Professional Documents

Culture Documents

Brother Bas-311h Leaflet PDF

Brother Bas-311h Leaflet PDF

Uploaded by

Ashraaf aushiCopyright:

Available Formats

You might also like

- Fintech Fundamentals Big Data Cloud Computing Digital Economy (Len Mei, PH.D.)Document239 pagesFintech Fundamentals Big Data Cloud Computing Digital Economy (Len Mei, PH.D.)albert AungNo ratings yet

- Activity 3Document11 pagesActivity 3EFFranciscoNo ratings yet

- BAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmDocument2 pagesBAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmAshraaf aushiNo ratings yet

- Buttonholing Machine Juki Lbh1790anDocument4 pagesButtonholing Machine Juki Lbh1790anSayantan RahaNo ratings yet

- FLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Document4 pagesFLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Sayantan RahaNo ratings yet

- L K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To OperatorsDocument4 pagesL K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To Operatorsdharmik borisagarNo ratings yet

- Supreme SP-3020ASDocument2 pagesSupreme SP-3020ASAlexandruNo ratings yet

- MO-6900S SeriesDocument8 pagesMO-6900S Seriesvijay maharNo ratings yet

- Asn 690Document2 pagesAsn 690fikriimam1No ratings yet

- Abin Cablel Drag Chains: NSB028NDocument1 pageAbin Cablel Drag Chains: NSB028NNageswar MakalaNo ratings yet

- 570 590 LeafletDocument12 pages570 590 LeafletfgfgfgNo ratings yet

- Meb 3200 PDFDocument6 pagesMeb 3200 PDFWajid WajidNo ratings yet

- Mo 6700 DaDocument2 pagesMo 6700 DafatagiuNo ratings yet

- 105-Dynapac F181CDocument1 page105-Dynapac F181CAliNo ratings yet

- Installation Procedure, Electronic Vessel Control, Gas and D3 EVC - BDocument1 pageInstallation Procedure, Electronic Vessel Control, Gas and D3 EVC - BRaul JosingNo ratings yet

- LH-4500C SeriesDocument4 pagesLH-4500C SeriesZaid StoreNo ratings yet

- Standard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGDocument2 pagesStandard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGjackson.santosgreentechNo ratings yet

- MO-6800S SeriesDocument2 pagesMO-6800S SeriesDanielNo ratings yet

- MB 1370Document4 pagesMB 1370azizNo ratings yet

- JUKI's Industrial Sewing MachinesDocument4 pagesJUKI's Industrial Sewing MachinesfilisavicNo ratings yet

- LU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeDocument2 pagesLU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeRaitziel KlossNo ratings yet

- Brother S6200A CatalogDocument2 pagesBrother S6200A CatalogSir LuoNo ratings yet

- PRO-76T: Multifunctional Drilling & Tapping MachineDocument4 pagesPRO-76T: Multifunctional Drilling & Tapping MachineBouraoui Ben AyedNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our DrillingrU sNo ratings yet

- Juki Series C Mo6900cDocument2 pagesJuki Series C Mo6900cKabir MahlotraNo ratings yet

- KM-T20 CatalogDocument1 pageKM-T20 CatalogJackson SilvaNo ratings yet

- Brushing Sueding MachineDocument4 pagesBrushing Sueding MachineZheejae Lao-atenNo ratings yet

- Brushing Sueding MachineDocument4 pagesBrushing Sueding MachineMazharul IslamNo ratings yet

- Apw 895 NeDocument2 pagesApw 895 NeCarlos Paul TorresNo ratings yet

- Sainte Lizaigne e Cub sl003 enDocument4 pagesSainte Lizaigne e Cub sl003 enPartene PaulaNo ratings yet

- MO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsDocument2 pagesMO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsShafikul IslamNo ratings yet

- Cc4ii8 en VSDocument1 pageCc4ii8 en VSEngineer WaleedNo ratings yet

- Standard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250Document2 pagesStandard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250jackson.santosgreentechNo ratings yet

- Wire StripperDocument2 pagesWire StripperMim MamNo ratings yet

- Q.Peak Duo Xl-G11.3: Enduring High PerformanceDocument2 pagesQ.Peak Duo Xl-G11.3: Enduring High PerformanceSánchez Condado JesúsNo ratings yet

- Laser G2: Storage Feeder: Perfection in Yarn ControlDocument2 pagesLaser G2: Storage Feeder: Perfection in Yarn ControlcobaNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingrandy yupanqui100% (1)

- Pneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationDocument4 pagesPneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationBe HappyNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingyo2k_123No ratings yet

- DDL 5600 NDocument2 pagesDDL 5600 NJesús Sánchez CarriónNo ratings yet

- LDS - Permanent - Magnet - Shakers - Brochure - LR 2Document3 pagesLDS - Permanent - Magnet - Shakers - Brochure - LR 2snowflakefiat121No ratings yet

