Professional Documents

Culture Documents

Absplus-P430: Production-Grade Thermoplastic For 3D Printers

Absplus-P430: Production-Grade Thermoplastic For 3D Printers

Uploaded by

controlorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Absplus-P430: Production-Grade Thermoplastic For 3D Printers

Absplus-P430: Production-Grade Thermoplastic For 3D Printers

Uploaded by

controlorCopyright:

Available Formats

ABSplus-P430

PRODUCTION-GRADE THERMOPLASTIC

FOR 3D PRINTERS

ABSplus™ is a true production-grade thermoplastic that is durable enough to perform virtually the same as production parts. When

combined with FDM® 3D Printers, ABSplus is ideal for building 3D models and prototypes in an office environment.

ENGLISH METRIC

MECHANICAL PROPERTIES 1 TEST METHOD

XZ A xis XZ A xis

Tensile Strength, Ultimate (Type 1, 0.125”, 0.2”/min) ASTM D638 4,700 psi 33 MPa

Tensile Strength, Yield (Type 1, 0.125”, 0.2”/min) ASTM D638 4,550 psi 31 MPa

Tensile Modulus (Type 1, 0.125”, 0.2”/min) ASTM D638 320,000 psi 2,200 MPa

Tensile Elongation at Break (Type 1, 0.125”, 0.2”/min) ASTM D638 6% 6%

Tensile Elongation at Yield (Type 1, 0.125”, 0.2”/min) ASTM D638 2% 2%

IZOD Impact, notched (Method A, 23 °C) ASTM D256 2.0 ft-lb/in 106 J/m

ENGLISH METRIC

MECHANICAL PROPERTIES TEST METHOD

XZ A xis ZX A xis XZ A xis ZX A xis

Flexural Strength (Method 1, 0.05”/min) ASTM D790 8,450 psi 5,050 psi 58 MPa 35 MPa

Flexural Modulus (Method 1, 0.05”/min) ASTM D790 300,000 psi 240,000 psi 2,100 MPa 1,650 MPa

Flexural Strain at Break (Method 1, 0.05”/min) ASTM D790 4% 4% 2% 2%

THERMAL PROPERTIES 2 TEST METHOD ENGLISH METRIC

Heat Deflection (HDT) @ 66 psi ASTM D648 204 °F 96 °C

Heat Deflection (HDT) @ 264 psi ASTM D648 180 °F 82 °C

Glass Transition Temperature (Tg) DSC (SSYS) 226 °F 108 °C

Melting Point --------- Not Applicable 3 Not Applicable 3

Coefficient of Thermal Expansion ASTM E831 4.90x10 -05

in/in/°F 8.82x10 -05 mm/mm/°C

S T R ATA S Y S . C O M

A GLOBAL LEADER IN APPLIED ADDITIVE TECHNOLOGY SOLUTIONS

ABSplus-P430

PRODUCTION-GRADE THERMOPLASTIC

FOR 3D PRINTERS

ELECTRICAL PROPERTIES 4 TEST METHOD VALUE RANGE

Volume Resistivity ASTM D257 2.6x1015 - 5.0x1016 ohm-cm

Dielectric Constant ASTM D150-98 2.3 - 2.85

Dissipation Factor ASTM D150-98 0.0046 - 0.0053

Dielectric Strength ASTM D149-09, Method A, XZ Orientation 130 V/mil

Dielectric Strength ASTM D149-09, Method A, ZX Orientation 290 V/mil

OTHER 2 TEST METHOD VALUE

Specific Gravity ASTM D792 1.04

Rockwell Hardness ASTM D785 109.5

SYSTEM LAYER THICKNESS SUPPORT AVAIL ABLE

AVAIL ABILIT Y CAPABILITY STRUCTURE COLORS

uPrint SE Plus™ 0.013 inch (0.330 mm) Soluble Support Ivory 6 White

0.010 inch (0.254 mm) Black Dark Grey

0.007 inch (0.178 mm) 5

Red Blue

Olive Green Nectarine

Fluorescent Yellow

The information presented are typical values intended for reference and comparison purposes only. They should not be used for design specifications or quality control purposes. End-use

material performance can be impacted (+/-) by, but not limited to, part design, end-use conditions, test conditions, color etc. Actual values will vary with build conditions. Product specifications

are subject to change without notice.

