Professional Documents

Culture Documents

Single-Stage Centrifugal Compressor Modifications and Rerates

Single-Stage Centrifugal Compressor Modifications and Rerates

Uploaded by

Ali BarzegarCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- FAST Transmission-7 GearsDocument28 pagesFAST Transmission-7 Gearseman haghshenas100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- The Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinDocument40 pagesThe Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinMara Rebeka Herzog100% (7)

- H E Parts Brochure Wheel GroupsDocument7 pagesH E Parts Brochure Wheel GroupsSebastiao DuarteNo ratings yet

- Wind Capability Brochure 14480 EN - V4Document36 pagesWind Capability Brochure 14480 EN - V4williams vasquezNo ratings yet

- SKF Industrial PricelistApril2017 Edition2Document140 pagesSKF Industrial PricelistApril2017 Edition2shekar_991985346No ratings yet

- The Maximizer Pumping UnitDocument16 pagesThe Maximizer Pumping UnitJORGE ELIECER RUEDA PINZONNo ratings yet

- Bulletin - 47085 SalesDocument24 pagesBulletin - 47085 Sales83998399No ratings yet

- PVWJ Open Loop Pumps: Bulletin 47085Document24 pagesPVWJ Open Loop Pumps: Bulletin 47085CARLOS RAMIREZ100% (1)

- Brochure - Rigid Renold Page 40 PDFDocument76 pagesBrochure - Rigid Renold Page 40 PDFCarlos Gallardo LagosNo ratings yet

- 00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsDocument1 page00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsKaran AgrawalNo ratings yet

- Reliable Solutions For Continuous Casters BrochureDocument24 pagesReliable Solutions For Continuous Casters BrochureMario RossiNo ratings yet

- Performance Spectrum: Heart of HightechDocument5 pagesPerformance Spectrum: Heart of Hightecharun manchekarNo ratings yet

- OSepaseparator 1Document6 pagesOSepaseparator 1Slobodan StrainovićNo ratings yet

- Self-Study Program 951703 - 09D - TransmissionDocument79 pagesSelf-Study Program 951703 - 09D - TransmissionManuel GoncalvesNo ratings yet

- 31X - 33XN Gearbox Upgrade BrochureDocument3 pages31X - 33XN Gearbox Upgrade Brochuredhana adidhanuNo ratings yet

- 315GFBA - QSK19G DatashhetDocument5 pages315GFBA - QSK19G DatashhetedilbertoNo ratings yet

- HT VarleyGearPumps 4pages 2018 V2Document4 pagesHT VarleyGearPumps 4pages 2018 V2MvrbeckszNo ratings yet

- Cat 966GDocument2 pagesCat 966GCarlos Arturo AcevedoNo ratings yet

- 2463248Document12 pages2463248Dexter Hawkins100% (1)

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesLuis Guillermo BlandónNo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesSiddharth VNo ratings yet

- Audi 09D Transmission PDFDocument79 pagesAudi 09D Transmission PDFJOHNNY5377100% (4)

- Important Information: Section 1B - Maintenance For Sterndrive ModelsDocument50 pagesImportant Information: Section 1B - Maintenance For Sterndrive ModelsJason WilliamNo ratings yet

- NEMO-CPro 0313 ENDocument4 pagesNEMO-CPro 0313 ENrosario medinaNo ratings yet

- HVT R2 Hydromechanical Variable TransmissionDocument12 pagesHVT R2 Hydromechanical Variable TransmissionShubham JaruharNo ratings yet

- KEN 557 3620K 3630K InstructionsDocument4 pagesKEN 557 3620K 3630K InstructionsBM TRUCK ALIGNMENT MOBILE SERVICENo ratings yet

- Goulds 3171 / CV3171: Vertical Sump and Process PumpsDocument16 pagesGoulds 3171 / CV3171: Vertical Sump and Process PumpsJavier Fernando Agudelo GómezNo ratings yet

- Royal Enfield Bullet 1995 Owners ManualDocument109 pagesRoyal Enfield Bullet 1995 Owners ManualAndrea De SantisNo ratings yet

- Santorq ST Series Rev1Document5 pagesSantorq ST Series Rev1rupeshp1989No ratings yet

- Shell Tonna: Extra Separation From Coolants Standard ApplicationsDocument4 pagesShell Tonna: Extra Separation From Coolants Standard ApplicationsHUM CIREBON DFLTSNo ratings yet

