Professional Documents

Culture Documents

5313 Red Eye 2G Water-Cut Meter PDF

5313 Red Eye 2G Water-Cut Meter PDF

Uploaded by

Truecaller CallerCopyright:

Available Formats

You might also like

- Ansi - Api MPMS Chapter 14.6 2ND Ed (E1)Document66 pagesAnsi - Api MPMS Chapter 14.6 2ND Ed (E1)zidinhoNo ratings yet

- Handbook of Biological ConfocalDocument1,010 pagesHandbook of Biological ConfocalBoris Olifirov100% (1)

- RBTUsers GuideDocument20 pagesRBTUsers GuideIngel Ingel100% (4)

- MIT User Guide PDFDocument17 pagesMIT User Guide PDFTruecaller Caller100% (1)

- GANGSTALKINGDocument395 pagesGANGSTALKINGGeneration GenerationNo ratings yet

- Swift 1Document47 pagesSwift 1Ahmad Fauzie Ibrahim Ismail100% (1)

- CBG PL Tool Broch Web PDFDocument4 pagesCBG PL Tool Broch Web PDFTruecaller CallerNo ratings yet

- CCC Series5 - Vanguard - Systems - MS82Document4 pagesCCC Series5 - Vanguard - Systems - MS82dylan_dearing@hotmail.comNo ratings yet

- Versa ValveDocument24 pagesVersa ValvetalangocdayNo ratings yet

- Instrument Air Dryer Maintenance Plan - 1 YEARDocument2 pagesInstrument Air Dryer Maintenance Plan - 1 YEARtskumarNo ratings yet

- PCG ADocument247 pagesPCG Aameen shuhaimiNo ratings yet

- EG001 IC SPE 11 0029rB01v3 - 4Document6 pagesEG001 IC SPE 11 0029rB01v3 - 4Cristinel NechiforNo ratings yet

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Document138 pagesOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- Adnoc - Introduction To Process ControlDocument10 pagesAdnoc - Introduction To Process Controlnagarajanprabhu89No ratings yet

- GEBENGDocument5 pagesGEBENGPY YouNo ratings yet

- Tank Gauging Systems (2018)Document6 pagesTank Gauging Systems (2018)sure100% (1)

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- What Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationDocument2 pagesWhat Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationKyrie AbayaNo ratings yet

- MPFM Handbook Program Version 1Document20 pagesMPFM Handbook Program Version 1AhmedNo ratings yet

- Subsea Production Control Systems: 1 ForewordDocument25 pagesSubsea Production Control Systems: 1 ForewordBSFNo ratings yet

- Indian Oil & GasDocument15 pagesIndian Oil & GasMeena HarryNo ratings yet

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituNo ratings yet

- Section 34 - Sight GlassDocument27 pagesSection 34 - Sight GlasshammamiNo ratings yet

- Swro Vs Med Vs Med TVC PDFDocument2 pagesSwro Vs Med Vs Med TVC PDFgochi bestNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- Week 4 - Control Valve PDFDocument13 pagesWeek 4 - Control Valve PDFNur Ain100% (1)

- Watercut MeterDocument3 pagesWatercut MeterprabhuarunkumarNo ratings yet

- ID-017 Instrument Communications PDFDocument70 pagesID-017 Instrument Communications PDFФизули АбиловNo ratings yet

- HSSDDocument3 pagesHSSDamijetomar08No ratings yet

- Control Valves Interview QuestionsDocument7 pagesControl Valves Interview QuestionsDerbel WalidNo ratings yet

- Orbit 60 Series System Datasheet - 137M5182Document27 pagesOrbit 60 Series System Datasheet - 137M5182NoetNo ratings yet

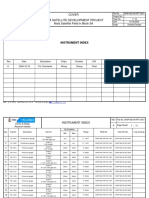

- Cover Mala Satellite Development Project Mala Satellite Field in Block 5ADocument16 pagesCover Mala Satellite Development Project Mala Satellite Field in Block 5AMohamedNo ratings yet

- Quotation Request Form For BALL VALVESDocument2 pagesQuotation Request Form For BALL VALVESSreekumar Nair100% (1)

- Control Operation Philosophy of Ac PDFDocument24 pagesControl Operation Philosophy of Ac PDFĐặng Trung AnhNo ratings yet

- C 002Document99 pagesC 002Dem68100% (1)

