Professional Documents

Culture Documents

Business Marketing Project Report: November 2010

Business Marketing Project Report: November 2010

Uploaded by

Parsva SaikiaCopyright:

Available Formats

You might also like

- Top Glove Financial AssignmentDocument23 pagesTop Glove Financial Assignmentnigina2lips100% (1)

- Harvard Business Review on Rebuilding Your Business ModelFrom EverandHarvard Business Review on Rebuilding Your Business ModelRating: 4 out of 5 stars4/5 (8)

- Report On Akij GroupDocument36 pagesReport On Akij GroupMohammad Shaniaz Islam73% (22)

- Akij GroupDocument14 pagesAkij Groupi_sonet100% (2)

- Packages Internship ReportDocument75 pagesPackages Internship ReportHamza Hassan0% (2)

- Shopping and Small Value Procurement Requirements Checklist PDFDocument1 pageShopping and Small Value Procurement Requirements Checklist PDFNorman FloresNo ratings yet

- Final Term Paper On TK GroupDocument32 pagesFinal Term Paper On TK GroupSyed Salman RahmanNo ratings yet

- SrutiDocument11 pagesSrutisabbir194121No ratings yet

- University ReportDocument15 pagesUniversity ReportAhsan KhurramNo ratings yet

- Cats and DodsDocument42 pagesCats and DodsCA's HobbyNo ratings yet

- Cildro Plywood: Business Economics Business Administration FacultyDocument11 pagesCildro Plywood: Business Economics Business Administration FacultySilvia Cristina ButurcaNo ratings yet

- Pantaloon Mis AssignmentDocument17 pagesPantaloon Mis AssignmentSachinVJNo ratings yet

- Brand Awareness and Marketing Campaign For NilkamalDocument6 pagesBrand Awareness and Marketing Campaign For NilkamalEditor IJTSRDNo ratings yet

- Summer Internship Project Report Kajal BhaliyaDocument27 pagesSummer Internship Project Report Kajal Bhaliyakajal bhaliyaNo ratings yet

- Vishal Containers Pvt. Ltd.Document94 pagesVishal Containers Pvt. Ltd.patelhardik2420100% (1)

- SCM Lucky Textile MillsDocument17 pagesSCM Lucky Textile MillsBs-52 Reejab ImranNo ratings yet

- Group 9Document31 pagesGroup 9Nabeel MalikNo ratings yet

- Financial Analysis Project On Packages LimitedDocument26 pagesFinancial Analysis Project On Packages LimitedsobiaNo ratings yet

- HRM Research ReportDocument34 pagesHRM Research Reportsadmanthesis2024No ratings yet

- Brand Audit NestleDocument10 pagesBrand Audit NestleAqib tanoliNo ratings yet

- Internship Report PackagesDocument9 pagesInternship Report PackagesElina PashaNo ratings yet

- Project - Business Plan EntrepreneurshipDocument26 pagesProject - Business Plan EntrepreneurshipfizaAhaiderNo ratings yet

- Packages BIGDocument170 pagesPackages BIGShahid Iqbal GorayaNo ratings yet

- Management of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceDocument87 pagesManagement of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinancePrasad KushalappaNo ratings yet

- MBA Finance ProjectsDocument104 pagesMBA Finance ProjectsKusum Kusum0% (1)

- ID Name 1330265 1320789 1420656 1421259 1330668 1321464Document14 pagesID Name 1330265 1320789 1420656 1421259 1330668 1321464Yuuvraj SinghNo ratings yet

- NPD Business Cases - Group 1Document40 pagesNPD Business Cases - Group 1api-511839958No ratings yet

- Packages FinalDocument17 pagesPackages FinalAysha AhmedNo ratings yet

- Full Project On StressDocument63 pagesFull Project On Stresssrinivasan008No ratings yet

- Vignesh A IIP Report Final ReportDocument31 pagesVignesh A IIP Report Final ReportvigneshNo ratings yet

- Individual AssignmentDocument17 pagesIndividual AssignmentTom NgNo ratings yet

- Dhinesh Minor Project (Final)Document32 pagesDhinesh Minor Project (Final)kgopinath060201No ratings yet

- IoBM Final Internship ReportDocument13 pagesIoBM Final Internship ReportPrime ministerNo ratings yet

- Report On Industrial Visit: Hindusthan National Glass & Industries Limited RishraDocument11 pagesReport On Industrial Visit: Hindusthan National Glass & Industries Limited RishrabhubaneshwariNo ratings yet

- Individual Assignment: Technology Park Malaysia BM028-3-M-ENT EntrepreneurshipDocument18 pagesIndividual Assignment: Technology Park Malaysia BM028-3-M-ENT EntrepreneurshipShruti JaisNo ratings yet

- Ed Cia 3Document9 pagesEd Cia 3Sanchit MaitraNo ratings yet

- Term Project-Motivation at Work-MODDocument15 pagesTerm Project-Motivation at Work-MODLalit Kumar ThakwaniNo ratings yet

- ENG HelloFresh Non-Financial Report 2022Document34 pagesENG HelloFresh Non-Financial Report 2022deepanshusharma017No ratings yet