- Comprehensive Engine Part Repair: The Eagle Is EverywhereDocument4 pagesComprehensive Engine Part Repair: The Eagle Is EverywhereAlejandroNo ratings yet

- 1540 PDFDocument6 pages1540 PDFOscar Fernando Guerrero RomeroNo ratings yet

- Transmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitDocument7 pagesTransmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitAwan dwi cahyo100% (1)

- Automax Actuators & Accessories English PDFDocument18 pagesAutomax Actuators & Accessories English PDFSt. Labuhan MaringgaiNo ratings yet

- AHLSTAR™ Process Pumps: The Heart of Your ProcessDocument15 pagesAHLSTAR™ Process Pumps: The Heart of Your ProcessFerry AndriansyahNo ratings yet

- Robotarm II G-Series Pneumatic Hydraulic ActuatorsDocument8 pagesRobotarm II G-Series Pneumatic Hydraulic ActuatorsYuri Soverika SitepuNo ratings yet

- Railroad Engine Oil Brochure - 2012Document2 pagesRailroad Engine Oil Brochure - 2012Marcelo ViscardiNo ratings yet

- KTA 50 G3 1250 KVA Operation and Maintenance ProcedureDocument20 pagesKTA 50 G3 1250 KVA Operation and Maintenance ProcedureWaruna Pasan100% (1)

- Draglines Family BrochureDocument5 pagesDraglines Family Brochuresoulaimane BOUASRIANo ratings yet

- Mining Equipment Sealing SolutionsDocument5 pagesMining Equipment Sealing SolutionsSenthilKumar100% (1)

- Component ServiceDocument7 pagesComponent ServiceFahmi AliNo ratings yet

- D7 at PDFDocument4 pagesD7 at PDFStathis MoumousisNo ratings yet

- BR Cone RingDocument16 pagesBR Cone Ringricky pradanaNo ratings yet

- Engine Driven ProductsDocument24 pagesEngine Driven ProductsSomsak ChaonramNo ratings yet

- LH Omega Undercarriage For Electric Rope ShovelsDocument2 pagesLH Omega Undercarriage For Electric Rope ShovelsjacolienjvvuurenNo ratings yet

- Wind-Services Wikov en 1809 PDFDocument2 pagesWind-Services Wikov en 1809 PDFleosac6No ratings yet

- Direct Drive Brochure - US - 071218Document16 pagesDirect Drive Brochure - US - 071218johnnyNo ratings yet

- American Kuhne Life Cycle ManagementDocument4 pagesAmerican Kuhne Life Cycle ManagementNitin PatilNo ratings yet

- Molykote M Gear Oil AdditiveDocument3 pagesMolykote M Gear Oil AdditiveJuan Pablo Fernandez ZuñigaNo ratings yet

- Pipeline Booster Pump BrochureDocument16 pagesPipeline Booster Pump Brochurehermit44535No ratings yet

- QSV81G Data SheetsDocument6 pagesQSV81G Data SheetsSaban Sang Petualang Return100% (1)

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Repair Options: Cat 777D Off-Highway TruckDocument4 pagesRepair Options: Cat 777D Off-Highway TruckmkNo ratings yet

- KTA50 Series 50HzDocument4 pagesKTA50 Series 50HzBalamurugan ArumugamNo ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- Guidelines Current List Updated March 2019Document9 pagesGuidelines Current List Updated March 2019MehrdadNo ratings yet

- Cold Injuries and HypothermiaDocument34 pagesCold Injuries and HypothermiaRam Kirubakar ThangarajNo ratings yet

- FAI Free Flight Team Selection Process History NotebookDocument176 pagesFAI Free Flight Team Selection Process History NotebookRussell HartillNo ratings yet

- Technical Schedule 3Document16 pagesTechnical Schedule 3Prasenjit DeyNo ratings yet

- 2019-9-09 - Stella Maris - Lengua Extranjera (Inglés) - b2 Unit 3 CultureDocument2 pages2019-9-09 - Stella Maris - Lengua Extranjera (Inglés) - b2 Unit 3 CulturemncskillsNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistAriq RaihanNo ratings yet

- Rom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicDocument14 pagesRom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicVu LeNo ratings yet

- QM in Curved SpacetimeDocument12 pagesQM in Curved SpacetimeSourasish KarmakarNo ratings yet

- wk06 IVDocument34 pageswk06 IVyingdong liuNo ratings yet

- Series & Parallel PumpsDocument48 pagesSeries & Parallel PumpsMoh AmmNo ratings yet

