Professional Documents

Culture Documents

Gas Density Monitor Model GDM-100: Applications

Gas Density Monitor Model GDM-100: Applications

Uploaded by

denny yusufCopyright:

Available Formats

You might also like

- Kinsley David R Tantric Visions of The Divine Feminine 330p PDFDocument330 pagesKinsley David R Tantric Visions of The Divine Feminine 330p PDFvoiddoor94% (18)

- Chemrite Grout NSDocument2 pagesChemrite Grout NSghazanfar0% (1)

- DM - Model GDM-100-TADocument5 pagesDM - Model GDM-100-TAvladaemsNo ratings yet

- Ds sp6005 Archived en CoDocument5 pagesDs sp6005 Archived en CoJanaka GunawardhanaNo ratings yet

- Gas Density Monitor Model 233.52.063, With Gas Filling: ApplicationsDocument3 pagesGas Density Monitor Model 233.52.063, With Gas Filling: Applicationsdenny yusufNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAdenny yusufNo ratings yet

- Ds sp6002 en CoDocument5 pagesDs sp6002 en CoJanaka GunawardhanaNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- SF6 Meter DatasheetDocument3 pagesSF6 Meter DatasheetHaider-e-KararNo ratings yet

- Osisense XM Xmla070d2s11Document6 pagesOsisense XM Xmla070d2s11Amer CajdricNo ratings yet

- Attachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFDocument17 pagesAttachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFIbrahim Ben AmeurNo ratings yet

- Presostato Nautilus - XMLA070D2S11Document6 pagesPresostato Nautilus - XMLA070D2S11Fabian PerezNo ratings yet

- Gas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionDocument12 pagesGas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionchauNo ratings yet

- PRESSURE SWITCH - OsiSense XM ATEX D - XMLB020A2S11Document6 pagesPRESSURE SWITCH - OsiSense XM ATEX D - XMLB020A2S11Sigit KuncoroNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAbehnamatgNo ratings yet

- Osisense XM Xmlb020c2s12Document6 pagesOsisense XM Xmlb020c2s12Iman FaisalNo ratings yet

- Bourdon Tube Pressure Gauge With Switch Contacts Model 232.30.063, Stainless Steel Safety VersionDocument4 pagesBourdon Tube Pressure Gauge With Switch Contacts Model 232.30.063, Stainless Steel Safety VersionAnonymous 4MwmDaNbNo ratings yet

- Eds 300 ShippingDocument2 pagesEds 300 ShippingARINo ratings yet

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 pagesPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaNo ratings yet

- OsiSense XM - XMLB300D2S12Document6 pagesOsiSense XM - XMLB300D2S12Cricri CriNo ratings yet

- Ds pv3542 en CoDocument6 pagesDs pv3542 en CoPajnuNo ratings yet

- DatasheetDocument2 pagesDatasheetsolar desalinationNo ratings yet

- Gs1r1b2e (Ramc)Document20 pagesGs1r1b2e (Ramc)apisituNo ratings yet

- Electrical Contact Devices For Pressure and Temperature GaugesDocument2 pagesElectrical Contact Devices For Pressure and Temperature GaugesrhomadonaNo ratings yet

- Bourdon Tube Pressure Gauges Industrial Series Gauge Type 212.20Document2 pagesBourdon Tube Pressure Gauges Industrial Series Gauge Type 212.20Samruddha S KulkarniNo ratings yet

- DS PV2101 GB 8017Document2 pagesDS PV2101 GB 8017josip miskovicNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

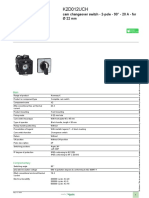

- Harmony K - K2D012UCHDocument9 pagesHarmony K - K2D012UCHGregory CoerielNo ratings yet

- Gasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01Document5 pagesGasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01mdkhandaveNo ratings yet

- Siemens 5sy62017Document4 pagesSiemens 5sy62017Kleiber OrtegaNo ratings yet

- Ficha TecnicaDocument2 pagesFicha Tecnicaluis.trigosNo ratings yet

- 2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmDocument5 pages2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmSohail AhmedNo ratings yet

- Ds Sf6 GDT Gd10cl en Us 27789Document4 pagesDs Sf6 GDT Gd10cl en Us 27789behnamatgNo ratings yet

