Professional Documents

Culture Documents

PDS Na GTS65 PDF

PDS Na GTS65 PDF

Uploaded by

Moaatazz NouisriCopyright:

Available Formats

You might also like

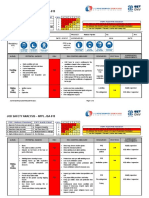

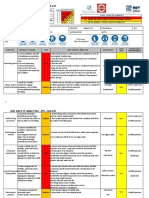

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri83% (6)

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000100% (1)

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- Zinc Rich Anticorrosive Primer PDFDocument53 pagesZinc Rich Anticorrosive Primer PDFDhruv SevakNo ratings yet

- Weld History Sheet A103Document48 pagesWeld History Sheet A103Sahad VarambankallanNo ratings yet

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 pagesLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraNo ratings yet

- 20G Boiler Steel Pipe PDFDocument5 pages20G Boiler Steel Pipe PDFHeza FirdausNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- 15CrMo Alloy Steel TubeDocument5 pages15CrMo Alloy Steel TubeIbnu KhusnaNo ratings yet

- ASME Sección V - Artículo 6Document9 pagesASME Sección V - Artículo 6Jhonathan ST100% (1)

- 3LPE 1d44a0 PDFDocument33 pages3LPE 1d44a0 PDFHotnCrispy CrispyNo ratings yet

- Brochure HPX1 PLUS 201601Document8 pagesBrochure HPX1 PLUS 201601Serkan KılıçaslanNo ratings yet

- Impressor BarcolDocument8 pagesImpressor BarcolMarco CortésNo ratings yet

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Sfa-5 28Document32 pagesSfa-5 28Bruno FDNo ratings yet

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDocument4 pagesHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Astm A516 Grade 70Document1 pageAstm A516 Grade 70Javier Caamaño VillafañeNo ratings yet

- ITP - Field Application of Heat Shrink SleeveDocument6 pagesITP - Field Application of Heat Shrink SleeveVasilica BArbarasaNo ratings yet

- 23 Astm A790 A790m-2018Document10 pages23 Astm A790 A790m-2018FYNo ratings yet

- SSPC sp1Document2 pagesSSPC sp1Malik AzeemNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Comparison Table of Standard Sieve SeriesDocument3 pagesComparison Table of Standard Sieve SeriesAlexander HillNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Asme Section 1 - Pmi PDFDocument3 pagesAsme Section 1 - Pmi PDFArul Edwin VijayNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- Tbe Field Joint Coating For TialDocument3 pagesTbe Field Joint Coating For TialPer Bagus HandokoNo ratings yet

- Understanding API 1104 - Technical ToolboxesDocument2 pagesUnderstanding API 1104 - Technical Toolboxesinspector620% (1)

- Letter For Testing of PQRDocument1 pageLetter For Testing of PQRPA PROJECTS PVT LTDNo ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- ASME Section IX Appendix-4 (Rounded Indicaion) For RTDocument9 pagesASME Section IX Appendix-4 (Rounded Indicaion) For RTGoutam Kumar DebNo ratings yet

- PWHT Asme B31 3 2010 PDFDocument3 pagesPWHT Asme B31 3 2010 PDFErick HoganNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- ASME Section V Article 5 (2019)Document7 pagesASME Section V Article 5 (2019)Baguz SaputraNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- ACME Chemicals: High Pressure Steam (HS) PipingDocument40 pagesACME Chemicals: High Pressure Steam (HS) PipingRamu NallathambiNo ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- GRE INS-009, Flange Bolting ProcedureDocument6 pagesGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- Radiography AcceptanceDocument1 pageRadiography Acceptanceagus sukmanaNo ratings yet

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADocument12 pagesComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Is 9902 2004 PDFDocument11 pagesIs 9902 2004 PDFAgniva DuttaNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Field Practice SpecificationDocument20 pagesField Practice SpecificationRichart SembiringNo ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- 4215107-01 Flash Inspection ReportDocument2 pages4215107-01 Flash Inspection Reportyat_alaydrusNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayNo ratings yet

- En 16094 (2021) (E)Document8 pagesEn 16094 (2021) (E)Material Science Division0% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Canusa PDS A4 GTSPP65Document2 pagesCanusa PDS A4 GTSPP65Michel Simas de OliveiraNo ratings yet

