Professional Documents

Culture Documents

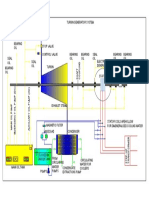

Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810

Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810

Uploaded by

ErmiasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810

Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810

Uploaded by

ErmiasCopyright:

Available Formats

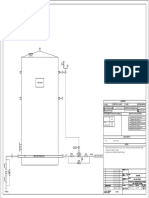

CONTROL APPLICATION DIAGRAM

FOR FOUR BOILERS

LINEAR-TEMP* INSTALLATION

HW-300 THRU HW-670

DURA-MAX 720 THRU 1810

The following control application diagram shows the routing The panel requires 120VAC, 60 Hz power. Depending upon

of the electric power between the individual controls for the number of boilers, one or two 30 amp maximum

LINEAR-TEMP* installation of four boilers. capacity circuits must be provided. A fuse disconnect

switch should be installed in line(s) serving panel to

facilitate servicing.

THIS SCHEMATIC LAYOUT IS NOT A WIRING DIAGRAM.

RELAY RATED TO CARRY

ALL MOTORS - GAS

VALVES, ETC. BUILDING

MAIN WATER CIRCULATOR

OUTDOOR

TEMP. BULBS

BULBS

120 VAC

FROM BUILDING

CONTROL SYSTEM

HONEYWELL HONEYWELL

T6788 T6788

LOW WATER CUT-OFF

(IF REQUIRED)

LINEAR-TEMP

CIRCULATORS

THERMAL

BALANCERS

FLOW

MAIN WATER

SWITCHES

FLOW SWITCH

OUTDOOR THERMOSTAT

(IF REQUIRED)

HONEYWELL

T675A

ENTRANCE

JUNCTION

BOXES

BOILER NO.1 BOILER NO.2 BOILER NO.3 BOILER NO.4

NOTE:

1. Building temperature controls supply electric power to building circulator.

2. Main flow switch proves main water flow before energizing sequencing and resetting controls.

3. Outdoor thermostat required if building controls do not provide automatic shut-down

of reset controls during warm weather.

CONTROL APPLICATION DIAGRAM

FOUR BOILER LINEAR-TEMP INSTALLATION WITH FOUR CIRCULATORS

Boilers and secondary circulators are controlled by

Two Dual Bulb, Dual Switch Mechanical Controllers

Sequencing and Outdoor Reset of Main Water Temperature

*Trademark, A.O. Smith Corp.

Revised February 1997 © A. O. SMITH CORP. 1997 E 128.1

You might also like

- 08 Kobelco MARK 8 Mechatron Control SistemDocument45 pages08 Kobelco MARK 8 Mechatron Control SistemNadiel Aceto 46100% (1)

- 5R55S Cooler Thermal Bypass FixDocument4 pages5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- Diagrama Elecrico HUSKY 400TON 3745428Document57 pagesDiagrama Elecrico HUSKY 400TON 3745428Roberto VillegasNo ratings yet

- P94 1170 PDFDocument4 pagesP94 1170 PDFeduardonemoNo ratings yet

- WIRING DIAGRAM Wifi VendoDocument5 pagesWIRING DIAGRAM Wifi VendoDikdik PribadiNo ratings yet

- Control Systems Body Electrical Vitara NewDocument49 pagesControl Systems Body Electrical Vitara Newjulio montenegro100% (1)

- Rev2 3.0bpmg Technical ManDocument58 pagesRev2 3.0bpmg Technical ManLalo LopezNo ratings yet

- ZVC406Document2 pagesZVC406elias garibayNo ratings yet

- Pumps SheduleDocument1 pagePumps SheduleriyasudheenmhNo ratings yet

- Wiring Digram For ACDocument3 pagesWiring Digram For ACahmed HOSNYNo ratings yet

- Caterpillar 322 Electrical System 15c16945Document9 pagesCaterpillar 322 Electrical System 15c16945laura100% (61)

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Wijaya GultomNo ratings yet

- AKX-Cummins 125KVA-S.SDocument2 pagesAKX-Cummins 125KVA-S.SAlfredo JimenezNo ratings yet

- Gsky Green Wall Panels: Irrigation Control Unit (Icu) DesignsDocument1 pageGsky Green Wall Panels: Irrigation Control Unit (Icu) DesignsAbbasi HussainNo ratings yet

- MODEL: T101: 24 Hour Dial Time SwitchDocument1 pageMODEL: T101: 24 Hour Dial Time SwitchMarcosNo ratings yet

- Boeing 737-800 Freighter Conversion Course Related AMM PagesDocument80 pagesBoeing 737-800 Freighter Conversion Course Related AMM Pagessomesh pandeyNo ratings yet

- Sonnax VW Audi Ag4Document1 pageSonnax VW Audi Ag4vaskaservNo ratings yet

- HuskyDocument102 pagesHuskyravicaribeinc100% (1)