- 5.14.1 Norgren Pneumatic Pressure SwitchDocument4 pages5.14.1 Norgren Pneumatic Pressure SwitchMarleny Lindo CajusolNo ratings yet

- Dungs GW 50 A5 ManualDocument5 pagesDungs GW 50 A5 ManualMazhar IqbalNo ratings yet

- Pressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFDocument6 pagesPressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFRichard Mayk teodoroNo ratings yet

- Pressure Sensors XM - ADW5M129012Document2 pagesPressure Sensors XM - ADW5M129012Carlos RodriguezNo ratings yet

- DS PV2201 GB 10873Document6 pagesDS PV2201 GB 10873eeghbaliNo ratings yet

- Ds pv3331 en CoDocument7 pagesDs pv3331 en Co9033301054No ratings yet

- Siemems RCDDocument4 pagesSiemems RCDDavid LimNo ratings yet

- VKGDocument6 pagesVKGJean DejardinNo ratings yet

- Pressure Transmitter With Thin Film Technology For Mobile Hydraulic Applications Model MH-1Document7 pagesPressure Transmitter With Thin Film Technology For Mobile Hydraulic Applications Model MH-1Larbi BelazizNo ratings yet

- Ds pv3560 en inDocument5 pagesDs pv3560 en inravisingh12911No ratings yet

- DS PV2001 GB 14782Document2 pagesDS PV2001 GB 14782josip miskovicNo ratings yet

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataHendra WiratamaNo ratings yet

- 01 Pressure SwitchesDocument4 pages01 Pressure SwitchesfaviomarchantNo ratings yet

- Catalogue RelayDocument5 pagesCatalogue RelayElectrical CheminNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- DS B4B7 EN PressostatDocument2 pagesDS B4B7 EN PressostatmarouaneNo ratings yet

- Domat shd692 enDocument2 pagesDomat shd692 enLap Vo NhuNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- Pressure Measurement: Pressure Sensor For General Air and Gas Applications - Stainless Steel CTX-#.#.#.###.#Document6 pagesPressure Measurement: Pressure Sensor For General Air and Gas Applications - Stainless Steel CTX-#.#.#.###.#Henry DavichoNo ratings yet

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocument3 pagesBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNo ratings yet

- MCB - 5sy5102-7Document6 pagesMCB - 5sy5102-7ThinhNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Data Sheet: Trs 24Vdc 1coDocument14 pagesData Sheet: Trs 24Vdc 1coibrahim abd elhadyNo ratings yet

- En18068-3-02-18 Eds3300 Plus VdmaDocument4 pagesEn18068-3-02-18 Eds3300 Plus VdmaigorNo ratings yet

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Document4 pages2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Sohail AhmedNo ratings yet

- 2p en dpd1t - dpd2tDocument2 pages2p en dpd1t - dpd2tghNo ratings yet

- Osisense XM Xmah12l2135Document2 pagesOsisense XM Xmah12l2135Milan StefanovicNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- PDSimply (UHF Version)Document2 pagesPDSimply (UHF Version)denny yusufNo ratings yet

- 240-Article Text-484-3-10-20210620Document7 pages240-Article Text-484-3-10-20210620denny yusufNo ratings yet

- 23-FP EPI CI MII AD 2023 DTD AUGUSTDocument1 page23-FP EPI CI MII AD 2023 DTD AUGUSTdenny yusufNo ratings yet

- Cired2013 ProsedureDocument6 pagesCired2013 Proseduredenny yusufNo ratings yet

- Cigre 157Document12 pagesCigre 157denny yusufNo ratings yet

- 36-42 ComemDocument7 pages36-42 Comemdenny yusufNo ratings yet

- Cpdm04en Course DetailsDocument1 pageCpdm04en Course Detailsdenny yusufNo ratings yet

- 1 s2.0 S1471490622000254 Main 2Document38 pages1 s2.0 S1471490622000254 Main 2denny yusufNo ratings yet

- Pengumuman DPT Vendor Komponen TrafoDocument3 pagesPengumuman DPT Vendor Komponen Trafodenny yusufNo ratings yet

- Wcica 2006 1714078Document4 pagesWcica 2006 1714078denny yusufNo ratings yet

- Marketing Porposal INED 2021-24082021Document13 pagesMarketing Porposal INED 2021-24082021denny yusufNo ratings yet

- Winning by Design - Blueprint - Metric Based LeadershipDocument6 pagesWinning by Design - Blueprint - Metric Based Leadershipdenny yusufNo ratings yet