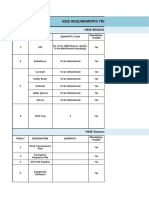

- Hsse Requirements Trakcing RegisterDocument4 pagesHsse Requirements Trakcing RegisterMoaatazz NouisriNo ratings yet

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- Daily HSE Report 22-12-2018Document117 pagesDaily HSE Report 22-12-2018Moaatazz NouisriNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 pagesDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriNo ratings yet

- 120021-Hse-003 - Waste Management PlanDocument21 pages120021-Hse-003 - Waste Management PlanMoaatazz NouisriNo ratings yet

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- 120025-Hse-002 Company Hse Project StandardsDocument25 pages120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriNo ratings yet

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pages220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriNo ratings yet

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 pagesReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriNo ratings yet

- Instrument & Control Engineering Head: Curriculum Vitae PirecoDocument2 pagesInstrument & Control Engineering Head: Curriculum Vitae PirecoMoaatazz NouisriNo ratings yet

- CV Civil & Structural Head-O.RAJEHDocument2 pagesCV Civil & Structural Head-O.RAJEHMoaatazz NouisriNo ratings yet

- CV Project Manager-M.Ammar PDFDocument6 pagesCV Project Manager-M.Ammar PDFMoaatazz NouisriNo ratings yet

- CV Business Adm Mgr-S.DridiDocument2 pagesCV Business Adm Mgr-S.DridiMoaatazz NouisriNo ratings yet

- Attachment 4.1.1Document16 pagesAttachment 4.1.1Moaatazz NouisriNo ratings yet

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- 4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameDocument1 page4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameMoaatazz NouisriNo ratings yet

- JSA-017 Lifting With Forklift 2Document4 pagesJSA-017 Lifting With Forklift 2Moaatazz NouisriNo ratings yet

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- Tool Box Talk - 14 Working at HeightsDocument2 pagesTool Box Talk - 14 Working at HeightsMoaatazz NouisriNo ratings yet

- Filmterm FC 25Document1 pageFilmterm FC 25Naseem AtiaNo ratings yet

- Design of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orDocument35 pagesDesign of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orJoseph Cloyd L. LamberteNo ratings yet

- Syllabus AMIIWDocument1 pageSyllabus AMIIWdebduttamallikNo ratings yet

- Rui Bridge - Final - WingDocument3 pagesRui Bridge - Final - WingHimal KafleNo ratings yet

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Lining Railway Tunnels - 2012 - : Section/Article DescriptionDocument8 pagesLining Railway Tunnels - 2012 - : Section/Article DescriptionMike2322No ratings yet

- Stress Corrosion Cracking and Component Failure Causes andDocument2 pagesStress Corrosion Cracking and Component Failure Causes andaecf_130% (1)

- Road Building MaterialsDocument8 pagesRoad Building MaterialsKalim AhmadNo ratings yet

- Initial and Final Setting Times of CementDocument3 pagesInitial and Final Setting Times of Cementk_98196636850% (2)

- Amfine Chemical Corporation: Strictly ConfidentialDocument28 pagesAmfine Chemical Corporation: Strictly Confidentials0n1907No ratings yet

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- Eastern RlyDocument25 pagesEastern Rlyshivam.jhawar95No ratings yet

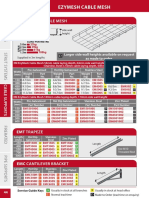

- EzyMesh and Accessories DataSheetDocument2 pagesEzyMesh and Accessories DataSheet30101985No ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- DasdDocument2 pagesDasdAnonymous lApm6PsfNo ratings yet

- Clear LiteDocument2 pagesClear LitemanojNo ratings yet

- Industrial Structures Brochure 041609Document8 pagesIndustrial Structures Brochure 041609Brad BobichNo ratings yet

- Chemrite NNDocument3 pagesChemrite NNghazanfarNo ratings yet

- STI SP001 - SP031 Repairs 5th Edition GuidelinesDocument33 pagesSTI SP001 - SP031 Repairs 5th Edition GuidelinesJade Geronimo80% (5)

- LowCarbonConcrete ConcreteMagazineDocument4 pagesLowCarbonConcrete ConcreteMagazineRdhn fingerstyleNo ratings yet

- Wood Packer Sample Inspection ReportDocument1 pageWood Packer Sample Inspection Reportmanjunath RNo ratings yet

- Orifice Plates & AssembliesDocument12 pagesOrifice Plates & AssembliesAjay CNo ratings yet