- Inb301 20017Document38 pagesInb301 20017Puja SahaNo ratings yet

- THE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDDocument45 pagesTHE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDHardik JaniNo ratings yet

- Laiqa Fabrics Ltd. Business PlanDocument14 pagesLaiqa Fabrics Ltd. Business PlanFayoma SignsNo ratings yet

- My AssignmentDocument17 pagesMy AssignmentHafiz AzamNo ratings yet

- PackagesDocument11 pagesPackagesfarooq_khan852000No ratings yet

- Management of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceDocument87 pagesManagement of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceRickson P Antony PulickalNo ratings yet

- Strategic Management: Authors: (B00185272)Document46 pagesStrategic Management: Authors: (B00185272)Sue SNo ratings yet

- Packraft Corrugate India Pvt. LTD Internship ReportDocument21 pagesPackraft Corrugate India Pvt. LTD Internship ReportSushant ChauhanNo ratings yet

- PackagingIndustryfinal Onicra Mar 14Document25 pagesPackagingIndustryfinal Onicra Mar 14Niraj ThiraniNo ratings yet

- WATEROMATIC Business Plan PDFDocument39 pagesWATEROMATIC Business Plan PDFJacob MillerNo ratings yet

- GM PPP Ss (Repaired)Document44 pagesGM PPP Ss (Repaired)Sachin KumarNo ratings yet

- Industrial Visit / HNG: Submitted By: Tamal Mishra PG/K/10/07Document10 pagesIndustrial Visit / HNG: Submitted By: Tamal Mishra PG/K/10/07Jaiprakash SainiNo ratings yet

- Packing SAS-211Document16 pagesPacking SAS-211Karen MartinNo ratings yet

- HRM410 - Research TopicDocument25 pagesHRM410 - Research TopicZulkarnain SeamNo ratings yet

- REPORT ON THE MARKET EXPANSION OF DPL CompanyDocument22 pagesREPORT ON THE MARKET EXPANSION OF DPL CompanyNipun Chanuka GunasekaraNo ratings yet

- OPM Case StudyDocument9 pagesOPM Case StudyFarukIslamNo ratings yet

- BPS Final Project ReportDocument10 pagesBPS Final Project ReportOsama khanNo ratings yet

- Advance Diploma in Marketing Management Intake VII: Subject: Case AnalysisDocument17 pagesAdvance Diploma in Marketing Management Intake VII: Subject: Case AnalysisVajira RohanNo ratings yet

- Intelligent M&A: Navigating the Mergers and Acquisitions MinefieldFrom EverandIntelligent M&A: Navigating the Mergers and Acquisitions MinefieldNo ratings yet

- The Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsFrom EverandThe Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsNo ratings yet

- Beyond Traditional Marketing: Innovations in Marketing PracticeFrom EverandBeyond Traditional Marketing: Innovations in Marketing PracticeNo ratings yet

- Contract Lift Terms and Conditions For Crane OperationDocument2 pagesContract Lift Terms and Conditions For Crane OperationegyinspectoryahooNo ratings yet

- CLSA and Olam ResearchDocument3 pagesCLSA and Olam ResearchCharles TayNo ratings yet

- The Effects of Human Resource Management Practices On Employees Motivation and Retention.Document11 pagesThe Effects of Human Resource Management Practices On Employees Motivation and Retention.nebuloasaNo ratings yet

- Ratio Analysis 3Document33 pagesRatio Analysis 3Mohd Zubair KhanNo ratings yet

- ECO101 Week10 Monopoly&MarketPowerDocument30 pagesECO101 Week10 Monopoly&MarketPowerShawn MaNo ratings yet

- Promotional StrategyDocument11 pagesPromotional StrategyDuhita ANo ratings yet

- Solved Consider A Differentiated Duopoly Market in Which Firms CompeteDocument5 pagesSolved Consider A Differentiated Duopoly Market in Which Firms CompeteMesso FrancisNo ratings yet

- Chapter 17 Labour Cost Accounting PDFDocument20 pagesChapter 17 Labour Cost Accounting PDFzahir202095% (19)

- Business Research MethodsDocument58 pagesBusiness Research MethodsusmanivNo ratings yet

- Softscape Executive Brief: Driving Growth Through Workforce Empowerment: The Business Case For Integrated HCM Human Capital ManagemeDocument5 pagesSoftscape Executive Brief: Driving Growth Through Workforce Empowerment: The Business Case For Integrated HCM Human Capital ManagemeChristopher FaustNo ratings yet

- ReportDocument21 pagesReportrpNo ratings yet

- SAP OverviewDocument34 pagesSAP Overviewนพ บีเคเค100% (1)

- Sop-Hr-02 - Time and AttendanceDocument6 pagesSop-Hr-02 - Time and Attendanceapi-27819317167% (3)

- Annual Appraisal Form PDFDocument1 pageAnnual Appraisal Form PDFChandra ShekarNo ratings yet

- BRC Food 6 Calculador Tempo AuditoriasDocument3 pagesBRC Food 6 Calculador Tempo AuditoriasAndré SantosNo ratings yet

- ThirdPartyRetrieveDocument AspDocument3 pagesThirdPartyRetrieveDocument Aspjgher14No ratings yet

