Professional Documents

Culture Documents

Condenser Design

Condenser Design

Uploaded by

rcalaforraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condenser Design

Condenser Design

Uploaded by

rcalaforraCopyright:

Available Formats

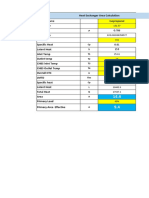

Shell and Tube heat exchanger design

1578 0.438

650

Data Shell Tube

Fluid Circulation Unit Ethanol Water Tube OD

Density of the shell side fluid, ℓ kg/m3 789 995 Tube ID

Inlet temperature Deg C 80 30 Tube thickness, t

Outlet temperature Deg C 45 38 Tube sheet thickness, t

Viscosity of the fluid, µ N/m2. s 0.00038 0.00078 Tube length. L

Specific heat capacity, Cp KJ/kg C 2.8 4.187 Tube length. Le

Thermal conductivity of the fluid, K W/m. C 0.155 0.62 Tube surface area, As

Fouling resistance m2/W. C 0.0002 0.000176 Tube cross sectional ar

Latent heat of vapourization of ethanol Kj/Kg 841 Assume heat transfer c

LMTD Correction factor 0.85 Tube side pass

Rdio m2/W. C 0.00020 Thermal conductivity o

Rw m2/W. C 0.00011

1 Total condensation Kw 368.6

2 Heat load Kw 368.6 42.956667

3 Water flow rate Kg/Hr 39620 11.01

4 LMTD C 26.2

5 Tm C 22.3

6 Ao m2 25.4

7 Number of tubes, Nt Nos 117

8 Number of tubes Per pass, Nt 58

9 Bundle diameter, Db mm 411.3

10 Tube Pitch, Pt m 0.032

11 Number of tubes in centre row, Nr Nos 9

12 Th 0.0051

13 Nr^(-1/6) 0.71

14 Film transfer co efficient, hc W/m2 C 1851.1

15 Tube velocity, Ut m/s 0.49 0.569

16 Tube velocity, Ut C 62.50

17 Tube side heat transfer, hi W/m2 C 3345.8

18 hio W/m2 C 2909.8

19 Calculated, 1/Uo W/m2 C 0.0013693

20 Uo W/m2 C 730.28

21 Ar m2 22.65

22 Aa m2 25.44

23 % Excess area % 12.35 % Excess area should 1

Tube OD m 0.0254

Tube ID m 0.0221 1.86

Tube thickness, t m 0.00125

Tube sheet thickness, ts m 0.035

Tube length. L m 2.8

Tube length. Le m 2.73

Tube surface area, As m2 0.218

Tube cross sectional area m2 0.0004

Assume heat transfer co efficienW/m2 C 6000

Tube side pass No 2

Thermal conductivity of SS316 W/m. C 16.2

hc= 0.95*KL*((ℓL(ℓL-ℓg)g)/uL*Th)^0.34*Nr^-0.16

% Excess area should 10-20%, So the design is safe

You might also like

- Napoleon'S Buttons: Chapter SummariesDocument21 pagesNapoleon'S Buttons: Chapter SummariesrcalaforraNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Assignment 2Document28 pagesAssignment 2ahsan aliNo ratings yet

- Experiment of Shell & Tube Heat ExchangerDocument29 pagesExperiment of Shell & Tube Heat ExchangerNanaNaurah9578% (9)

- Material Design Full Report CPE601Document41 pagesMaterial Design Full Report CPE601Amni SaufianNo ratings yet

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Finned Tube Heat ExchangerDocument2 pagesFinned Tube Heat ExchangerjnmanivannanNo ratings yet

- Air Cooled Condenser Design SpreadsheetDocument8 pagesAir Cooled Condenser Design Spreadsheetjamil100% (2)

- Equipment DetailsDocument33 pagesEquipment DetailsSaif Siddiqui100% (1)

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Heat Exchanger DesignDocument20 pagesHeat Exchanger Designpav270875% (4)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 pagesA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Shell Side Fluid SteamDocument6 pagesShell Side Fluid SteamrajachemNo ratings yet

- Shell & Tube Condenser Design Method: Propanol WaterDocument4 pagesShell & Tube Condenser Design Method: Propanol WaterwestewrNo ratings yet