- GRILL StationDocument19 pagesGRILL Stationradwa.talaatNo ratings yet

- Agri Plas GreenhouseDocument6 pagesAgri Plas GreenhouseBendzGeronaNo ratings yet

- S 125Document317 pagesS 125ronaldosilva2100% (1)

- Bondship BookDocument252 pagesBondship Bookmehrdad_5233No ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- Section 5 - E&A Drawings PDFDocument1,288 pagesSection 5 - E&A Drawings PDFAndrii PodgornyiNo ratings yet

- Method Statement For Water Recticulation (16.12.04)Document8 pagesMethod Statement For Water Recticulation (16.12.04)mochacino6867% (6)

- Grade 9 Math Q1 M1Document12 pagesGrade 9 Math Q1 M1Renny Romero Luzada100% (2)

- Wastewater Characteristics: Table 7.1.5 Table 7.1.6Document4 pagesWastewater Characteristics: Table 7.1.5 Table 7.1.6Amin EnviroNo ratings yet

- Kuensel IssuesDocument12 pagesKuensel IssuesDeepen SharmaNo ratings yet

- Cross 1987 Catecholamines LympohcytesDocument7 pagesCross 1987 Catecholamines LympohcytesMartin BadovNo ratings yet

- Aip 2023 2 3Document29 pagesAip 2023 2 3menchiemanaloNo ratings yet

- List of en StandardsDocument21 pagesList of en StandardsKaranjaNo ratings yet

- Fracture CrurisDocument44 pagesFracture CrurisAnonymous turPUJtErNo ratings yet

- Cucumber Production GuideDocument4 pagesCucumber Production Guideeduard dugayNo ratings yet

- Blouse Body Measurement ChartDocument2 pagesBlouse Body Measurement ChartScarletBeauty Enriquez-DiagbelNo ratings yet

- Test 6Document33 pagesTest 6Балнур АмантайNo ratings yet

Single-Stage Centrifugal Compressor Modifications and Rerates

Single-Stage Centrifugal Compressor Modifications and Rerates

Uploaded by

Ali BarzegarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single-Stage Centrifugal Compressor Modifications and Rerates

Single-Stage Centrifugal Compressor Modifications and Rerates

Uploaded by

Ali BarzegarCopyright:

Available Formats

SERVICE

Single-Stage Centrifugal Compressor

Modifications and Rerates

Single-stage centrifugal compressors often operate in corrosive, high-temperature conditions in petrochemical

plants, refineries, natural gas processing, coal gasification, and power stations. Low maintenance and continuous

service are extremely important under these conditions. Elliott Engineered Solutions can upgrade these machines

to increase reliability, improve safety, and increase overall efficiency. Upgrades of single-stage centrifugal compres-

sors can also enhance environmental compliance and reduce operating costs.

A site audit by Elliott Engineered Solutions will identify appropriate modifications for improving a single-stage

compressor’s reliability and efficiency. Upgrading impeller eye seals can minimize internal recirculation. A bearing

upgrade can reduce the potential for oil whirl and other associated vibration problems. Installing inlet guide vanes

can improve performance on partial-load conditions. Elliott modifications and rerates are designed to keep your

turbomachinery performance high and your maintenance costs low.

Replace Iso-carbon or

Iso-sleeve seals with

Upgrade flow path (impeller, dry gas seals s

eye seal, rotor) s

Add or upgrade

machinery performance,

diagnostic, and protective

Replace impeller eye instrumentation n l

seal with abradable

seals n s Upgrade journal bearings to

directed lube, offset pivot, Upgrade thrust

or chrome copper pads n bearings to directed

lube, offset pivot,

or chrome copper

pads n s

Add oil

wash spray

nozzles n

Upgrade

coupling from

lubricated to

dry-type n

Upgrade bearing

housing oil seals n l

Install adjustable

inlet guide vanes

(IGV) s

Add instrumentation

wire quick

disconnect n l

Upgrade impeller

and volute with

Pos-E-Coat n s

Other Modifications

Change driver from fixed speed to variable speed n n Reliability

Perform site audit n s l s Efficiency

Upgrade control system n l l Safety Controls

Elliott Engineered Solutions

Elliott Engineered Solutions has one focus – to help turbomachinery operators obtain the highest value from their critical rotat-

ing equipment. Elliott has more than 100 years of experience in engineering, manufacturing, repairing, and modifying all types

of turbomachinery. Elliott Engineered Solutions specializes in the following areas:

Modifications and rerates of turbomachinery to increase the operational life and value of your investment by optimizing

performance and reducing downtime.

