Professional Documents

Culture Documents

The Purpose of Sulfur Guard Bed

The Purpose of Sulfur Guard Bed

Uploaded by

Alia KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Purpose of Sulfur Guard Bed

The Purpose of Sulfur Guard Bed

Uploaded by

Alia KhanCopyright:

Available Formats

Sulfur Guard Bed

The purpose of the Sulfur Guard Bed is to protect the DHDS product from sulfur in the

liquid feed. The Sulfur Guard Bed reduces the sulfur to a safe level to be transported and

distributed to be used by automobiles and serves as protection against upsets in the product

which could result in higher than normal levels of sulfur in the feed.

The Sulfur Guard Bed is loaded with either UOP ADS-11L (nickel) or ADS-12/ADS- 120

(copper) adsorbent designed to chemisorb sulfur from the liquid feed. The feedstock is

heated to the required temperature for sulfur removal, usually between 121°C to 150°C and

passed downflow over the adsorbent.

The Sulfur Guard Bed vessel is constructed of carbon steel. The bottom of the vessel is

equipped with an outlet collector to prevent loss of adsorbent or support material. The

adsorbent is loaded between a graduated system of ceramic/alumina inert balls. The vessel

operates liquid full with the feed entering the Guard Bed through an inlet pipe.

You might also like

- Chapter No 2 Process Selection: 2.1 Manufacturing Processes For Caustic SodaDocument28 pagesChapter No 2 Process Selection: 2.1 Manufacturing Processes For Caustic SodaAlia Khan100% (1)

- Rate-Based NaOH ModelDocument21 pagesRate-Based NaOH Modelniawd100% (3)

- 50 Olefin ReductionDocument2 pages50 Olefin ReductiondimkuhNo ratings yet

- Liquid SO2.1Document13 pagesLiquid SO2.1Musyafa WiryantoNo ratings yet

- Kurita Mitigating Coke FormationDocument3 pagesKurita Mitigating Coke FormationMarcelNo ratings yet

- October 1, 2012 - December 14 2012: Andrew - Jones@netl - Doe.govDocument15 pagesOctober 1, 2012 - December 14 2012: Andrew - Jones@netl - Doe.govnarasimhamurthy414No ratings yet

- Maximise Ethylene Gain PDFDocument4 pagesMaximise Ethylene Gain PDFRaj KumarNo ratings yet

- SulfolaneAppendices A EDocument158 pagesSulfolaneAppendices A Erkhandelwal9604No ratings yet

- Ar001Document10 pagesAr001Gary ClarkNo ratings yet

- Design A De-Iso Hexanizer (DIH) For A Isomerization Unit To Boost RON From 82-84 To 90-93 of Gasoline by Using Light NaphthaDocument9 pagesDesign A De-Iso Hexanizer (DIH) For A Isomerization Unit To Boost RON From 82-84 To 90-93 of Gasoline by Using Light NaphthaBakhtyar AhmedNo ratings yet

- C350450001VDocument1 pageC350450001Vrajindo1No ratings yet

- De Sulfur IzationDocument2 pagesDe Sulfur IzationngotrongthucNo ratings yet

- STRATCO AlkylationTechnologyImprovementsDocument23 pagesSTRATCO AlkylationTechnologyImprovementsAli YousefNo ratings yet

- Sablin Alpha Raab FDocument3 pagesSablin Alpha Raab Fsk281No ratings yet

- Petroleum Refinery EngineeringDocument9 pagesPetroleum Refinery EngineeringMahtab SajnaniNo ratings yet

- Review of Small Stationary Reformers For Hydrogen ProductionDocument52 pagesReview of Small Stationary Reformers For Hydrogen ProductionSoineth GuzmánNo ratings yet

- Anderson Albemarle FCC-PTDocument25 pagesAnderson Albemarle FCC-PTrujunli0% (1)

- 142 Yer HS PSM 0001Document75 pages142 Yer HS PSM 0001Janakiraman MalligaNo ratings yet

- Unit 2 Refining Process - 3Document28 pagesUnit 2 Refining Process - 3prathamesh singhNo ratings yet

- Thermal Denitration of Ammonium Nitrate Solution in A Fluidized-Bed ReactorDocument10 pagesThermal Denitration of Ammonium Nitrate Solution in A Fluidized-Bed ReactorgauravNo ratings yet

- Uop Unionfining Technology: Peter KokayeffDocument12 pagesUop Unionfining Technology: Peter KokayeffBharavi K SNo ratings yet