The performance characteristics of these materials may vary according to application, operating conditions, or end use. Each user is responsible for determining that the Stratasys material

is safe, lawful, and technically suitable for the intended application, as well as for identifying the proper disposal (or recycling) method consistent with applicable environmental laws and

regulations. Stratasys makes no warranties of any kind, express or implied, including, but not limited to, the warranties of merchantability, fitness for a particular use, or warranty against

patent infringement.

1

Build orientation is on side long edge. 2Literature value unless otherwise noted. 3 Due to amorphous nature, material does not display a melting point. 4All Electrical Property values were

generated from the average of test plaques built with default part density (sparse). Test plaques were 4.0 x 4.0 x 0.1 inches (102 x 102 x 2.5 mm) and were built both in the flat and vertical

orientation. The range of values is mostly the result of the difference in properties of test plaques built in the flat vs. vertical orientation. 50.007 inch (0.178 mm) layer thickness available on

Dimension Elite and Fortus 250mc only. 6Ivory is the only color option for uPrintSE. The test data was collected using ABSplus Ivory (Natural) specimens. ABSplus colored materials will have

similar properties, but can vary up to 10%.

Orientation: See Stratasys Testing white paper for more detailed description of build orientations.

XZ = X or “on edge”

XY = Y or “flat”

ZX = or “upright”

HEADQUARTERS

7665 Commerce Way, Eden Prairie, MN 55344 1 Holtzman St., Science Park, PO Box 2496

+1 888 480-3548 (US Toll Free) Rehovot 76124, Israel

+1 952 937-3000 (Intl) +972 74 745-4000

S TR ATA SYS.C OM +1 952 937-0070 (Fax) +972 74 745-5000 (Fax)

ISO 9001:2008 Certified

©2014, 2015, 2017 Stratasys Inc. All rights reserved. Stratasys, Stratasys signet, FDM Technology, Fused Deposition Modeling, uPrint SE Plus, ABSplus, Catalyst EX, and Smart Supports are trademarks of Stratasys, Inc. All other trade-

marks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products. Product specifications subject to change without notice. Printed

in the USA. MSS_FDM_ABSplusP430_1117a

You might also like

- RTU232 HardwareDocument216 pagesRTU232 HardwareSud Joshi100% (1)

- Signature RBC Rewards Visa: Previous Account Balance $2,646.15Document5 pagesSignature RBC Rewards Visa: Previous Account Balance $2,646.15Hoang DucNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- POM Delrin 500CLDocument2 pagesPOM Delrin 500CLcountzeroaslNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialDocument1 pagePowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialLuiskar MedinaNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- POM Delrin 900 HFDocument2 pagesPOM Delrin 900 HFcountzeroaslNo ratings yet

- Xydar® SRT-900 by Syensqo ADPDocument3 pagesXydar® SRT-900 by Syensqo ADPFAUSANo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

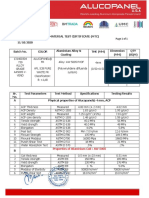

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Delrin100 NC10Document2 pagesDelrin100 NC10avinashchauhan2695No ratings yet

- Mirafi S800: Gai-LapDocument1 pageMirafi S800: Gai-LapRamiro ChambiNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- PA 66 Zytel 101Document2 pagesPA 66 Zytel 101countzeroaslNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- ThermaCool Gap Filler BRO 1372Document8 pagesThermaCool Gap Filler BRO 1372xingdrewNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- Nexeo Plastics Kumho+PS HI+425EDocument2 pagesNexeo Plastics Kumho+PS HI+425Epedro pedroNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- PEI Ultem 2310R 30%GLDocument4 pagesPEI Ultem 2310R 30%GLcountzeroaslNo ratings yet

- LEXAN™ Resin - 141 - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141 - Americas - Technical - Data - Sheetrichardhe528000No ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- PBT Valox 865 30% GLDocument4 pagesPBT Valox 865 30% GLcountzeroaslNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- Versaflex OM1060-1Document2 pagesVersaflex OM1060-1Javier RuizNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Document2 pages2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNo ratings yet

- Directional Valves: Characteristic Value / Characteristic / InformationDocument1 pageDirectional Valves: Characteristic Value / Characteristic / InformationcontrolorNo ratings yet

