel Catenary Riser: September 2011Ashin VargheseNo ratings yet

- Establishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsDocument75 pagesEstablishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsNavnath GawasNo ratings yet

- MECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashDocument8 pagesMECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashMikeNo ratings yet

- MECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashDocument8 pagesMECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashMikeNo ratings yet

- OMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersDocument5 pagesOMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersdmlsfmmNo ratings yet

- MNL 34-1998 PDFDocument161 pagesMNL 34-1998 PDFjjgnzgarciaNo ratings yet

- Ac 2009-2529: Whistle-Blowing by Engineers and Reverse Whistle-Blowing On EngineersDocument12 pagesAc 2009-2529: Whistle-Blowing by Engineers and Reverse Whistle-Blowing On EngineersOdoch HerbertNo ratings yet

- 2 Dolphin Design With STAD PRODocument48 pages2 Dolphin Design With STAD PROFachreza AkbarNo ratings yet

- Carbonate Stress Corrosion Cracking (ACSCC)Document11 pagesCarbonate Stress Corrosion Cracking (ACSCC)Ajmi HmidaNo ratings yet

- HISC NORSOK Workshop Agreement M-WA-01Rev1Document18 pagesHISC NORSOK Workshop Agreement M-WA-01Rev1naveen_86No ratings yet

- Microsoft Word - 2028B - Rev - 0Document10 pagesMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshNo ratings yet

- Oe Pipelines1Document3 pagesOe Pipelines1babakNo ratings yet

- Sabp L 002 PDFDocument27 pagesSabp L 002 PDFshyamNo ratings yet

- WD-70BD10 Rev-3Document47 pagesWD-70BD10 Rev-3PAWAN KNo ratings yet

- Matterhorn Steel Catenary Risers Critical Issues and Lessons Learned For Reel-Layed SCRs To A TLPDocument16 pagesMatterhorn Steel Catenary Risers Critical Issues and Lessons Learned For Reel-Layed SCRs To A TLPTee Shi FengNo ratings yet

- Sabp L 003Document46 pagesSabp L 003Li PengNo ratings yet

- SR.11.10961 - Sour Well Design GuideDocument52 pagesSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- 1416-MC-DBS-101 - Mechanical Design Basis - R1Document19 pages1416-MC-DBS-101 - Mechanical Design Basis - R1KrunalNo ratings yet

- Boric Acid CorrosionDocument47 pagesBoric Acid CorrosionFedak MarosNo ratings yet

- Evaluation - 2012-256 - Responsive - 4Document74 pagesEvaluation - 2012-256 - Responsive - 4Bob MackinNo ratings yet

- SPE 39320 New Generation Drill String Safety ValveDocument12 pagesSPE 39320 New Generation Drill String Safety ValveBruceNo ratings yet

- Corrosion of Reactor Effluent Air Coolers-20180315Document47 pagesCorrosion of Reactor Effluent Air Coolers-20180315庄查理100% (1)

- Resolution Technical Review Board 2017Document16 pagesResolution Technical Review Board 2017geolvmNo ratings yet

- Regulatory GuideDocument13 pagesRegulatory GuideMohammad AliNo ratings yet

- 01 Appende PDFDocument21 pages01 Appende PDFArun VaithyanathanNo ratings yet

- Sabp A 016Document60 pagesSabp A 016sethu1091100% (6)

- B 03 Marine Air ReceiversDocument9 pagesB 03 Marine Air ReceiversarunNo ratings yet

- Maste: Evaluation of Tubular Reactor Designs For Supercritical Water Oxidation of U.S. Department of Energy Mixed WasteDocument53 pagesMaste: Evaluation of Tubular Reactor Designs For Supercritical Water Oxidation of U.S. Department of Energy Mixed WasteardiNo ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- Caustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliaDocument8 pagesCaustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliajaNo ratings yet

- WD 70 BD 10 - Rev - 2Document47 pagesWD 70 BD 10 - Rev - 2N Say100% (1)

- Sabp W 002Document7 pagesSabp W 002zoopladoNo ratings yet

- P13-005-UE-10-SPC-0001-4 - (SPEC110 Struct. Steel Skids)Document9 pagesP13-005-UE-10-SPC-0001-4 - (SPEC110 Struct. Steel Skids)Enabulele OsakpamwanNo ratings yet

- QC10-H-044 M04 Factory Made Bends For Mainlines-Rev01Document10 pagesQC10-H-044 M04 Factory Made Bends For Mainlines-Rev01kkrq13No ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Sabp D 002Document16 pagesSabp D 002engforever AdnanNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- (Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JDocument8 pages(Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JMarcus BaltesNo ratings yet