- Operation of A Distillate Hydrot UnitDocument18 pagesOperation of A Distillate Hydrot UnitFranklin RevillNo ratings yet

- SiCl4 PreparationDocument5 pagesSiCl4 PreparationAdam FlynnNo ratings yet

- Sweetening LPG With AminesDocument8 pagesSweetening LPG With AminessizwehNo ratings yet

- Steam Cracking of Naphtha in Packed Bed ReactorsDocument6 pagesSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- PFDDocument1 pagePFDDenny FirmansyahNo ratings yet

- Nicholas Oligomerization PDFDocument16 pagesNicholas Oligomerization PDFTanase DianaNo ratings yet

- KFBE Fluidized Bed Structured PackingDocument8 pagesKFBE Fluidized Bed Structured PackingMeli ChiambaNo ratings yet

- A Financial Analysis For The Production of HQ Propylene-MustangDocument19 pagesA Financial Analysis For The Production of HQ Propylene-Mustangandrei12320003181No ratings yet

- Hydrogen Sulfide (H S) Production Technology: The Worldwide Market For H2S Continues To Grow at An Impressive RateDocument4 pagesHydrogen Sulfide (H S) Production Technology: The Worldwide Market For H2S Continues To Grow at An Impressive Rateingegnere1234100% (1)

- Refinery Configurations - Designs For Heavy Oil - Hydrocarbon Processing - October 2011Document12 pagesRefinery Configurations - Designs For Heavy Oil - Hydrocarbon Processing - October 2011SumitAggarwalNo ratings yet

- Solvent Extraction of Palladium From Chloride Media by TBPDocument6 pagesSolvent Extraction of Palladium From Chloride Media by TBPMoreno MarcatiNo ratings yet

- 10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFDocument26 pages10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFmujeebtalib100% (1)

- Ammonia CrackerDocument2 pagesAmmonia CrackerPuneet Kumar SharmaNo ratings yet

- SRC Supplemental Rectification With CompressionDocument2 pagesSRC Supplemental Rectification With Compressionquocthuong1988 leNo ratings yet

- Basics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, CatalystsDocument5 pagesBasics of Hydrotreating Catalyst Sulfiding - Reactor Resources - Sulfiding Services, Alumina, Metal Reclamation, Catalystsonizuka-t2263No ratings yet

- DRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEODocument7 pagesDRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOMohsen ArdestaniNo ratings yet

- Debottlenecking An FCC Gas Concentration UnitDocument4 pagesDebottlenecking An FCC Gas Concentration UnitShivam MishraNo ratings yet

- Refinery PDFDocument22 pagesRefinery PDFromulussikalitNo ratings yet

- CoMo PDFDocument4 pagesCoMo PDFNeniitha SánchezNo ratings yet

- Rp-1 Fuel Physical PropertiesDocument12 pagesRp-1 Fuel Physical PropertiesDanielRobertoFerreiraNo ratings yet

- Process Design LurgiDocument2 pagesProcess Design Lurgimasoud132No ratings yet

- Reducing Pressure - Increasing Efficiency: PanoramaDocument4 pagesReducing Pressure - Increasing Efficiency: PanoramapsshnkrNo ratings yet

- Process DescriptionDocument6 pagesProcess Descriptionافكر اشتري كورياNo ratings yet

- Mercaptans Removal From Gases by Absorption Into Amines and CausticDocument8 pagesMercaptans Removal From Gases by Absorption Into Amines and Causticgopal100% (1)

- (R) FCC Slurry Oil Filtration: Technical Information PaperDocument12 pages(R) FCC Slurry Oil Filtration: Technical Information Papersuraj pandeyNo ratings yet

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocument16 pagesCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Oxosynthesis, Udex and Fischer Tropsch SynthesisDocument21 pagesOxosynthesis, Udex and Fischer Tropsch SynthesisNisha SubashNo ratings yet

- Eaton Pipeline Strainer Pressure Drop CalculationsDocument1 pageEaton Pipeline Strainer Pressure Drop Calculationsreborn_willyNo ratings yet

- BF-9201 US F-200 DatasheetDocument3 pagesBF-9201 US F-200 DatasheetNguyễn Kim HùngNo ratings yet

- Hydrocracking ModelDocument6 pagesHydrocracking Modelantzlck100% (1)

- MetoxidoDocument8 pagesMetoxidocessavelinoNo ratings yet

- Maximization of Diesel ProductionDocument9 pagesMaximization of Diesel ProductionPriya NarayanNo ratings yet

