Professional Documents

Culture Documents

How TO

How TO

Uploaded by

Judson GortonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How TO

How TO

Uploaded by

Judson GortonCopyright:

Available Formats

How TO: Build a 'Nino' Adjustable RPM Module

The "Nino" Adjustable RPM Module (ARM) was created to replace the expensive and inflexible RPM plug

modules that MSD sells for their RPM Activated Window Switch. In order to come close to having the flexibility

the "Nino" ARM offers, you would have to buy the MSD Adjustable Low RPM Module (1000 to 3000 RPM) plus

all eight MSD Plug Module packs (3000 to 10,800 RPM), which would set you back about $185! Total material

cost for the "Nino" ARM is around $5. This device was created specifically for the MSD RPM Activated Window

Switch, but the underlying idea can be used to make modules for other types of RPM switches.

Special Notes

All parts were purchased from Radio Shack. The part number for the crimp terminals corresponds to a package

that contains six terminals. Radio Shack offers a package with four terminals for a couple cents less, but it

might save you a trip to buy the six-terminal package in case you accidentally break one. If you find a slightly

longer crimp terminal of the same diameter, buy it, as these where a little short (but they will work just fine.)

Some of you may wonder why I used a 4.7K-ohm potentiometer and not just two 10k-ohm potentiometers.

Well, I figured I would never want to activate my nitrous anywhere after 5000 RPM (!). Plus, by choosing the

4.7k-ohm potentiometer I can adjust the "ON" setting more accurately because each incremental turn of the

potentiometer is a smaller change in resistance when compared to the 10k-ohm potentiometer.

TOOLS SECTION

1.Ruler and pencil

2.Drill, including a 3/32" and ¼" drill bit

3.Hot glue gun

4.Soldering iron and wire

5.Multimeter

6.Small flat-head screwdriver

PARTS SECTION

1.Mini Project Enclosure (part #270-288)

2.Crimp Terminals (part #274-226)

3.4.7k-ohm Micro Potentiometer (part #271-281)

4.10k-ohm Micro Potentiometer (part #271-282)

5.Jumper wire, 22 gauge solid core

Assembling The ARM

Begin by marking the holes on the enclosure according to the Figure 1. Notice the dimensions for the holes are

referenced from the middle of the rectangular trench. Drill the four holes and make sure that the

potentiometers will turn freely when inserted. You may have to make the holes a little bigger than the drill bit

to get it perfect, but don’t make them too big or everything will fit loosely.

Insert the four crimp terminals until the barbs lock the terminal into place. Glue the terminals to the inside of

the enclosure, making sure that they are aligned straight and that you leave a clean spot for soldering. Cut

four small pieces of wire and solder one end of each wire to each terminal. Before you solder the

potentiometers, turn both of them all the way counter-clockwise with the screwdriver. Notice that there is a

large and small groove on the heads of the potentiometers. Insert the 4.7k-ohm potentiometer into the left

hole in the enclosure and position the potentiometer so the large groove points to 7 o’clock. Hold the

potentiometer in this position and glue it into place. Repeat this procedure with the 10k-ohm potentiometer.

Now, notice that there are three legs on the potentiometers, one "middle" leg and two "side" legs. Beginning

with the 4.7k-ohm potentiometer, connect one lead from the multimeter to the "middle" leg and the other lead

to either of the "side" legs. If the multimeter reads zero or very low resistance then you have found the legs

that are going to be soldered to the terminals. If you get a resistance near 4.7k-ohms then keep one lead on

the "middle" leg, and change the other lead to the other "side" leg. Now you should get a very low resistance.

Do the same for the 10k-ohm potentiometer.

You are almost ready to solder the potentiometers, but first you need to orient both halves of the enclosure

correctly. When the enclosure is assembled you want to have the 4.7k-ohm potentiometer on the left AND the

crimp terminals on the bottom (see the illustration). Now that you have everything oriented correctly, open

the enclosure and solder the corresponding terminals to the CORRECT legs of the potentiometers. Assemble

the enclosure and we are ready to test.

Testing The ARM

Using the multimeter, check the resistance between the 4.7k-ohm terminals. If you haven’t rotated the

potentiometer, it should still read a very low resistance. Now turn the potentiometer all the way clockwise and

the resistance should read very close to 4.7k-ohms. Check the 10k-ohm terminal resistance. If there is no

change in resistance after turning a potentiometer, then a wire must have become loose so check its

connections.