- BVR - Copper Core PVC Insulated Flexible CableDocument11 pagesBVR - Copper Core PVC Insulated Flexible Cableyalewlet tarekeggnNo ratings yet

- Random Rubble Masonry in Cement Mortar 1:5 in SuperstructureDocument6 pagesRandom Rubble Masonry in Cement Mortar 1:5 in Superstructuredimuthu lasinthaNo ratings yet

- Manufacturing of Dish End PDFDocument48 pagesManufacturing of Dish End PDFravi2007No ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- Electroplating and Electroless Plating (Dr. Aravinda)Document6 pagesElectroplating and Electroless Plating (Dr. Aravinda)Shashank K BNo ratings yet

- Ampco Mold Design GuidelinesDocument39 pagesAmpco Mold Design GuidelinesNaukowyDrpNo ratings yet

- Isoltubex en PDFDocument14 pagesIsoltubex en PDFJavierNo ratings yet

PDS Na GTS65 PDF

PDS Na GTS65 PDF

Uploaded by

Moaatazz NouisriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDS Na GTS65 PDF

PDS Na GTS65 PDF

Uploaded by

Moaatazz NouisriCopyright:

Available Formats

Product Data Sheet

GTS-65

Girth-weld protection of elevated operating temperature pipelines

Canusa-CPS is a leading manufacturer of

specialty pipeline coatings which, for over

35 years, have been used for sealing and

corrosion protection of pipeline joints and

other substrates. Canusa high

performance products are manufactured

to the highest quality standards and are

available in a number of configurations to

accommodate your specific project

applications.

Product Description

The GTS-65 system provides superior Optional

corrosion protection and excellent Epoxy

bonding on pipelines operating up to 65°C.

GTS-65 has been designed with a unique

adhesive technology that remains “open”

Flexible Installation. Applications

longer than traditional adhesives. Also, GTS-65 can be used as a 2-layer or

special surface active agents allow 3-layer sleeve system at the same low Oil & Gas

bonding to lower surface energy coatings pre-heat temperature. For added flexibility,

(such as polypropylene). As a result, lower CanusaWrap bulk rolls are also available.

preheat temperatures are required to Consult your Canusa representative to Offshore Pipelines

attain true adhesive wet-out and superior review your specific project requirements.

bonding to PE, PP and FBE surfaces is

Polypropylene

achieved. Long Term Corrosion Protection.

GTS-65 Sleeves provide superior corrosion Configurations

Features & Benefits protection because of the high perfor-

Superior Force Cured Epoxy Method mance system approach. This combina- Wrapid Sleeve™

Canusa’s proven method of force curing tion provides a protective coating with the

the epoxy primer to the steel allows the structural integrity of a seamless tube,

installer to “pre-inspect” the joint prior to providing excellent resistance to cathodic CanusaWrap™

sleeve application. The epoxy will not be disbondment and excellent durability

displaced during the aligning and shrink- against abrasion and chemical attack. The

ing stages of the sleeve installation. This result is effective, long term protection 2-Layer

provides the assurance that the pipe is against corrosion.

fully protected. Canusa’s epoxy primer

3-Layer

can be applied to an even, nominal 150µm Saves Time & Money.

(6 mil) thickness for maximum corrosion

protection. Time is saved in three ways; lower pre- Pipe Sizes

heat means less time heating; epoxy on

Unique Adhesive Technology the steel only, means less time applying 55-3048 (2"-120")

Canusa's unique adhesive technology the epoxy; and the pre-attached closure

allows for lower installation pre-heat means less time handling, positioning and

temperatures and superior bonding to PE, installing the sleeve. The overall system Temperature Range

PP and FBE coatings. The adhesive has minimizes installation time and labour

been formulated to bond directly to the costs while promoting high production Up to 65°C (149°F)

main line coating; epoxy is applied to the rates.

steel only. The result is a superior bond to Approvals

the substrate, easier application and

significant cost savings. EN 12068, SNAM, Gazprom,

CANUSA-CPS is registered to ISO 9001:2008. TransCanada, Gaz de France

GTS-65

The product selection chart shown here is intended as a guide for standard products.

Consult your Canusa representative for specific projects or unique applications.

Below are typical values based on Heavy Duty (L-thickness) Sleeves.

Product Selection Guide Global Transmission Sleeve

Choose your sleeve based on Operating Temperature and Characteristics listed below.

