Professional Documents

Culture Documents

MCAT 001 Rev 0 (WLIMS) LR

MCAT 001 Rev 0 (WLIMS) LR

Uploaded by

Krishnadas GopalakrishnanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ZF CatalogueDocument379 pagesZF Cataloguedeisy ortega86% (7)

- Estrela de Montagem 9Document2 pagesEstrela de Montagem 9Celiocp PinheiroNo ratings yet

- Ebjbbgbfimiaigagiah: Malar DiagnosticsDocument1 pageEbjbbgbfimiaigagiah: Malar DiagnosticsKrishnadas GopalakrishnanNo ratings yet

- Personal Cyclone Preparedness and Safety Procedures by CCRWADocument2 pagesPersonal Cyclone Preparedness and Safety Procedures by CCRWAKrishnadas GopalakrishnanNo ratings yet

- Krishnadas 2008.0kcl 147.0g 184.0g 76.0g: Food Quantity Calories Protein Carbs Fats BreakfastDocument2 pagesKrishnadas 2008.0kcl 147.0g 184.0g 76.0g: Food Quantity Calories Protein Carbs Fats BreakfastKrishnadas GopalakrishnanNo ratings yet

- Safex Optionsand Greeks 101Document11 pagesSafex Optionsand Greeks 101Krishnadas GopalakrishnanNo ratings yet

- Title: AuthorsDocument14 pagesTitle: AuthorsKrishnadas GopalakrishnanNo ratings yet

- The Theoretical Partition Curve of The Hydrocyclone: Minerals Engineering July 2014Document7 pagesThe Theoretical Partition Curve of The Hydrocyclone: Minerals Engineering July 2014Krishnadas GopalakrishnanNo ratings yet

- 10 5923 J Clothing 20180501 01Document6 pages10 5923 J Clothing 20180501 01Krishnadas GopalakrishnanNo ratings yet

- Advanced Process Control For The Minerals Industry PDFDocument12 pagesAdvanced Process Control For The Minerals Industry PDFKrishnadas GopalakrishnanNo ratings yet

- Multotec Dmlib-#2735640-V1-Sales Quote 15000034 QN 00300 Multotec Process Equipment Cod Rev 1 2Document34 pagesMultotec Dmlib-#2735640-V1-Sales Quote 15000034 QN 00300 Multotec Process Equipment Cod Rev 1 2Krishnadas GopalakrishnanNo ratings yet

- Grind Size Vs FloatationDocument24 pagesGrind Size Vs FloatationKrishnadas GopalakrishnanNo ratings yet

- NF2201616844369 EticketDocument2 pagesNF2201616844369 EticketKrishnadas GopalakrishnanNo ratings yet

- Air Slide Working ManualDocument20 pagesAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- DS10 Umuk PDFDocument86 pagesDS10 Umuk PDFcucuNo ratings yet

- Ng8038 Valve Name Tag List (9 Mar 20)Document18 pagesNg8038 Valve Name Tag List (9 Mar 20)thova weeNo ratings yet

- Pioneer Plasma PDP-502MX - ARP3037Document78 pagesPioneer Plasma PDP-502MX - ARP3037littlem2aNo ratings yet

- Brochure Force SensorDocument7 pagesBrochure Force SensorGunjan TrivediNo ratings yet

- Ebara 3d SeriesDocument45 pagesEbara 3d SeriesqmqsNo ratings yet

- Power Supply: For The Budgie Album, SeeDocument9 pagesPower Supply: For The Budgie Album, SeeKecik ChelseaNo ratings yet

- Computer Hardware-Related AcronymsDocument3 pagesComputer Hardware-Related Acronymsghoul ciprianoNo ratings yet

- Original Instructions - Battery and ChargerDocument25 pagesOriginal Instructions - Battery and ChargerKiều Văn TrungNo ratings yet

- Reverse Indiglo Gauge Face Installation Instructions, Cont 4Document4 pagesReverse Indiglo Gauge Face Installation Instructions, Cont 4Hans OosthuizenNo ratings yet

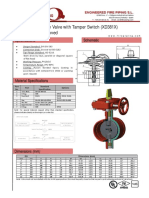

- Grooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedDocument1 pageGrooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedMohamed KhaldiNo ratings yet