- Screw Conveyor CalculationDocument1 pageScrew Conveyor Calculationmanoj983@gmail.comNo ratings yet

- BASS2565 ProspektEngDocument2 pagesBASS2565 ProspektEngSaùl Torres GarcìaNo ratings yet

- Topcon Brochure ALE-5100 Series en PDFDocument4 pagesTopcon Brochure ALE-5100 Series en PDFAndrii Horban100% (1)

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Prep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDDocument5 pagesPrep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDJorgeNo ratings yet

- ASK ASM200-20230614pdfDocument2 pagesASK ASM200-20230614pdfdroessaert_stijnNo ratings yet

- Leno 4: Circular LoomDocument4 pagesLeno 4: Circular Loomss_abbu0% (1)

- LH-3500A Series: Adoption of The Direct-Drive Mechanism Promises Energy-Saving and Increased WorkabilityDocument4 pagesLH-3500A Series: Adoption of The Direct-Drive Mechanism Promises Energy-Saving and Increased WorkabilityfatagiuNo ratings yet

- High and Long Arm Sewing Machine With Automatic Thread TrimmerDocument2 pagesHigh and Long Arm Sewing Machine With Automatic Thread TrimmerSheikh RizwanNo ratings yet

- Brother LH4-B814-4 Instruction ManualDocument35 pagesBrother LH4-B814-4 Instruction ManualJuple My IguanaNo ratings yet

- Tapping Machine Mar 2021Document6 pagesTapping Machine Mar 2021Remmy Torres VegaNo ratings yet

- PDF 1440580617Document1 pagePDF 1440580617skf urbanoNo ratings yet

- BT430Q-438Q-530Q-630Q_A4DM_20220610_sDocument2 pagesBT430Q-438Q-530Q-630Q_A4DM_20220610_sNathalia ChaconNo ratings yet

- Nb1433pssm Et MDDocument1 pageNb1433pssm Et MDDavid SanchesNo ratings yet

- Catalogue HACINT MEGAINDUS 2023 Fully Automatic MachineDocument31 pagesCatalogue HACINT MEGAINDUS 2023 Fully Automatic MachineNabil daiouneNo ratings yet

- Boschert: CNC Busbar Cutting - Punching - Bending SolutionDocument42 pagesBoschert: CNC Busbar Cutting - Punching - Bending SolutiondemdiinNo ratings yet

- 2agujas PDFDocument4 pages2agujas PDFMeneses Chino ChinoNo ratings yet

- Louvretec Design Manual Section 7 300mm AirfoilDocument10 pagesLouvretec Design Manual Section 7 300mm AirfoiljoseocsilvaNo ratings yet

- KM 857Document2 pagesKM 857Juan Carlos Soriano GiménezNo ratings yet

- MO-6900G MO-6900J: Series SeriesDocument4 pagesMO-6900G MO-6900J: Series SeriescrisplasticoNo ratings yet

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterRating: 4 out of 5 stars4/5 (3)

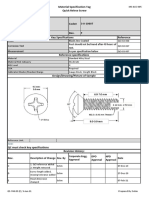

- MS-ACC-007 (D) M3X6mm Long Trust Head Screw, FKB, CinchingDocument1 pageMS-ACC-007 (D) M3X6mm Long Trust Head Screw, FKB, CinchingAshraaf aushiNo ratings yet

- MS-ACC-009 (D) Gear Metric Lower, Cinching SystemDocument2 pagesMS-ACC-009 (D) Gear Metric Lower, Cinching SystemAshraaf aushiNo ratings yet

- MS-ACC-006 (C) Wing ScrewDocument1 pageMS-ACC-006 (C) Wing ScrewAshraaf aushiNo ratings yet

- MS-ACC-005 (F) Quick Relese ScrewDocument2 pagesMS-ACC-005 (F) Quick Relese ScrewAshraaf aushiNo ratings yet

- MS-ACC-008 (D) Slotted Shaft, Cinching SystemDocument2 pagesMS-ACC-008 (D) Slotted Shaft, Cinching SystemAshraaf aushiNo ratings yet

- MS-PAC-019 (G) Non Permeable (NP) PolybagDocument3 pagesMS-PAC-019 (G) Non Permeable (NP) PolybagAshraaf aushiNo ratings yet

- 144 Tev Tex 02 052Document1 page144 Tev Tex 02 052Ashraaf aushiNo ratings yet

- TR-22006-L-Mtl - Hot Melt Adhesive From NanpaoDocument2 pagesTR-22006-L-Mtl - Hot Melt Adhesive From NanpaoAshraaf aushiNo ratings yet

- TR-22001-I-Mtl Testing of Indian Velcro Hook-Loop-ExistingDocument3 pagesTR-22001-I-Mtl Testing of Indian Velcro Hook-Loop-ExistingAshraaf aushiNo ratings yet