- SM MethodDocument16 pagesSM MethodMd AfzanNo ratings yet

- Neral & Staad Diag.Document130 pagesNeral & Staad Diag.IkramNo ratings yet

- API 610 CentrifugalDocument6 pagesAPI 610 CentrifugalAnonymous 4lFgg25MENo ratings yet

- Spe 77357 MSDocument14 pagesSpe 77357 MSmohamedabbas_us3813No ratings yet

- DM 002Document25 pagesDM 002Jonathan Romero AlfaroNo ratings yet

- Caustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)Document8 pagesCaustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)APINo ratings yet

- Regulatory Guide: Control of Electroslag Weld PropertiesDocument3 pagesRegulatory Guide: Control of Electroslag Weld PropertiesAlex GutierrezNo ratings yet

- Koc L 026 PDFDocument32 pagesKoc L 026 PDFJigarNo ratings yet

- IS3370 Part4 Sec2 2021Document352 pagesIS3370 Part4 Sec2 2021gunjanatulbansalNo ratings yet

- I) CBC Spec No. Wd-70-Bd-10 (Rev.1)Document47 pagesI) CBC Spec No. Wd-70-Bd-10 (Rev.1)devgreatNo ratings yet

- UntitledDocument47 pagesUntitledbarian karopebokaNo ratings yet

- 11.113 Well Integrity Assessment ReportDocument144 pages11.113 Well Integrity Assessment ReportIgorCencič100% (1)

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardFrom EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNo ratings yet

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageFrom EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNo ratings yet

- The Marine Corrosion Process and Control: Design Guides for Oil and Gas FacilitiesFrom EverandThe Marine Corrosion Process and Control: Design Guides for Oil and Gas FacilitiesNo ratings yet

- Alcatel Lucent 4305Document2 pagesAlcatel Lucent 4305mandingos707No ratings yet

- TigerSecu 2MP PDFDocument38 pagesTigerSecu 2MP PDFmandingos707100% (1)

- Matlab AnswersDocument4 pagesMatlab Answersmandingos707No ratings yet

- 2013 Unix BookDocument61 pages2013 Unix Bookmandingos707No ratings yet

- Tata Projects Limited BTRS, SVS Road, Mayor's Bunglow, Shivaji Park, Dadar West Scope Matrix For Secant Piling WorksDocument1 pageTata Projects Limited BTRS, SVS Road, Mayor's Bunglow, Shivaji Park, Dadar West Scope Matrix For Secant Piling WorksSabyasachi BangalNo ratings yet

- Communication MatrixDocument1 pageCommunication Matrixrohini kadamNo ratings yet

- Chords Like Jeff BuckleyDocument5 pagesChords Like Jeff BuckleyTDROCKNo ratings yet

- Comparison of Starbucks With The Coffee BeanDocument16 pagesComparison of Starbucks With The Coffee BeanshaiNo ratings yet

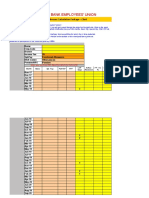

- Karur Vysya Bank Employees' Union: 11th Bipartite Arrears Calculation Package - ClerkDocument10 pagesKarur Vysya Bank Employees' Union: 11th Bipartite Arrears Calculation Package - ClerkDeepa ManianNo ratings yet

- JD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XDocument530 pagesJD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XGaurav SahuNo ratings yet

- Reblex AnswersDocument17 pagesReblex AnswersAerol Buenaventura100% (1)

- Maternal and Infant Care Beliefs Aeta Mothers in PhilippinesDocument8 pagesMaternal and Infant Care Beliefs Aeta Mothers in PhilippinesChristine Joy MolinaNo ratings yet

- Organisational BehaviourDocument279 pagesOrganisational BehaviourSumitha SelvarajNo ratings yet

- (GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENDocument9 pages(GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENHakim-Aarifah BeyNo ratings yet

- Barcode Scanner, Wireless Barcode Scanner, DC5112 Barcode ScannerDocument3 pagesBarcode Scanner, Wireless Barcode Scanner, DC5112 Barcode ScannerdcodeNo ratings yet

- Oracle Weblogic Server 12c Troubleshooting WorkshopDocument3 pagesOracle Weblogic Server 12c Troubleshooting WorkshopMarcelo BerriosNo ratings yet

- Redeemable Preference SharesDocument2 pagesRedeemable Preference Sharestanvia KNo ratings yet

- Mehdi To TestDocument13 pagesMehdi To Testtestcoolvms16No ratings yet

- Alternative Substrates As A Native Oyster (Crassostrea Virginica) Reef Restoration Strategy in Chesapeake BayDocument286 pagesAlternative Substrates As A Native Oyster (Crassostrea Virginica) Reef Restoration Strategy in Chesapeake BayMandi MynyddNo ratings yet

- VHDL Processes: Cwru Eecs 318Document24 pagesVHDL Processes: Cwru Eecs 318KarThikNo ratings yet