- Accessory Brochure FABIA Feb 2021Document29 pagesAccessory Brochure FABIA Feb 2021controlorNo ratings yet

- Manufacturing Co.: Mini 5/16-18 Standard 1/2-13 Heavy 5/18-11Document1 pageManufacturing Co.: Mini 5/16-18 Standard 1/2-13 Heavy 5/18-11controlorNo ratings yet

- Directional Valves: Characteristic Value / Characteristic / InformationDocument1 pageDirectional Valves: Characteristic Value / Characteristic / InformationcontrolorNo ratings yet

- SK Accessory Brochure - ENYAQ - May 2021 AW - Priclist IncDocument42 pagesSK Accessory Brochure - ENYAQ - May 2021 AW - Priclist InccontrolorNo ratings yet

- SKODA - FABIA Estate - Brochure - DEC21Document25 pagesSKODA - FABIA Estate - Brochure - DEC21controlorNo ratings yet

- Directional Valves: Characteristic Value / Characteristic / InformationDocument1 pageDirectional Valves: Characteristic Value / Characteristic / InformationcontrolorNo ratings yet

- 4aa7 6630eeeDocument4 pages4aa7 6630eeecontrolorNo ratings yet

- Toggle Clamp Conversion Chart: Manufacturing CoDocument1 pageToggle Clamp Conversion Chart: Manufacturing CocontrolorNo ratings yet

- General Information: Ordering Information: Engineering ChangesDocument1 pageGeneral Information: Ordering Information: Engineering ChangescontrolorNo ratings yet

- More Good News For CAD Tool Design!: Manufacturing CoDocument1 pageMore Good News For CAD Tool Design!: Manufacturing CocontrolorNo ratings yet

- E51400 1 06 17 - MiniventileDocument37 pagesE51400 1 06 17 - MiniventilecontrolorNo ratings yet

- General Information: Toggle-Action PrinciplesDocument1 pageGeneral Information: Toggle-Action PrinciplescontrolorNo ratings yet

- Technical Information: Multipurpose HolesDocument1 pageTechnical Information: Multipurpose HolescontrolorNo ratings yet

- Hole and Dowel Systems 58279Document1 pageHole and Dowel Systems 58279controlorNo ratings yet

- Air Feed: NEW Heavy - Duty Version!Document1 pageAir Feed: NEW Heavy - Duty Version!controlorNo ratings yet

- Mercedes Driver - December 2018 PDFDocument100 pagesMercedes Driver - December 2018 PDFcontrolor100% (2)

- EH 1500.200 - EH 1600.900: Base PlatesDocument4 pagesEH 1500.200 - EH 1600.900: Base PlatescontrolorNo ratings yet

- Lean Manufacturing in The Job Shop - 5 Steps To Building A Value Network MapDocument6 pagesLean Manufacturing in The Job Shop - 5 Steps To Building A Value Network MapcontrolorNo ratings yet

- MicroCentric Diaphragm Chuck Catalog 1010 - UnlockedDocument15 pagesMicroCentric Diaphragm Chuck Catalog 1010 - UnlockedcontrolorNo ratings yet

- EH 1100.300 - EH 1100.500: Base PlatesDocument5 pagesEH 1100.300 - EH 1100.500: Base PlatescontrolorNo ratings yet

- Characterization of ABS Material: A Review: July 2017Document5 pagesCharacterization of ABS Material: A Review: July 2017controlorNo ratings yet

- Management Process ManufacturingDocument4 pagesManagement Process ManufacturingcontrolorNo ratings yet

- Book On TribologyDocument22 pagesBook On Tribologycontrolor100% (1)

- Bearing Designs Cylindrical Roller Bearings and UnitsDocument10 pagesBearing Designs Cylindrical Roller Bearings and UnitscontrolorNo ratings yet

- 06 Lista de Pret Noul Golf VariantDocument20 pages06 Lista de Pret Noul Golf VariantcontrolorNo ratings yet

- Bearings: A. Advantages of Plain BearingsDocument13 pagesBearings: A. Advantages of Plain BearingscontrolorNo ratings yet