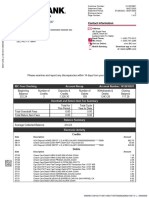

- Account Statement 20230530 20230629 110547Document3 pagesAccount Statement 20230530 20230629 110547DARANo ratings yet

- Case: 3 Question & AnswersDocument2 pagesCase: 3 Question & AnswersHamza ZainNo ratings yet

- LEA Associates (LASA) Is Urgently LookingDocument3 pagesLEA Associates (LASA) Is Urgently Lookingishfaq.hamidNo ratings yet

- Quiz Section 5 Cia Part 1 Governance, Risk Management, and ControlDocument15 pagesQuiz Section 5 Cia Part 1 Governance, Risk Management, and ControlMitch Minglana100% (1)

- Ten e 1344518576Document88 pagesTen e 1344518576vijayNo ratings yet

- Order in The Matter of Sai Prasad Properties LimitedDocument25 pagesOrder in The Matter of Sai Prasad Properties LimitedShyam SunderNo ratings yet

- Faktor-Faktor Yang Mempengaruhi Personal Auditor Independen Terhadap Perilaku Disfungsional AuditDocument10 pagesFaktor-Faktor Yang Mempengaruhi Personal Auditor Independen Terhadap Perilaku Disfungsional AuditAsty AstitiNo ratings yet

- Wa0007Document2 pagesWa0007sandhya.iyyanar1992No ratings yet

- 2017-2018 Rumseys Guide To Ib BM FinalDocument39 pages2017-2018 Rumseys Guide To Ib BM FinalChislin RazvanNo ratings yet

- Services and Customers: Promoting EducatingDocument28 pagesServices and Customers: Promoting EducatingneilbryanbolanoNo ratings yet

- ITSMNGT - Midterm ExaminationDocument5 pagesITSMNGT - Midterm ExaminationRommel L. DorinNo ratings yet

- Richport Company Manufactures Products That Often Require SpecifDocument1 pageRichport Company Manufactures Products That Often Require SpecifAmit PandeyNo ratings yet

- Pas 1,2,16Document17 pagesPas 1,2,16Cristopherson PerezNo ratings yet

Business Marketing Project Report: November 2010

Business Marketing Project Report: November 2010

Uploaded by

Parsva SaikiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Business Marketing Project Report: November 2010

Business Marketing Project Report: November 2010

Uploaded by

Parsva SaikiaCopyright:

Available Formats

November 2010

Section-A Group-2

Business Marketing Project Report

on Classic Packbox (India) Pvt.

Submitted to:

Dr. Vinod Kalia

By:

Amitesh Dayal 09P006

Parsva Saikia 09P040

Ruchira Khanna 09P050

Shailender Singh 09P053

Rinshul Pruthi 09P110

Benjamin Patte 10ESCP04

Contents

Acknowledgement.................................................................................................................................3

Executive Summary...............................................................................................................................4

About the Company...............................................................................................................................5

Introduction.......................................................................................................................................5

Existing Organization Structure.........................................................................................................5

Classic’s Existing business model...........................................................................................................6

The product.......................................................................................................................................6

The manufacturing Process...............................................................................................................7

Suppliers............................................................................................................................................8

Technological Developments Affecting Supply..............................................................................8

Buyers................................................................................................................................................8

The Competition................................................................................................................................8

Classic’s Quality Policy...........................................................................................................................9

Classic’s Sales Process...........................................................................................................................9

Acquiring a new customer.................................................................................................................9

Product Delivery Process...................................................................................................................9

Issues in the current business model of Classic Packbox.....................................................................11

Possible Strategies to meet current goals of Classic............................................................................12

BM Project Report: GROUP 2 Section-A

Acknowledgement

We take this opportunity to thank Prof. (Dr.) Vinod Kalia for providing incessant

knowledge on the subject. Without his guidance it would not have been possible for

us to do this piece of work on Business Marketing.

Group -2

Section-A

BM Project Report: GROUP 2 Section-A

Executive Summary

Classic Packbox (India) Private Limited is a small albeit up and coming firm in the corrugated

boxes space. The company has achieved reasonable success in North Indian markets. A

small company, the chain of command is simple and the organization on a whole is heavily

manufacturing-oriented. The company prides itself on its client relations and the clients in

turn are highly loyal. The management is cross –functional, taking up a part of the sales role

and the sales function itself is limited to order taking.

However, given the growth of the company and the low level of differentiation of the

product in a highly competitive market, the director has envisioned changes that have put

him at odds with the rest of the management. These changes include expanding into

geographically new markets and adoption of a departmentalized and process driven

approach to business.

The company is also experiencing typical growing pains – the managers are being forced to

focus more on the internal working of the company rather than personally calling on clients.

However the reins cannot yet be passed on to the inexperienced sales force. Also, every

member of the organization is on a fixed income which is proving to be ineffective for both

talent retention and employee motivation in a variable-pay world.

A fascinating phase in any organization’s growth, we have identified the current challenges,

potential pitfalls that the company might face as well as solutions of both a preventive and

curative nature.