- FisheriesDocument31 pagesFisheriesGarima LoonaNo ratings yet

- Reading Passage 1: Succeed in IELTS Volume 8Document16 pagesReading Passage 1: Succeed in IELTS Volume 8Huyền Kiệt thươngNo ratings yet

- Comsys 2Document10 pagesComsys 2MarjorieNo ratings yet

- Why Romanian Journal of Food ScienceDocument2 pagesWhy Romanian Journal of Food ScienceAna Vitelariu - RaduNo ratings yet

- TDS Conbextra GP2 BFLDocument4 pagesTDS Conbextra GP2 BFLsabbirNo ratings yet

- General: Specific: Leading Statement:: TITLE: A Healthy LifestyleDocument2 pagesGeneral: Specific: Leading Statement:: TITLE: A Healthy LifestyleM Arshad M AmirNo ratings yet

- TELECONFERENCINGDocument5 pagesTELECONFERENCINGAbhinav SharmaNo ratings yet

- EvalsDocument11 pagesEvalsPaul Adriel Balmes50% (2)

- Will or Going To 90069Document2 pagesWill or Going To 90069Dragana ZafirovskaNo ratings yet

- Petitioner vs. VS.: Third DivisionDocument12 pagesPetitioner vs. VS.: Third DivisionAnonymous QR87KCVteNo ratings yet

- Application DevelopmentDocument14 pagesApplication DevelopmentReema MubarakNo ratings yet

- Schmeling - The Role of Hydrothermal Cooling of The Oceanic Lithosphere For Ocean Floor Bathymetry 2017Document19 pagesSchmeling - The Role of Hydrothermal Cooling of The Oceanic Lithosphere For Ocean Floor Bathymetry 2017utsav mannuNo ratings yet

- Tools, Materials and Equipment in Nail Care: Learning Activity Sheet Week 1 Quarter 1Document8 pagesTools, Materials and Equipment in Nail Care: Learning Activity Sheet Week 1 Quarter 1Barbara PosoNo ratings yet

- Maribelle Z. Neri vs. Ryan Roy Yu (Full Text, Word Version)Document11 pagesMaribelle Z. Neri vs. Ryan Roy Yu (Full Text, Word Version)Emir MendozaNo ratings yet

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Uploaded by

mandingos707Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Davis-Besse Reactor Pressure Vessel Head Degradation: Overview, Lessons Learned, and NRC Actions Based On Lessons Learned

Uploaded by

mandingos707Copyright:

Available Formats

Davis-Besse Reactor

Pressure Vessel Head

Degradation

Overview, Lessons Learned, and

NRC Actions Based on Lessons

Learned

1 | Davis Besse Reactor Pressure Vessel Head Degradation

Davis-Besse Reactor Pressure Vessel

Head Degradation: Overview

Background

The reactor pressure vessel (RPV) heads of pressurized water reac-

tors (PWR) have penetrations for control rod drive mechanisms

and instrumentation systems made from nickel-based alloys (e.g.,

Alloy 600) and related weld metals (Figure 1). Primary coolant and

the operating conditions of PWR plants can cause cracking of these

nickel-based alloys and weldments through a process called pri-

mary water stress corrosion cracking (PWSCC). In response to the

detection of PWSCC at several plants, the NRC issued NRC Bul-

letin 2001-01, “Circumferential Cracking of Reactor Pressure Vessel

Head Penetration Nozzles,” which requested information related to

licensees’ programs for inspection of vessel head penetration (VHP)

nozzles.

Through-Wall Cracking Detected

On February 16, 2002, in response to Bulletin 2001-01, the Davis-

Besse Nuclear Power Station (DBNPS), located in Oak Harbor,

Ohio, began a refueling outage with the intent to perform work that

included remotely inspecting the VHP nozzles from underneath the

head focusing on the control rod drive mechanisms (CRDM). The

licensee found that three CRDM nozzles had indications of through-

wall axial cracking. Specifically, the licensee found these indications

in CRDM nozzles 1, 2, and 3, which are located near the top of the

RPV head.

Repair Attempts

The repair of these nozzles was performed remotely from under-

neath the head. On March 6, 2002, the licensee terminated the

repair process on CRDM nozzle 3 to determine the cause of unusual

equipment operation, and removed the machining apparatus from

the nozzle. During the removal, the nozzle tipped in the downhill

direction until it rested against an adjacent CRDM. If structurally

sound, the surrounding steel should have held the nozzle in place.