- Shenzhen Minghui Antibacterial Technology Co.,Ltd: Material Safety Data SheetDocument4 pagesShenzhen Minghui Antibacterial Technology Co.,Ltd: Material Safety Data SheetAshraaf aushiNo ratings yet

- BAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmDocument2 pagesBAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmAshraaf aushiNo ratings yet

- Welcome TO MY PresentationDocument37 pagesWelcome TO MY PresentationAshraaf aushiNo ratings yet

- Master Project Tracker1.4Document53 pagesMaster Project Tracker1.4Ashraaf aushiNo ratings yet

- Geographic Information SystemDocument17 pagesGeographic Information Systemupayarakhmat6711No ratings yet

- Customer Segmentation Using Unsupervised Learning On Daily Energy Load ProfilesDocument7 pagesCustomer Segmentation Using Unsupervised Learning On Daily Energy Load ProfilesPablo OrricoNo ratings yet

- Lec-3 Layer OSI ModelDocument34 pagesLec-3 Layer OSI ModelDivya GuptaNo ratings yet

- Electrical Test Data ClassSubClassMakeMOCParameterTemplate PVTDocument10 pagesElectrical Test Data ClassSubClassMakeMOCParameterTemplate PVTOmkarNo ratings yet

- HBL Payments - User Manual For Payment V1Document32 pagesHBL Payments - User Manual For Payment V1Nasir R AyubNo ratings yet

- Oracle Server X8-2 X8-2L Technical Introduction AssessmentDocument5 pagesOracle Server X8-2 X8-2L Technical Introduction AssessmentAl MamunNo ratings yet

- Sketchchair: Greg Saul JST Erator Design Ui GroupDocument7 pagesSketchchair: Greg Saul JST Erator Design Ui GroupGuaka WoodNo ratings yet

- Digital Video ProcessingDocument19 pagesDigital Video ProcessingArjun Hande0% (1)

- Kernel Context Recommender System PDFDocument19 pagesKernel Context Recommender System PDFSri Lalitha MunukutlaNo ratings yet

- Lean Canvas - SWI Nazier AriffinDocument71 pagesLean Canvas - SWI Nazier AriffinNoeNo ratings yet

- Ibm Module 1 HW Acquisition InstallationDocument3 pagesIbm Module 1 HW Acquisition Installationmana45No ratings yet

- A Step-By-Step Identification Method For Non-Intrusive Loads Based On Fused Features - RemovedDocument20 pagesA Step-By-Step Identification Method For Non-Intrusive Loads Based On Fused Features - RemovedricardomedinavNo ratings yet

- Working With The Class System in Python Chapter4Document29 pagesWorking With The Class System in Python Chapter4FgpeqwNo ratings yet

- Oxhorn's Settlement Happiness CalculatorDocument1 pageOxhorn's Settlement Happiness CalculatorMuhammad IlmiNo ratings yet

- Data Warehousing: Version 6.0 - 04/18/2000Document60 pagesData Warehousing: Version 6.0 - 04/18/2000udaya_ms52No ratings yet

- SAFe Implementation Roadmap 6.0 Partner 11.7x8.5Document1 pageSAFe Implementation Roadmap 6.0 Partner 11.7x8.5deartoreadbookNo ratings yet

- 3 PDFDocument1 page3 PDFaritw541214No ratings yet

- Uplift Modeling: A Quick Introduction: Learn How Uplift Modeling Can Improve Classic Data Science ApplicationsDocument1 pageUplift Modeling: A Quick Introduction: Learn How Uplift Modeling Can Improve Classic Data Science ApplicationsFares HasnaouiNo ratings yet

- T6990 Depliant ENG PDFDocument2 pagesT6990 Depliant ENG PDFForTestNo ratings yet

- What Is Big DataDocument3 pagesWhat Is Big DataBalkaran singhNo ratings yet

- College of Computer Studies: 454 Rizal Ave Ext Cor 9th Ave, Grace Park, CaloocanDocument6 pagesCollege of Computer Studies: 454 Rizal Ave Ext Cor 9th Ave, Grace Park, Caloocanann camile maupayNo ratings yet

- Chinese Wall Security Model Buzulan and TeleghinDocument13 pagesChinese Wall Security Model Buzulan and TeleghinLoryQa LoryNo ratings yet

- Student Information Management SystemDocument11 pagesStudent Information Management SystemKashif RasheedNo ratings yet

- iVMS-4200-Client-Software Datasheet V3.11.0 20240126Document9 pagesiVMS-4200-Client-Software Datasheet V3.11.0 20240126Yasmin SunartaNo ratings yet

- g6 Os Installation GuideDocument7 pagesg6 Os Installation GuideRK shuklaNo ratings yet

- Performances of Computer Systems: CSE 675.02: Introduction To Computer ArchitectureDocument52 pagesPerformances of Computer Systems: CSE 675.02: Introduction To Computer ArchitectureshubhamNo ratings yet