- Fabia 2017Document31 pagesFabia 2017controlorNo ratings yet

- Rapid 2017Document18 pagesRapid 2017controlorNo ratings yet

- Holistic DevelopmentDocument24 pagesHolistic DevelopmentMary Rose LlamasNo ratings yet

- Managing The Operations FunctionDocument26 pagesManaging The Operations FunctionDumplings DumborNo ratings yet

- Power Electronics Drives U1Document67 pagesPower Electronics Drives U1Ruvenderan SuburamaniamNo ratings yet

- H2A Hydrogen Delivery Infrastructure Analysis Models and Conventional Pathway Options Analysis ResultsDocument153 pagesH2A Hydrogen Delivery Infrastructure Analysis Models and Conventional Pathway Options Analysis Results林立No ratings yet

- ALGEBRA (Practice Sheet) PDFDocument132 pagesALGEBRA (Practice Sheet) PDFManavSaksariaNo ratings yet

- The List of Educational Emphasis For Your Daily Lesson Plan WritingDocument1 pageThe List of Educational Emphasis For Your Daily Lesson Plan WritingAzni ZulaikhaNo ratings yet

- NoneDocument18 pagesNoneSino KaNo ratings yet

- 001-BS Iso 247 (2006) Rubber - Determination of AshDocument10 pages001-BS Iso 247 (2006) Rubber - Determination of AshQuality MSIPLNo ratings yet

- Exploring Arcobjects PDFDocument2 pagesExploring Arcobjects PDFElenaNo ratings yet

- NH 6035448106 PreviewDocument51 pagesNH 6035448106 PreviewYesenia Gpe Vega0% (1)

- Healthstream - SwetaDocument3 pagesHealthstream - Swetaapi-608195339No ratings yet

- Detector de AmoniacoDocument4 pagesDetector de AmoniacoSegundo Teofilo Cadenillas CabanillasNo ratings yet

- ScaffoldsDocument1 pageScaffoldsChiara PaulinNo ratings yet

- Gender and ActivismDocument10 pagesGender and ActivismErika Mae SicadNo ratings yet

- Call Total CW Time Change in Oi Strike Price: Bank Nifty Intraday OI Data AnalysisDocument6 pagesCall Total CW Time Change in Oi Strike Price: Bank Nifty Intraday OI Data AnalysisDisha ParabNo ratings yet

- Optimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFDocument19 pagesOptimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFEnrique Javier González HenríquezNo ratings yet

- Instantaneous Reactive Power Compensators Comprising Switching Devices Without Energy Storage ComponentsDocument6 pagesInstantaneous Reactive Power Compensators Comprising Switching Devices Without Energy Storage ComponentsHosung AhnNo ratings yet

- ANSI Z49-1 (1967) Safety in Welding and CuttingDocument78 pagesANSI Z49-1 (1967) Safety in Welding and Cuttingbreeeeezzzzze100% (1)

- Mohd Khairul Akhmal Abd Jalil: Name Hand Phone Number AddressDocument4 pagesMohd Khairul Akhmal Abd Jalil: Name Hand Phone Number AddressOwais Manzoor MalikNo ratings yet

- Library Management SystemDocument6 pagesLibrary Management SystemNaana SmartNo ratings yet

- Application For The Post of Director, IPGTRA, GAU, JamnagarDocument12 pagesApplication For The Post of Director, IPGTRA, GAU, JamnagarKirankumar MutnaliNo ratings yet

- Iesco Tariff 2015Document19 pagesIesco Tariff 2015sam vaidNo ratings yet

- Jaguar Twister: Bagless VacuumDocument12 pagesJaguar Twister: Bagless VacuumKambrookNo ratings yet

- Advantages Disadvantages EssayDocument2 pagesAdvantages Disadvantages EssaylilalilakNo ratings yet

- International CatalogDocument128 pagesInternational CatalogDavid HicksNo ratings yet

- Specific and Non Specific DimersDocument6 pagesSpecific and Non Specific DimersDattu AbhiNo ratings yet

- Amrut Deshmukh Open Interview Chinmayee Bhange2Document5 pagesAmrut Deshmukh Open Interview Chinmayee Bhange2Aman GamingNo ratings yet

- E-Business - Assignment Dec 2022 OCo0L3Zpp0Document2 pagesE-Business - Assignment Dec 2022 OCo0L3Zpp0Nilesh SatoseNo ratings yet