- 1.5 NPS RecuperatorDocument7 pages1.5 NPS RecuperatorAnonymous pVoSWn8yh0No ratings yet

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaNo ratings yet

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlNo ratings yet

- Boiler CalculationsDocument6 pagesBoiler CalculationsJesther Marlou C. OrongNo ratings yet

- Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersDocument1 pageTransfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersMarco Ordoñez0% (1)

- Latest Design of ChimneysDocument2 pagesLatest Design of ChimneysHussam Udein0% (1)

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- Condenser Without SubcoolingDocument19 pagesCondenser Without SubcoolingtatvaNo ratings yet

- Boiler Efficiency Calculation Tabel Data MethodDocument2 pagesBoiler Efficiency Calculation Tabel Data MethodSomplak KudaNo ratings yet

- Steam Pressure DropDocument8 pagesSteam Pressure DropDavid Muñoz CastroNo ratings yet

- HX Design v1Document12 pagesHX Design v1mansourotaibiNo ratings yet

- Condenser CalculationDocument6 pagesCondenser Calculationgreenenergykolkata100% (2)

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 pagesWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- Distillation Column Dia CalculationDocument14 pagesDistillation Column Dia CalculationLovely TarunNo ratings yet

- Cooling - Tower and Boiler CalculationDocument47 pagesCooling - Tower and Boiler CalculationDavid LambertNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- Economizer Design CalculationsDocument4 pagesEconomizer Design CalculationsDaniyal HashmiNo ratings yet

- Steam CalculationDocument27 pagesSteam CalculationRAVI KUMAR CarpenterNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Heat Transfer in Jacketed VesselDocument2 pagesHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Document14 pagesRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaNo ratings yet

- Combustion CalcsDocument8 pagesCombustion Calcs31331311313No ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel Sizingzamijaka100% (1)

- Steam Coil DesignDocument2 pagesSteam Coil DesignHendri SinagaNo ratings yet

- Heat DutyDocument7 pagesHeat Dutyingegnere1234No ratings yet

- Condenser Design CalculationDocument11 pagesCondenser Design CalculationAlMakhie0% (1)

- Energy BalanceDocument22 pagesEnergy BalanceAishNo ratings yet

- Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesDocument3 pagesCalculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesBagadi AvinashNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456No ratings yet

- Cooling Tower FinalDocument10 pagesCooling Tower Finalmkha87100% (4)

- Design 2-Pass Shell and Tube Heat ExchangerDocument20 pagesDesign 2-Pass Shell and Tube Heat Exchangerazib100% (1)

- Reactors Dimensions - 1Document10 pagesReactors Dimensions - 1Abhijit MoreNo ratings yet

- Condenser CalculationDocument42 pagesCondenser CalculationIir Mnemonis0% (1)

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwNo ratings yet

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- Process Calculations For DesignDocument26 pagesProcess Calculations For DesignOmprakaash MokideNo ratings yet

- Desing of HEDocument25 pagesDesing of HEmeetNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- The correct mean ΔTDocument4 pagesThe correct mean ΔTManoj ManivasagamNo ratings yet

- Hi 0367 598X1700007ZDocument37 pagesHi 0367 598X1700007ZrcalaforraNo ratings yet

- Ri29 PDFDocument7 pagesRi29 PDFrcalaforraNo ratings yet

- Droplet Vaporization: Single Spherically Symmetric DropletDocument7 pagesDroplet Vaporization: Single Spherically Symmetric DropletrcalaforraNo ratings yet

- Aq2 41Document17 pagesAq2 41rcalaforraNo ratings yet

- Finhubblefocusthelivesofstarsnasa 0Document55 pagesFinhubblefocusthelivesofstarsnasa 0rcalaforraNo ratings yet

- Valve Sizing W IEC Noise - Gas MassDocument69 pagesValve Sizing W IEC Noise - Gas MassrcalaforraNo ratings yet

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing CalculationAbelardo Contreras100% (1)

- Table S1. List of Compounds Collected From The DIPPR Database and Used To Develop The QSPR Models ForDocument6 pagesTable S1. List of Compounds Collected From The DIPPR Database and Used To Develop The QSPR Models ForrcalaforraNo ratings yet

- Gas Sweetening Process PDFDocument57 pagesGas Sweetening Process PDFrcalaforraNo ratings yet