- El Mercado NBA 2020-2021, Al Día - Noticias, Rumores, Traspasos, Fichajes y Más - NBA - Com España - El Sitio Oficial de La NBADocument194 pagesEl Mercado NBA 2020-2021, Al Día - Noticias, Rumores, Traspasos, Fichajes y Más - NBA - Com España - El Sitio Oficial de La NBAPsychic PrinceNo ratings yet

- Final Report On Face RecognitionDocument22 pagesFinal Report On Face RecognitionSubhash Kumar67% (6)

Brother Bas-311h Leaflet PDF

Brother Bas-311h Leaflet PDF

Uploaded by

Ashraaf aushiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brother Bas-311h Leaflet PDF

Brother Bas-311h Leaflet PDF

Uploaded by

Ashraaf aushiCopyright:

Available Formats

Specifications/ Application

3 Medium-weight materials Work clamp

BAS-311H-0

5 Heavy-weight materials S Motor-driven work clamp

7 Seatbelt A Pneumatic work clamp

BAS-311H

BAS-311H

Stitch formation Single needle lock stitch

Max. sewing speed 2,800 sti/min*1

Sewing area (X-Y) 150mm×100mm 150mm x 100mm

Feed mechanism Intermittent feed,pulse motor drive

Stitch length 0.05 12.7mm Direct Drive Programmable electronic pattern sewer with cylinder bed

2

No. of stitches 500,000-stitch internal memory*

Max. no. of stitches 20,000 stitches (per program)

With the world’s top-class sewing speed, this machine provides high and stable sewing quality while

Motor-driven work clamp specifications: Pulse motor drive method

achieving energy savings. The enlarged sewing area enables for a wide range of materials and applications.

Work clamp lift method

Pneumatic work clamp specifications: Pneumatic method -High and stable sewing quality

Motor-driven work clamp specifications: Max.25mm -Enlarged sewing area to 150mmx100mm

Work clamp height

Pneumatic work clamp specifications: Max. 30mm

-High productivity with max. sewing speed of 2,800sti/min

Motor-driven work clamp specifications: Integrated-type work clamp

2-step work clamp

Pneumatic work clamp specifications: Separate-type work clamp -User-friendly operation panel

Intermittent presser foot lift amount 22mm -Environment-conscious

Intermittent stroke 2 4.5mm, 4.5 10mm or 0 (Default setting: 3mm)

Hook Double-capacity shuttle hook (Standard shuttle hook : Option)

Wiper device Standard equipment

Thread trimmer Standard equipment

Data storage media Internal memory(Flash memory), SD card*3

Motor AC servo motor 550W

Weight Machine head: Approx. 88kg, Operation panel: Approx.0.4kg, Control box: Approx. 9kg(Differs depending on destination)

Single phase 100V/220V, 3-phase 200V/220V/380V400V 400VA

Power supply

(For single-phase 100V and 3-phase 380V/400V, the trans box is required.)

Air pressure/consumption 0.5Mpa 1.8 l/min

Optional parts/ •Needle cooler *4 <SA5559101>

•Thread wiper set (Pneumatic type) *4 <SA5575101>

•Inner clamp device *4 <SA7189101>

•Thread breakage detector <SA5193101>

•Triple pedal foot switch <SA6495101>

Peripheral equipment/ •Sewing data programming software PS-300B

*1 When sewing at a sewing speed of 2,800 sti/min, set the stitch length to 4mm and under.

*2 The number of data items and stitches that can be stored will vary depending on the number of stitches in each program.

*3 No guarantees of operation can be given for any media.

*4 This device requires the optional solenoid valve set.

Boosting absolute reliability and brand recognition in the market,

the BAS-300G and BAS-311G have taken the industry lead in this market.

RoHS

BAS-311H is compliant with the RoHS Directive(the Brother has established voluntary environmental standards

With the world‘s top-class sewing speed and enlarged sewing area, restriction of the use of certain hazardous for products and created the “Brother Green Label”.

Compliant substances in electrical and electronic equipment)

which came into effect in the EU in July 2006.

BAS-311H is certified as an environment-conscious sewing

machine according to the “Brother Green Label” standard.

they became more attractive as a new model BAS-311H. Please read instruction manual before using the machine for safety operation.

-Product specifications are subject to change for improvement without notice.

-Photographs are for illustration purpose. They may not represent actual operating conditions and may display optional parts.

CHINA http://www.brother.cn/ +86-21-3135-3355

HONG KONG http://www.brother.com.hk/ +852-3589-9040

ASIA http://www.brother.com.sg/ +65-6536-8891

EUROPE AFRICA, MIDDLE EAST http://www.brother-ism.com/ +49-2822-6090

AMERICAS http://www.brother-usa.com/ +1-908-704-1700

1-5, Kitajizoyama, Noda-cho, Kariya-shi, Aichi 448-0803, Japan.