BM Project Report: GROUP 2 Section-A

About the Company

Introduction

Classic Packbox is a regional manufacturer of all types of corrugated boxes. Founded in

1996, Classic Packbox has established itself as a highly trusted brand in its region of

operation. It offers quality products to some of the leading companies like Perfetti India

Ltd., Indonesian Foods Ltd., Becton Dickinson’s India Ltd. etc.

Classic Packbox is driving sustainable regional growth through high quality products and

services, leading technology and innovation, and manufacturing excellence to exceed

customer, shareholder and employee expectations.

The company has a complete plant and machinery with offset printing for manufacturing

quality corrugated boxes and also has complete laboratory for testing Kraft paper &

corrugated boxes. It has well trained staff and sufficient space for assuring timely delivery of

material to the customers. It is engaged in supply to the number of industries including

multinationals, 100% export oriented units and food processing unit.

They initially started operations by setting a plant in Palwal, Faridabad. Recently they have

established a new unit in the name of Uttrakhand Industrial Corporation at Rudrapur. The

company is also planning to set-up a plant in Chennai by 2011.

Existing Organization Structure

Classic Packbox is a relatively small organization when it comes to the B2B space, with total

employee strength of only 60. This is explained by the fact that they are established only at

two places (Palwal and Rudrapur) and also those they maintain a more personalised way of

business when dealing with their small base of customers.

At the head of their organization is the director. His subordinates comprise of three general

managers, who basically look after the whole sales process once the lead is generated by

one of the two sales executives. In addition, there are two accountants who look after the

accounts of Classic Packbox.

Almost 90% of their employees currently work on the shop floor as Classic Packbox, as 52 of

their 60 employees are manufacturing workers. This also highlights Classic Packbox’s focus

on quality, as majority of their workforce is centred towards production of quality

corrugated boxes.

BM Project Report: GROUP 2 Section-A

M

f

u

n

a

r

n

G

s

e

l

a

S t

c

a

r

u

l

e

g c

r

i

D

o

c

A

n

i o

t

u

n

g

n

a

M

ti

u

c

e

x

E

e

k

r

o

W r

e

s

v

s

r

1

(

r

)

s

t

n

a

3

)

2

(

)

2

5

(

)

2

(

Figure 1: The Classic Organization Structure

Classic’s Existing business model

The product

Corrugated boxes are designed to be very strong. They are made of corrugated paperboard,

which is different from the stiff paper known as “cardboard.” The edge of corrugated

paperboard consists of a row of air columns. The air acts as a cushion, while the paper

columns make the material strong. Each box is made to hold something just right, protect it

from banging around, and keep it from spilling. Boxes are made with important information

printed on them about what’s inside, or how to lift or move them. Carefully designed inserts

hold items in place so they won’t spill or become damaged.

The wavy paper inside the corrugated board is called the corrugating medium. The flat

sheets on the outside are called liners. Liner paperboard can be a natural brown color,

mottled white, or all white. Most is made with about 35 percent recycled fiber, but recycled

content can be up to 100 percent. There are standard sizes of ridges in the corrugated

medium. Some corrugated boards have small numbers of very large flutes; others have

higher numbers of very small flutes. The use of the box determines which flute style is best.

There are three types of boxes manufactured at Classic Packbox:

A single liner, glued to corrugating medium, creates single-face corrugated board.

This flexible material is sometimes used to cushion items such as light bulbs.

BM Project Report: GROUP 2 Section-A

Corrugating medium glued between two fl at liners forms a single wall corrugated

board. Most of the boxes we see every day are made of this material, and in fact

about 90 percent of corrugated board is single wall.

Adding another corrugating medium and a third flat liner creates a double wall

corrugated board. Stronger than the single wall board, it’s also heavier and more

expensive. Furniture, appliances and products such as nails, meat, and bulk peanuts

are packed in boxes made from double wall corrugated board.

Due to the advantages like light weight, case in fabrication and good preferability as per the

requirement of end users, the demand of corrugated boxes is encouraging. The demand for

corrugated boxes is growing mainly where there is scope for packing, like in FMCG industries

and processed product companies.

However, the product as a whole is very lowly differentiated from all of Classic Packbox’s

competitors. In fact, some of the competitors even make triple wall corrugated boxes.

Hence, given the product and its select set of variants given above, most of Classic Packbox’s

business relies on long-terms deals with a select set of trusted clients.

The manufacturing Process

The raw materials for corrugated boxes are linerboard (the flat facings), corrugating medium

(the wavy material separating the facings), and adhesive. These materials go through the

following steps to manufacture corrugated boxes:

The materials are combined on a machine called a corrugator to form a flat product

called combined board. The board is also cut on this machine to the desired size for a

specific box.

The cut combined board is called blanks, and next moves to a machine called a

Flexo-folder-gluer, where the blanks are printed, folded into a 4-sided tube, and the

vertical seam is applied. The product, known as a knocked-down box, is then shipped

to the customer for filling with a product.

Since boxes take up a lot of space, customers do not want to carry an inventory, and

insist upon just-in-time deliveries (often for next day use). Thus it is hard for a box

plant to plan more than 2 weeks ahead. Finished boxes are rarely inventoried at

Classic Packbox’s plants, and if so, in only small amounts.

