Professional Documents

Culture Documents

K & B Industries: Welding Procedure Specification (Wps

K & B Industries: Welding Procedure Specification (Wps

Uploaded by

Raja Hone0 ratings0% found this document useful (0 votes)

28 views4 pagesOriginal Title

K&B 4 2G

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

28 views4 pagesK & B Industries: Welding Procedure Specification (Wps

K & B Industries: Welding Procedure Specification (Wps

Uploaded by

Raja HoneCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

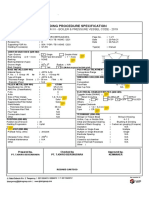

K & B Industries

WELDING PROCEDURE SPECIFICATION(WPS)

(Requirement of AWS D 1.2 )

WPS No: NVI K&B /04A Rev 00 Date 7/1/2020

Supporting PQR No. NVI K&B /04 B Rev 00

Welding Process (es): GTAW Types: Manual

Joint Sketch 65 +/- 2.5 deg.

1/16”Max

Joint Design Single V- forged Plate

Backing None

Backing Material None

Misalignment 1/16” Max 1/8” max

Base Material Filler Metal

P No NA Group No. 23 to P No NA Group No.23 AWS No.(class) 5.10 - R 4047

GTAW - Root/ HP/Filler/ Cap/back weld

Specification ,Type & Grade ASMESB221-6061 T6511 Group F No. 23

to ASME SB 221-6061 T6511 Size of Filler Metal 1/16”,3/32” OR 1/8”

Groove& Fillet- Groove Thickness Range WT + 1/16” Root and Cap

Plate Thickness range qualified to 1” to unlimited Filler – Manual , No weld without filler

Position Post weld Heat Treatment N/A

Position(s) of Groove(s) 2G (F,H)

Welding Progression Down hill /up hill – NA

Pre Heat Gas

Pre Heat Temp. Min. Amb. Minimum 70 degree F Gas(es) Argon 99.97% GTAW

Inter Pass Temp. 70 - 250 deg. F Shielding-30-50 CFH

Electrical Characteristics Technique

String or Weave Bead - Both

Current(AC/DC) AC Polarity Orifice or Gas Cup- 6-8

Amps Range 140-240 Voltage Range 12-18 Initial or Inter pass Cleaning/ back gauging- SS Wire

Tungsten Electrode Type & Size 1/8” 2% Ceriated Brush /sigma green / Tungsten Carbide tools cone burr

Mode of Metal Transfer: NA Oscillation None

Multiple/Single filler - Single

Others: Impulse- Triangular wave sign Travel Speed 2-6 Inches / Min.

Peening - None

Weld pass- Multi pass

Suggested weld Parameters Weaving 3X of filler size max

Weld pass Amps Voltage Speed inch/Min.

Root or first Pass 150-170 13-15 2.5-3.5

Back weld if applicable 160-200 13-16 2.-4

Fillers 160-200 13-16 3-6

Caps 190-240 13-16 4-7

Witnessed By. Reviewed By

Prakash B. Pahilajani

NVI LLC (Manager QA/QC) BE mech.& Metallurgy

Masters In welding CSWIP Welding Inspector

Approved By

ASNT ACCP & PED Level III 75650

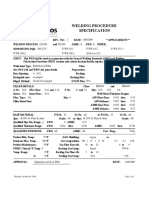

K & B Industries

PROCEDURE QUALIFICATION RECORD(PQR)

(Requirement of AWS D 1.2 )

PQR No: NVI K&B /04B Rev 00 Date 7/1/2020

Supporting WPS No. NVI K&B /04 A Rev 00

Welding Process (es): GTAW Types: Manual

Joint Sketch 65 +/- 2.5 deg.

1/16”Max

Joint Design Single V- forged Plate

Backing None

Backing Material None

Misalignment 1/16” Max 1/8” max

Base Material Filler Metal

P No NA Group No. 23 to P No NA Group No.23 AWS No.(class) 5.10 - R 4047

GTAW - Root/ HP/Filler/ Cap/back weld

Specification ,Type & Grade ASMESB221-6061 T6511 Group F No. 23

to ASME SB 221-6061 T6511 Size of Filler Metal 1/8”

Groove& Fillet- Groove Thickness Range WT + 1/16” Root and Cap

Plate Thickness 1” Filler – Manual - No weld without filler

Position Post weld Heat Treatment N/A

Position(s) of Groove(s) 2G

Welding Progression Down hill /up hill – NA

Pre Heat Gas

Pre Heat Temp. Min. Amb. Minimum 70 degree F Gas(es) Argon 99.97% GTAW

Inter Pass Temp. 70 - 240 deg. F Shielding-38 CFH

Electrical Characteristics Technique

String or Weave Bead - Both

Current(AC/DC) AC Polarity Orifice or Gas Cup- 7

Amps Range 150-230 Voltage Range 14-17 Initial or Inter pass Cleaning/ back gauging- SS Wire

Tungsten Electrode Type & Size 1/8” 2% Ceriated Brush /sigma green / Tungsten Carbide tools cone burr

Mode of Metal Transfer: NA Oscillation None

Multiple/Single filler - Single

Others: Impulse- Triangular wave sign Travel Speed 3-5 Inches / Min.