Phone: 81-566-95-0088 Fax: 81-566-25-3721 http://www.brother.com/ 2013.9 I3091008B Vol.1

Flexibility & Accuracy

Flexibility & Accuracy

With the world’s top-class sewing speed, this machine provides high and stable sewing quality while

achieving energy savings. The enlarged sewing area enables for a wide range of materials and applications.

3

With the World’s Top-class Sewing Speed of 2,800sti/min,

1 High Quality Sewing Can Be Produced.

The operation panel is designed to be user-friendly

Achieving High Productivity Beautiful and High Sewing and to improve the ease of operation.

With the adoption of a Quality

Brother-developed direct drive motor, With its accurate stitch point even at

the BAS-311H achieved the world’s high speed, the BAS-311H provides

top-class sewing speed of high quality stitching exactly the way

2,800sti/min. This enhances it is programmed. The high-rigid feed

productivity with quick starting and mechanism realizes high-precision 2 1

stopping. and stable stitching even with high

*When sewing at a sewing speed of 2,800sti/min, set the stitch

speed or weighty material sewing. 9

length to 4mm and under.

Sewing sample 4 5 6

7

2 Sewing Area is Enlarged to 150mmx100mm

8

The sewing area is enlarged 20mm in X direction(width),

compared to the previous model BAS-311G. It enhances

automation from a lock stitch process for wide range of 150mm 100mm

materials and applications.

Sewing area 10

Digital tension is an option.

3 High Energy Saving 5 Uniform and stable thread tightness 7 Easy and Accurate Positioning of Materials 9 Simple and Easy Sewing Pattern Change

Application Examples Easy Sewing Data Creation

The power consumption has

been reduced at 13% less than (wh)

Comparison of power consumption It realized stable thread tightening at low tension sewing and enlarged

the range of balanced thread tensions. Setting of the suitable height of

You can select a desired work clamp

lowering operation from three patterns

Work Clamp Can Be Replaced

Quickly and Accurately

with Programmer PD-3000A

the previous model BAS-311G, 13% the presser foot for the thickness of the material can be set on the by changing memory switch settings

Reduction Simply by loosening the two screws, the Label Attaching Sewing data can easily be

which had been manufactured operation panel or in a program. Excessive or insufficient pressing by (Two-step lowering, One-step work clamp can be replaced quickly. It

as the industry’s top-class the presser foot can be prevented, enabling a finish with uniform lowering and Analog lowering). By created with a large color LCD.

can also be installed accurately by using Sewing data management is

energy saver. This machine is thread tightening. selecting the optimal work clamp the positioning pins.

the programmable electronic height, quick and accurate positioning easy because sewing data

pattern sewing machine with the of materials can be made. image can be displayed ,

Feed Plate Can Be Replaced copied and moved easily.

lowest power consumption *The default setting is two-step lowering.

*This feature is only solenoid type. Accurately Velcro Attaching 11 languages are supported as

among this sewing-area class

models in the market, while When replacing the feed plate, stitch data display language.

realizing high-speed sewing and BAS-311G BAS-311H can be easily and accurately aligned with *The programmer is an optional product.

the feed plate by aligning the reference

8

strong needle penetration force. (3minutes cycle,200V)

Simple Adjustment holes of the needle plate and the feed

plate. Leather Case Equipped with a USB port,

(Smartphone case etc)

The driver phase can be adjusted from

Smooth and Beautiful Stitches with it became more convenient.

4 Great Needle Penetration 6 A Minimum Resolution of 0.05 mm

the side without tilting the sewing

machine. The needle guard also can Ensure the Safety with

Powerful motor (550W) outputs large amounts of torque even at slow Since the data is resolved at 0.05 mm per pulse for the feed, slanted be adjusted at one time. 10 Shock Absorber

speeds so that strong needle penetration force can be obtained. If the lines and curves are accurately sewn with beautiful finishes. Also, a The shock absorber is equipped in order Key Ring

needle penetration resistance increases, vibration control simple single point embroidery motif can be sewn, and embroidering to ensure the safety during maintenance

(intermittent impact) automatically increases the penetration force. on heavy materials, which is not easy with a general embroidery when the machine head is tilted back.

machine, is also possible.

In addition, decorative stitching for shoes etc...