2 | Davis-Besse Reactor Pressure Vessel Head Degradation

Figure 1a. Typical pressurized water reactor

Figure 1b. Detail of vessel head penetration nozzles

Davis-Besse Reactor Pressure Vessel Head Degradation | 3

Investigation

The licensee investigated the condition of the RPV head surround-

ing CRDM nozzle 3. The investigation included removing the CRDM

nozzle and removing boric acid deposits from the top of the RPV

head. Upon completing the boric acid removal on March 7, 2002, the

licensee conducted a visual examination of the area and identified a

large cavity in the RPV head on the downhill side of CRDM nozzle

3 (Figure 2). The corrosion was caused by borated water that leaked

from the reactor coolant system onto the vessel head (Figures 3 and

4) through cracks in the nozzle and the weld that attached nozzle 3 to

the RPV head (Figures 5 and 6). The remaining thickness of the RPV

head in the wastage area was found to be approximately 3/8 inch. This

thickness consisted of the thickness of the stainless steel cladding

on the inside surface of the RPV head, which is nominally 3/8 inch

thick. The stainless steel cladding is resistant to corrosion by boric

acid, but it is not intended to provide structural integrity to the ves-

sel. Failure of the stainless steel cladding would have resulted in a

loss-of-coolant accident (LOCA). The LOCA would have resulted in

actuation of the plant’s emergency systems.

NRC Actions

NRC issued a confirmatory action letter that required the plant to

remain shut down until the situation could be satisfactorily ad-

dressed and invoked the process outlined in Inspection Manual

Chapter 0350, “Oversight of Reactor Facilities in a Shutdown Condi-

tion Due to Significant Performance and/or Operation Concern.”

This process establishes guidelines for the oversight of licensee per-

formance during the shutdown. The process requires that specific

criteria must be met before the plant can restart, to ensure that the

plant is operated in a manner that provides adequate protection of

public health and safety.

4 | Davis-Besse Reactor Pressure Vessel Head Degradation

Figure 2. Region of the vessel head depicted by the model and photo of the cavity after it was removed

from the vessel head

Davis-Besse Reactor Pressure Vessel Head Degradation | 5

Davis-Besse Reactor Pressure Vessel

Head Degradation: Lessons Learned

Operational Experience

During the early 1990’s, the NRC and industry recognized the

potential for boric acid corrosion of an RPV head. In 1993, the

industry and NRC specifically addressed the possibility of extensive

RPV head wastage stemming from undetected VHP nozzle leaks

involving axial cracking caused by PWSCC. The industry concluded

and the NRC agreed that the likelihood of this happening was low

because VHP nozzle leaks would be detected before significant RPV

head degradation could occur. Nevertheless, in spite of this aware-

ness and contrary to this conclusion, the DBNPS event occurred.

Lessons Learned Task Force

The NRC’s Executive Director for Operations (EDO) directed the

formation of an NRC task force in response to the issues associ-

ated with the DBNPS event. The objective of this task force was to

independently evaluate the NRC’s regulatory processes related to as-

suring RPV head integrity in order to identify and recommend areas

for improvement that may be applicable to either the NRC or the

nuclear industry. Consistent with its charter, the task force reviewed

five general areas, including: (1) reactor oversight process issues; (2)

regulatory process issues; (3) research activities; (4) international

practices; and (5) the NRC’s Generic Issues Program.

Task Force Conclusions

The lessons learned task force (LLTF) concluded that the DBNPS VHP

nozzle leakage and RPV head degradation event was preventable. While

this review was primarily introspective, this question could not be

answered without considering industry activities and DBNPS’s per-

formance. At DBNPS, early indications of RPV corrosion were missed

such as radiation element system filters being clogged by boric acid and

corrosion fines, the build up of boric acid deposits on containment air

cooler fins and large amounts of boric acid deposits on the RPV head.

The task force concluded that the event was not prevented because: (1)

the NRC, DBNPS, and the nuclear industry failed to adequately review,

assess, and follow-up on relevant operating experience, (2) DBNPS

6 | Davis-Besse Reactor Pressure Vessel Head Degradation

Figure 3a. RPV head flange area showing significant amounts of boric acid deposits

(photo taken during the 2000 refueling outage at DBNPS)

Boric acid

deposits

weep hole

Boric acid

deposits

CRDM

nozzle

Figure 3b. Boric acid deposits accumulating near a

CRDM nozzle (still photo of video taken during the 2000

refueling outage at DBNPS)

Figure 4a. Close-up view of the cavity

Figure 4b. Oblique view of the cavity

partially showing the J-groove weld

at the bottom of the cavity

Davis-Besse Reactor Pressure Vessel Head Degradation | 7

failed to assure that plant safety issues received appropriate attention,

and (3) the NRC failed to integrate known or available information into

its assessments of DBNPS’s safety performance. Furthermore, an NRC

investigation concluded that DBNPS did not adequately execute the

boric acid corrosion control program in response to an NRC Generic

Communication, and the NRC did not adequately review the industry

implementation of long term commitments, such as the commitment to

maintain a boric acid corrosion control program.