Reverse engineering and comprehensive analytical studies such as lateral and torsional rotor analysis, root-cause failure

analysis, mechanical evaluation analysis, finite element analysis (FEA), and aerodynamic analysis.

Onsite audits to evaluate turbomachinery efficiency and determine potential reliability improvements to maximize your return

on existing equipment.

Reapplication of previously owned equipment for emergency installation or cost-effective replacement.

Equipment configuration designs to precisely fit existing footprints.

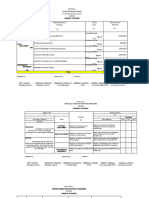

Enhancement Category Benefit

Add instrumentation wire quick disconnect Reliability. Safety Reduce chance of oil leak; Reduce maintenance time

Add oil wash spray nozzles Reliability Reduce/eliminate internal fouling by mechanical cleaning

Add or upgrade machinery performance, diagnostic, Improve machinery performance, health monitoring

Reliability. Safety

and protective instrumentation and protective instrumentation

Maintain optimal running speeds for peak efficiency;

Change driver from fixed speed to variable speed Efficiency

Eliminate suction throttling

Install adjustable inlet guide vanes Efficiency Save energy by controlling inlet flow

Perform site audit Reliability. Safety. Efficiency Identify areas to upgrade for peak performance

Replace impeller eye seal with abradable seals Efficiency. Reliability Improve efficiency by reducing internal seal leakage

Replace Iso-carbon or Iso-sleeve seals with dry gas seals Efficiency Save power loss by eliminating oil shear; Reduce oil consumption

Upgrade control system Reliability. Safety Keep compressor operating within a safe range

Upgrade bearing housing oil seals Safety Reduce oil leaks to atmosphere/Buffered design to eliminate leakage

Upgrade coupling from lubricated to dry-type Reliability Eliminate oil requirements; Improve rotor dynamics

Upgrade flow path (impeller, eye seal, rotor) Efficiency Increase performance or capacity

Upgrade Impeller and volute with Pos-E-Coat Reliability. Efficiency Reduce internal fouling and corrosion effects

Upgrade journal bearings to directed lube, offset pivot,

Reliability Improve rotor stability at running speeds

or chrome copper pads

Upgrade thrust bearings to directed lube, offset pivot, Reduce oil requirements, bearing temperature,

Reliability. Efficiency

or chrome copper pads and bearing heat loss

901 North Fourth Street

Jeannette, PA 15644-1473

Phone: 724-527-2811

Fax: 724-600-8442

Email: info@elliott-turbo.com

www.elliott-turbo.com

© 2014 Elliott Group SVS.4041.0914

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- FAST Transmission-7 GearsDocument28 pagesFAST Transmission-7 Gearseman haghshenas100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- The Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinDocument40 pagesThe Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinMara Rebeka Herzog100% (7)

- H E Parts Brochure Wheel GroupsDocument7 pagesH E Parts Brochure Wheel GroupsSebastiao DuarteNo ratings yet

- Wind Capability Brochure 14480 EN - V4Document36 pagesWind Capability Brochure 14480 EN - V4williams vasquezNo ratings yet

- SKF Industrial PricelistApril2017 Edition2Document140 pagesSKF Industrial PricelistApril2017 Edition2shekar_991985346No ratings yet

- The Maximizer Pumping UnitDocument16 pagesThe Maximizer Pumping UnitJORGE ELIECER RUEDA PINZONNo ratings yet

- Bulletin - 47085 SalesDocument24 pagesBulletin - 47085 Sales83998399No ratings yet

- PVWJ Open Loop Pumps: Bulletin 47085Document24 pagesPVWJ Open Loop Pumps: Bulletin 47085CARLOS RAMIREZ100% (1)

- Brochure - Rigid Renold Page 40 PDFDocument76 pagesBrochure - Rigid Renold Page 40 PDFCarlos Gallardo LagosNo ratings yet

- 00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsDocument1 page00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsKaran AgrawalNo ratings yet

- Reliable Solutions For Continuous Casters BrochureDocument24 pagesReliable Solutions For Continuous Casters BrochureMario RossiNo ratings yet

- Performance Spectrum: Heart of HightechDocument5 pagesPerformance Spectrum: Heart of Hightecharun manchekarNo ratings yet

- OSepaseparator 1Document6 pagesOSepaseparator 1Slobodan StrainovićNo ratings yet

- Self-Study Program 951703 - 09D - TransmissionDocument79 pagesSelf-Study Program 951703 - 09D - TransmissionManuel GoncalvesNo ratings yet