- Servo Gauge TI00452G08EN06.14Document41 pagesServo Gauge TI00452G08EN06.14jeduardo2325No ratings yet

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- PVC - Explosion Caused by Flashing Liquid in A Process VesselDocument8 pagesPVC - Explosion Caused by Flashing Liquid in A Process Vesselwiboonwi100% (1)

- Visio Loop Diagram Cascade Loop2Document1 pageVisio Loop Diagram Cascade Loop2jmnyoungNo ratings yet

- Sharing Bpcs - SisDocument4 pagesSharing Bpcs - Sissatan556No ratings yet

- Charge PanelDocument5 pagesCharge PanelSanjeev Kumar T MNo ratings yet

- Pamplate Fusible LoopDocument2 pagesPamplate Fusible Loopbastian99No ratings yet

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocument13 pagesNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNo ratings yet

- Spe 46642 MSDocument17 pagesSpe 46642 MSanaghaNo ratings yet

- Process Control (Level)Document12 pagesProcess Control (Level)Gino GalanoNo ratings yet

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Document8 pagesTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNo ratings yet

- 105M6369 Cda 000Document65 pages105M6369 Cda 000Rabah AmidiNo ratings yet

- Instrumentation Part1omkarDocument173 pagesInstrumentation Part1omkaromkarvadlooriNo ratings yet

- Yokogawa CVP - Old.Document11 pagesYokogawa CVP - Old.Karthikeya Rao KNo ratings yet

- Iooc Idhc BDP Ins SPC 015 016 Dcs r2Document29 pagesIooc Idhc BDP Ins SPC 015 016 Dcs r2Fatholla SalehiNo ratings yet

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Mokveld-Brochure Angle Choke Valve enDocument16 pagesMokveld-Brochure Angle Choke Valve enerscecNo ratings yet

- 2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)Document32 pages2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)JGlobexNo ratings yet

- Control Philosophy Rev 01Document12 pagesControl Philosophy Rev 01Surendra KumarNo ratings yet

- Rosemount 3051S Multivariable Transmitter: Simplifying Mass Flow MeasurementDocument2 pagesRosemount 3051S Multivariable Transmitter: Simplifying Mass Flow MeasurementYogi KipiantoNo ratings yet

- 2004A Rev.4Document83 pages2004A Rev.4Ridwan Baharum100% (2)

- Monitoring and Reporting of Flare Emissions Under The EU ETS II UK Offshore Oil GasDocument4 pagesMonitoring and Reporting of Flare Emissions Under The EU ETS II UK Offshore Oil GasAlvaro Andres Blanco GomezNo ratings yet

- Pig Signaller PDFDocument2 pagesPig Signaller PDFMargaret DaughertyNo ratings yet

- Tdoct1551b Eng PDFDocument738 pagesTdoct1551b Eng PDFzikhail93No ratings yet

- Technologies ListDocument121 pagesTechnologies ListrasthoenNo ratings yet

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocument3 pagesEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNo ratings yet

- CHROMATOGRAPHYDocument9 pagesCHROMATOGRAPHYKarthi Keyan KanagarajNo ratings yet

- AN 10101 Moisture in Natural Gas PDFDocument2 pagesAN 10101 Moisture in Natural Gas PDFJaime Andres Villegas MansillaNo ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Reservoir PDFDocument5 pagesReservoir PDFTruecaller CallerNo ratings yet

- Product & Service Catalog: Lee Specialties LTDDocument124 pagesProduct & Service Catalog: Lee Specialties LTDTruecaller Caller100% (1)

- Best Shutin Tool Ps PDFDocument2 pagesBest Shutin Tool Ps PDFTruecaller CallerNo ratings yet

- Natural Convection in Enclosure With Heating and Cooling by Sinusoidal Temperature Profiles On One SideDocument12 pagesNatural Convection in Enclosure With Heating and Cooling by Sinusoidal Temperature Profiles On One SideTruecaller CallerNo ratings yet

- Head A (Branding) - One Line Only BestDocument2 pagesHead A (Branding) - One Line Only BestTruecaller CallerNo ratings yet

- CBG PL Tool Broch Web PDFDocument4 pagesCBG PL Tool Broch Web PDFTruecaller CallerNo ratings yet

- High Rate Lithium Cell PMX150 SERIES: 3B3700 Size C Lithium Sulfuryl Chloride CellDocument1 pageHigh Rate Lithium Cell PMX150 SERIES: 3B3700 Size C Lithium Sulfuryl Chloride CellTruecaller CallerNo ratings yet