Celsius Fahrenheit GTS-65 Epoxy Primer Information

Sleeve Operating Characteristics

200° 392°

GTS-65 (3-layer) require epoxy on the cut-back area

175° 347°

and 10 mm (0.5") onto the adjacent pipe coating.

125° 257°

100° 212°

Typical Primer Coverage

75° 167° Epoxy Primer Kits Joints per US gallon assuming

This kit includes measured 300mm (12") total cutback

50° 122° quantities of base resin and and 150µm (6mils)

Pipeline Operating Temp. °C (°F) cure, a stirring stick, applicator coating thickness

65 (150)

Minimum Installation Temp. °C (°F) 90 (195) pad or roller and gloves. The kit

Pipe diameter joints/

contains sufficient primer for up

Resistance to Circumferential Forces excellent mm in US gallon

to 1 square meter (10 sq. ft) of

Resistance to Soil Stress excellent coverage. For example: 1 kit is

Resistance to Axial Pipe Movement sufficient for a 915mm (36")

170 6.6 130

excellent

Main Line Coating Compatibility FBE, PE, HPCC, PP diameter pipe with a 300mm 230 8.6 97

(12") total cutback.

Typical Product Properties 280 10¾ 78

Test Standard Unit 315 12¾ 70

GTS-65 Bulk Epoxy Primer

Adhesive

Softening point ASTM E28 °C (°F) 94 (201) Bulk epoxy components must be 400 16 60

2 ordered separately. The mixing

Lap shear @ 23°C EN 12068 N/cm 245 450 18 55

2

ratio for the E primer is 4 parts

Lap Shear @ 60°C EN 12068 N/cm 8 base, 1 part cure by volume,

and 6.3 parts base, 1 part cure

500 20 43

Specific gravity ASTM D792 0.93 by weight. Pumps are available 610 24 35

to facilitate mixing operation.

Tensile strength ASTM D638 MPa (psi) 24 (3480) 760 30 28

Average coverage for bulk

Elongation ASTM D638 % 700

Backing

primers is 20 square meters per

Hardness ASTM D2240 Shore D 50 U.S. gallon, (220 sq. ft / U.S.

915 36 23

Abrasion resistance ASTM D1044 mg 35 gallon). 1060 42 20

17

Volume Resistivity ASTM D257 ohm-cm 10 1220 48 18

Dielectric Voltage Brkdwn ASTM D149 kV/mm 27

1422 56 15

Impact EN 12068 J >15 1525 60 14

Indentation EN 12068 mm 0.65 (pass)

Peel Adhesion ASTM D1000 N/cm (pli) 120 (70) **

Peel Adhesion EN 12068 N/cm >100 **

Epoxy Properties

Sleeve

Cathodic Disbondment ASTM G8 mm rad 3

Water Absorption ASTM D570 % 0.05

Low Temp. Flexibility ASTM D2671-C °C (°F) >-32 (-26) Pot life @ 23°C (73°F) 20 minutes

Fully Recovered T Thickness mm (mils) 1.9 (77) Typical epoxy coated thickness 100-150µm (4 - 6 mils)

Fully Recovered L Thickness mm (mils) 2.4 (96) Shelf Life @ 23°C, when properly stored 3 years

Fully Recovered S Thickness mm (mils) 3.0 (121)

**force result of backing elongation during peeling due to superior bond strength

How To Order¹: Ordering Options - Global Transmission Sleeve

Dimensions & Ordering Info

GTS-65 900-450 BK/L T Thickness L Thickness S Thickness sleeve

width

Thickness T L S

Colour BK-Black S

SA-CP

CANU

Sleeve Width 300, 450, 600, 900mm (12", 18", 24", 36")

Pipe Size 55-500mm (2"-20") 55 - 3048 mm (2" - 120")

pipe

Primer Canusa "E" Epoxy (Optional) size

Adhesive (min. thickness as supplied) 1.1 mm (45 mils) 1.3 mm (50 mils) 1.6 mm (65 mils)

Min. Sleeve Width =

Backing (min. thickness as supplied) 0.6 mm (25 mils) 0.9 mm (36 mils) 1.1 mm (43 mils) Bare Steel Dimension + 50 mm (2")

Configuration GTS-65 - 65°C (149°F) on each side of the pipe joint.

The above represent standard Wrapid Sleeve™ ordering options. Consult your Canusa representative for any unique project requirements.