- Front Axle: SectionDocument26 pagesFront Axle: Sectionfearimus1No ratings yet

- Catalog - H Hydraulic Setting ToolDocument1 pageCatalog - H Hydraulic Setting ToolCarlos Alberto Aguilera MendezNo ratings yet

- Doosan DX225LCA Excavator Error Codes PDFDocument3 pagesDoosan DX225LCA Excavator Error Codes PDFYasintra SirikulNo ratings yet

- 01 - IntroductionDocument74 pages01 - IntroductionchaddNo ratings yet

- EHS Common Mistakes BookletDocument32 pagesEHS Common Mistakes BookletpapisNo ratings yet

- Tableros de Distribución PZ4 SchneiderDocument220 pagesTableros de Distribución PZ4 SchneiderDarien PadillaNo ratings yet

- Installation ManualDocument90 pagesInstallation Manuallupin30000No ratings yet

- Go-Kart Designing ReportDocument56 pagesGo-Kart Designing ReportPraveen Sah84% (25)

- Procedure For Fiber Optic Cable Installation and TerminationDocument15 pagesProcedure For Fiber Optic Cable Installation and TerminationAdil IjazNo ratings yet

- Incremental: Heavy Duty HD 25Document4 pagesIncremental: Heavy Duty HD 25Matias de los Santos de la FuenteNo ratings yet

- MANUAL Sbm100whi 00 Dfu AenDocument10 pagesMANUAL Sbm100whi 00 Dfu AenMary Carmen Andreu MerinoNo ratings yet

- User's Manual: LED Portable Industrial Film ViewerDocument2 pagesUser's Manual: LED Portable Industrial Film ViewerMuhammed Abo-FandoodNo ratings yet

- PC Quanta ZN1 Rev B PDFDocument41 pagesPC Quanta ZN1 Rev B PDFserrano.flia.coNo ratings yet

- Servovalvula Buschjost 85370Document2 pagesServovalvula Buschjost 85370Base SistemasNo ratings yet

- FireDETEC - Installation Manual CO2 - DHP - en - 0213 eDocument12 pagesFireDETEC - Installation Manual CO2 - DHP - en - 0213 ebmxmmxNo ratings yet

- Catalogue Nxplus C enDocument72 pagesCatalogue Nxplus C enSheik HussainNo ratings yet

- 01 35 26-5 CLP-Lift Plan & Appendix For GFE 40 Container PlacementDocument12 pages01 35 26-5 CLP-Lift Plan & Appendix For GFE 40 Container PlacementVerde GriNo ratings yet

MCAT 001 Rev 0 (WLIMS) LR

MCAT 001 Rev 0 (WLIMS) LR

Uploaded by

Krishnadas GopalakrishnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCAT 001 Rev 0 (WLIMS) LR

MCAT 001 Rev 0 (WLIMS) LR

Uploaded by

Krishnadas GopalakrishnanCopyright:

Available Formats

Note: Should you require a size which is outside the standard range given above please contact us.

DESIGN FEATURES

OPERATIONAL THEORY

Application Tank Style Features

Separate tailings underflow and overflow

Counter

outlets. Underflow is controlled via valves.

Rotation

Heavy Maximizes Recovery.

Medium

Recovery Similar to counter-rotation but with single

and for Ore tailings outlet. Tank is self - leveling in

Concentration Opti-Flow design. Operational ease. Silting up issues

may be addressed by providing a tank

flushing system to the underside of the tank.

Counter Recommended for cleaner and finisher

Current application. No tailings control required.

Ore

Concentration

Underflow valves required. Drum rotates in

the same direction as the incoming feed

Concurrent

slurry. Recommended for coarser particle

sizes.

Type Features

Twin Orifice Plate Relatively easy to set, can become silted up if not maintained.

Counter Weight Orifice Inexpensive, easy to adjust and reset if oversize particles become entrapped.

Manually adjusted valve Easy to set, most expensive option.