- API Recommended Practice 1171Document3 pagesAPI Recommended Practice 1171Truecaller Caller0% (1)

- Memory Production Logging System: Short Portable Easy To UseDocument1 pageMemory Production Logging System: Short Portable Easy To UseTruecaller CallerNo ratings yet

- Write Log (%WL) A Production Logging Utility For Data Transactional LogsDocument4 pagesWrite Log (%WL) A Production Logging Utility For Data Transactional LogsTruecaller CallerNo ratings yet

- CBG PL Tool Broch WebDocument4 pagesCBG PL Tool Broch WebTruecaller CallerNo ratings yet

- High-Temperature Memory Production Logging (MPLT)Document1 pageHigh-Temperature Memory Production Logging (MPLT)Truecaller CallerNo ratings yet

- CPLT Combinable Production Logging ToolDocument1 pageCPLT Combinable Production Logging ToolTruecaller CallerNo ratings yet

- Guva S12SDDocument1 pageGuva S12SDyaumil akbarNo ratings yet

- Thermal ImagingDocument21 pagesThermal ImagingAmit Bhatnagar50% (2)

- 5surveying PDFDocument33 pages5surveying PDFMohit RahangdaleNo ratings yet

- Fiber Optics - L 4Document43 pagesFiber Optics - L 4iNo ratings yet

- CommScope TeraSPEED Tech Report.Document6 pagesCommScope TeraSPEED Tech Report.Marco Rodriguez ZorrillaNo ratings yet

- Final Report PVDDocument23 pagesFinal Report PVDDiego MndezNo ratings yet

- Brochure & Specification Total Station Sokkia IM-100-101-102-103-105 / 081297551995@rinaDocument4 pagesBrochure & Specification Total Station Sokkia IM-100-101-102-103-105 / 081297551995@rinaRina WahyuniNo ratings yet

- SOSPB-2399-20 40 SFP+ Bidi 20km SinovoDocument9 pagesSOSPB-2399-20 40 SFP+ Bidi 20km SinovomelissaNo ratings yet

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocument2 pagesExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanNo ratings yet

- Heat Transfer Engineering ApplicationsDocument412 pagesHeat Transfer Engineering ApplicationsGanesh Mandpe100% (1)

- User Manual: EasywrapDocument13 pagesUser Manual: EasywrapLeonel GrimardiNo ratings yet

- Bionest: Bioincubators Nurturing Entrepreneurship For Scaling TechnologiesDocument35 pagesBionest: Bioincubators Nurturing Entrepreneurship For Scaling TechnologiesPankaj PhukanNo ratings yet

- Cuñas Phased ArrayDocument11 pagesCuñas Phased ArrayNorman ricardoNo ratings yet

- Comparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and MeasurementDocument9 pagesComparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and Measurementdogukan duranNo ratings yet

- Holopoetry, Hypertext, HyperpoetryDocument11 pagesHolopoetry, Hypertext, Hyperpoetrycangurorojo100% (1)

- Super High-Power AlGaInN-based Laser DiodesDocument4 pagesSuper High-Power AlGaInN-based Laser DiodesPawan KumarNo ratings yet

- Ricoh Aficio SP 4210N SMDocument324 pagesRicoh Aficio SP 4210N SMdwina roche100% (1)

- Motionless Electromagnetic GeneratorDocument11 pagesMotionless Electromagnetic GeneratorChaitanya TummalaNo ratings yet

- Codex Eldar Harlequins v3.1 (6th Edition)Document44 pagesCodex Eldar Harlequins v3.1 (6th Edition)forishm0% (1)

- Codigos PanasonicDocument41 pagesCodigos Panasonicjorgsant1311No ratings yet

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- STL FiberDocument180 pagesSTL FiberKevin Daniel Casta?O CorreaNo ratings yet

- Assignment No. 3Document5 pagesAssignment No. 3Srinivas DixitNo ratings yet

- 9 Wireless Power Transfer Projects PDF: Accelerate Your InnovationDocument15 pages9 Wireless Power Transfer Projects PDF: Accelerate Your InnovationSouvik KoleNo ratings yet

- Rega Planet 2000 ManualDocument14 pagesRega Planet 2000 ManualjamocasNo ratings yet