NRC Actions

As a result of its review, the task force determined that the NRC should

take specific actions to address contributing factors that led to the DB-

NPS event. The recommendations made involved the following areas: 1)

stress corrosion cracking, 2) reactor coolant pressure boundary integrity,

3) operational experience and 4) inspection and program management.

Select examples of NRC actions taken to address recommendations of

the LLTF in these areas are described in a later section.

Davis-Besse Reactor Pressure Vessel

Head Degradation: NRC Actions

Based on Lessons Learned

The LLTF developed recommendations in key technical and pro-

grammatic areas. Examples of some of the actions taken by the NRC

to address the recommendations of the task force in the areas of

stress corrosion cracking, operating experience, and inspection and

program management are discussed below.

Stress Corrosion Cracking

NRC Order EA-03-009 was issued requiring all licensees with plants

susceptible to RPV head degradation to visually inspect the reac-

tor vessel head surface area for indications of leakage and boric acid

accumulation, as well as inspect head penetrations using methods to

detect cracks before leakage starts.

The NRC worked with the American Society of Mechanical Engineers

(ASME) to develop Code Case N-729-1 to develop long-term inspection

8 | Davis-Besse Reactor Pressure Vessel Head Degradation

Figure 5. Schematic of the nozzle penetration cross section showing the leak path of the reactor coolant

Top View of J-Groove Weld

J-Groove Weld

Figure 6. Top photo: Top view of the J-groove weld with an arrow pointing to a crack

Top-right photo: Polished cross section of the area shown in the top photo showing the through-wall crack in

the J-groove weld

Davis-Besse Reactor Pressure Vessel Head Degradation | 9

requirements of RPV heads into the ASME Code. The finalized inspec-

tion requirements will be incorporated into 10 CFR 50.55a and allow

the rescission of NRC Order EA-03-009.

Operating Experience

In December 2004, the NRC codified a new operating experience

program in Management Directive 8.7, “Reactor Operating Experi-

ence Program,” to systematically collect, communicate and evaluate

operating experience information, including foreign operating experi-

ence. The program makes significant use of information technology

to make operating experience information available to internal users

and members of the public through a single Web access page.

An organization within the NRC was established to act as a clearing-

house that collects, communicates and evaluates operating experience

and applies the lessons learned to the core regulatory functions of

oversight, licensing, rulemaking, and incident response. It also con-

ducts a daily screening meeting at which incoming event reports and

other operating experience items are reviewed. There is a new power-

ful database for managing all reported events, as well as a new operat-

ing experience information gateway that consolidates a large collec-

tion of individual databases and Web sources of information onto a

single Web access page.

The NRC developed a new communication tool to promptly notify

NRC staff of developing operating experience in their areas of ex-

pertise or practice. Users may also use this tool to examine recent or

developing operating experience in their respective areas.

To ensure plant experience is adequately considered in licensing deci-

sions, new or revised expectations were established with regard to the

duration of a licensing Project Manager assignment to a specific plant,

frequency of site visits, communication with the resident inspector

staff and maintaining a questioning safety attitude about plant events.

Inspection and Program Management

The staff made several changes to the process to enhance the NRC’s

ability to detect declining plant performance, including the specific

issues identified at the DBNPS. For example, the review of the event

10 | Davis-Besse Reactor Pressure Vessel Head Degradation

indicated the deteriorating condition had been underway for several

years and that the planned inspection, maintenance, and modification

activities that could have prevented, or enabled earlier discovery of the

condition were frequently deferred.

The NRC increased the evaluation of licensees’ programs and actions

relating to long-standing unresolved problems. In addition, the NRC

now audits the licensees’ commitment management programs every

three years by assessing the adequacy of the licensees’ implementa-

tion of a sample of commitments made to the NRC in past licensing

actions and activities.

The NRC inspector training program has been enhanced by a Web-

based system to provide more timely dissemination of information to

the inspection staff, and a method for individual study. New training

modules were developed to address lessons learned from the DBNPS

event, such as the effects of boric acid corrosion and the importance of

maintaining a questioning attitude toward safety.

Safety culture weaknesses at Davis-Besse were determined to be one

of the root causes of the reactor vessel head degradation event. There-

fore, the NRC took significant steps within the Reactor Oversight

Process to strengthen the ability to detect a weak safety culture in

our inspections and performance assessments. In this context, safety

culture is defined as “that assembly of characteristics and attitudes in

organizations and individuals which establishes that, as an overriding

priority, nuclear plant safety issues receive the attention warranted by

their significance.” The NRC continues to seek ways to improve this

and other aspects of its oversight processes.