¹ For CanusaWrap™ bulk rolls, consult you Canusa representative. GTS-65 requires CLW closures.

www.canusacps.com

Canada U.S.A./Latin America Europe/Middle East Asia/Pacific

CANUSA-CPS CANUSA-CPS CANUSA-CPS CANUSA-CPS

a division of SHAWCOR LTD. a division of SHAWCOR INC. a division of Canusa Systems Ltd. a division of SHAWCOR LTD.

25 Bethridge Road 2408 Timberloch Place Unit 3, Sterling Park #05-31, Blk 52, Frontier

Toronto, Ontario Building C-8 Gatwick Road Ubi Avenue 3

M9W 1M7, The Woodlands, Texas Crawley, West Sussex Singapore

Canada 77380, U.S.A. England RH10 9QT 408867

Tel: +1 (416) 743-7111 Tel: +1 (281) 367-8866 Tel: +44 (1293) 541254 Tel: +65-6749-8918

Fax: +1 (416) 743-5927 Fax: +1 (281) 367-4304 Fax: +44 (1293) 541777 Fax: +65-6749-8919

Canusa warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the installation guide when used in compliance with Canusa’s written instructions. Since

many installation factors are beyond our control, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities in connection therewith. Canusa’s liability is stated in the

standard terms and conditions of sale. Canusa makes no other warranty either expressed or implied. All information contained in this installation guide is to be used as a guide and is subject to change without notice.

This installation guide supersedes all previous installation guides on this product. E&OE Printed on recycled paper. Recyclable. PDS-GTS65-rev012

You might also like

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri83% (6)

- MTC Forged Fitting ElbowDocument1 pageMTC Forged Fitting Elbowfreeman11072000100% (1)

- Fir-001 - 10 03 18Document1 pageFir-001 - 10 03 18Kartik SolankiNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Ometry of Bolted Connections:: Hole Spacing and Code FormulaDocument17 pagesOmetry of Bolted Connections:: Hole Spacing and Code FormulaSimi NagyNo ratings yet

- Zinc Rich Anticorrosive Primer PDFDocument53 pagesZinc Rich Anticorrosive Primer PDFDhruv SevakNo ratings yet

- Weld History Sheet A103Document48 pagesWeld History Sheet A103Sahad VarambankallanNo ratings yet

- Luxaprime1400 Alkyd Zinc Phosphate PrimerDocument2 pagesLuxaprime1400 Alkyd Zinc Phosphate PrimerGurdeep Sungh AroraNo ratings yet

- 20G Boiler Steel Pipe PDFDocument5 pages20G Boiler Steel Pipe PDFHeza FirdausNo ratings yet

- Bristle Blaster BrochureDocument6 pagesBristle Blaster BrochureDom BergeronNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- 15CrMo Alloy Steel TubeDocument5 pages15CrMo Alloy Steel TubeIbnu KhusnaNo ratings yet

- ASME Sección V - Artículo 6Document9 pagesASME Sección V - Artículo 6Jhonathan ST100% (1)

- 3LPE 1d44a0 PDFDocument33 pages3LPE 1d44a0 PDFHotnCrispy CrispyNo ratings yet

- Brochure HPX1 PLUS 201601Document8 pagesBrochure HPX1 PLUS 201601Serkan KılıçaslanNo ratings yet

- Impressor BarcolDocument8 pagesImpressor BarcolMarco CortésNo ratings yet

- GMAW Welding Gas SelectionDocument4 pagesGMAW Welding Gas SelectionkapsarcNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Sfa-5 28Document32 pagesSfa-5 28Bruno FDNo ratings yet

- Holiday Detection in Pipeline Coatings: Standard Test Methods ForDocument4 pagesHoliday Detection in Pipeline Coatings: Standard Test Methods ForAlejandro ValdesNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Astm A516 Grade 70Document1 pageAstm A516 Grade 70Javier Caamaño VillafañeNo ratings yet

- ITP - Field Application of Heat Shrink SleeveDocument6 pagesITP - Field Application of Heat Shrink SleeveVasilica BArbarasaNo ratings yet

- 23 Astm A790 A790m-2018Document10 pages23 Astm A790 A790m-2018FYNo ratings yet

- SSPC sp1Document2 pagesSSPC sp1Malik AzeemNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Comparison Table of Standard Sieve SeriesDocument3 pagesComparison Table of Standard Sieve SeriesAlexander HillNo ratings yet