- Introduction To PhotonicsDocument32 pagesIntroduction To Photonicsmani_vlsiNo ratings yet

- 577 ExerciseDocument40 pages577 Exerciseariyamanjula2914100% (1)

- Project Synopsis CNC Laser EngraverDocument11 pagesProject Synopsis CNC Laser EngraverNgangom Maximus100% (4)

5313 Red Eye 2G Water-Cut Meter PDF

5313 Red Eye 2G Water-Cut Meter PDF

Uploaded by

Truecaller CallerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5313 Red Eye 2G Water-Cut Meter PDF

5313 Red Eye 2G Water-Cut Meter PDF

Uploaded by

Truecaller CallerCopyright:

Available Formats

Red Eye® 2G Water-cut Meter

Unmatched accuracy across all water cuts in real-world situations.

Red Eye 2G Water-cut Meter

The Red Eye 2G water-cut meter uses patented optical sensor technology

to accurately measure the full range of water cut (0 to 100%) in a

commingled oil and water stream. Very high accuracy across all water-

cut levels and easy installation and configuration make this unique meter

suitable for numerous applications. The meter can be used in stand alone

mode to measure and report instantaneous water cut and in conjunction

with the Red Eye net oil computer (NOC) to perform timed production well

tests, or as part of the Red Eye multiphase metering system (REMMS).

How Does It Work?

The measurement is based on near-infrared absorption spectroscopy

where oil and water are easily differentiated.

The water-cut meter achieves unmatched accuracy at high water-cut levels

as well as lower water-cut measurements by simultaneously measuring

multiple wavelengths that include both water and oil absorption peaks.

Absorption Spectroscopy

15

12

Water

9

absorption

Oil B

Oil A

Condensate

0

800 1000 1200 1400 1600 1800 2000

wavelength (nm)

The graph shows several bands of infrared wavelengths that are absorbed by the

components of the produced fluids.

Unmatched Accuracy in Production Environments

The Red Eye 2G water-cut meter delivers high accuracy performance

under actual production environments, not just in laboratory conditions.

Water-cut measurement uncertainties are less than 2% even with

situations of varying salinity and when entrained gas is present.

2 © 2008 Weatherford. All rights reserved.

Red Eye 2G Water-cut Meter

Gas Volume Fraction (GVF) Effects

This meter is designed to handle real-world issues such as entrained

gas. By using the technique of multiple wavelength measurements as

employed by the Red Eye water-cut meter, great tolerance to varying gas

conditions is possible. GVFs of up to 5% have no effect on unit accuracy

and up to 20% have only minimal effect.

Emulsion Handling and Salinity Effects

The Red Eye 2G water-cut meter works with emulsions as well as fluids

that separate easily. Emulsions tend to cause light scattering in addition

to absorption. The scattering is equal at all wavelengths whereas the

absorption is strongly dependent on wavelength. The water-cut meter

nulls out the scattering effect and measures the absorptions which are

directly related to the water cut. Salinity has no effect on the measurement

since water absorption is based on the water molecule itself, not the

dissolved salts. Accuracy is, therefore, unaffected by different and

changing salinities.

A local two-line display provides an

instantaneous water-cut reading, active

well number and instrument status

information for user convenience.

Collector Optics

Probe Assembly

Sapphire Window

Sapphire Window

NIR Emitter

© 2008 Weatherford. All rights reserved. 3

Red Eye 2G Water-cut Meter

Typical Installation

Red Eye

Net Oil Computer

RED EYE

A Weatherford Company

Net Oil Computer

Flowmeter Host

Pulse Output

Red Eye 2G Water-cut Meter Highlights

• Unmatched accuracy in real-world situations

• Insensitive to entrained gas

• Ignores salinity and dissolved gas

• Easy installation, calibration and service

4 © 2008 Weatherford. All rights reserved.

Red Eye 2G Water-cut Meter

Typical Applications

Well Testing

The water-cut meter is typically used downstream from a two phase test

separator in the liquid leg. The meter can be combined with a total liquid

flowmeter and NOC for individual oil and water flow rates.

Individual Well Monitoring

The Red Eye 2G water-cut meter can be used to monitor individual wells

and provide continuous real-time, water-cut data. When streams contain

free gas (up to 20% gas void fraction) the meter provides unsurpassed

performance in accurate determination of oil and water rates.

Group Production at Centralized Facilities

The water-cut meter can be used to monitor group production lines as well

as individual test lines. The compact insertion style design is very cost

effective even for large line sizes.