Peening - None

Weld pass- Multi pass

Weaving 3X of filler size max

Witnessed By. Reviewed By

Prakash B. Pahilajani

NVI LLC (Manager QA/QC) BE mech.& Metallurgy

Masters In welding CSWIP Welding Inspector

Approved By

ASNT ACCP & PED Level III 75650

K & B Industries

PROCEDURE QUALIFICATION RECORD(PQR)

(Requirement of AWS D 1.2 )

PQR No: NVI K&B /04 B Rev 00 Date 7/1/2020

Supporting WPS No. NVI K&B /04 A Rev 00

Welding Process (es): GTAW Types: Manual

Welding Parameters

Weld Pass Welding Amperage Voltage Travel speed Interposes

Consumable and Inches per minute temperature F

Size

Root ER 4047 1/8” 160 14 3 83 (preheat)

Back weld ER 4047 1/8” 180 15 3 120

Fillers 13 ER 4047 1/8” 180 15 2.5-4 155

Cap 1,2 ER 4047 1/8” 210 15 4-5 175

Cap 3,4 ER 4047 1/8” 210 15 6 225

Reduced Section -Tensile Test

Ultimate Type of

Specimen Width Thickness Area Ultimate Unit Stress, Failure

No. inches Inches Square Inches Total Load ksi and

ksi Location

1 0.985 0.760 0.750 20.400 27.2 Ductile

BM

2 0.978 0.810 0.792 21.800 27.6 Ductile

BM

Guided-Bend Tests

Type Result

Side Bend Acceptable

Side Bend Acceptable

Side Bend Acceptable

Side Bend Acceptable

Note: For Inter Pass Cooling Use dry & clean air, to avoid delay in welding

Welder’s Name Jeff Landry ID 6556

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance

with the requirements as listed.

Witnessed By Reviewed by Approved By

Prakash B. Pahilajani

NVI LLC (Manager QA/QC) BE Mech.& Metallurgy

Masters In welding CSWIP Welding Inspector

ASNT ACCP & PED Level III 75650

(Detail of record of tests are illustrative only and be modified to conform to the type and number of tests required by the code)

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- AC7114 Rev M NADCAP AUDIT CRITERIADocument37 pagesAC7114 Rev M NADCAP AUDIT CRITERIARaja Hone100% (2)

- Electrical Design CriteriaDocument37 pagesElectrical Design CriteriaIsmailNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- 2009 Ajax CatalogDocument88 pages2009 Ajax Cataloglemiis93No ratings yet

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 pagesEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneNo ratings yet

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 pageWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS FormatDocument2 pagesWPS FormatHarshit AdwaniNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- WPS (Gtaw)Document2 pagesWPS (Gtaw)Ramadhan AdityaNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- STD WPSDocument1 pageSTD WPSWaqas WaqasNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Weld in G P Ro Cedu Re SP Ecifica Tio N (WP S)Document2 pagesWeld in G P Ro Cedu Re SP Ecifica Tio N (WP S)almasrizalNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 pagesKaushik Shah Date: 2011 Form 001 - Format CsriramNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Aluminim WPSDocument2 pagesAluminim WPSmahmoud_allam3No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- ISO To ASDocument16 pagesISO To ASRaja HoneNo ratings yet

- NANDTB Identification Number: NANDTB N.D.T. LEVEL 3 Application Form Transition To EN4179Document11 pagesNANDTB Identification Number: NANDTB N.D.T. LEVEL 3 Application Form Transition To EN4179Raja HoneNo ratings yet

- AC7114-4 Rev M Final EDITORIAL 2DECDocument60 pagesAC7114-4 Rev M Final EDITORIAL 2DECRaja HoneNo ratings yet

- AC7114-1 Rev M Final Editorial 5 DECDocument60 pagesAC7114-1 Rev M Final Editorial 5 DECRaja HoneNo ratings yet

- AC7114 REV N - 1 EDITORIAL FinalDocument35 pagesAC7114 REV N - 1 EDITORIAL FinalRaja HoneNo ratings yet

- Eddyfi Ectane2: Getting Started WithDocument68 pagesEddyfi Ectane2: Getting Started WithRaja HoneNo ratings yet

- Digital Ferrite Meter TMF110: Product DescriptionDocument2 pagesDigital Ferrite Meter TMF110: Product DescriptionRaja HoneNo ratings yet