- Porosity in WeldingDocument13 pagesPorosity in Weldingbn pandeyNo ratings yet

- Asme Section 1 - Pmi PDFDocument3 pagesAsme Section 1 - Pmi PDFArul Edwin VijayNo ratings yet

- Barcol ProcedureDocument1 pageBarcol ProcedureseetharamannNo ratings yet

- Tbe Field Joint Coating For TialDocument3 pagesTbe Field Joint Coating For TialPer Bagus HandokoNo ratings yet

- Understanding API 1104 - Technical ToolboxesDocument2 pagesUnderstanding API 1104 - Technical Toolboxesinspector620% (1)

- Letter For Testing of PQRDocument1 pageLetter For Testing of PQRPA PROJECTS PVT LTDNo ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocument28 pagesSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenNo ratings yet

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- ASME Section IX Appendix-4 (Rounded Indicaion) For RTDocument9 pagesASME Section IX Appendix-4 (Rounded Indicaion) For RTGoutam Kumar DebNo ratings yet

- PWHT Asme B31 3 2010 PDFDocument3 pagesPWHT Asme B31 3 2010 PDFErick HoganNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- ASME Section V Article 5 (2019)Document7 pagesASME Section V Article 5 (2019)Baguz SaputraNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- ACME Chemicals: High Pressure Steam (HS) PipingDocument40 pagesACME Chemicals: High Pressure Steam (HS) PipingRamu NallathambiNo ratings yet

- P 54 Holiday Testing Procedure R1Document43 pagesP 54 Holiday Testing Procedure R1rahul reyashNo ratings yet

- GRE INS-009, Flange Bolting ProcedureDocument6 pagesGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- Radiography AcceptanceDocument1 pageRadiography Acceptanceagus sukmanaNo ratings yet

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADocument12 pagesComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoNo ratings yet

- Luxathane 5000 Polyurethane High Gloss Finish: Technical DataDocument3 pagesLuxathane 5000 Polyurethane High Gloss Finish: Technical DataPV AnandNo ratings yet

- Is 9902 2004 PDFDocument11 pagesIs 9902 2004 PDFAgniva DuttaNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Field Practice SpecificationDocument20 pagesField Practice SpecificationRichart SembiringNo ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- 4215107-01 Flash Inspection ReportDocument2 pages4215107-01 Flash Inspection Reportyat_alaydrusNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayNo ratings yet

- En 16094 (2021) (E)Document8 pagesEn 16094 (2021) (E)Material Science Division0% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Canusa PDS A4 GTSPP65Document2 pagesCanusa PDS A4 GTSPP65Michel Simas de OliveiraNo ratings yet

- Hsse Requirements Trakcing RegisterDocument4 pagesHsse Requirements Trakcing RegisterMoaatazz NouisriNo ratings yet

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- Daily HSE Report 22-12-2018Document117 pagesDaily HSE Report 22-12-2018Moaatazz NouisriNo ratings yet

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 pagesDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriNo ratings yet

- 120021-Hse-003 - Waste Management PlanDocument21 pages120021-Hse-003 - Waste Management PlanMoaatazz NouisriNo ratings yet

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- 120025-Hse-002 Company Hse Project StandardsDocument25 pages120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriNo ratings yet

- 220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanDocument47 pages220024-ZAL-DAAM-PM-SF-001 Project HSSE PlanMoaatazz NouisriNo ratings yet

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- Replacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Document19 pagesReplacement (5.2km) of 24'' Sirtica Pipeline (BEDA Junction - ASSIDA Junction)Moaatazz NouisriNo ratings yet

- Instrument & Control Engineering Head: Curriculum Vitae PirecoDocument2 pagesInstrument & Control Engineering Head: Curriculum Vitae PirecoMoaatazz NouisriNo ratings yet

- CV Civil & Structural Head-O.RAJEHDocument2 pagesCV Civil & Structural Head-O.RAJEHMoaatazz NouisriNo ratings yet

- CV Project Manager-M.Ammar PDFDocument6 pagesCV Project Manager-M.Ammar PDFMoaatazz NouisriNo ratings yet

- CV Business Adm Mgr-S.DridiDocument2 pagesCV Business Adm Mgr-S.DridiMoaatazz NouisriNo ratings yet