- E-01-01 Sơ Đ Nguyên Lý-E-01-01Document1 pageE-01-01 Sơ Đ Nguyên Lý-E-01-01Luke LuckyNo ratings yet

- Turbin N Generator SystemDocument1 pageTurbin N Generator Systemtetsu kurokoNo ratings yet

- YZ-Systems - Crude Oil Sampling System - Datasheet - HiResDocument2 pagesYZ-Systems - Crude Oil Sampling System - Datasheet - HiResCuong TranHungNo ratings yet

- American Water Heater Electric ThermostatsDocument32 pagesAmerican Water Heater Electric ThermostatsmachinchouetteNo ratings yet

- Aircon & Heating Electrical SystemDocument2 pagesAircon & Heating Electrical SystemFajrin niswatinNo ratings yet

- Lesson01 (Videos From 02 To 04)Document5 pagesLesson01 (Videos From 02 To 04)Franco Claudio Antonio Porras YarascaNo ratings yet

- FLOW DIAGRAM MANELICK-ModelDocument1 pageFLOW DIAGRAM MANELICK-ModelManelick Jaudiel Monroy VargasNo ratings yet

- Cabezal de Control Electrico Kidde FinwalDocument1 pageCabezal de Control Electrico Kidde FinwalJose V LopezNo ratings yet

- Backhoe Loaders: Service Training MalagaDocument7 pagesBackhoe Loaders: Service Training MalagaMahmmod Al-QawasmehNo ratings yet

- Algas Torrexx Broch FM 2021Document4 pagesAlgas Torrexx Broch FM 2021Pedro RochaNo ratings yet

- Kobelco Mark IV: KobeiDocument12 pagesKobelco Mark IV: KobeiVictor Hugo MezquitaNo ratings yet

- 757-200 & 200 COMBI SERIES Flammable Material Locations: 757.0.1 October 31, 2007Document18 pages757-200 & 200 COMBI SERIES Flammable Material Locations: 757.0.1 October 31, 2007nejib benamorNo ratings yet

- Pepsico International VN Co.: AbbreviationsDocument1 pagePepsico International VN Co.: AbbreviationsLai HuynhNo ratings yet

- Hec P&idDocument47 pagesHec P&idAhmad Afeeq100% (2)

- C4 4Document2 pagesC4 4Martin FrancoNo ratings yet

- Hfo Heating System P&idDocument1 pageHfo Heating System P&idAbdur RehmanNo ratings yet

- Steam Turbine - Various ApplicationsDocument3 pagesSteam Turbine - Various ApplicationsSyed Mohammad Naveed100% (1)

- AD75019 Analog DeviceDocument5 pagesAD75019 Analog DeviceTognon MarcoNo ratings yet

- Diesel Generator SDDocument16 pagesDiesel Generator SDphyowintsoeNo ratings yet

- T101 InstructionsDocument1 pageT101 Instructionsnside1No ratings yet

- H-623500mkb51-Sa00fb-01 - D - Water Cooling DiagramDocument1 pageH-623500mkb51-Sa00fb-01 - D - Water Cooling DiagramTigistuNo ratings yet

- C1 D E F C: Honeywell Security & FireDocument1 pageC1 D E F C: Honeywell Security & FireAjay WankhedeNo ratings yet

- How Electricity Distribution in Building: Electrical GridDocument1 pageHow Electricity Distribution in Building: Electrical GridpiangphetNo ratings yet

- VONBERG-Relief Valve - Diff. Area-INLINE-49023 Series PDFDocument1 pageVONBERG-Relief Valve - Diff. Area-INLINE-49023 Series PDFNikoNo ratings yet

- Model 250 250WC Instructions R12a 120622Document8 pagesModel 250 250WC Instructions R12a 120622zidan080606No ratings yet

- Bbypass Damper VVTDocument1 pageBbypass Damper VVTAshraf N HaniaNo ratings yet

- CS 563 Hydraulic PDFDocument2 pagesCS 563 Hydraulic PDFanggieNo ratings yet

- Wind Power Sea Power Hydropower: World Association of Technology TeachersDocument1 pageWind Power Sea Power Hydropower: World Association of Technology Teacherstanya khomuskoNo ratings yet

- Remote Control Circuits (See Note 1) : SMW-SI-002Document1 pageRemote Control Circuits (See Note 1) : SMW-SI-002Fabián GuzmanNo ratings yet

- Colum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption TestedDocument1 pageColum n3 Area Cable ID Service Level Cable Code Eng Length Cable Size System Hold Misc 1 From Eq - ID From Eq - Descrption To Eq - ID TO Eq - Descrption Testedmohamed mostafaNo ratings yet

- SENR89170001Document2 pagesSENR89170001Ηρακλης ΤσαπραζηςNo ratings yet

- Electrical Abbrevations Electrical Symbols Legend Drawing Index Drawing Index Electrical ... PDFDocument70 pagesElectrical Abbrevations Electrical Symbols Legend Drawing Index Drawing Index Electrical ... PDFGoliBharggavNo ratings yet