- Apartment Lease Contract: October 5, 2020Document54 pagesApartment Lease Contract: October 5, 2020Raja HoneNo ratings yet

- AC7114-2 Rev LDocument41 pagesAC7114-2 Rev LRaja Hone100% (2)

- Feritscope FMP30: Operators ManualDocument240 pagesFeritscope FMP30: Operators ManualRaja HoneNo ratings yet

- Brittle Fracture and Reporting OverviewDocument38 pagesBrittle Fracture and Reporting OverviewRaja HoneNo ratings yet

- Evers and Sons Inc.: Welding Procedure Specification (WpsDocument3 pagesEvers and Sons Inc.: Welding Procedure Specification (WpsRaja HoneNo ratings yet

- Procedures For Assessing The FitnessDocument12 pagesProcedures For Assessing The FitnessRaja HoneNo ratings yet

- Study 2016 Article ManagingColdTemperatureAndBritDocument12 pagesStudy 2016 Article ManagingColdTemperatureAndBritRaja HoneNo ratings yet

- WPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWDocument1 pageWPS Butt Repair A 53 FAB-GTAW-GMAW-FCAWRaja HoneNo ratings yet

- ASTM Comparison PDFDocument1 pageASTM Comparison PDFRaja HoneNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument9 pagesAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Offshore Applications of SRTPDocument5 pagesOffshore Applications of SRTPArif AshrafNo ratings yet

- Proddocspdf 2 248 PDFDocument20 pagesProddocspdf 2 248 PDFRaj KrishNo ratings yet

- Sta 434aDocument3 pagesSta 434aChack RelaxsNo ratings yet

- Service ManualDocument44 pagesService ManualjulianoNo ratings yet

- GS Ep Ele 011 enDocument14 pagesGS Ep Ele 011 enCandice WilliamsNo ratings yet

- 1S 3.7V 3A PCB Protection Board For 18650 Li-Ion Lithium Battery CellDocument23 pages1S 3.7V 3A PCB Protection Board For 18650 Li-Ion Lithium Battery Cellyewie561No ratings yet

- WWTP HazopDocument12 pagesWWTP HazopMarco MazzucatoNo ratings yet

- Daily Log BookDocument12 pagesDaily Log BookdipawanshNo ratings yet

- Expeller Material BalanceDocument1 pageExpeller Material BalanceSrikanth KesanakurthiNo ratings yet

- I-Line Circuit Breaker PanelboardsDocument32 pagesI-Line Circuit Breaker PanelboardsGabriel GonzalezNo ratings yet

- Energy Medicine PDFDocument14 pagesEnergy Medicine PDFMonicaNo ratings yet

- PV Input Voltage Sense (Isolated) : C47 0.1u C97 0.1uDocument10 pagesPV Input Voltage Sense (Isolated) : C47 0.1u C97 0.1uPhani ArvapalliNo ratings yet

- D3516C 2500kvaDocument6 pagesD3516C 2500kvaarehman.shahidNo ratings yet

- GaussDocument6 pagesGausserickNo ratings yet

- Jet Fuel Colonial Grade 54 - JP54Document1 pageJet Fuel Colonial Grade 54 - JP54BernhardNo ratings yet

- 1 s2.0 S0360319912017181 MainDocument8 pages1 s2.0 S0360319912017181 MainNafees VakilNo ratings yet

- Prosonic B200 - TI01018DEN - 0518Document52 pagesProsonic B200 - TI01018DEN - 0518claus.skjoethNo ratings yet

- ANSI Guideline For Injection MoldingDocument83 pagesANSI Guideline For Injection Moldingbabb3r75% (4)

- AnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyDocument9 pagesAnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyAniketsingh MundlothNo ratings yet

- R7410207 High Voltage EngineeringDocument4 pagesR7410207 High Voltage EngineeringsivabharathamurthyNo ratings yet

- Response To Senator - Climate ChangeDocument5 pagesResponse To Senator - Climate ChangeChris ColoseNo ratings yet

- Chapter 4.5 SC f5Document7 pagesChapter 4.5 SC f5kwongyawNo ratings yet

- Full ManuscriptDocument25 pagesFull ManuscriptMichael MellaNo ratings yet

- Putting A Circular Economy Into Practice in ChinaDocument7 pagesPutting A Circular Economy Into Practice in ChinaManaspratim DasNo ratings yet

- GreenDocument55 pagesGreendurgas_1988No ratings yet

- Manual UPS 20KVADocument40 pagesManual UPS 20KVAMarian MihaiNo ratings yet

- 01062020Document14 pages01062020Kishore KunduNo ratings yet

- OMNIPOWER 3-Phase - Installation and User Guide - EnglishDocument8 pagesOMNIPOWER 3-Phase - Installation and User Guide - EnglishSamuel KamauNo ratings yet