- Safari - 20 Nov 2022 20.55Document1 pageSafari - 20 Nov 2022 20.55denny yusufNo ratings yet

- Gas Density Monitor Model 233.52.063, With Gas Filling: ApplicationsDocument3 pagesGas Density Monitor Model 233.52.063, With Gas Filling: Applicationsdenny yusufNo ratings yet

- Guidance - Electrical Switch Contact PDFDocument24 pagesGuidance - Electrical Switch Contact PDFdenny yusufNo ratings yet

- All Marketing Are Liars SummaryDocument16 pagesAll Marketing Are Liars Summarydenny yusufNo ratings yet

- Azure Product Catalogue 01-13Document1 pageAzure Product Catalogue 01-13denny yusufNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAdenny yusufNo ratings yet

- Partial Discharge Investigation and Failure Analysis On Distribution Network Using Acousic Camera, 2021, SuwansariDocument4 pagesPartial Discharge Investigation and Failure Analysis On Distribution Network Using Acousic Camera, 2021, Suwansaridenny yusufNo ratings yet

- Brochure ABB - SF6 Gas Management Solutions Managing SF6 in Switchgear InstallationsDocument8 pagesBrochure ABB - SF6 Gas Management Solutions Managing SF6 in Switchgear Installationsdenny yusufNo ratings yet

- Myoillab To 20 Health ConcernsDocument5 pagesMyoillab To 20 Health Concernsdenny yusufNo ratings yet

- Senseor TeaserDocument16 pagesSenseor Teaserdenny yusufNo ratings yet

- Calibration System For SF Gas Density Measuring Instruments, Model BCS10Document5 pagesCalibration System For SF Gas Density Measuring Instruments, Model BCS10denny yusufNo ratings yet

- SF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000Document4 pagesSF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000denny yusufNo ratings yet

- 1.0 PT STP1 - BQDocument46 pages1.0 PT STP1 - BQdenny yusufNo ratings yet

- Gas Presence Detector, Model GPD-1000: Operating InstructionsDocument12 pagesGas Presence Detector, Model GPD-1000: Operating Instructionsdenny yusufNo ratings yet

- Pioneer Deh-2200ub 2250ub KeyboardDocument6 pagesPioneer Deh-2200ub 2250ub KeyboardYEMC YEMC0% (1)

- Stem 2c-Music On Plant Growth FinalDocument91 pagesStem 2c-Music On Plant Growth FinalYonaNo ratings yet

- Abruptio PlacentaDocument20 pagesAbruptio PlacentaHizkia Mangaraja Hasiholan LimNo ratings yet

- Tascam Us2400 ManualDocument24 pagesTascam Us2400 ManualDiego Guirado JimenezNo ratings yet

- Membean RootsDocument14 pagesMembean RootsMuhammad Sohail SialNo ratings yet

- Building Your Emotional Grid For The Law of AttractionDocument28 pagesBuilding Your Emotional Grid For The Law of AttractionMeraki Mary100% (2)

- Solar Street LightDocument26 pagesSolar Street LightAr Abhinav SrivastavNo ratings yet

- Catchillar - Environmental LawsDocument10 pagesCatchillar - Environmental LawsPam SyNo ratings yet

- A Playwriting Technique To Engage On A Shared Reflective Enquiry PDFDocument10 pagesA Playwriting Technique To Engage On A Shared Reflective Enquiry PDFEduardo orozco oteroNo ratings yet

- Class 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetDocument4 pagesClass 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetPPNo ratings yet

- Straight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedDocument12 pagesStraight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedKrupali JainNo ratings yet

- Control Panel ETV 0551Document40 pagesControl Panel ETV 0551Thillainathan So ThanabhalanNo ratings yet

- Heiser - Temperature Charts For Induction and Constant Temperature HeatingDocument10 pagesHeiser - Temperature Charts For Induction and Constant Temperature Heatingsharkdude1134No ratings yet

- Pentosin MTF-2Document1 pagePentosin MTF-2Taller MarioNo ratings yet

- REPORTDocument6 pagesREPORTrachana singhNo ratings yet

- AP II Assignment 1Document2 pagesAP II Assignment 1manan khndlwlNo ratings yet

- Rtaf SVX001C en - 11252015Document106 pagesRtaf SVX001C en - 11252015Thiraviam AyyappanNo ratings yet