Determining RPM with a multimeter

I picked up this valuable piece of information, along with the idea of using potentiometers, on the net (thanks

KK). Basically, the formula goes like this:

Desired RPM = (Resistance in ohms) + 1000

So, say you want to activate the nitrous at 3500 RPM and cut it off at 6500 RPM. Using the screwdriver you

would turn the 4.7k-ohm potentiometer until the multimeter reads 2.5k-ohms (or 2500 ohms). Similarly, you

would turn the 10k-ohm potentiometer until the multimeter reads 5.5k-ohms (or 5500 ohms).

Labeling the "tach gauges" on the ARM

There are several options here:

1. You can set the potentiometers to the desired RPM and not label anything. In this case, you may want to

carry a multimeter in case you want to "tune" the nitrous at the track or on the street.

2. Using the multimeter you can mark off key RPM points (2000, 3000, 4000, etc.) around the potentiometers

(so they’ll look like tachometers, see illustration), enabling you to make rough adjustments without a

multimeter. In this case, remember that most factory tachometers are off by a couple hundred RPM so, what

you "dial in" on the ARM and what you see on the car’s tach may be different. If you use an aftermarket tach,

this method would be a good choice since the tach and the ARM will likely match exactly.

3. You can use you car’s tachometer to mark off key RPM points on the enclosure. The following instructions

may differ depending on how you have your nitrous kit installed, but I think you’ll get the idea. Connect the

"Nino" ARM to the MSD Window Switch, turn the car on, arm the nitrous system, but KEEP THE BOTTLE

CLOSED! Rev the engine to, say, 3000 RPM and hold it steady. Turn the 4.7k-ohm potentiometer until you

hear the solenoids (or the relay) click. Label the position of the potentiometer as 3000 RPM. Do this for all the

RPM points you want to label. This method will match the RPM points between the car’s tachometer and the

ARM.

Installing the "Nino" A.R.M.

Once you have set up the desired RPM points, you can insert the ARM into the MSD RPM Activated Window

Switch. If you hooked up everything correctly, the 4.7k-ohm potentiometer will be logically positioned on the

same side as the Window Switch’s "ON" label. You will now have complete control of your nitrous system’s

activation and shut-off RPM. If the nitrous is coming on a little too early resulting in E.T.-robbing wheelspin,

simply experiment with a higher "ON" RPM until you find the optimum setting for the existing track or street

conditions. You should probably "set and forget" the shut-off RPM at a couple hundred RPM before redline.

Now when you flip the switch, your nitrous system is truly ARM’ed. Happy hunting.

Credit to Corral, not me.

You might also like

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Maf Map EnhancerDocument4 pagesMaf Map Enhancerlucian_vNo ratings yet

- Ajuste de TPS DucatiDocument35 pagesAjuste de TPS DucatiGerardo Espinola CardozoNo ratings yet

- MD 100T00 ENU PowerPoint - M00Document12 pagesMD 100T00 ENU PowerPoint - M00CourageMarumeNo ratings yet

- How To Wind Your Own Audio TransformerDocument8 pagesHow To Wind Your Own Audio TransformerOscar Pacheco100% (1)

- Robotics Module 3 ExperimentDocument33 pagesRobotics Module 3 ExperimentmaxmanishNo ratings yet

- Robotics Module 3 PRINTDocument32 pagesRobotics Module 3 PRINTmaxmanishNo ratings yet

- How To Wind Your Own Audio TransformersDocument6 pagesHow To Wind Your Own Audio TransformersSougata DasNo ratings yet

- Constructing A Matrix KeypadDocument13 pagesConstructing A Matrix KeypadGeo BabuNo ratings yet

- s38 Base SettingDocument3 pagess38 Base SettingporkfaceNo ratings yet

- Aetna Tachometer Manual-Rev-7.0Document27 pagesAetna Tachometer Manual-Rev-7.0Alfonso Vallejo AguilarNo ratings yet

- 开关磁阻电机的ANSOFT建模方法Document28 pages开关磁阻电机的ANSOFT建模方法Nuwantha FernandoNo ratings yet

- Oxygen Sensor Simulator - JumperDocument7 pagesOxygen Sensor Simulator - JumperBrianssrt4100% (2)

- Ducati 2V Non Linear TPS Baseline AdjustmentDocument10 pagesDucati 2V Non Linear TPS Baseline AdjustmentmpkosaNo ratings yet

- Understanding MR GeneralDocument8 pagesUnderstanding MR GeneralRicardo Antonio VasquezNo ratings yet

- Este Man Si Explica Radio Control Como Es y Con TodoDocument216 pagesEste Man Si Explica Radio Control Como Es y Con TodoTg WallasNo ratings yet