The program management aspects of the Reactor Oversight Process

have been enhanced. For example, the guidance for managing NRC

resources devoted to plants in an extended shutdown as a result of per-

formance issues was revised to ensure less impact on routine oversight

at other plants. Also, to ensure continuity of regulatory oversight, the

staff developed and issued a site staffing metric to monitor gaps in per-

manent resident and senior resident staffing at reactor sites, and estab-

lished the criterion of maintaining a minimum of 90-percent coverage.

Davis-Besse Reactor Pressure Vessel Head Degradation | 11

NUREG/BR-0353, Rev. 1

August 2008

12 | Davis Besse Reactor Pressure Vessel Head Degradation

You might also like

- Method of Statement For R.C.C Jacketing - Rev.0 PDFDocument5 pagesMethod of Statement For R.C.C Jacketing - Rev.0 PDFrobin7No ratings yet

- BS 6144 1990 Specification For Expansion Vessels Using An Internal Diaphragm, For Unvented Hot WDocument14 pagesBS 6144 1990 Specification For Expansion Vessels Using An Internal Diaphragm, For Unvented Hot WRamiAl-fuqahaNo ratings yet

- Safebuck Design Guideline and DNV RP F110Document8 pagesSafebuck Design Guideline and DNV RP F110Константин ДмитриевNo ratings yet

- QC10-H-049 M09 Steel Tanks-Rev6 PDFDocument14 pagesQC10-H-049 M09 Steel Tanks-Rev6 PDFMohammed HilalNo ratings yet

- Stress Analysis Using Actual Coke DrumDocument11 pagesStress Analysis Using Actual Coke Drumash1968No ratings yet

- 2002 Davis-Besse Reactor Pressure Vessel Head Degradation Knowledge Management DigestDocument24 pages2002 Davis-Besse Reactor Pressure Vessel Head Degradation Knowledge Management DigestBraedonNo ratings yet

- Mechanics of Deepwater Steel Catenary Riser: September 2011Document29 pagesMechanics of Deepwater Steel Catenary Riser: September 2011Ashin VargheseNo ratings yet

- Establishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsDocument75 pagesEstablishing Shipbuilding Quality Requirements For Hull Structure, Outfitting, and CoatingsNavnath GawasNo ratings yet

- MECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashDocument8 pagesMECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashMikeNo ratings yet

- MECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashDocument8 pagesMECCOCT18-12509: Managing Corrosion Challenges in Crude Overhead Condensers With Intermittent Water WashMikeNo ratings yet

- OMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersDocument5 pagesOMAE2012-8: Fatigue Life Analysis For A Steel Catenary Riser in Ultra-Deep WatersdmlsfmmNo ratings yet

- MNL 34-1998 PDFDocument161 pagesMNL 34-1998 PDFjjgnzgarciaNo ratings yet

- Ac 2009-2529: Whistle-Blowing by Engineers and Reverse Whistle-Blowing On EngineersDocument12 pagesAc 2009-2529: Whistle-Blowing by Engineers and Reverse Whistle-Blowing On EngineersOdoch HerbertNo ratings yet

- 2 Dolphin Design With STAD PRODocument48 pages2 Dolphin Design With STAD PROFachreza AkbarNo ratings yet

- Carbonate Stress Corrosion Cracking (ACSCC)Document11 pagesCarbonate Stress Corrosion Cracking (ACSCC)Ajmi HmidaNo ratings yet

- HISC NORSOK Workshop Agreement M-WA-01Rev1Document18 pagesHISC NORSOK Workshop Agreement M-WA-01Rev1naveen_86No ratings yet

- Microsoft Word - 2028B - Rev - 0Document10 pagesMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshNo ratings yet

- Oe Pipelines1Document3 pagesOe Pipelines1babakNo ratings yet

- Sabp L 002 PDFDocument27 pagesSabp L 002 PDFshyamNo ratings yet

- WD-70BD10 Rev-3Document47 pagesWD-70BD10 Rev-3PAWAN KNo ratings yet

- Matterhorn Steel Catenary Risers Critical Issues and Lessons Learned For Reel-Layed SCRs To A TLPDocument16 pagesMatterhorn Steel Catenary Risers Critical Issues and Lessons Learned For Reel-Layed SCRs To A TLPTee Shi FengNo ratings yet

- Sabp L 003Document46 pagesSabp L 003Li PengNo ratings yet

- SR.11.10961 - Sour Well Design GuideDocument52 pagesSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- 1416-MC-DBS-101 - Mechanical Design Basis - R1Document19 pages1416-MC-DBS-101 - Mechanical Design Basis - R1KrunalNo ratings yet

- Boric Acid CorrosionDocument47 pagesBoric Acid CorrosionFedak MarosNo ratings yet

- Evaluation - 2012-256 - Responsive - 4Document74 pagesEvaluation - 2012-256 - Responsive - 4Bob MackinNo ratings yet