Dewatering Monitoring Systems for Crude Oil Tanks

When a Red Eye 2G water-cut meter is installed on the discharge line from

a tank, the operator can easily identify the rag layer (interface between

the oil and water in the tank). The optical sensors of the meter sense very

small amounts of oil in the rag layer as it passes through the pipe allowing

the operator to shut off the flow from the tank.

© 2008 Weatherford. All rights reserved. 5

Red Eye 2G Water-cut Meter

Configuration

The meter includes RedLine™ configuration software designed for pocket

PCs. The software allows the user to configure communications, perform

one-button fluid calibrations and check system diagnostics. The connection

can be done through either of the meter’s communication ports.

Simplified Installation and Operation

The insertion style design reduces installation costs, particularly in large

line sizes. The electronics are mounted directly on the measurement

probe, limiting field wiring requirements to power and output signal cables.

For NOC applications, the Red Eye 2G unit can accommodate either a 4

to 20 mA or a pulse input from a flowmeter. The flow rate is available as a

Modbus™ readable parameter. The NOC unit requires a two-wire RS-485

connection to the meter for both water-cut and flow-rate information.

Simplified Calibration

All that is needed is a small, 50 ml, sample of dry oil at atmospheric

conditions. The operator puts dry oil from the well to be tested in the

sensor slot and pushes one button to calibrate. That’s it!

6 © 2008 Weatherford. All rights reserved.

Red Eye 2G Water-cut Meter

Specifications

Power 10 to 30 Vdc, 8 W

Wetted Parts 316 L SS or Hastelloy C 276 with sapphire windows

Operating Temperature 32 to 302 (0 to 150) (standard) process fluid

(°F/°C) -40 to 149 (-40 to 65) (standard) ambient temp

Operating Pressure Equal to carbon steel ANSI pressure rating

1 (2.54) NPT for pipe sizes 2 to 10 (5.08 to 25.4)

Process Connection 1.5 (3.81) RF flange ANSI 600 for pipe sizes 2 to 24 (5.08 to 60.96)

(in./cm) 1.5 (3.81) RF flange ANSI 900/1500 for pipe sizes 2 to 24 (5.08 to 60.96)

2 (5.08) RTJ flange ANSI 900/1500 for pipe sizes 3 to 8 (7.62 to 20.32)

Sour Service NACE MR0175/ISO 15156

Accuracy ±2% water cut

Communication Ports RS232 and RS485

Flowmeter Inputs Pulse or 4 to 20 mA

Display 2-line, 16-character vacuum fluorescent display (LCD available)

Output 4 to 20 mA water cut

Communications Modbus RTU (standard)

Factory Mutual Approvals Project I.D. 3022805 XP Class I, Division 1, Groups C & D,

T3C, Ta=+85°C, CSA

Sira Certification Services Certificate SIRA 05ATEX1138 EEx’d IIB T3 Ta=+85°C, IP66

Hazardous Area

Canadian Standards Association Certificate Number 1675737, Class I, Division 1,

Classification

Groups C & D, T3C, Ta=+85°C, Type 4

Serial Production Gosstandart of Russia Certificate of Conformity

Gosstandart of Russia Explosion-proof Certificate

A hot tap version of the Red Eye 2G water-cut meter is available,

Hot Tap

contact the factory for details

© 2008 Weatherford. All rights reserved. 7

515 Post Oak Blvd., Suite 600 Weatherford products and services are subject to the Company’s standard terms and conditions, available on request or

at www.weatherford.com. For more information contact an authorized Weatherford representative. Unless noted otherwise,

Houston, Texas 77027 USA trademarks and service marks herein are the property of Weatherford. Specifications are subject to change without notice.