You might also like

- Fintech Fundamentals Big Data Cloud Computing Digital Economy (Len Mei, PH.D.)Document239 pagesFintech Fundamentals Big Data Cloud Computing Digital Economy (Len Mei, PH.D.)albert AungNo ratings yet

- Activity 3Document11 pagesActivity 3EFFranciscoNo ratings yet

- BAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmDocument2 pagesBAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmAshraaf aushiNo ratings yet

- Buttonholing Machine Juki Lbh1790anDocument4 pagesButtonholing Machine Juki Lbh1790anSayantan RahaNo ratings yet

- FLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Document4 pagesFLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Sayantan RahaNo ratings yet

- L K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To OperatorsDocument4 pagesL K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To Operatorsdharmik borisagarNo ratings yet

- Supreme SP-3020ASDocument2 pagesSupreme SP-3020ASAlexandruNo ratings yet

- MO-6900S SeriesDocument8 pagesMO-6900S Seriesvijay maharNo ratings yet

- Asn 690Document2 pagesAsn 690fikriimam1No ratings yet

- Abin Cablel Drag Chains: NSB028NDocument1 pageAbin Cablel Drag Chains: NSB028NNageswar MakalaNo ratings yet

- 570 590 LeafletDocument12 pages570 590 LeafletfgfgfgNo ratings yet

- Meb 3200 PDFDocument6 pagesMeb 3200 PDFWajid WajidNo ratings yet

- Mo 6700 DaDocument2 pagesMo 6700 DafatagiuNo ratings yet

- 105-Dynapac F181CDocument1 page105-Dynapac F181CAliNo ratings yet

- Installation Procedure, Electronic Vessel Control, Gas and D3 EVC - BDocument1 pageInstallation Procedure, Electronic Vessel Control, Gas and D3 EVC - BRaul JosingNo ratings yet

- LH-4500C SeriesDocument4 pagesLH-4500C SeriesZaid StoreNo ratings yet

- Standard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGDocument2 pagesStandard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGjackson.santosgreentechNo ratings yet

- MO-6800S SeriesDocument2 pagesMO-6800S SeriesDanielNo ratings yet

- MB 1370Document4 pagesMB 1370azizNo ratings yet

- JUKI's Industrial Sewing MachinesDocument4 pagesJUKI's Industrial Sewing MachinesfilisavicNo ratings yet

- LU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeDocument2 pagesLU-2810-6 LU-2860-6: Is Added To The Machine Lineup Following The Direct-Drive TypeRaitziel KlossNo ratings yet

- Brother S6200A CatalogDocument2 pagesBrother S6200A CatalogSir LuoNo ratings yet

- PRO-76T: Multifunctional Drilling & Tapping MachineDocument4 pagesPRO-76T: Multifunctional Drilling & Tapping MachineBouraoui Ben AyedNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our DrillingrU sNo ratings yet

- Juki Series C Mo6900cDocument2 pagesJuki Series C Mo6900cKabir MahlotraNo ratings yet

- KM-T20 CatalogDocument1 pageKM-T20 CatalogJackson SilvaNo ratings yet

- Brushing Sueding MachineDocument4 pagesBrushing Sueding MachineZheejae Lao-atenNo ratings yet

- Brushing Sueding MachineDocument4 pagesBrushing Sueding MachineMazharul IslamNo ratings yet

- Apw 895 NeDocument2 pagesApw 895 NeCarlos Paul TorresNo ratings yet

- Sainte Lizaigne e Cub sl003 enDocument4 pagesSainte Lizaigne e Cub sl003 enPartene PaulaNo ratings yet

- MO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsDocument2 pagesMO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsShafikul IslamNo ratings yet

- Cc4ii8 en VSDocument1 pageCc4ii8 en VSEngineer WaleedNo ratings yet

- Standard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250Document2 pagesStandard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250jackson.santosgreentechNo ratings yet

- Wire StripperDocument2 pagesWire StripperMim MamNo ratings yet

- Q.Peak Duo Xl-G11.3: Enduring High PerformanceDocument2 pagesQ.Peak Duo Xl-G11.3: Enduring High PerformanceSánchez Condado JesúsNo ratings yet

- Laser G2: Storage Feeder: Perfection in Yarn ControlDocument2 pagesLaser G2: Storage Feeder: Perfection in Yarn ControlcobaNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingrandy yupanqui100% (1)

- Pneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationDocument4 pagesPneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationBe HappyNo ratings yet

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingyo2k_123No ratings yet

- DDL 5600 NDocument2 pagesDDL 5600 NJesús Sánchez CarriónNo ratings yet

- LDS - Permanent - Magnet - Shakers - Brochure - LR 2Document3 pagesLDS - Permanent - Magnet - Shakers - Brochure - LR 2snowflakefiat121No ratings yet

- Screw Conveyor CalculationDocument1 pageScrew Conveyor Calculationmanoj983@gmail.comNo ratings yet

- BASS2565 ProspektEngDocument2 pagesBASS2565 ProspektEngSaùl Torres GarcìaNo ratings yet

- Topcon Brochure ALE-5100 Series en PDFDocument4 pagesTopcon Brochure ALE-5100 Series en PDFAndrii Horban100% (1)

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Prep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDDocument5 pagesPrep 16 Pipe Bevelling 3" To 16": Pipe Equipment Specialists LTDJorgeNo ratings yet