- Attachment 4.1.1Document16 pagesAttachment 4.1.1Moaatazz NouisriNo ratings yet

- JSA-019 Manual WeldingDocument5 pagesJSA-019 Manual WeldingMoaatazz Nouisri0% (1)

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- 4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameDocument1 page4.1.3 PIRECO Current Backlog and Book Orders in EPC: Project NameMoaatazz NouisriNo ratings yet

- JSA-017 Lifting With Forklift 2Document4 pagesJSA-017 Lifting With Forklift 2Moaatazz NouisriNo ratings yet

- JSA-049 LVS Equipment & Material InstallationDocument10 pagesJSA-049 LVS Equipment & Material InstallationMoaatazz NouisriNo ratings yet

- Tool Box Talk - 14 Working at HeightsDocument2 pagesTool Box Talk - 14 Working at HeightsMoaatazz NouisriNo ratings yet

- Filmterm FC 25Document1 pageFilmterm FC 25Naseem AtiaNo ratings yet

- Design of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orDocument35 pagesDesign of Isolated Square Footing: 2-Storey Residential BLDG.: Poblacion Initao, Mis. orJoseph Cloyd L. LamberteNo ratings yet

- Syllabus AMIIWDocument1 pageSyllabus AMIIWdebduttamallikNo ratings yet

- Rui Bridge - Final - WingDocument3 pagesRui Bridge - Final - WingHimal KafleNo ratings yet

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Lining Railway Tunnels - 2012 - : Section/Article DescriptionDocument8 pagesLining Railway Tunnels - 2012 - : Section/Article DescriptionMike2322No ratings yet

- Stress Corrosion Cracking and Component Failure Causes andDocument2 pagesStress Corrosion Cracking and Component Failure Causes andaecf_130% (1)

- Road Building MaterialsDocument8 pagesRoad Building MaterialsKalim AhmadNo ratings yet

- Initial and Final Setting Times of CementDocument3 pagesInitial and Final Setting Times of Cementk_98196636850% (2)

- Amfine Chemical Corporation: Strictly ConfidentialDocument28 pagesAmfine Chemical Corporation: Strictly Confidentials0n1907No ratings yet

- Block Works & Plastering DraftDocument4 pagesBlock Works & Plastering DraftEljo AndsNo ratings yet

- Eastern RlyDocument25 pagesEastern Rlyshivam.jhawar95No ratings yet

- EzyMesh and Accessories DataSheetDocument2 pagesEzyMesh and Accessories DataSheet30101985No ratings yet

- TDCDocument6 pagesTDCalex hutaurukNo ratings yet

- DasdDocument2 pagesDasdAnonymous lApm6PsfNo ratings yet

- Clear LiteDocument2 pagesClear LitemanojNo ratings yet

- Industrial Structures Brochure 041609Document8 pagesIndustrial Structures Brochure 041609Brad BobichNo ratings yet

- Chemrite NNDocument3 pagesChemrite NNghazanfarNo ratings yet

- STI SP001 - SP031 Repairs 5th Edition GuidelinesDocument33 pagesSTI SP001 - SP031 Repairs 5th Edition GuidelinesJade Geronimo80% (5)

- LowCarbonConcrete ConcreteMagazineDocument4 pagesLowCarbonConcrete ConcreteMagazineRdhn fingerstyleNo ratings yet

- Wood Packer Sample Inspection ReportDocument1 pageWood Packer Sample Inspection Reportmanjunath RNo ratings yet

- Orifice Plates & AssembliesDocument12 pagesOrifice Plates & AssembliesAjay CNo ratings yet

- BVR - Copper Core PVC Insulated Flexible CableDocument11 pagesBVR - Copper Core PVC Insulated Flexible Cableyalewlet tarekeggnNo ratings yet

- Random Rubble Masonry in Cement Mortar 1:5 in SuperstructureDocument6 pagesRandom Rubble Masonry in Cement Mortar 1:5 in Superstructuredimuthu lasinthaNo ratings yet

- Manufacturing of Dish End PDFDocument48 pagesManufacturing of Dish End PDFravi2007No ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- Electroplating and Electroless Plating (Dr. Aravinda)Document6 pagesElectroplating and Electroless Plating (Dr. Aravinda)Shashank K BNo ratings yet

- Ampco Mold Design GuidelinesDocument39 pagesAmpco Mold Design GuidelinesNaukowyDrpNo ratings yet

- Isoltubex en PDFDocument14 pagesIsoltubex en PDFJavierNo ratings yet