- Samsung SH09xWH SH12xWH SERVICE MANUALDocument46 pagesSamsung SH09xWH SH12xWH SERVICE MANUALIoannis Perperis100% (1)

- Additive OF: Physical Characteristics FeaturesDocument1 pageAdditive OF: Physical Characteristics Featuresmarco_ravelo_10No ratings yet

- Schrack Accessories Industrial Power Relay RT: General Purpose RelaysDocument6 pagesSchrack Accessories Industrial Power Relay RT: General Purpose RelaysUlfran MedinaNo ratings yet

- Chapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Document33 pagesChapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Xwag 12No ratings yet

- Bersa Arms 2011 CatalogDocument16 pagesBersa Arms 2011 CatalogAmmoLand Shooting Sports News100% (1)

- Borrowing Costs PDFDocument9 pagesBorrowing Costs PDFanjcabsNo ratings yet

- Euro Currency MarketDocument33 pagesEuro Currency Marketsfkokane83% (6)

- LG 42lk410-tb Chassis Lp91u mfl62461536 1102-Rev00Document31 pagesLG 42lk410-tb Chassis Lp91u mfl62461536 1102-Rev00chathush.mihirangaNo ratings yet

- Defect ListDocument7 pagesDefect ListriaNo ratings yet

- Good and Evil of Moby Dick and Captain AhabDocument4 pagesGood and Evil of Moby Dick and Captain AhabCismaru ElenaNo ratings yet

- ERQ LocalisationDocument4 pagesERQ Localisationsvarit chakraNo ratings yet

Gas Density Monitor Model GDM-100: Applications

Gas Density Monitor Model GDM-100: Applications

Uploaded by

denny yusufOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Density Monitor Model GDM-100: Applications

Gas Density Monitor Model GDM-100: Applications

Uploaded by

denny yusufCopyright:

Available Formats

Instrumentation

Gas density monitor

Model GDM-100

WIKA data sheet SP 60.02

Applications

■■ Medium and high-voltage instruments

■■ Monitoring of the density of SF6 gas in closed tanks

■■ Raising an alarm when defined limit values have been

reached

Special features

■■ Case and wetted parts from stainless steel

■■ On-site display with switch contact

■■ Temperature-compensated and hermetically sealed,

therefore no influence of temperature fluctuations, diffe-

rences in level and atmospheric pressure fluctuations

■■ Compensation for gas mixtures possible

Gas density monitor model GDM-100

■■ Traceability by serial number

Description

Gas density is a crucial operating parameter for high-voltage

equipment. If the required gas density is not present, safe

operation of the plant cannot be guaranteed.

The WIKA gas density measuring instruments provide

reliable warnings against dangerously low gas levels, even in

extreme environmental conditions. Electrical switch contacts

warn the plant operator when the gas density drops below

defined levels due to leakage.

Numerous fields of application

The WIKA gas density monitor is hermetically sealed and

temperature-compensated. Measured value fluctuations

and erroneous alarms caused by changes in either ambient

temperature or air pressure are therefore prevented.

Via the on-site display, the system pressure based on 20 °C

can be read directly on the instrument. With the integrated

switch contacts, simple switching tasks can be realised

quickly and without complication.

WIKA data sheet SP 60.02 ∙ 08/2015 Page 1 of 4

Gas density monitor Ring

Bayonet ring, stainless steel, secured by means of 3 welding

Nominal size spots

100

Permissible humidity

Calibration pressure PE ≤ 90 % r. h. (non-condensing)

To customer specification

Ingress protection

Accuracy specifications IP 65 per EN 60529 / IEC 529

■■ ±1 % at ambient temperature +20 °C

■■ ±2.5 % at ambient temperature -20 … +60 °C and with Weight

calibration pressure in accordance with reference isochor With gas filling: approx. 0.8 kg

(reference diagram KALI-Chemie AG, Hanover, prepared With filling liquid: approx. 1.2 kg

by Dr. Döring 1979)

High-voltage test 100 %

Scale range 2 kV, 50 Hz, 1s

Vacuum and overpressure range with measuring span of

1.6 ... 25 bar (with an ambient temperature of 20 °C and

gaseous phase) Switch contacts

Permissible ambient temperature Electrical connection

Operation: -20 ... +60 °C (-4 ... +140 °F), gaseous phase Cable socket with compression fitting M20 x 1.5