- Motorized Damper Kits 10-600kW Gensets: DescriptionDocument1 pageMotorized Damper Kits 10-600kW Gensets: DescriptionJuly E. Maldonado M.No ratings yet

- Valve Interchange Guide: Trailer SystemsDocument1 pageValve Interchange Guide: Trailer SystemsLina Delgado OsorioNo ratings yet

- Pages25208 PROD FILEDocument1 pagePages25208 PROD FILEODILENo ratings yet

- IAME Factory Engines Tech Sheet V082016 X30 Spec UK USADocument1 pageIAME Factory Engines Tech Sheet V082016 X30 Spec UK USACarlos TurpoNo ratings yet

- Pribor Za Transformatore: Accesories For TransformersDocument4 pagesPribor Za Transformatore: Accesories For TransformerslidijaNo ratings yet

- Lead-Lag Catalog-77-04-February 2011Document16 pagesLead-Lag Catalog-77-04-February 2011asddasswxlNo ratings yet

- Specifications, Applications, Service Instructions & Parts: Motorized Control Valve & ControllersDocument38 pagesSpecifications, Applications, Service Instructions & Parts: Motorized Control Valve & Controllersjorge alvarezNo ratings yet

- 035 Pnevmoraspredeliteli Namur PDFDocument37 pages035 Pnevmoraspredeliteli Namur PDFbrij singhNo ratings yet

- 8 - D9R SLDDocument61 pages8 - D9R SLDmeyega noe sergeNo ratings yet

- EN TSM PD14 Datasheet 2016 A WebDocument2 pagesEN TSM PD14 Datasheet 2016 A WebRodrigo Domínguez MNo ratings yet

- FG 1628 CREW: Key Features Key SpecificationsDocument4 pagesFG 1628 CREW: Key Features Key SpecificationsPatriciaNo ratings yet

- VCM LocationDocument2 pagesVCM LocationLatifa EngineeringNo ratings yet

- E39 PDC InstallDocument11 pagesE39 PDC Installnoentery_2007100% (1)

- DB1 Sounders Range Up To 113 DB (A) : Ex D, WeatherproofDocument2 pagesDB1 Sounders Range Up To 113 DB (A) : Ex D, WeatherproofAceel FitchNo ratings yet

- InSinkErator Steaming Hot Water Taps Installation GuideDocument80 pagesInSinkErator Steaming Hot Water Taps Installation Guideliamdixonau100% (1)

- Data Sheet: W-Series WTR 4Document5 pagesData Sheet: W-Series WTR 4feromagnetizamNo ratings yet

- PGT120 Wolfgang Warmbier Personal Grounding Tester Data Sheet PDFDocument2 pagesPGT120 Wolfgang Warmbier Personal Grounding Tester Data Sheet PDFJesus RodriguezNo ratings yet

- WorksheetDocument14 pagesWorksheetAziz MostaphaNo ratings yet

- IEC Standard ListingDocument19 pagesIEC Standard Listingreji1usNo ratings yet

- KQ2 NewDocument226 pagesKQ2 NewMae BecherNo ratings yet

- Lamps:: Types AND Purpos ESDocument48 pagesLamps:: Types AND Purpos ESsaloni92No ratings yet

- Part 2Document49 pagesPart 2Sandro AraújoNo ratings yet

- Antipona, Clarence A. - Chapter 5-1, 5-2, 5-3 SummaryDocument3 pagesAntipona, Clarence A. - Chapter 5-1, 5-2, 5-3 Summaryclarence antiponaNo ratings yet

- Quote No 8907Document1 pageQuote No 8907Huurum MaqsuurahNo ratings yet

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocument111 pagesThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsTiago MatiasNo ratings yet

- Magnetic Contact GuideDocument109 pagesMagnetic Contact GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- XC7 SR07Document6 pagesXC7 SR07EKKO CONSTRUCTORESNo ratings yet

- 19dk - IOMDocument42 pages19dk - IOMPraveesh ThomasNo ratings yet

- Magic Sine ChipDocument11 pagesMagic Sine ChipgokerarNo ratings yet

- AX8052F143Document61 pagesAX8052F143Andrew RoeschNo ratings yet

- Treadmill Service ManualDocument111 pagesTreadmill Service ManualBashar MohammadNo ratings yet

- 2 - Ejemplo LimpiezaDocument552 pages2 - Ejemplo LimpiezaGilberto FigueroaNo ratings yet

- Compressor SealDocument6 pagesCompressor SealManojkumarNo ratings yet

- ExperimentalResultsofalocallydevelopedBLDC PDFDocument5 pagesExperimentalResultsofalocallydevelopedBLDC PDFAsmaa Hachimi El AlaouiNo ratings yet

- Rxysq-T8yb Databook Eeden19Document43 pagesRxysq-T8yb Databook Eeden19zoltanNo ratings yet

- Grua Liebherr LTM 1060 - 2Document68 pagesGrua Liebherr LTM 1060 - 2cesar alejandro scavo100% (1)