- 31X - 33XN Gearbox Upgrade BrochureDocument3 pages31X - 33XN Gearbox Upgrade Brochuredhana adidhanuNo ratings yet

- 315GFBA - QSK19G DatashhetDocument5 pages315GFBA - QSK19G DatashhetedilbertoNo ratings yet

- HT VarleyGearPumps 4pages 2018 V2Document4 pagesHT VarleyGearPumps 4pages 2018 V2MvrbeckszNo ratings yet

- Cat 966GDocument2 pagesCat 966GCarlos Arturo AcevedoNo ratings yet

- 2463248Document12 pages2463248Dexter Hawkins100% (1)

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesLuis Guillermo BlandónNo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesSiddharth VNo ratings yet

- Audi 09D Transmission PDFDocument79 pagesAudi 09D Transmission PDFJOHNNY5377100% (4)

- Important Information: Section 1B - Maintenance For Sterndrive ModelsDocument50 pagesImportant Information: Section 1B - Maintenance For Sterndrive ModelsJason WilliamNo ratings yet

- NEMO-CPro 0313 ENDocument4 pagesNEMO-CPro 0313 ENrosario medinaNo ratings yet

- HVT R2 Hydromechanical Variable TransmissionDocument12 pagesHVT R2 Hydromechanical Variable TransmissionShubham JaruharNo ratings yet

- KEN 557 3620K 3630K InstructionsDocument4 pagesKEN 557 3620K 3630K InstructionsBM TRUCK ALIGNMENT MOBILE SERVICENo ratings yet

- Goulds 3171 / CV3171: Vertical Sump and Process PumpsDocument16 pagesGoulds 3171 / CV3171: Vertical Sump and Process PumpsJavier Fernando Agudelo GómezNo ratings yet

- Royal Enfield Bullet 1995 Owners ManualDocument109 pagesRoyal Enfield Bullet 1995 Owners ManualAndrea De SantisNo ratings yet

- Santorq ST Series Rev1Document5 pagesSantorq ST Series Rev1rupeshp1989No ratings yet

- Shell Tonna: Extra Separation From Coolants Standard ApplicationsDocument4 pagesShell Tonna: Extra Separation From Coolants Standard ApplicationsHUM CIREBON DFLTSNo ratings yet

- Comprehensive Engine Part Repair: The Eagle Is EverywhereDocument4 pagesComprehensive Engine Part Repair: The Eagle Is EverywhereAlejandroNo ratings yet

- 1540 PDFDocument6 pages1540 PDFOscar Fernando Guerrero RomeroNo ratings yet

- Transmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitDocument7 pagesTransmission Report: The Right Kit For The Rebuild Is A Genuine SONNAX KitAwan dwi cahyo100% (1)

- Automax Actuators & Accessories English PDFDocument18 pagesAutomax Actuators & Accessories English PDFSt. Labuhan MaringgaiNo ratings yet

- AHLSTAR™ Process Pumps: The Heart of Your ProcessDocument15 pagesAHLSTAR™ Process Pumps: The Heart of Your ProcessFerry AndriansyahNo ratings yet

- Robotarm II G-Series Pneumatic Hydraulic ActuatorsDocument8 pagesRobotarm II G-Series Pneumatic Hydraulic ActuatorsYuri Soverika SitepuNo ratings yet

- Railroad Engine Oil Brochure - 2012Document2 pagesRailroad Engine Oil Brochure - 2012Marcelo ViscardiNo ratings yet

- KTA 50 G3 1250 KVA Operation and Maintenance ProcedureDocument20 pagesKTA 50 G3 1250 KVA Operation and Maintenance ProcedureWaruna Pasan100% (1)

- Draglines Family BrochureDocument5 pagesDraglines Family Brochuresoulaimane BOUASRIANo ratings yet

- Mining Equipment Sealing SolutionsDocument5 pagesMining Equipment Sealing SolutionsSenthilKumar100% (1)

- Component ServiceDocument7 pagesComponent ServiceFahmi AliNo ratings yet

- D7 at PDFDocument4 pagesD7 at PDFStathis MoumousisNo ratings yet

- BR Cone RingDocument16 pagesBR Cone Ringricky pradanaNo ratings yet

- Engine Driven ProductsDocument24 pagesEngine Driven ProductsSomsak ChaonramNo ratings yet

- LH Omega Undercarriage For Electric Rope ShovelsDocument2 pagesLH Omega Undercarriage For Electric Rope ShovelsjacolienjvvuurenNo ratings yet