- Open Channel Flow Calculations With The Manning Equation 12 11 14 FinalDocument25 pagesOpen Channel Flow Calculations With The Manning Equation 12 11 14 FinalrcalaforraNo ratings yet

- Pop 1955 01Document132 pagesPop 1955 01rcalaforraNo ratings yet

- Tuvwxyvyz (-) - Z - X (Y) Z - ( y Vy T Zy Uvyuw - ( - T Y)Document40 pagesTuvwxyvyz (-) - Z - X (Y) Z - ( y Vy T Zy Uvyuw - ( - T Y)rcalaforraNo ratings yet

- 2011 - Extraction by Us and MicrowavesDocument12 pages2011 - Extraction by Us and MicrowavesrcalaforraNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- Heat Exchanger Design Handbook: SecondeditionDocument59 pagesHeat Exchanger Design Handbook: SecondeditionDanielNo ratings yet

- Introduction To Heat ExchangersDocument44 pagesIntroduction To Heat ExchangersmujeebtalibNo ratings yet

- Assignment 5: Unit 7 - Week 5Document1 pageAssignment 5: Unit 7 - Week 5atulNo ratings yet

- Design of A Heat Exchanger For A Supercritical CO2 Turbine SystemDocument68 pagesDesign of A Heat Exchanger For A Supercritical CO2 Turbine SystemTanatswa MoyoNo ratings yet

- Heat TransmissionDocument24 pagesHeat Transmissionespinosa_mra978No ratings yet

- Selecting of Vaporizer in LNG Regasification Plant: M. Ebrahimi Gardeshi, M. A. ShobeiriDocument7 pagesSelecting of Vaporizer in LNG Regasification Plant: M. Ebrahimi Gardeshi, M. A. ShobeiriundungNo ratings yet

- Seminar Topic:: Compact Heat ExchangerDocument14 pagesSeminar Topic:: Compact Heat ExchangerPankaj DohaleNo ratings yet

- Heat Exchanger For LectureDocument51 pagesHeat Exchanger For Lectureemielyn lafortezaNo ratings yet

- Oua3-Srme-lt-0001 Rev 3 Mechanical Equipment ListDocument5 pagesOua3-Srme-lt-0001 Rev 3 Mechanical Equipment ListmessaoudiNo ratings yet

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MNo ratings yet

- 418 - EWWD-VZ Chiller Series - Product ProfileDocument12 pages418 - EWWD-VZ Chiller Series - Product ProfileFabio AssoniNo ratings yet

- Heat Exchangers: S.SindhuDocument62 pagesHeat Exchangers: S.SindhuShivahari GopalakrishnanNo ratings yet

- Final ReportDocument70 pagesFinal ReportSudarshan KulandhaivelNo ratings yet

- Heat Exchangers: 12.7.1. Fluid Allocation: Shell or TubesDocument8 pagesHeat Exchangers: 12.7.1. Fluid Allocation: Shell or TubesAravind MuthiahNo ratings yet

- PDH Shell and Tube Heat Exchangers - Basic Calculations PDFDocument31 pagesPDH Shell and Tube Heat Exchangers - Basic Calculations PDFmordidomiNo ratings yet

- Tutorial Materials SelectionDocument2 pagesTutorial Materials SelectionSyahmiNo ratings yet

- IndexDocument134 pagesIndexKaleem UllahNo ratings yet

- Title of ExperimentDocument19 pagesTitle of ExperimentLi Xian YongNo ratings yet

- 3.1 Mass Transfer Equipment Design: H O CH Cooh CHDocument61 pages3.1 Mass Transfer Equipment Design: H O CH Cooh CHZAINOR SYAHIRA BINTI ZAINAL STUDENTNo ratings yet

- InternDocument22 pagesInternWorld Statistics AnalysisNo ratings yet

- Ni 2649Document18 pagesNi 2649Bruno Henrique LourencoNo ratings yet

- Z-17 Diesel Topping PlantsDocument29 pagesZ-17 Diesel Topping Plantssfar yassine100% (1)

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoNo ratings yet

- KR20601 3.7 Shell and Tube Heat ExchangerDocument4 pagesKR20601 3.7 Shell and Tube Heat ExchangerRiethanelia UsunNo ratings yet

- Internship at IOCL BarauniDocument36 pagesInternship at IOCL BarauniOMAR SULTANNo ratings yet