For the manufacturing process, Classic Packbox’s plant normally carries 2-4 weeks of

inventory of containerboard.

BM Project Report: GROUP 2 Section-A

Suppliers

The suppliers for the Raw materials of corroborated packaging are mainly large and small

scale paper mills. Classic Packbox source most of their raw materials from such mills and

factories in the north zone. Their monthly purchase of Raw materials is around Rs. 50 lakhs,

which comprises mainly of 250 tonnes of Recycled paper.

Technological Developments Affecting Supply

Very few new paper machines have been built in the past 10 years, so almost all

companies use similar technology to manufacture.

Big differences exist within the industry with respect to productivity, operating costs,

and debt. The more efficient mills suffer less erosion of margin at the same market

price.

Classic Packbox believes they are more efficient compared to other companies (in

the nearby locations)

Buyers

The buyers of corrugated boxes are mainly the nearby factories of the clients mentioned in

the introduction, with who Classic Packbox has been in a relation for a long time. These

relationships have helped Classic Packbox increase their set of buyers to member factories

in the north zone, which has been the base for their success in this business so far.

The Competition

Since the product is so lowly differentiated, the competition is very high in the corrugated

boxes business. The main competition for Classic Packbox is:

Khemka Containers Ltd.

Perfect Pack Ltd.

BL Containers

Packraft Containers India Pvt. Ltd

A-One Packaging Co.

There are 7-8 companies manufacturing corrugated boxes in the north region, and each

company relies upon building long term relationships with their customers. Classic is one of

the most trusted companies in the region and has Perfetti India Ltd. and Indonesian Foods

Ltd. as the two of its biggest clients. Perfetti has its plant in Gurgaon and Rudrapur, which

are served by Classic’s plants in Palwal and Rudrapur. Indonesian Foods has its plants in

Rewadi and Bangalore. Classic’s boxes are delivered from Palwal to customer’s plant in

Rewadi.

Classic’s Quality Policy

BM Project Report: GROUP 2 Section-A

Classic’s value proposition is based on quality, wherein:

"Classic" is committed to total quality in all aspects of its operations to provide total

customer satisfaction.

Classic believes in continuous improvement of its processes and products through

“zero defects approach” for maximizing value for money for its customers.

Classic tries to make conscious efforts to do its work right at the first time itself,

every time.

Hence, Classic actually aims to manufacture and supply packing material for safe and

reliable packaging of the customers’ products by the use of good quality inputs and

working with the best of available production technology in a harmonious and

motivating atmosphere for its employees. It aims to make the delivery just in time, to

reduce the inventory costs for both.

Classic’s Sales Process

Acquiring a new customer

The Sales Executives approach the potential customer, with a catalogue containing

the company and product details and fix an appointment for meeting

This is followed by the General Manager meeting the client and negotiating on Price

Quotes/ Time of Delivery etc

If both parties agree on terms, Classic prepares a sample order

The customer accepts/ rejects/ suggest changes in the product, and after the final

acceptance, GM closes the deal with the customer

Product Delivery Process

Once the sales order has been procured, it is submitted to the production

department

Production Department manufactures and maintains job cards at various production

stages

Packing department then packs and the Dispatch department prepares invoice and

related documents pertaining to the sale

BM Project Report: GROUP 2 Section-A

Figure 2: The sales process - players involved

In this model, the role of the sales executive is pretty restricted – he basically functions as an

order taker only. Throughout the sales process, from the time the order is taken by the

Sales Executives to the final delivery of the order, the whole process is overseen by the

concerned general manager who fixes the contract with the client. The general manager,

leveraging his cross-functional ability, is able to not only understand the client organization

and its needs well, but is also able to customize his sales pitch based on the same in order

to try and get the best possible deal from the client, and at the same time develop and

enhance his relationships with the client. In fact, one of the main advantages of this sales

process is that the personalized touch brought over by the general manager dealing with

the client leads to:

Developing excellent relationship with the client

Classic feel that this sales model has helped them form a client base which has

remained loyal to them till now

However, this model is capable only in this case as Classic is dealing with a handful of client,

and hence, having GMs deal with each client end-to-end is possible.

BM Project Report: GROUP 2 Section-A

Issues in the current business model of Classic Packbox

1) A Single director is looking after Palwal and Rudrapur- and is now looking for

Chennai

a. Divided focus of mgmt.- leading to some dissatisfaction with clients

The organization is growing well and hence the director is keen on expanding

the business further. He is eyeing Chennai as the next market to cater to

given it potential sales; however this has not gone down well with the rest of

the management. Their reluctance arises from the fact that they have thus

far catered only to clients in North India markets and have a strong

understanding of this market. They are keen to continue to leverage this

rather than attempt to expand in unknown territory.

b. Customers are still with Classic because of their relationship with the

Director & also because they spent huge investments in time & money to

build this relationship & understanding

Managers in the organization had thus far played cross-functional roles.

While they were the overseers of the manufacturing process and other

functions within the company, they were also the one who approach clients

with their value proposition and once converted, worked on maintaining

relations by deeply understanding and fulfilling their needs. Now however

since the company is growing, the managers are finding that they are having

to dedicate more and more time towards the internal workings of the

company and are unable to create and sustain relations with the customers

like they used to.