- Wind-Services Wikov en 1809 PDFDocument2 pagesWind-Services Wikov en 1809 PDFleosac6No ratings yet

- Direct Drive Brochure - US - 071218Document16 pagesDirect Drive Brochure - US - 071218johnnyNo ratings yet

- American Kuhne Life Cycle ManagementDocument4 pagesAmerican Kuhne Life Cycle ManagementNitin PatilNo ratings yet

- Molykote M Gear Oil AdditiveDocument3 pagesMolykote M Gear Oil AdditiveJuan Pablo Fernandez ZuñigaNo ratings yet

- Pipeline Booster Pump BrochureDocument16 pagesPipeline Booster Pump Brochurehermit44535No ratings yet

- QSV81G Data SheetsDocument6 pagesQSV81G Data SheetsSaban Sang Petualang Return100% (1)

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Repair Options: Cat 777D Off-Highway TruckDocument4 pagesRepair Options: Cat 777D Off-Highway TruckmkNo ratings yet

- KTA50 Series 50HzDocument4 pagesKTA50 Series 50HzBalamurugan ArumugamNo ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- Guidelines Current List Updated March 2019Document9 pagesGuidelines Current List Updated March 2019MehrdadNo ratings yet

- Cold Injuries and HypothermiaDocument34 pagesCold Injuries and HypothermiaRam Kirubakar ThangarajNo ratings yet

- FAI Free Flight Team Selection Process History NotebookDocument176 pagesFAI Free Flight Team Selection Process History NotebookRussell HartillNo ratings yet

- Technical Schedule 3Document16 pagesTechnical Schedule 3Prasenjit DeyNo ratings yet

- 2019-9-09 - Stella Maris - Lengua Extranjera (Inglés) - b2 Unit 3 CultureDocument2 pages2019-9-09 - Stella Maris - Lengua Extranjera (Inglés) - b2 Unit 3 CulturemncskillsNo ratings yet

- Lenntech: Engineering Drawing PacketDocument7 pagesLenntech: Engineering Drawing PacketjazaibNo ratings yet

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistAriq RaihanNo ratings yet

- Rom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicDocument14 pagesRom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicVu LeNo ratings yet

- QM in Curved SpacetimeDocument12 pagesQM in Curved SpacetimeSourasish KarmakarNo ratings yet

- wk06 IVDocument34 pageswk06 IVyingdong liuNo ratings yet

- Series & Parallel PumpsDocument48 pagesSeries & Parallel PumpsMoh AmmNo ratings yet

- GRILL StationDocument19 pagesGRILL Stationradwa.talaatNo ratings yet

- Agri Plas GreenhouseDocument6 pagesAgri Plas GreenhouseBendzGeronaNo ratings yet

- S 125Document317 pagesS 125ronaldosilva2100% (1)

- Bondship BookDocument252 pagesBondship Bookmehrdad_5233No ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- Section 5 - E&A Drawings PDFDocument1,288 pagesSection 5 - E&A Drawings PDFAndrii PodgornyiNo ratings yet

- Method Statement For Water Recticulation (16.12.04)Document8 pagesMethod Statement For Water Recticulation (16.12.04)mochacino6867% (6)

- Grade 9 Math Q1 M1Document12 pagesGrade 9 Math Q1 M1Renny Romero Luzada100% (2)

- Wastewater Characteristics: Table 7.1.5 Table 7.1.6Document4 pagesWastewater Characteristics: Table 7.1.5 Table 7.1.6Amin EnviroNo ratings yet

- Kuensel IssuesDocument12 pagesKuensel IssuesDeepen SharmaNo ratings yet

- Cross 1987 Catecholamines LympohcytesDocument7 pagesCross 1987 Catecholamines LympohcytesMartin BadovNo ratings yet

- Aip 2023 2 3Document29 pagesAip 2023 2 3menchiemanaloNo ratings yet

- List of en StandardsDocument21 pagesList of en StandardsKaranjaNo ratings yet

- Fracture CrurisDocument44 pagesFracture CrurisAnonymous turPUJtErNo ratings yet

- Cucumber Production GuideDocument4 pagesCucumber Production Guideeduard dugayNo ratings yet

- Blouse Body Measurement ChartDocument2 pagesBlouse Body Measurement ChartScarletBeauty Enriquez-DiagbelNo ratings yet

- Test 6Document33 pagesTest 6Балнур АмантайNo ratings yet