- Manual Takometro MegelliDocument21 pagesManual Takometro MegelliPablo Hernan Acuña25% (4)

- BMW ResetDocument6 pagesBMW ResetDaniel BarsanNo ratings yet

- AEM Undocumented Settings v1Document13 pagesAEM Undocumented Settings v1Franklyn RamirezNo ratings yet

- 3D Printed Hovercraft ManualDocument30 pages3D Printed Hovercraft Manualdfdf dgfdNo ratings yet

- Constructing The Shift Light HondaDocument6 pagesConstructing The Shift Light HondaosmangutierrezencinasNo ratings yet

- EFI ModDocument1 pageEFI Modbluebelle2No ratings yet

- BMW - K1200 - Throttle-Position-Sensor TPS (Version 1-2)Document7 pagesBMW - K1200 - Throttle-Position-Sensor TPS (Version 1-2)steveNo ratings yet

- Mass Air FlowsensorDocument59 pagesMass Air Flowsensorcork_ieNo ratings yet

- How To Wind Your Own Audio TransformersDocument3 pagesHow To Wind Your Own Audio TransformerspomodoroNo ratings yet

- MeasurementOf SinglePhaseMotor2017Document6 pagesMeasurementOf SinglePhaseMotor2017KHULNA KINGS gamingNo ratings yet

- The Dial-a-Speed: One Motor Controller To Rule Them AllDocument12 pagesThe Dial-a-Speed: One Motor Controller To Rule Them AllluisaNo ratings yet

- How To Build An FM TransmitterDocument8 pagesHow To Build An FM Transmitterbrogan97% (38)

- Hyundai Elantra 1.6 Engine Electrical1Document55 pagesHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLNo ratings yet

- Manual Futaba 4nl 6nlkDocument6 pagesManual Futaba 4nl 6nlkanafrancaNo ratings yet

- PWMcircuit 08Document10 pagesPWMcircuit 08kcarringNo ratings yet

- 27MHz LinksDocument32 pages27MHz LinksNguyễn Vĩnh ThắngNo ratings yet

- S.No. TopicsDocument71 pagesS.No. TopicsKratika JainNo ratings yet

- MeasurementOf SinglePhaseMotor2019Document6 pagesMeasurementOf SinglePhaseMotor2019fissahayehadgu284No ratings yet

- Distributor Less Ignition SystemsDocument4 pagesDistributor Less Ignition SystemsxLibelle100% (5)

- Oxygen Sensor TestingDocument11 pagesOxygen Sensor TestingEl Gil R G100% (2)

- Automatic Pump ON - OFF Based On FireDocument5 pagesAutomatic Pump ON - OFF Based On Firesmartxdigital marketNo ratings yet

- 800m (2400ft) FM Transmitter That Fits On Top of A 9v BatteryDocument7 pages800m (2400ft) FM Transmitter That Fits On Top of A 9v BatteryDiego SeguroNo ratings yet

- Activity 4 CompleteDocument12 pagesActivity 4 CompleteMelissa CamargoNo ratings yet

- Calculations For Design Parameters of TransformerDocument3 pagesCalculations For Design Parameters of TransformerSiva MuruganNo ratings yet

- Electric Motor Diagnostics Defect Frequencies and Data ColleDocument51 pagesElectric Motor Diagnostics Defect Frequencies and Data ColleSubrata Dubey50% (2)

- Alternator & Regulator - BoschDocument6 pagesAlternator & Regulator - BoschIordan AdrianNo ratings yet

- Rewind Motor BrushlessDocument11 pagesRewind Motor Brushlesssharingiscaring69No ratings yet

- CK 1404Document3 pagesCK 1404Mahua ChandaNo ratings yet

- 4w FM TransmitterDocument9 pages4w FM TransmitterMantas PauliukonisNo ratings yet

- EE40 Final Hack Writeup: Project Name: Analog Line FollowerDocument6 pagesEE40 Final Hack Writeup: Project Name: Analog Line FollowerabdullahNo ratings yet

- Building A Three Phase Conv...Document9 pagesBuilding A Three Phase Conv...VYNZ Store100% (1)

- DESHENG PL550 Circuit AnalysisDocument9 pagesDESHENG PL550 Circuit AnalysisJose MesquitaNo ratings yet

- FM Transmitter PDFDocument6 pagesFM Transmitter PDFGoncalo EscusaNo ratings yet

- Antenna Ham Radio 2 MDocument2 pagesAntenna Ham Radio 2 MMunte si mareNo ratings yet