- ASK ASM200-20230614pdfDocument2 pagesASK ASM200-20230614pdfdroessaert_stijnNo ratings yet

- Leno 4: Circular LoomDocument4 pagesLeno 4: Circular Loomss_abbu0% (1)

- LH-3500A Series: Adoption of The Direct-Drive Mechanism Promises Energy-Saving and Increased WorkabilityDocument4 pagesLH-3500A Series: Adoption of The Direct-Drive Mechanism Promises Energy-Saving and Increased WorkabilityfatagiuNo ratings yet

- High and Long Arm Sewing Machine With Automatic Thread TrimmerDocument2 pagesHigh and Long Arm Sewing Machine With Automatic Thread TrimmerSheikh RizwanNo ratings yet

- Brother LH4-B814-4 Instruction ManualDocument35 pagesBrother LH4-B814-4 Instruction ManualJuple My IguanaNo ratings yet

- Tapping Machine Mar 2021Document6 pagesTapping Machine Mar 2021Remmy Torres VegaNo ratings yet

- PDF 1440580617Document1 pagePDF 1440580617skf urbanoNo ratings yet

- BT430Q-438Q-530Q-630Q_A4DM_20220610_sDocument2 pagesBT430Q-438Q-530Q-630Q_A4DM_20220610_sNathalia ChaconNo ratings yet

- Nb1433pssm Et MDDocument1 pageNb1433pssm Et MDDavid SanchesNo ratings yet

- Catalogue HACINT MEGAINDUS 2023 Fully Automatic MachineDocument31 pagesCatalogue HACINT MEGAINDUS 2023 Fully Automatic MachineNabil daiouneNo ratings yet

- Boschert: CNC Busbar Cutting - Punching - Bending SolutionDocument42 pagesBoschert: CNC Busbar Cutting - Punching - Bending SolutiondemdiinNo ratings yet

- 2agujas PDFDocument4 pages2agujas PDFMeneses Chino ChinoNo ratings yet

- Louvretec Design Manual Section 7 300mm AirfoilDocument10 pagesLouvretec Design Manual Section 7 300mm AirfoiljoseocsilvaNo ratings yet

- KM 857Document2 pagesKM 857Juan Carlos Soriano GiménezNo ratings yet

- MO-6900G MO-6900J: Series SeriesDocument4 pagesMO-6900G MO-6900J: Series SeriescrisplasticoNo ratings yet

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterRating: 4 out of 5 stars4/5 (3)

- MS-ACC-007 (D) M3X6mm Long Trust Head Screw, FKB, CinchingDocument1 pageMS-ACC-007 (D) M3X6mm Long Trust Head Screw, FKB, CinchingAshraaf aushiNo ratings yet

- MS-ACC-009 (D) Gear Metric Lower, Cinching SystemDocument2 pagesMS-ACC-009 (D) Gear Metric Lower, Cinching SystemAshraaf aushiNo ratings yet

- MS-ACC-006 (C) Wing ScrewDocument1 pageMS-ACC-006 (C) Wing ScrewAshraaf aushiNo ratings yet

- MS-ACC-005 (F) Quick Relese ScrewDocument2 pagesMS-ACC-005 (F) Quick Relese ScrewAshraaf aushiNo ratings yet

- MS-ACC-008 (D) Slotted Shaft, Cinching SystemDocument2 pagesMS-ACC-008 (D) Slotted Shaft, Cinching SystemAshraaf aushiNo ratings yet

- MS-PAC-019 (G) Non Permeable (NP) PolybagDocument3 pagesMS-PAC-019 (G) Non Permeable (NP) PolybagAshraaf aushiNo ratings yet

- 144 Tev Tex 02 052Document1 page144 Tev Tex 02 052Ashraaf aushiNo ratings yet

- TR-22006-L-Mtl - Hot Melt Adhesive From NanpaoDocument2 pagesTR-22006-L-Mtl - Hot Melt Adhesive From NanpaoAshraaf aushiNo ratings yet

- TR-22001-I-Mtl Testing of Indian Velcro Hook-Loop-ExistingDocument3 pagesTR-22001-I-Mtl Testing of Indian Velcro Hook-Loop-ExistingAshraaf aushiNo ratings yet

- Shenzhen Minghui Antibacterial Technology Co.,Ltd: Material Safety Data SheetDocument4 pagesShenzhen Minghui Antibacterial Technology Co.,Ltd: Material Safety Data SheetAshraaf aushiNo ratings yet

- BAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmDocument2 pagesBAS-342H BAS-311HN BAS-341H BAS-326H: 150mm X 100mm 250mm X 160mm 220mm X 100mmAshraaf aushiNo ratings yet

- Welcome TO MY PresentationDocument37 pagesWelcome TO MY PresentationAshraaf aushiNo ratings yet

- Master Project Tracker1.4Document53 pagesMaster Project Tracker1.4Ashraaf aushiNo ratings yet