2) Classic has no Business Development Managers, Key Acc. Managers etc. -

Therefore, the GMs handling everything- Business Dev., Day-to-Day

Manufacturing, Ensuring In time Delivery etc.

The only kinds of managers are General Managers – overseers with cross-

functional skills. Given that the company is expanding, managers will have to

be given specific roles such as Business Development Manager, Key Account

Managers etc. This however goes against the conventional wisdom of what is

essentially a conservative company.

BM Project Report: GROUP 2 Section-A

3) An Untrained Sales Force- Their only task is to ask the client about order size,

specific requirements and fix meeting with GMs

The sales executive role so far has been limited to order-taking. These

members simply make appointments between the General Managers and the

clients, and take down orders in terms of size and specification. Hence the

burden on creating orders lies with the managers. Given the growth of the

company, the challenge before the company now is to evolve the sales

function to incorporate order-getting in addition to order-taking.

4) Everyone is working on fixed income - no incentives for business growth

While the company is doing well, the growth of the company is not tied in

with the growth of the employees. Even for the managers, there is no

concept of either variable pay or incentive payouts. Possible problems with

this approach in the future include retention of talent and employee

motivation.

Possible Strategies to meet current goals of Classic

1) To meet the customer demand in most effective manner:

As there is a high competition in the business the company have to meet the

customer demand in most effective manner. For this they have to integrate

the various functions mainly the production unit with the sales and marketing

department. As a result of which the production department can easily assess

the demand and can schedule the production accordingly. This can help them

reducing the inventory cost and they can also avoid any delay in delivery.

Also with the integration sales people will be able to give better commitment

to the customers and hence will be able to improve the customer

relationship.

2) To increase the customer base because of cut throat competition:

The Company needs to provide its customer best products at best prices so

that it can attract more customers and can increase its customer base and

become the leading corrugated boxes manufacturer.

3) To reduce manufacturing and inventory cost so as to maximize the profit:

Since boxes take up a lot of space, customers do not want to carry an

inventory, and insist upon just-in-time deliveries (often for next day use). So

the company needs to have a proper inventory management system so that

BM Project Report: GROUP 2 Section-A

they can minimize the inventory level and hence inventory cost. They also

have to take care of the quality of the product so that they can minimize the

rework cost hence improving the overall productivity. They also have to

identify the expenses at each manufacturing process so as to increase the

productivity.

4) To provide the best quality corrugated boxes to the customer:

The Company needs to identify the sources of defects in the manufacturing

process so that they can improve the quality. They should also document

these causes of defects so that they are not repeated in future. Also SOPs and

maintenance guides for equipments can be maintained to avoid any

breakdown of the machine and insure smooth running production process.

5) To have highly motivated employees at workforce:

The employees can be motivated if they know about the various current

scenarios prevailing in the company along with current payrolls, incentives,

leave status etc. For this they can connect their employees through

information system so that the employees will be highly motivated to do

their work.

BM Project Report: GROUP 2 Section-A

BM Project Report: GROUP 2 Section-A

You might also like

- Top Glove Financial AssignmentDocument23 pagesTop Glove Financial Assignmentnigina2lips100% (1)

- Harvard Business Review on Rebuilding Your Business ModelFrom EverandHarvard Business Review on Rebuilding Your Business ModelRating: 4 out of 5 stars4/5 (8)

- Report On Akij GroupDocument36 pagesReport On Akij GroupMohammad Shaniaz Islam73% (22)

- Akij GroupDocument14 pagesAkij Groupi_sonet100% (2)

- Packages Internship ReportDocument75 pagesPackages Internship ReportHamza Hassan0% (2)

- Shopping and Small Value Procurement Requirements Checklist PDFDocument1 pageShopping and Small Value Procurement Requirements Checklist PDFNorman FloresNo ratings yet

- Final Term Paper On TK GroupDocument32 pagesFinal Term Paper On TK GroupSyed Salman RahmanNo ratings yet

- SrutiDocument11 pagesSrutisabbir194121No ratings yet

- University ReportDocument15 pagesUniversity ReportAhsan KhurramNo ratings yet

- Cats and DodsDocument42 pagesCats and DodsCA's HobbyNo ratings yet

- Cildro Plywood: Business Economics Business Administration FacultyDocument11 pagesCildro Plywood: Business Economics Business Administration FacultySilvia Cristina ButurcaNo ratings yet

- Pantaloon Mis AssignmentDocument17 pagesPantaloon Mis AssignmentSachinVJNo ratings yet

- Brand Awareness and Marketing Campaign For NilkamalDocument6 pagesBrand Awareness and Marketing Campaign For NilkamalEditor IJTSRDNo ratings yet

- Summer Internship Project Report Kajal BhaliyaDocument27 pagesSummer Internship Project Report Kajal Bhaliyakajal bhaliyaNo ratings yet

- Vishal Containers Pvt. Ltd.Document94 pagesVishal Containers Pvt. Ltd.patelhardik2420100% (1)

- SCM Lucky Textile MillsDocument17 pagesSCM Lucky Textile MillsBs-52 Reejab ImranNo ratings yet