- SPE 39320 New Generation Drill String Safety ValveDocument12 pagesSPE 39320 New Generation Drill String Safety ValveBruceNo ratings yet

- Corrosion of Reactor Effluent Air Coolers-20180315Document47 pagesCorrosion of Reactor Effluent Air Coolers-20180315庄查理100% (1)

- Resolution Technical Review Board 2017Document16 pagesResolution Technical Review Board 2017geolvmNo ratings yet

- Regulatory GuideDocument13 pagesRegulatory GuideMohammad AliNo ratings yet

- 01 Appende PDFDocument21 pages01 Appende PDFArun VaithyanathanNo ratings yet

- Sabp A 016Document60 pagesSabp A 016sethu1091100% (6)

- B 03 Marine Air ReceiversDocument9 pagesB 03 Marine Air ReceiversarunNo ratings yet

- Maste: Evaluation of Tubular Reactor Designs For Supercritical Water Oxidation of U.S. Department of Energy Mixed WasteDocument53 pagesMaste: Evaluation of Tubular Reactor Designs For Supercritical Water Oxidation of U.S. Department of Energy Mixed WasteardiNo ratings yet

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzNo ratings yet

- Caustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliaDocument8 pagesCaustic SCCPaper 080 ACACorrosion Control 0072007 Sydney AustraliajaNo ratings yet

- WD 70 BD 10 - Rev - 2Document47 pagesWD 70 BD 10 - Rev - 2N Say100% (1)

- Sabp W 002Document7 pagesSabp W 002zoopladoNo ratings yet

- P13-005-UE-10-SPC-0001-4 - (SPEC110 Struct. Steel Skids)Document9 pagesP13-005-UE-10-SPC-0001-4 - (SPEC110 Struct. Steel Skids)Enabulele OsakpamwanNo ratings yet

- QC10-H-044 M04 Factory Made Bends For Mainlines-Rev01Document10 pagesQC10-H-044 M04 Factory Made Bends For Mainlines-Rev01kkrq13No ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Sabp D 002Document16 pagesSabp D 002engforever AdnanNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- (Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JDocument8 pages(Doi 10.1115/PVP2016-63253) Lu, James Antalffy, Leslie P. Millet, Barry Smythe, Dennis - (ASME ASME 2016 Pressure Vessels and Piping Conference - Vancouver, British Columbia, Canada (Sunday 17 JMarcus BaltesNo ratings yet

- SM MethodDocument16 pagesSM MethodMd AfzanNo ratings yet

- Neral & Staad Diag.Document130 pagesNeral & Staad Diag.IkramNo ratings yet

- API 610 CentrifugalDocument6 pagesAPI 610 CentrifugalAnonymous 4lFgg25MENo ratings yet

- Spe 77357 MSDocument14 pagesSpe 77357 MSmohamedabbas_us3813No ratings yet

- DM 002Document25 pagesDM 002Jonathan Romero AlfaroNo ratings yet

- Caustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)Document8 pagesCaustic SCC Paper 080, (ACA, Corrosion Control 007, 2007 Sydney, Australia)APINo ratings yet

- Regulatory Guide: Control of Electroslag Weld PropertiesDocument3 pagesRegulatory Guide: Control of Electroslag Weld PropertiesAlex GutierrezNo ratings yet

- Koc L 026 PDFDocument32 pagesKoc L 026 PDFJigarNo ratings yet

- IS3370 Part4 Sec2 2021Document352 pagesIS3370 Part4 Sec2 2021gunjanatulbansalNo ratings yet

- I) CBC Spec No. Wd-70-Bd-10 (Rev.1)Document47 pagesI) CBC Spec No. Wd-70-Bd-10 (Rev.1)devgreatNo ratings yet

- UntitledDocument47 pagesUntitledbarian karopebokaNo ratings yet

- 11.113 Well Integrity Assessment ReportDocument144 pages11.113 Well Integrity Assessment ReportIgorCencič100% (1)

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardFrom EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNo ratings yet

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageFrom EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNo ratings yet

- The Marine Corrosion Process and Control: Design Guides for Oil and Gas FacilitiesFrom EverandThe Marine Corrosion Process and Control: Design Guides for Oil and Gas FacilitiesNo ratings yet

- Alcatel Lucent 4305Document2 pagesAlcatel Lucent 4305mandingos707No ratings yet

- TigerSecu 2MP PDFDocument38 pagesTigerSecu 2MP PDFmandingos707100% (1)

- Matlab AnswersDocument4 pagesMatlab Answersmandingos707No ratings yet

- 2013 Unix BookDocument61 pages2013 Unix Bookmandingos707No ratings yet

- Tata Projects Limited BTRS, SVS Road, Mayor's Bunglow, Shivaji Park, Dadar West Scope Matrix For Secant Piling WorksDocument1 pageTata Projects Limited BTRS, SVS Road, Mayor's Bunglow, Shivaji Park, Dadar West Scope Matrix For Secant Piling WorksSabyasachi BangalNo ratings yet