Tel: 281-348-1000 Weatherford sells its products and services in accordance with the terms and conditions set forth in the applicable contract

between Weatherford and the client.

info@ep-weatherford.com

www.ep-weatherford.com © 2008 Weatherford. All rights reserved. Brochure 5313.00

You might also like

- Ansi - Api MPMS Chapter 14.6 2ND Ed (E1)Document66 pagesAnsi - Api MPMS Chapter 14.6 2ND Ed (E1)zidinhoNo ratings yet

- Handbook of Biological ConfocalDocument1,010 pagesHandbook of Biological ConfocalBoris Olifirov100% (1)

- RBTUsers GuideDocument20 pagesRBTUsers GuideIngel Ingel100% (4)

- MIT User Guide PDFDocument17 pagesMIT User Guide PDFTruecaller Caller100% (1)

- GANGSTALKINGDocument395 pagesGANGSTALKINGGeneration GenerationNo ratings yet

- Swift 1Document47 pagesSwift 1Ahmad Fauzie Ibrahim Ismail100% (1)

- CBG PL Tool Broch Web PDFDocument4 pagesCBG PL Tool Broch Web PDFTruecaller CallerNo ratings yet

- CCC Series5 - Vanguard - Systems - MS82Document4 pagesCCC Series5 - Vanguard - Systems - MS82dylan_dearing@hotmail.comNo ratings yet

- Versa ValveDocument24 pagesVersa ValvetalangocdayNo ratings yet

- Instrument Air Dryer Maintenance Plan - 1 YEARDocument2 pagesInstrument Air Dryer Maintenance Plan - 1 YEARtskumarNo ratings yet

- PCG ADocument247 pagesPCG Aameen shuhaimiNo ratings yet

- EG001 IC SPE 11 0029rB01v3 - 4Document6 pagesEG001 IC SPE 11 0029rB01v3 - 4Cristinel NechiforNo ratings yet

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Document138 pagesOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- Adnoc - Introduction To Process ControlDocument10 pagesAdnoc - Introduction To Process Controlnagarajanprabhu89No ratings yet

- GEBENGDocument5 pagesGEBENGPY YouNo ratings yet

- Tank Gauging Systems (2018)Document6 pagesTank Gauging Systems (2018)sure100% (1)

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- What Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationDocument2 pagesWhat Is ESD & PSD? Difference Between ESD & PSD Field InstrumentationKyrie AbayaNo ratings yet

- MPFM Handbook Program Version 1Document20 pagesMPFM Handbook Program Version 1AhmedNo ratings yet

- Subsea Production Control Systems: 1 ForewordDocument25 pagesSubsea Production Control Systems: 1 ForewordBSFNo ratings yet

- Indian Oil & GasDocument15 pagesIndian Oil & GasMeena HarryNo ratings yet

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituNo ratings yet

- Section 34 - Sight GlassDocument27 pagesSection 34 - Sight GlasshammamiNo ratings yet

- Swro Vs Med Vs Med TVC PDFDocument2 pagesSwro Vs Med Vs Med TVC PDFgochi bestNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- Week 4 - Control Valve PDFDocument13 pagesWeek 4 - Control Valve PDFNur Ain100% (1)

- Watercut MeterDocument3 pagesWatercut MeterprabhuarunkumarNo ratings yet

- ID-017 Instrument Communications PDFDocument70 pagesID-017 Instrument Communications PDFФизули АбиловNo ratings yet

- HSSDDocument3 pagesHSSDamijetomar08No ratings yet

- Control Valves Interview QuestionsDocument7 pagesControl Valves Interview QuestionsDerbel WalidNo ratings yet

- Orbit 60 Series System Datasheet - 137M5182Document27 pagesOrbit 60 Series System Datasheet - 137M5182NoetNo ratings yet

- Cover Mala Satellite Development Project Mala Satellite Field in Block 5ADocument16 pagesCover Mala Satellite Development Project Mala Satellite Field in Block 5AMohamedNo ratings yet

- Quotation Request Form For BALL VALVESDocument2 pagesQuotation Request Form For BALL VALVESSreekumar Nair100% (1)

- Control Operation Philosophy of Ac PDFDocument24 pagesControl Operation Philosophy of Ac PDFĐặng Trung AnhNo ratings yet

- C 002Document99 pagesC 002Dem68100% (1)

- Servo Gauge TI00452G08EN06.14Document41 pagesServo Gauge TI00452G08EN06.14jeduardo2325No ratings yet

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- PVC - Explosion Caused by Flashing Liquid in A Process VesselDocument8 pagesPVC - Explosion Caused by Flashing Liquid in A Process Vesselwiboonwi100% (1)

- Visio Loop Diagram Cascade Loop2Document1 pageVisio Loop Diagram Cascade Loop2jmnyoungNo ratings yet

- Sharing Bpcs - SisDocument4 pagesSharing Bpcs - Sissatan556No ratings yet

- Charge PanelDocument5 pagesCharge PanelSanjeev Kumar T MNo ratings yet

- Pamplate Fusible LoopDocument2 pagesPamplate Fusible Loopbastian99No ratings yet