Storage: -50 ... +60 °C (-58 ... +140 °F) Wire cross-section max. 2.5 mm²

Process connection Number of switch contacts

G ½ B per EN 837, lower mount

Selectable versions

Stainless steel, spanner flats 22 mm

Option 1 1 magnetic snap-action contact

Other connections or connection locations on request. Option 2 2 magnetic snap-action contacts

Option 3 3 magnetic snap-action contacts

Pressure element

Stainless steel, welded

Switching directions

Gas-tight: leak rate ≤ 1 · 10-8 mbar · l / s

Test method: helium mass spectrometry Selectable versions

Option 1 Falling pressure

Movement Option 2 Rising pressure

Stainless steel

Bimetal link (temperature compensation)

Switching functions

Dial Selectable versions

Aluminium Option 1 Normally open

The scale range is subdivided into red, yellow and green

Option 2 Normally closed

ranges

Option 3 Change-over contact (max. 2 switch points)

Pointer

Aluminium, black Circuits

Selectable versions

Case

Option 1 Galvanically connected (not for change-over

Selectable versions contact)

Option 1 Stainless steel, with gas filling Option 2 Galvanically isolated

Option 2 Stainless steel, with filling liquid

Switching accuracy

Gas-tight: leak rate ≤ 1 · 10-5 mbar · l / s Switch point = calibration see accuracy specifications

pressure PE:

Window

Switch point ≠ calibration Shifted parallel to calibration

Selectable versions pressure PE: pressure

Option 1 Laminated safety glass

Option 2 Clear non-splintering plastic

Page 2 ov 4 WIKA data sheet SP 60.02 ∙ 08/2015

Max. switching voltage

AC 250 V

Switching power

With gas filling: 30 W / 50 VA, max. 1 A

With filling liquid: 20 W / 20 VA, max. 1 A

Material of switch contacts

80 % Ag / 20 % Ni, gold-plated

Further information on magnetic snap-action contacts in data

sheet AC 08.01

Dimensions in mm

Approvals

Logo Description Land

EC declaration of conformity European Community

Low voltage directive 2006/95/EC, EN 61010-1

Manufacturer‘s information and certifications

■■ RoHS conformity 2011/65/EC

Approvals and certificates, see website

WIKA data sheet SP 60.02 ∙ 08/2015 Page 3 of 4

Ordering information

Model / Process connection / Pressure unit / Measuring range / Filling pressure / Switch configuration / Gas mixture / Options

© 2015 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

Page 4 of 4 WIKA data sheet SP 60.02 ∙ 08/2015

08/2015 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Kinsley David R Tantric Visions of The Divine Feminine 330p PDFDocument330 pagesKinsley David R Tantric Visions of The Divine Feminine 330p PDFvoiddoor94% (18)

- Chemrite Grout NSDocument2 pagesChemrite Grout NSghazanfar0% (1)

- DM - Model GDM-100-TADocument5 pagesDM - Model GDM-100-TAvladaemsNo ratings yet

- Ds sp6005 Archived en CoDocument5 pagesDs sp6005 Archived en CoJanaka GunawardhanaNo ratings yet

- Gas Density Monitor Model 233.52.063, With Gas Filling: ApplicationsDocument3 pagesGas Density Monitor Model 233.52.063, With Gas Filling: Applicationsdenny yusufNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAdenny yusufNo ratings yet

- Ds sp6002 en CoDocument5 pagesDs sp6002 en CoJanaka GunawardhanaNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- SF6 Meter DatasheetDocument3 pagesSF6 Meter DatasheetHaider-e-KararNo ratings yet

- Osisense XM Xmla070d2s11Document6 pagesOsisense XM Xmla070d2s11Amer CajdricNo ratings yet

- Attachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFDocument17 pagesAttachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFIbrahim Ben AmeurNo ratings yet

- Presostato Nautilus - XMLA070D2S11Document6 pagesPresostato Nautilus - XMLA070D2S11Fabian PerezNo ratings yet

- Gas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionDocument12 pagesGas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionchauNo ratings yet

- PRESSURE SWITCH - OsiSense XM ATEX D - XMLB020A2S11Document6 pagesPRESSURE SWITCH - OsiSense XM ATEX D - XMLB020A2S11Sigit KuncoroNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAbehnamatgNo ratings yet