- Geographic Information SystemDocument17 pagesGeographic Information Systemupayarakhmat6711No ratings yet

- Customer Segmentation Using Unsupervised Learning On Daily Energy Load ProfilesDocument7 pagesCustomer Segmentation Using Unsupervised Learning On Daily Energy Load ProfilesPablo OrricoNo ratings yet

- Lec-3 Layer OSI ModelDocument34 pagesLec-3 Layer OSI ModelDivya GuptaNo ratings yet

- Electrical Test Data ClassSubClassMakeMOCParameterTemplate PVTDocument10 pagesElectrical Test Data ClassSubClassMakeMOCParameterTemplate PVTOmkarNo ratings yet

- HBL Payments - User Manual For Payment V1Document32 pagesHBL Payments - User Manual For Payment V1Nasir R AyubNo ratings yet

- Oracle Server X8-2 X8-2L Technical Introduction AssessmentDocument5 pagesOracle Server X8-2 X8-2L Technical Introduction AssessmentAl MamunNo ratings yet

- Sketchchair: Greg Saul JST Erator Design Ui GroupDocument7 pagesSketchchair: Greg Saul JST Erator Design Ui GroupGuaka WoodNo ratings yet

- Digital Video ProcessingDocument19 pagesDigital Video ProcessingArjun Hande0% (1)

- Kernel Context Recommender System PDFDocument19 pagesKernel Context Recommender System PDFSri Lalitha MunukutlaNo ratings yet

- Lean Canvas - SWI Nazier AriffinDocument71 pagesLean Canvas - SWI Nazier AriffinNoeNo ratings yet

- Ibm Module 1 HW Acquisition InstallationDocument3 pagesIbm Module 1 HW Acquisition Installationmana45No ratings yet

- A Step-By-Step Identification Method For Non-Intrusive Loads Based On Fused Features - RemovedDocument20 pagesA Step-By-Step Identification Method For Non-Intrusive Loads Based On Fused Features - RemovedricardomedinavNo ratings yet

- Working With The Class System in Python Chapter4Document29 pagesWorking With The Class System in Python Chapter4FgpeqwNo ratings yet

- Oxhorn's Settlement Happiness CalculatorDocument1 pageOxhorn's Settlement Happiness CalculatorMuhammad IlmiNo ratings yet

- Data Warehousing: Version 6.0 - 04/18/2000Document60 pagesData Warehousing: Version 6.0 - 04/18/2000udaya_ms52No ratings yet

- SAFe Implementation Roadmap 6.0 Partner 11.7x8.5Document1 pageSAFe Implementation Roadmap 6.0 Partner 11.7x8.5deartoreadbookNo ratings yet

- 3 PDFDocument1 page3 PDFaritw541214No ratings yet

- Uplift Modeling: A Quick Introduction: Learn How Uplift Modeling Can Improve Classic Data Science ApplicationsDocument1 pageUplift Modeling: A Quick Introduction: Learn How Uplift Modeling Can Improve Classic Data Science ApplicationsFares HasnaouiNo ratings yet

- T6990 Depliant ENG PDFDocument2 pagesT6990 Depliant ENG PDFForTestNo ratings yet

- What Is Big DataDocument3 pagesWhat Is Big DataBalkaran singhNo ratings yet

- College of Computer Studies: 454 Rizal Ave Ext Cor 9th Ave, Grace Park, CaloocanDocument6 pagesCollege of Computer Studies: 454 Rizal Ave Ext Cor 9th Ave, Grace Park, Caloocanann camile maupayNo ratings yet

- Chinese Wall Security Model Buzulan and TeleghinDocument13 pagesChinese Wall Security Model Buzulan and TeleghinLoryQa LoryNo ratings yet

- Student Information Management SystemDocument11 pagesStudent Information Management SystemKashif RasheedNo ratings yet

- iVMS-4200-Client-Software Datasheet V3.11.0 20240126Document9 pagesiVMS-4200-Client-Software Datasheet V3.11.0 20240126Yasmin SunartaNo ratings yet

- g6 Os Installation GuideDocument7 pagesg6 Os Installation GuideRK shuklaNo ratings yet

- Performances of Computer Systems: CSE 675.02: Introduction To Computer ArchitectureDocument52 pagesPerformances of Computer Systems: CSE 675.02: Introduction To Computer ArchitectureshubhamNo ratings yet

- El Mercado NBA 2020-2021, Al Día - Noticias, Rumores, Traspasos, Fichajes y Más - NBA - Com España - El Sitio Oficial de La NBADocument194 pagesEl Mercado NBA 2020-2021, Al Día - Noticias, Rumores, Traspasos, Fichajes y Más - NBA - Com España - El Sitio Oficial de La NBAPsychic PrinceNo ratings yet

- Final Report On Face RecognitionDocument22 pagesFinal Report On Face RecognitionSubhash Kumar67% (6)