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocument13 pagesNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNo ratings yet

- Spe 46642 MSDocument17 pagesSpe 46642 MSanaghaNo ratings yet

- Process Control (Level)Document12 pagesProcess Control (Level)Gino GalanoNo ratings yet

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Document8 pagesTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNo ratings yet

- 105M6369 Cda 000Document65 pages105M6369 Cda 000Rabah AmidiNo ratings yet

- Instrumentation Part1omkarDocument173 pagesInstrumentation Part1omkaromkarvadlooriNo ratings yet

- Yokogawa CVP - Old.Document11 pagesYokogawa CVP - Old.Karthikeya Rao KNo ratings yet

- Iooc Idhc BDP Ins SPC 015 016 Dcs r2Document29 pagesIooc Idhc BDP Ins SPC 015 016 Dcs r2Fatholla SalehiNo ratings yet

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Mokveld-Brochure Angle Choke Valve enDocument16 pagesMokveld-Brochure Angle Choke Valve enerscecNo ratings yet

- 2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)Document32 pages2600T Basic Transmitter Theory (TI - 266-En - B-09 - 2013)JGlobexNo ratings yet

- Control Philosophy Rev 01Document12 pagesControl Philosophy Rev 01Surendra KumarNo ratings yet

- Rosemount 3051S Multivariable Transmitter: Simplifying Mass Flow MeasurementDocument2 pagesRosemount 3051S Multivariable Transmitter: Simplifying Mass Flow MeasurementYogi KipiantoNo ratings yet

- 2004A Rev.4Document83 pages2004A Rev.4Ridwan Baharum100% (2)

- Monitoring and Reporting of Flare Emissions Under The EU ETS II UK Offshore Oil GasDocument4 pagesMonitoring and Reporting of Flare Emissions Under The EU ETS II UK Offshore Oil GasAlvaro Andres Blanco GomezNo ratings yet

- Pig Signaller PDFDocument2 pagesPig Signaller PDFMargaret DaughertyNo ratings yet

- Tdoct1551b Eng PDFDocument738 pagesTdoct1551b Eng PDFzikhail93No ratings yet

- Technologies ListDocument121 pagesTechnologies ListrasthoenNo ratings yet

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocument3 pagesEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNo ratings yet

- CHROMATOGRAPHYDocument9 pagesCHROMATOGRAPHYKarthi Keyan KanagarajNo ratings yet

- AN 10101 Moisture in Natural Gas PDFDocument2 pagesAN 10101 Moisture in Natural Gas PDFJaime Andres Villegas MansillaNo ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Reservoir PDFDocument5 pagesReservoir PDFTruecaller CallerNo ratings yet

- Product & Service Catalog: Lee Specialties LTDDocument124 pagesProduct & Service Catalog: Lee Specialties LTDTruecaller Caller100% (1)

- Best Shutin Tool Ps PDFDocument2 pagesBest Shutin Tool Ps PDFTruecaller CallerNo ratings yet

- Natural Convection in Enclosure With Heating and Cooling by Sinusoidal Temperature Profiles On One SideDocument12 pagesNatural Convection in Enclosure With Heating and Cooling by Sinusoidal Temperature Profiles On One SideTruecaller CallerNo ratings yet

- Head A (Branding) - One Line Only BestDocument2 pagesHead A (Branding) - One Line Only BestTruecaller CallerNo ratings yet

- CBG PL Tool Broch Web PDFDocument4 pagesCBG PL Tool Broch Web PDFTruecaller CallerNo ratings yet

- High Rate Lithium Cell PMX150 SERIES: 3B3700 Size C Lithium Sulfuryl Chloride CellDocument1 pageHigh Rate Lithium Cell PMX150 SERIES: 3B3700 Size C Lithium Sulfuryl Chloride CellTruecaller CallerNo ratings yet

- API Recommended Practice 1171Document3 pagesAPI Recommended Practice 1171Truecaller Caller0% (1)

- Memory Production Logging System: Short Portable Easy To UseDocument1 pageMemory Production Logging System: Short Portable Easy To UseTruecaller CallerNo ratings yet

- Write Log (%WL) A Production Logging Utility For Data Transactional LogsDocument4 pagesWrite Log (%WL) A Production Logging Utility For Data Transactional LogsTruecaller CallerNo ratings yet