- Osisense XM Xmlb020c2s12Document6 pagesOsisense XM Xmlb020c2s12Iman FaisalNo ratings yet

- Bourdon Tube Pressure Gauge With Switch Contacts Model 232.30.063, Stainless Steel Safety VersionDocument4 pagesBourdon Tube Pressure Gauge With Switch Contacts Model 232.30.063, Stainless Steel Safety VersionAnonymous 4MwmDaNbNo ratings yet

- Eds 300 ShippingDocument2 pagesEds 300 ShippingARINo ratings yet

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 pagesPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaNo ratings yet

- OsiSense XM - XMLB300D2S12Document6 pagesOsiSense XM - XMLB300D2S12Cricri CriNo ratings yet

- Ds pv3542 en CoDocument6 pagesDs pv3542 en CoPajnuNo ratings yet

- DatasheetDocument2 pagesDatasheetsolar desalinationNo ratings yet

- Gs1r1b2e (Ramc)Document20 pagesGs1r1b2e (Ramc)apisituNo ratings yet

- Electrical Contact Devices For Pressure and Temperature GaugesDocument2 pagesElectrical Contact Devices For Pressure and Temperature GaugesrhomadonaNo ratings yet

- Bourdon Tube Pressure Gauges Industrial Series Gauge Type 212.20Document2 pagesBourdon Tube Pressure Gauges Industrial Series Gauge Type 212.20Samruddha S KulkarniNo ratings yet

- DS PV2101 GB 8017Document2 pagesDS PV2101 GB 8017josip miskovicNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

- Harmony K - K2D012UCHDocument9 pagesHarmony K - K2D012UCHGregory CoerielNo ratings yet

- Gasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01Document5 pagesGasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01mdkhandaveNo ratings yet

- Siemens 5sy62017Document4 pagesSiemens 5sy62017Kleiber OrtegaNo ratings yet

- Ficha TecnicaDocument2 pagesFicha Tecnicaluis.trigosNo ratings yet

- 2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmDocument5 pages2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmSohail AhmedNo ratings yet

- Ds Sf6 GDT Gd10cl en Us 27789Document4 pagesDs Sf6 GDT Gd10cl en Us 27789behnamatgNo ratings yet

- 5.14.1 Norgren Pneumatic Pressure SwitchDocument4 pages5.14.1 Norgren Pneumatic Pressure SwitchMarleny Lindo CajusolNo ratings yet

- Dungs GW 50 A5 ManualDocument5 pagesDungs GW 50 A5 ManualMazhar IqbalNo ratings yet

- Pressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFDocument6 pagesPressostato - Schneider - XMLA-300-D2S11 - MI-D-610-IN-DF-0007-R0-8-13 PDFRichard Mayk teodoroNo ratings yet

- Pressure Sensors XM - ADW5M129012Document2 pagesPressure Sensors XM - ADW5M129012Carlos RodriguezNo ratings yet

- DS PV2201 GB 10873Document6 pagesDS PV2201 GB 10873eeghbaliNo ratings yet

- Ds pv3331 en CoDocument7 pagesDs pv3331 en Co9033301054No ratings yet

- Siemems RCDDocument4 pagesSiemems RCDDavid LimNo ratings yet

- VKGDocument6 pagesVKGJean DejardinNo ratings yet

- Pressure Transmitter With Thin Film Technology For Mobile Hydraulic Applications Model MH-1Document7 pagesPressure Transmitter With Thin Film Technology For Mobile Hydraulic Applications Model MH-1Larbi BelazizNo ratings yet

- Ds pv3560 en inDocument5 pagesDs pv3560 en inravisingh12911No ratings yet

- DS PV2001 GB 14782Document2 pagesDS PV2001 GB 14782josip miskovicNo ratings yet

- Feed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataDocument5 pagesFeed-Through Terminal Block - UK 6 N - 3004524: Key Commercial DataHendra WiratamaNo ratings yet

- 01 Pressure SwitchesDocument4 pages01 Pressure SwitchesfaviomarchantNo ratings yet

- Catalogue RelayDocument5 pagesCatalogue RelayElectrical CheminNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- DS B4B7 EN PressostatDocument2 pagesDS B4B7 EN PressostatmarouaneNo ratings yet