- Group 9Document31 pagesGroup 9Nabeel MalikNo ratings yet

- Financial Analysis Project On Packages LimitedDocument26 pagesFinancial Analysis Project On Packages LimitedsobiaNo ratings yet

- HRM Research ReportDocument34 pagesHRM Research Reportsadmanthesis2024No ratings yet

- Brand Audit NestleDocument10 pagesBrand Audit NestleAqib tanoliNo ratings yet

- Internship Report PackagesDocument9 pagesInternship Report PackagesElina PashaNo ratings yet

- Project - Business Plan EntrepreneurshipDocument26 pagesProject - Business Plan EntrepreneurshipfizaAhaiderNo ratings yet

- Packages BIGDocument170 pagesPackages BIGShahid Iqbal GorayaNo ratings yet

- Management of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceDocument87 pagesManagement of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinancePrasad KushalappaNo ratings yet

- MBA Finance ProjectsDocument104 pagesMBA Finance ProjectsKusum Kusum0% (1)

- ID Name 1330265 1320789 1420656 1421259 1330668 1321464Document14 pagesID Name 1330265 1320789 1420656 1421259 1330668 1321464Yuuvraj SinghNo ratings yet

- NPD Business Cases - Group 1Document40 pagesNPD Business Cases - Group 1api-511839958No ratings yet

- Packages FinalDocument17 pagesPackages FinalAysha AhmedNo ratings yet

- Full Project On StressDocument63 pagesFull Project On Stresssrinivasan008No ratings yet

- Vignesh A IIP Report Final ReportDocument31 pagesVignesh A IIP Report Final ReportvigneshNo ratings yet

- Individual AssignmentDocument17 pagesIndividual AssignmentTom NgNo ratings yet

- Dhinesh Minor Project (Final)Document32 pagesDhinesh Minor Project (Final)kgopinath060201No ratings yet

- IoBM Final Internship ReportDocument13 pagesIoBM Final Internship ReportPrime ministerNo ratings yet

- Report On Industrial Visit: Hindusthan National Glass & Industries Limited RishraDocument11 pagesReport On Industrial Visit: Hindusthan National Glass & Industries Limited RishrabhubaneshwariNo ratings yet

- Individual Assignment: Technology Park Malaysia BM028-3-M-ENT EntrepreneurshipDocument18 pagesIndividual Assignment: Technology Park Malaysia BM028-3-M-ENT EntrepreneurshipShruti JaisNo ratings yet

- Ed Cia 3Document9 pagesEd Cia 3Sanchit MaitraNo ratings yet

- Term Project-Motivation at Work-MODDocument15 pagesTerm Project-Motivation at Work-MODLalit Kumar ThakwaniNo ratings yet

- ENG HelloFresh Non-Financial Report 2022Document34 pagesENG HelloFresh Non-Financial Report 2022deepanshusharma017No ratings yet

- Inb301 20017Document38 pagesInb301 20017Puja SahaNo ratings yet

- THE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDDocument45 pagesTHE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDHardik JaniNo ratings yet

- Laiqa Fabrics Ltd. Business PlanDocument14 pagesLaiqa Fabrics Ltd. Business PlanFayoma SignsNo ratings yet

- My AssignmentDocument17 pagesMy AssignmentHafiz AzamNo ratings yet

- PackagesDocument11 pagesPackagesfarooq_khan852000No ratings yet

- Management of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceDocument87 pagesManagement of Working Capital and Expense Analysis Pam Pac Machines Pvt. Ltd. by Neeta Wadhwani FinanceRickson P Antony PulickalNo ratings yet

- Strategic Management: Authors: (B00185272)Document46 pagesStrategic Management: Authors: (B00185272)Sue SNo ratings yet

- Packraft Corrugate India Pvt. LTD Internship ReportDocument21 pagesPackraft Corrugate India Pvt. LTD Internship ReportSushant ChauhanNo ratings yet

- PackagingIndustryfinal Onicra Mar 14Document25 pagesPackagingIndustryfinal Onicra Mar 14Niraj ThiraniNo ratings yet

- WATEROMATIC Business Plan PDFDocument39 pagesWATEROMATIC Business Plan PDFJacob MillerNo ratings yet

- GM PPP Ss (Repaired)Document44 pagesGM PPP Ss (Repaired)Sachin KumarNo ratings yet

- Industrial Visit / HNG: Submitted By: Tamal Mishra PG/K/10/07Document10 pagesIndustrial Visit / HNG: Submitted By: Tamal Mishra PG/K/10/07Jaiprakash SainiNo ratings yet

- Packing SAS-211Document16 pagesPacking SAS-211Karen MartinNo ratings yet

- HRM410 - Research TopicDocument25 pagesHRM410 - Research TopicZulkarnain SeamNo ratings yet

- REPORT ON THE MARKET EXPANSION OF DPL CompanyDocument22 pagesREPORT ON THE MARKET EXPANSION OF DPL CompanyNipun Chanuka GunasekaraNo ratings yet

- OPM Case StudyDocument9 pagesOPM Case StudyFarukIslamNo ratings yet

- BPS Final Project ReportDocument10 pagesBPS Final Project ReportOsama khanNo ratings yet