- K179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoDocument2 pagesK179. Unipolar Steppermotor Driver: Five, Six or Eight Wires. Five-Wire Motors Have The TwoducchungNo ratings yet

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10From EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10No ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- M3SD K003 Gen Hyd01 F DTL 0003 1Document1 pageM3SD K003 Gen Hyd01 F DTL 0003 1Shreyas ChawaleNo ratings yet

- DSC Tastatura Led Pc1404rkz SpecificatiiDocument2 pagesDSC Tastatura Led Pc1404rkz SpecificatiiAlexandru CraiovanNo ratings yet

- SAES-J-902-Electrical Systems For InstrumentationDocument32 pagesSAES-J-902-Electrical Systems For InstrumentationKarthikeyanNo ratings yet

- 5 X Appendix C Dimensional ResultsDocument5 pages5 X Appendix C Dimensional ResultsRene TapiaNo ratings yet

- Unit 9 Learning ResourcesDocument4 pagesUnit 9 Learning Resourcesapi-318119777No ratings yet

- CoalescedDocument202 pagesCoalescedPau Costa FerrerNo ratings yet

- Pascal StringsDocument5 pagesPascal StringsPutra PrasetyaNo ratings yet

- IC Agile Project Plan Template 8561Document3 pagesIC Agile Project Plan Template 8561khawjaarslanNo ratings yet

- Code Beautify: Showing 10 Goofy Ahh NamesDocument1 pageCode Beautify: Showing 10 Goofy Ahh NamesBernd WiesenmayerNo ratings yet

- BytesDocument21 pagesBytesBedeno HarargheNo ratings yet

- Med-Linket Special OfferDocument45 pagesMed-Linket Special OfferLogistica AquinoNo ratings yet

- Hive Properties:-: Hive - Metastore.warehouse - Dir Path You Want To Store Your Table and Database Directory and ItsDocument2 pagesHive Properties:-: Hive - Metastore.warehouse - Dir Path You Want To Store Your Table and Database Directory and ItsSaurabh KothariNo ratings yet

- Security Primer Ryuk 2Document5 pagesSecurity Primer Ryuk 2michael jackNo ratings yet

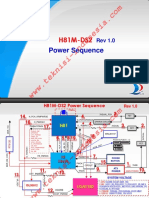

- H81M-DS2: Power SequenceDocument2 pagesH81M-DS2: Power SequenceHilario Serrano Flores100% (3)

- Network SecurityDocument66 pagesNetwork SecurityTariqul IslamNo ratings yet

- FLSNX04Document2 pagesFLSNX04Achmad ZakieNo ratings yet

- EE 315 Module 1Document10 pagesEE 315 Module 1Cedric Bernard100% (1)

- Assignment NO. 01: Semester - Spring 2021Document2 pagesAssignment NO. 01: Semester - Spring 2021amarjaved1No ratings yet

- 4 5792176376941381886 PDFDocument54 pages4 5792176376941381886 PDFAlex MekoNo ratings yet

- Hypack S H: R2Sonic 2022/2024, GPS With Dual Antenna Heading and MRUDocument11 pagesHypack S H: R2Sonic 2022/2024, GPS With Dual Antenna Heading and MRUutkuNo ratings yet

- Xladder User ManualDocument262 pagesXladder User ManualHyacinthe KOSSINo ratings yet

- Tom Clancy's Splinter Cell Chaos TheoryDocument35 pagesTom Clancy's Splinter Cell Chaos TheoryEmmanuel SibandaNo ratings yet

- FullStackCafe - Disgn PaterinDocument9 pagesFullStackCafe - Disgn PaterinMousa Nabil Al-KaloutiNo ratings yet

- Overview of Troubleshooting: Jason ZhangDocument49 pagesOverview of Troubleshooting: Jason ZhangMarco SánchezNo ratings yet

- Fundumental Group of A GraphDocument1 pageFundumental Group of A GraphMatan Even TsurNo ratings yet

- Sectigo-CPS-v5 2 2Document120 pagesSectigo-CPS-v5 2 2Nguyễn Đình PhúNo ratings yet

- Implementation Guide: Aiesec HubDocument33 pagesImplementation Guide: Aiesec Hubkerrouchi mohammed yakoubNo ratings yet

- Resume Tata Consultancy ServicesDocument3 pagesResume Tata Consultancy ServicesSubhashini 29No ratings yet

- Seema ChowhanDocument21 pagesSeema ChowhansarojNo ratings yet