- Communication MatrixDocument1 pageCommunication Matrixrohini kadamNo ratings yet

- Chords Like Jeff BuckleyDocument5 pagesChords Like Jeff BuckleyTDROCKNo ratings yet

- Comparison of Starbucks With The Coffee BeanDocument16 pagesComparison of Starbucks With The Coffee BeanshaiNo ratings yet

- Karur Vysya Bank Employees' Union: 11th Bipartite Arrears Calculation Package - ClerkDocument10 pagesKarur Vysya Bank Employees' Union: 11th Bipartite Arrears Calculation Package - ClerkDeepa ManianNo ratings yet

- JD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XDocument530 pagesJD Edwards Enterpriseone Tools: Form Design Aid Guide Release 9.1.XGaurav SahuNo ratings yet

- Reblex AnswersDocument17 pagesReblex AnswersAerol Buenaventura100% (1)

- Maternal and Infant Care Beliefs Aeta Mothers in PhilippinesDocument8 pagesMaternal and Infant Care Beliefs Aeta Mothers in PhilippinesChristine Joy MolinaNo ratings yet

- Organisational BehaviourDocument279 pagesOrganisational BehaviourSumitha SelvarajNo ratings yet

- (GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENDocument9 pages(GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENHakim-Aarifah BeyNo ratings yet

- Barcode Scanner, Wireless Barcode Scanner, DC5112 Barcode ScannerDocument3 pagesBarcode Scanner, Wireless Barcode Scanner, DC5112 Barcode ScannerdcodeNo ratings yet

- Oracle Weblogic Server 12c Troubleshooting WorkshopDocument3 pagesOracle Weblogic Server 12c Troubleshooting WorkshopMarcelo BerriosNo ratings yet

- Redeemable Preference SharesDocument2 pagesRedeemable Preference Sharestanvia KNo ratings yet

- Mehdi To TestDocument13 pagesMehdi To Testtestcoolvms16No ratings yet

- Alternative Substrates As A Native Oyster (Crassostrea Virginica) Reef Restoration Strategy in Chesapeake BayDocument286 pagesAlternative Substrates As A Native Oyster (Crassostrea Virginica) Reef Restoration Strategy in Chesapeake BayMandi MynyddNo ratings yet

- VHDL Processes: Cwru Eecs 318Document24 pagesVHDL Processes: Cwru Eecs 318KarThikNo ratings yet

- FisheriesDocument31 pagesFisheriesGarima LoonaNo ratings yet

- Reading Passage 1: Succeed in IELTS Volume 8Document16 pagesReading Passage 1: Succeed in IELTS Volume 8Huyền Kiệt thươngNo ratings yet

- Comsys 2Document10 pagesComsys 2MarjorieNo ratings yet

- Why Romanian Journal of Food ScienceDocument2 pagesWhy Romanian Journal of Food ScienceAna Vitelariu - RaduNo ratings yet

- TDS Conbextra GP2 BFLDocument4 pagesTDS Conbextra GP2 BFLsabbirNo ratings yet

- General: Specific: Leading Statement:: TITLE: A Healthy LifestyleDocument2 pagesGeneral: Specific: Leading Statement:: TITLE: A Healthy LifestyleM Arshad M AmirNo ratings yet

- TELECONFERENCINGDocument5 pagesTELECONFERENCINGAbhinav SharmaNo ratings yet

- EvalsDocument11 pagesEvalsPaul Adriel Balmes50% (2)

- Will or Going To 90069Document2 pagesWill or Going To 90069Dragana ZafirovskaNo ratings yet

- Petitioner vs. VS.: Third DivisionDocument12 pagesPetitioner vs. VS.: Third DivisionAnonymous QR87KCVteNo ratings yet

- Application DevelopmentDocument14 pagesApplication DevelopmentReema MubarakNo ratings yet

- Schmeling - The Role of Hydrothermal Cooling of The Oceanic Lithosphere For Ocean Floor Bathymetry 2017Document19 pagesSchmeling - The Role of Hydrothermal Cooling of The Oceanic Lithosphere For Ocean Floor Bathymetry 2017utsav mannuNo ratings yet

- Tools, Materials and Equipment in Nail Care: Learning Activity Sheet Week 1 Quarter 1Document8 pagesTools, Materials and Equipment in Nail Care: Learning Activity Sheet Week 1 Quarter 1Barbara PosoNo ratings yet

- Maribelle Z. Neri vs. Ryan Roy Yu (Full Text, Word Version)Document11 pagesMaribelle Z. Neri vs. Ryan Roy Yu (Full Text, Word Version)Emir MendozaNo ratings yet