- HPCL-Mittal Energy Limited: Corporate ProfileDocument11 pagesHPCL-Mittal Energy Limited: Corporate ProfileJordan RockNo ratings yet

- Reforming Catalyst Regenration: M.Saleem Chohan Syed Kashif HassanDocument17 pagesReforming Catalyst Regenration: M.Saleem Chohan Syed Kashif HassanSaleem ChohanNo ratings yet

- Hydrogen Science and Engineering: Materials, Processes, Systems, and TechnologyFrom EverandHydrogen Science and Engineering: Materials, Processes, Systems, and TechnologyNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Materials and Processes for CO2 Capture, Conversion, and SequestrationFrom EverandMaterials and Processes for CO2 Capture, Conversion, and SequestrationNo ratings yet

- R.V. College of Engineering, Bangalore-560059 (Autonomous Institution Affiliated To VTU, Belgaum)Document10 pagesR.V. College of Engineering, Bangalore-560059 (Autonomous Institution Affiliated To VTU, Belgaum)Paridhi GargNo ratings yet

- HEC Pakistan - Recommendations - 28 - JULY - 2021Document160 pagesHEC Pakistan - Recommendations - 28 - JULY - 2021Alia KhanNo ratings yet

- Annex 6: Content and Format of Iee and Siee: Environment Assessment & ReviewDocument8 pagesAnnex 6: Content and Format of Iee and Siee: Environment Assessment & ReviewAlia KhanNo ratings yet

- List of Documents To Be Attached With The Application Form For Registration As Professional Engineer (Pe) (Through Epe)Document6 pagesList of Documents To Be Attached With The Application Form For Registration As Professional Engineer (Pe) (Through Epe)Alia KhanNo ratings yet

- Connect: Picnic at Sunway LagoonDocument28 pagesConnect: Picnic at Sunway LagoonAlia KhanNo ratings yet

- Production of 250 MTPD Sodium HydroxideDocument99 pagesProduction of 250 MTPD Sodium HydroxideAlia KhanNo ratings yet

- DHA Flyer 2020Document2 pagesDHA Flyer 2020Alia KhanNo ratings yet

- Group 1: SR - No# Group Number Roll Number Names CGPA Proposed TopicDocument3 pagesGroup 1: SR - No# Group Number Roll Number Names CGPA Proposed TopicAlia KhanNo ratings yet

- Production of 250 MTPD Sodium HydroxideDocument18 pagesProduction of 250 MTPD Sodium HydroxideAlia KhanNo ratings yet

- Fauji Fertilizer Company Limited Management Trainees Test (Schedule 2021)Document1 pageFauji Fertilizer Company Limited Management Trainees Test (Schedule 2021)Alia KhanNo ratings yet

- Introduction of Production of Caustic SodaDocument14 pagesIntroduction of Production of Caustic SodaAlia Khan100% (2)

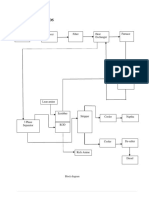

- Block Diagram of DHDS: Feed Tank Coalescer Filter Heat Exchanger FurnaceDocument2 pagesBlock Diagram of DHDS: Feed Tank Coalescer Filter Heat Exchanger FurnaceAlia KhanNo ratings yet

- Project Title: Production of Sodium Hydroxide From Brine Electrolysis Using Membrane CellDocument2 pagesProject Title: Production of Sodium Hydroxide From Brine Electrolysis Using Membrane CellAlia KhanNo ratings yet

- Experiment # 5: Objective of The StudyDocument2 pagesExperiment # 5: Objective of The StudyAlia KhanNo ratings yet

- Industrial Accidents: - Safety and Loss PreventionDocument13 pagesIndustrial Accidents: - Safety and Loss PreventionAlia KhanNo ratings yet

- Quantity Changes of Reactants / Products Total Time of ReactionDocument1 pageQuantity Changes of Reactants / Products Total Time of ReactionAlia KhanNo ratings yet

- Experiment No. 2: ObjectDocument3 pagesExperiment No. 2: ObjectAlia KhanNo ratings yet

- Bzu, Bahadur Campus, Layyah: Award List (Viva Voce)Document3 pagesBzu, Bahadur Campus, Layyah: Award List (Viva Voce)Alia KhanNo ratings yet

- 1038-Fourth Merit List-BBA (Morning) 2020Document3 pages1038-Fourth Merit List-BBA (Morning) 2020Alia KhanNo ratings yet