- CBG PL Tool Broch WebDocument4 pagesCBG PL Tool Broch WebTruecaller CallerNo ratings yet

- High-Temperature Memory Production Logging (MPLT)Document1 pageHigh-Temperature Memory Production Logging (MPLT)Truecaller CallerNo ratings yet

- CPLT Combinable Production Logging ToolDocument1 pageCPLT Combinable Production Logging ToolTruecaller CallerNo ratings yet

- Guva S12SDDocument1 pageGuva S12SDyaumil akbarNo ratings yet

- Thermal ImagingDocument21 pagesThermal ImagingAmit Bhatnagar50% (2)

- 5surveying PDFDocument33 pages5surveying PDFMohit RahangdaleNo ratings yet

- Fiber Optics - L 4Document43 pagesFiber Optics - L 4iNo ratings yet

- CommScope TeraSPEED Tech Report.Document6 pagesCommScope TeraSPEED Tech Report.Marco Rodriguez ZorrillaNo ratings yet

- Final Report PVDDocument23 pagesFinal Report PVDDiego MndezNo ratings yet

- Brochure & Specification Total Station Sokkia IM-100-101-102-103-105 / 081297551995@rinaDocument4 pagesBrochure & Specification Total Station Sokkia IM-100-101-102-103-105 / 081297551995@rinaRina WahyuniNo ratings yet

- SOSPB-2399-20 40 SFP+ Bidi 20km SinovoDocument9 pagesSOSPB-2399-20 40 SFP+ Bidi 20km SinovomelissaNo ratings yet

- Experiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedDocument2 pagesExperiment No.: 16 Title: Thermal Performance of Solar Water Heater Aim: Heating and Cooling Performance of Flat Plate Solar Collector Instruments UsedAngsuman PhukanNo ratings yet

- Heat Transfer Engineering ApplicationsDocument412 pagesHeat Transfer Engineering ApplicationsGanesh Mandpe100% (1)

- User Manual: EasywrapDocument13 pagesUser Manual: EasywrapLeonel GrimardiNo ratings yet

- Bionest: Bioincubators Nurturing Entrepreneurship For Scaling TechnologiesDocument35 pagesBionest: Bioincubators Nurturing Entrepreneurship For Scaling TechnologiesPankaj PhukanNo ratings yet

- Cuñas Phased ArrayDocument11 pagesCuñas Phased ArrayNorman ricardoNo ratings yet

- Comparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and MeasurementDocument9 pagesComparison of TOF, FMCW and Phase-Shift Laser Range-Finding Methods by Simulation and Measurementdogukan duranNo ratings yet

- Holopoetry, Hypertext, HyperpoetryDocument11 pagesHolopoetry, Hypertext, Hyperpoetrycangurorojo100% (1)

- Super High-Power AlGaInN-based Laser DiodesDocument4 pagesSuper High-Power AlGaInN-based Laser DiodesPawan KumarNo ratings yet

- Ricoh Aficio SP 4210N SMDocument324 pagesRicoh Aficio SP 4210N SMdwina roche100% (1)

- Motionless Electromagnetic GeneratorDocument11 pagesMotionless Electromagnetic GeneratorChaitanya TummalaNo ratings yet

- Codex Eldar Harlequins v3.1 (6th Edition)Document44 pagesCodex Eldar Harlequins v3.1 (6th Edition)forishm0% (1)

- Codigos PanasonicDocument41 pagesCodigos Panasonicjorgsant1311No ratings yet

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- STL FiberDocument180 pagesSTL FiberKevin Daniel Casta?O CorreaNo ratings yet

- Assignment No. 3Document5 pagesAssignment No. 3Srinivas DixitNo ratings yet

- 9 Wireless Power Transfer Projects PDF: Accelerate Your InnovationDocument15 pages9 Wireless Power Transfer Projects PDF: Accelerate Your InnovationSouvik KoleNo ratings yet

- Rega Planet 2000 ManualDocument14 pagesRega Planet 2000 ManualjamocasNo ratings yet

- Introduction To PhotonicsDocument32 pagesIntroduction To Photonicsmani_vlsiNo ratings yet

- 577 ExerciseDocument40 pages577 Exerciseariyamanjula2914100% (1)

- Project Synopsis CNC Laser EngraverDocument11 pagesProject Synopsis CNC Laser EngraverNgangom Maximus100% (4)