- Domat shd692 enDocument2 pagesDomat shd692 enLap Vo NhuNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- Pressure Measurement: Pressure Sensor For General Air and Gas Applications - Stainless Steel CTX-#.#.#.###.#Document6 pagesPressure Measurement: Pressure Sensor For General Air and Gas Applications - Stainless Steel CTX-#.#.#.###.#Henry DavichoNo ratings yet

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionDocument3 pagesBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranNo ratings yet

- MCB - 5sy5102-7Document6 pagesMCB - 5sy5102-7ThinhNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Data Sheet: Trs 24Vdc 1coDocument14 pagesData Sheet: Trs 24Vdc 1coibrahim abd elhadyNo ratings yet

- En18068-3-02-18 Eds3300 Plus VdmaDocument4 pagesEn18068-3-02-18 Eds3300 Plus VdmaigorNo ratings yet

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Document4 pages2/2-Way Solenoid Valve With Servo-Diaphragm, G 3/8 - G 1Sohail AhmedNo ratings yet

- 2p en dpd1t - dpd2tDocument2 pages2p en dpd1t - dpd2tghNo ratings yet

- Osisense XM Xmah12l2135Document2 pagesOsisense XM Xmah12l2135Milan StefanovicNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- PDSimply (UHF Version)Document2 pagesPDSimply (UHF Version)denny yusufNo ratings yet

- 240-Article Text-484-3-10-20210620Document7 pages240-Article Text-484-3-10-20210620denny yusufNo ratings yet

- 23-FP EPI CI MII AD 2023 DTD AUGUSTDocument1 page23-FP EPI CI MII AD 2023 DTD AUGUSTdenny yusufNo ratings yet

- Cired2013 ProsedureDocument6 pagesCired2013 Proseduredenny yusufNo ratings yet

- Cigre 157Document12 pagesCigre 157denny yusufNo ratings yet

- 36-42 ComemDocument7 pages36-42 Comemdenny yusufNo ratings yet

- Cpdm04en Course DetailsDocument1 pageCpdm04en Course Detailsdenny yusufNo ratings yet

- 1 s2.0 S1471490622000254 Main 2Document38 pages1 s2.0 S1471490622000254 Main 2denny yusufNo ratings yet

- Pengumuman DPT Vendor Komponen TrafoDocument3 pagesPengumuman DPT Vendor Komponen Trafodenny yusufNo ratings yet

- Wcica 2006 1714078Document4 pagesWcica 2006 1714078denny yusufNo ratings yet

- Marketing Porposal INED 2021-24082021Document13 pagesMarketing Porposal INED 2021-24082021denny yusufNo ratings yet

- Winning by Design - Blueprint - Metric Based LeadershipDocument6 pagesWinning by Design - Blueprint - Metric Based Leadershipdenny yusufNo ratings yet

- Safari - 20 Nov 2022 20.55Document1 pageSafari - 20 Nov 2022 20.55denny yusufNo ratings yet

- Gas Density Monitor Model 233.52.063, With Gas Filling: ApplicationsDocument3 pagesGas Density Monitor Model 233.52.063, With Gas Filling: Applicationsdenny yusufNo ratings yet

- Guidance - Electrical Switch Contact PDFDocument24 pagesGuidance - Electrical Switch Contact PDFdenny yusufNo ratings yet

- All Marketing Are Liars SummaryDocument16 pagesAll Marketing Are Liars Summarydenny yusufNo ratings yet

- Azure Product Catalogue 01-13Document1 pageAzure Product Catalogue 01-13denny yusufNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAdenny yusufNo ratings yet

- Partial Discharge Investigation and Failure Analysis On Distribution Network Using Acousic Camera, 2021, SuwansariDocument4 pagesPartial Discharge Investigation and Failure Analysis On Distribution Network Using Acousic Camera, 2021, Suwansaridenny yusufNo ratings yet

- Brochure ABB - SF6 Gas Management Solutions Managing SF6 in Switchgear InstallationsDocument8 pagesBrochure ABB - SF6 Gas Management Solutions Managing SF6 in Switchgear Installationsdenny yusufNo ratings yet

- Myoillab To 20 Health ConcernsDocument5 pagesMyoillab To 20 Health Concernsdenny yusufNo ratings yet

- Senseor TeaserDocument16 pagesSenseor Teaserdenny yusufNo ratings yet

- Calibration System For SF Gas Density Measuring Instruments, Model BCS10Document5 pagesCalibration System For SF Gas Density Measuring Instruments, Model BCS10denny yusufNo ratings yet