Item Description Material

Ÿ Aluminium

End Flanges

Ÿ 304 Stainless Steel

Drum Shell Ÿ 3.0, 4.5 and 5.0mm St. St - special applications Ø915 & 1220

Ÿ 1.6mm St. St – Special applications

Wear Wraps

Ÿ 3.0mm St. St – Standard for all diameters.

Tanks/Launders/Safety Guards Ÿ 3.0, 4.5 and 5.0 mm 304 Stainless Steel

Support Frames Ÿ Mild Steel

Drive Options Special Features

Drum (vertical

adjustment scale)

Direct Drive

Tank Flushing

System

Inline Helical 90° Helical Bevel

SLURRY VOLUMES IN M3/H FOR HEAVY MEDIA APPLICATION

915 1220 1525 1830 2135 2440 2745 3050 3660

Ø915 mm FLOW

RATE IN M3/H

85 110 145 175 205 240 270 300 375

SLURRY VOLUMES IN M3/H FOR HEAVY MEDIA RECOVERY APPLICATION

915 1220 1525 1830 2135 2440 2745 3050 3660

Ø1220 mm FLOW

RATE IN M3/H 120 145 185 225 260 290 330 370 440

Volumetric flows for feed pulp containing 11% magnetic’s by weight. The above values are indicative. Please

consult Malvern Engineering for project specific performance.

SLURRY VOLUMES IN M3/H FOR ORE CONCENTRATION APPLICATION

Ø1220 mm

915 1220 1525 1830 2135 2440 2745 3050 3660

ROUGHER 125 170 210 250 300 340 380 425 500

CLEANER 75 100 124 155 170 200 225 250 300

SLURRY VOLUMES IN M3/H FOR ORE CONCENTRATION APPLICATION

Ø915 mm

915 1220 1525 1830 2135 2440 2745 3050 3660

ROUGHER 92 120 150 185 215 258 275 305 365

CLEANER 50 65 80 96 110 130 145 160 195

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ZF CatalogueDocument379 pagesZF Cataloguedeisy ortega86% (7)

- Estrela de Montagem 9Document2 pagesEstrela de Montagem 9Celiocp PinheiroNo ratings yet

- Ebjbbgbfimiaigagiah: Malar DiagnosticsDocument1 pageEbjbbgbfimiaigagiah: Malar DiagnosticsKrishnadas GopalakrishnanNo ratings yet

- Personal Cyclone Preparedness and Safety Procedures by CCRWADocument2 pagesPersonal Cyclone Preparedness and Safety Procedures by CCRWAKrishnadas GopalakrishnanNo ratings yet

- Krishnadas 2008.0kcl 147.0g 184.0g 76.0g: Food Quantity Calories Protein Carbs Fats BreakfastDocument2 pagesKrishnadas 2008.0kcl 147.0g 184.0g 76.0g: Food Quantity Calories Protein Carbs Fats BreakfastKrishnadas GopalakrishnanNo ratings yet

- Safex Optionsand Greeks 101Document11 pagesSafex Optionsand Greeks 101Krishnadas GopalakrishnanNo ratings yet

- Title: AuthorsDocument14 pagesTitle: AuthorsKrishnadas GopalakrishnanNo ratings yet

- The Theoretical Partition Curve of The Hydrocyclone: Minerals Engineering July 2014Document7 pagesThe Theoretical Partition Curve of The Hydrocyclone: Minerals Engineering July 2014Krishnadas GopalakrishnanNo ratings yet

- 10 5923 J Clothing 20180501 01Document6 pages10 5923 J Clothing 20180501 01Krishnadas GopalakrishnanNo ratings yet

- Advanced Process Control For The Minerals Industry PDFDocument12 pagesAdvanced Process Control For The Minerals Industry PDFKrishnadas GopalakrishnanNo ratings yet

- Multotec Dmlib-#2735640-V1-Sales Quote 15000034 QN 00300 Multotec Process Equipment Cod Rev 1 2Document34 pagesMultotec Dmlib-#2735640-V1-Sales Quote 15000034 QN 00300 Multotec Process Equipment Cod Rev 1 2Krishnadas GopalakrishnanNo ratings yet

- Grind Size Vs FloatationDocument24 pagesGrind Size Vs FloatationKrishnadas GopalakrishnanNo ratings yet