- Advance Diploma in Marketing Management Intake VII: Subject: Case AnalysisDocument17 pagesAdvance Diploma in Marketing Management Intake VII: Subject: Case AnalysisVajira RohanNo ratings yet

- Intelligent M&A: Navigating the Mergers and Acquisitions MinefieldFrom EverandIntelligent M&A: Navigating the Mergers and Acquisitions MinefieldNo ratings yet

- The Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsFrom EverandThe Food Industry Innovation School: How to Drive Innovation through Complex OrganizationsNo ratings yet

- Beyond Traditional Marketing: Innovations in Marketing PracticeFrom EverandBeyond Traditional Marketing: Innovations in Marketing PracticeNo ratings yet

- Contract Lift Terms and Conditions For Crane OperationDocument2 pagesContract Lift Terms and Conditions For Crane OperationegyinspectoryahooNo ratings yet

- CLSA and Olam ResearchDocument3 pagesCLSA and Olam ResearchCharles TayNo ratings yet

- The Effects of Human Resource Management Practices On Employees Motivation and Retention.Document11 pagesThe Effects of Human Resource Management Practices On Employees Motivation and Retention.nebuloasaNo ratings yet

- Ratio Analysis 3Document33 pagesRatio Analysis 3Mohd Zubair KhanNo ratings yet

- ECO101 Week10 Monopoly&MarketPowerDocument30 pagesECO101 Week10 Monopoly&MarketPowerShawn MaNo ratings yet

- Promotional StrategyDocument11 pagesPromotional StrategyDuhita ANo ratings yet

- Solved Consider A Differentiated Duopoly Market in Which Firms CompeteDocument5 pagesSolved Consider A Differentiated Duopoly Market in Which Firms CompeteMesso FrancisNo ratings yet

- Chapter 17 Labour Cost Accounting PDFDocument20 pagesChapter 17 Labour Cost Accounting PDFzahir202095% (19)

- Business Research MethodsDocument58 pagesBusiness Research MethodsusmanivNo ratings yet

- Softscape Executive Brief: Driving Growth Through Workforce Empowerment: The Business Case For Integrated HCM Human Capital ManagemeDocument5 pagesSoftscape Executive Brief: Driving Growth Through Workforce Empowerment: The Business Case For Integrated HCM Human Capital ManagemeChristopher FaustNo ratings yet

- ReportDocument21 pagesReportrpNo ratings yet

- SAP OverviewDocument34 pagesSAP Overviewนพ บีเคเค100% (1)

- Sop-Hr-02 - Time and AttendanceDocument6 pagesSop-Hr-02 - Time and Attendanceapi-27819317167% (3)

- Annual Appraisal Form PDFDocument1 pageAnnual Appraisal Form PDFChandra ShekarNo ratings yet

- BRC Food 6 Calculador Tempo AuditoriasDocument3 pagesBRC Food 6 Calculador Tempo AuditoriasAndré SantosNo ratings yet

- ThirdPartyRetrieveDocument AspDocument3 pagesThirdPartyRetrieveDocument Aspjgher14No ratings yet

- Account Statement 20230530 20230629 110547Document3 pagesAccount Statement 20230530 20230629 110547DARANo ratings yet

- Case: 3 Question & AnswersDocument2 pagesCase: 3 Question & AnswersHamza ZainNo ratings yet

- LEA Associates (LASA) Is Urgently LookingDocument3 pagesLEA Associates (LASA) Is Urgently Lookingishfaq.hamidNo ratings yet

- Quiz Section 5 Cia Part 1 Governance, Risk Management, and ControlDocument15 pagesQuiz Section 5 Cia Part 1 Governance, Risk Management, and ControlMitch Minglana100% (1)

- Ten e 1344518576Document88 pagesTen e 1344518576vijayNo ratings yet

- Order in The Matter of Sai Prasad Properties LimitedDocument25 pagesOrder in The Matter of Sai Prasad Properties LimitedShyam SunderNo ratings yet

- Faktor-Faktor Yang Mempengaruhi Personal Auditor Independen Terhadap Perilaku Disfungsional AuditDocument10 pagesFaktor-Faktor Yang Mempengaruhi Personal Auditor Independen Terhadap Perilaku Disfungsional AuditAsty AstitiNo ratings yet

- Wa0007Document2 pagesWa0007sandhya.iyyanar1992No ratings yet

- 2017-2018 Rumseys Guide To Ib BM FinalDocument39 pages2017-2018 Rumseys Guide To Ib BM FinalChislin RazvanNo ratings yet

- Services and Customers: Promoting EducatingDocument28 pagesServices and Customers: Promoting EducatingneilbryanbolanoNo ratings yet

- ITSMNGT - Midterm ExaminationDocument5 pagesITSMNGT - Midterm ExaminationRommel L. DorinNo ratings yet

- Richport Company Manufactures Products That Often Require SpecifDocument1 pageRichport Company Manufactures Products That Often Require SpecifAmit PandeyNo ratings yet

- Pas 1,2,16Document17 pagesPas 1,2,16Cristopherson PerezNo ratings yet