- SF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000Document4 pagesSF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000denny yusufNo ratings yet

- 1.0 PT STP1 - BQDocument46 pages1.0 PT STP1 - BQdenny yusufNo ratings yet

- Gas Presence Detector, Model GPD-1000: Operating InstructionsDocument12 pagesGas Presence Detector, Model GPD-1000: Operating Instructionsdenny yusufNo ratings yet

- Pioneer Deh-2200ub 2250ub KeyboardDocument6 pagesPioneer Deh-2200ub 2250ub KeyboardYEMC YEMC0% (1)

- Stem 2c-Music On Plant Growth FinalDocument91 pagesStem 2c-Music On Plant Growth FinalYonaNo ratings yet

- Abruptio PlacentaDocument20 pagesAbruptio PlacentaHizkia Mangaraja Hasiholan LimNo ratings yet

- Tascam Us2400 ManualDocument24 pagesTascam Us2400 ManualDiego Guirado JimenezNo ratings yet

- Membean RootsDocument14 pagesMembean RootsMuhammad Sohail SialNo ratings yet

- Building Your Emotional Grid For The Law of AttractionDocument28 pagesBuilding Your Emotional Grid For The Law of AttractionMeraki Mary100% (2)

- Solar Street LightDocument26 pagesSolar Street LightAr Abhinav SrivastavNo ratings yet

- Catchillar - Environmental LawsDocument10 pagesCatchillar - Environmental LawsPam SyNo ratings yet

- A Playwriting Technique To Engage On A Shared Reflective Enquiry PDFDocument10 pagesA Playwriting Technique To Engage On A Shared Reflective Enquiry PDFEduardo orozco oteroNo ratings yet

- Class 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetDocument4 pagesClass 10 National Genius Search Examination: Advanced: Check The Correctness of The Roll No. With The Answer SheetPPNo ratings yet

- Straight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedDocument12 pagesStraight / Angulated Multi-Unit System: © MIS Corporation. All Rights ReservedKrupali JainNo ratings yet

- Control Panel ETV 0551Document40 pagesControl Panel ETV 0551Thillainathan So ThanabhalanNo ratings yet

- Heiser - Temperature Charts For Induction and Constant Temperature HeatingDocument10 pagesHeiser - Temperature Charts For Induction and Constant Temperature Heatingsharkdude1134No ratings yet

- Pentosin MTF-2Document1 pagePentosin MTF-2Taller MarioNo ratings yet

- REPORTDocument6 pagesREPORTrachana singhNo ratings yet

- AP II Assignment 1Document2 pagesAP II Assignment 1manan khndlwlNo ratings yet

- Rtaf SVX001C en - 11252015Document106 pagesRtaf SVX001C en - 11252015Thiraviam AyyappanNo ratings yet

- Samsung SH09xWH SH12xWH SERVICE MANUALDocument46 pagesSamsung SH09xWH SH12xWH SERVICE MANUALIoannis Perperis100% (1)

- Additive OF: Physical Characteristics FeaturesDocument1 pageAdditive OF: Physical Characteristics Featuresmarco_ravelo_10No ratings yet

- Schrack Accessories Industrial Power Relay RT: General Purpose RelaysDocument6 pagesSchrack Accessories Industrial Power Relay RT: General Purpose RelaysUlfran MedinaNo ratings yet

- Chapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Document33 pagesChapter 1 - CONCEPT OF PLANT BIOTECH AGT 566Xwag 12No ratings yet

- Bersa Arms 2011 CatalogDocument16 pagesBersa Arms 2011 CatalogAmmoLand Shooting Sports News100% (1)

- Borrowing Costs PDFDocument9 pagesBorrowing Costs PDFanjcabsNo ratings yet

- Euro Currency MarketDocument33 pagesEuro Currency Marketsfkokane83% (6)

- LG 42lk410-tb Chassis Lp91u mfl62461536 1102-Rev00Document31 pagesLG 42lk410-tb Chassis Lp91u mfl62461536 1102-Rev00chathush.mihirangaNo ratings yet

- Defect ListDocument7 pagesDefect ListriaNo ratings yet

- Good and Evil of Moby Dick and Captain AhabDocument4 pagesGood and Evil of Moby Dick and Captain AhabCismaru ElenaNo ratings yet

- ERQ LocalisationDocument4 pagesERQ Localisationsvarit chakraNo ratings yet