- NF2201616844369 EticketDocument2 pagesNF2201616844369 EticketKrishnadas GopalakrishnanNo ratings yet

- Air Slide Working ManualDocument20 pagesAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- DS10 Umuk PDFDocument86 pagesDS10 Umuk PDFcucuNo ratings yet

- Ng8038 Valve Name Tag List (9 Mar 20)Document18 pagesNg8038 Valve Name Tag List (9 Mar 20)thova weeNo ratings yet

- Pioneer Plasma PDP-502MX - ARP3037Document78 pagesPioneer Plasma PDP-502MX - ARP3037littlem2aNo ratings yet

- Brochure Force SensorDocument7 pagesBrochure Force SensorGunjan TrivediNo ratings yet

- Ebara 3d SeriesDocument45 pagesEbara 3d SeriesqmqsNo ratings yet

- Power Supply: For The Budgie Album, SeeDocument9 pagesPower Supply: For The Budgie Album, SeeKecik ChelseaNo ratings yet

- Computer Hardware-Related AcronymsDocument3 pagesComputer Hardware-Related Acronymsghoul ciprianoNo ratings yet

- Original Instructions - Battery and ChargerDocument25 pagesOriginal Instructions - Battery and ChargerKiều Văn TrungNo ratings yet

- Reverse Indiglo Gauge Face Installation Instructions, Cont 4Document4 pagesReverse Indiglo Gauge Face Installation Instructions, Cont 4Hans OosthuizenNo ratings yet

- Grooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedDocument1 pageGrooved Butterfly Valve With Tamper Switch (Xd381X) Ul/Fm/Vds ApprovedMohamed KhaldiNo ratings yet

- Front Axle: SectionDocument26 pagesFront Axle: Sectionfearimus1No ratings yet

- Catalog - H Hydraulic Setting ToolDocument1 pageCatalog - H Hydraulic Setting ToolCarlos Alberto Aguilera MendezNo ratings yet

- Doosan DX225LCA Excavator Error Codes PDFDocument3 pagesDoosan DX225LCA Excavator Error Codes PDFYasintra SirikulNo ratings yet

- 01 - IntroductionDocument74 pages01 - IntroductionchaddNo ratings yet

- EHS Common Mistakes BookletDocument32 pagesEHS Common Mistakes BookletpapisNo ratings yet

- Tableros de Distribución PZ4 SchneiderDocument220 pagesTableros de Distribución PZ4 SchneiderDarien PadillaNo ratings yet

- Installation ManualDocument90 pagesInstallation Manuallupin30000No ratings yet

- Go-Kart Designing ReportDocument56 pagesGo-Kart Designing ReportPraveen Sah84% (25)

- Procedure For Fiber Optic Cable Installation and TerminationDocument15 pagesProcedure For Fiber Optic Cable Installation and TerminationAdil IjazNo ratings yet

- Incremental: Heavy Duty HD 25Document4 pagesIncremental: Heavy Duty HD 25Matias de los Santos de la FuenteNo ratings yet

- MANUAL Sbm100whi 00 Dfu AenDocument10 pagesMANUAL Sbm100whi 00 Dfu AenMary Carmen Andreu MerinoNo ratings yet

- User's Manual: LED Portable Industrial Film ViewerDocument2 pagesUser's Manual: LED Portable Industrial Film ViewerMuhammed Abo-FandoodNo ratings yet

- PC Quanta ZN1 Rev B PDFDocument41 pagesPC Quanta ZN1 Rev B PDFserrano.flia.coNo ratings yet

- Servovalvula Buschjost 85370Document2 pagesServovalvula Buschjost 85370Base SistemasNo ratings yet

- FireDETEC - Installation Manual CO2 - DHP - en - 0213 eDocument12 pagesFireDETEC - Installation Manual CO2 - DHP - en - 0213 ebmxmmxNo ratings yet

- Catalogue Nxplus C enDocument72 pagesCatalogue Nxplus C enSheik HussainNo ratings yet

- 01 35 26-5 CLP-Lift Plan & Appendix For GFE 40 Container PlacementDocument12 pages01 35 26-5 CLP-Lift Plan & Appendix For GFE 40 Container PlacementVerde GriNo ratings yet