Professional Documents

Culture Documents

Torque - Tabla ASME PCC

Torque - Tabla ASME PCC

Uploaded by

YGC04Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque - Tabla ASME PCC

Torque - Tabla ASME PCC

Uploaded by

YGC04Copyright:

Available Formats

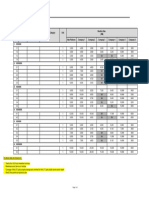

ASME PCC-1–2013

Table 1 Reference Values for Calculating Target Torque Values for Low-Alloy

Steel Bolting Based on Target Prestress of 50 ksi (Root Area)

(U.S. Customary Units)

(See section 12 for instructions on how to adjust torque values in this table.)

Target Torque, ft-lb

Nominal Bolt Size, in. Noncoated Bolts [Note (1)] Coated Bolts [Notes (1), (2), and (3)]

1

⁄2 60 45

5

⁄8 120 90

3

⁄4 210 160

7

⁄8 350 250

1 500 400

11⁄8 750 550

11⁄4 1,050 800

13⁄8 1,400 1,050

11⁄2 1,800 1,400

15⁄8 2,350 1,800

13⁄4 2,950 2,300

17⁄8 3,650 2,800

2 4,500 3,400

21⁄4 6,500 4,900

21⁄2 9,000 6,800

23⁄4 12,000 9,100

3 15,700 11,900

31⁄4 20,100 15,300

31⁄2 25,300 19,100

33⁄4 31,200 23,600

4 38,000 28,800

GENERAL NOTES:

(a) The values shown are based on a Target Prestress of 50 ksi (root area). See section 12 (Target

Torque Determination). The root areas are based on coarse-thread series for sizes 1 in. and

smaller, and 8-pitch thread series for sizes 11⁄8 in. and larger.

(b) There are many ways of calculating Target Torque values for bolted pressure joints. The basis for

the torque values in Table 1 are described in the Notes below. When conditions vary, such as dif-

ferent bolt materials or different coatings, from those considered in this table, refer to Appendix K,

or optionally to Appendix J, of these guidelines to compute appropriate torque values.

NOTES:

(1) The tabulated Target Torque values are based on “working” surfaces that comply with section 4

(Cleaning and Examination of Flange and Fastener Contact Surfaces) and section 7 (Lubrication of

“Working” Surfaces). The Target Torque values were computed using nut factors selected to achieve

a Target Prestress of 50 ksi. The torques were adjusted based on industry experience and verified

by bolt elongation measurements.

(2) The coating on coated bolts is polyimide/amide and is considered to be the sole source of

“working” surface lubrication; the application of a lubricant to the coated surfaces can result in a

considerable reduction in the assumed coefficient of friction of approximately 0.12. (See

Appendix K for equivalent nut factor.)

(3) Coated torque values apply only for initial tightening of new, coated bolts using the torque-

increment rounds shown in Table 2. For second and subsequent tightening by torquing methods,

use of lubricants and torque values as specified for noncoated bolts is recommended.

You might also like

- Oosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFDocument8 pagesOosterhof FG - Dietrich Bonhoeffer - The Cost of Discipleship PDFJoshua ChuaNo ratings yet

- UNxx H4200 AGDocument61 pagesUNxx H4200 AGpepe2176100% (1)

- Natsteel MeshDocument16 pagesNatsteel Meshsyafiqabang0% (1)

- Matlab Music SynthesisDocument11 pagesMatlab Music SynthesisDarwin Lajato Tipdas0% (1)

- Bolt Tigmetening Torque GuideDocument5 pagesBolt Tigmetening Torque GuidearomeroquirogaNo ratings yet

- Fig. 55 Fig. 55L: Structural AttachmentsDocument1 pageFig. 55 Fig. 55L: Structural Attachmentsvk1234No ratings yet

- HiMSEN General Instruction PDFDocument47 pagesHiMSEN General Instruction PDFjplm7881100% (3)

- Flushmax Running ProcedureDocument5 pagesFlushmax Running ProceduretonyNo ratings yet

- 3RD Floor: Flat Oval Duct - Joint Measurment SheetDocument3 pages3RD Floor: Flat Oval Duct - Joint Measurment Sheetsaquib715No ratings yet

- G For Every Episode: S#E# Half Killings Imdb GDocument7 pagesG For Every Episode: S#E# Half Killings Imdb GQandeelNo ratings yet

- Mubux 8500 8520 PDFDocument1 pageMubux 8500 8520 PDFnigel bellyNo ratings yet

- Morooka MST500 Service ManualDocument101 pagesMorooka MST500 Service Manualabdullah.rahmat93No ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- MST-Manual 19121735 PDFDocument101 pagesMST-Manual 19121735 PDFKároly VighNo ratings yet

- Control ValvesDocument1 pageControl ValvesJazielNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartVìctor ChicaìzaNo ratings yet

- Casing Patch Pressure Capacity ChartDocument2 pagesCasing Patch Pressure Capacity ChartRicardo ValeraNo ratings yet

- STAAD - Pro Report: Job InformationDocument12 pagesSTAAD - Pro Report: Job InformationMoinak BhattacharjeeNo ratings yet

- Ansi (Ok)Document34 pagesAnsi (Ok)Tran Anh TuanNo ratings yet

- 2009 BudgetDocument1 page2009 BudgetTeena Post/LaughtonNo ratings yet

- 2006 National Standard Plumbing Code ILLUSTRATED 255 PDFDocument1 page2006 National Standard Plumbing Code ILLUSTRATED 255 PDFAhmed Mohamed GadoNo ratings yet

- Tee Mixta (Push-On Brida)Document2 pagesTee Mixta (Push-On Brida)AugustoQuirozPanduroNo ratings yet

- AH EngDocument22 pagesAH EngcoachanzaiNo ratings yet

- Catalogo Uniones de Golpe Nov SaraDocument16 pagesCatalogo Uniones de Golpe Nov SaraCARLOS MORNo ratings yet

- CatalogFilename Gearing Catalog Form HSB MB0029E B9-B-10Document2 pagesCatalogFilename Gearing Catalog Form HSB MB0029E B9-B-10The Maison MaidsNo ratings yet

- IS 1538 Table 7 Flanged Sockets (Clause 9.1 and 11.1)Document1 pageIS 1538 Table 7 Flanged Sockets (Clause 9.1 and 11.1)Akshat Engineers Private LimitedNo ratings yet

- Ordering Information: Download TC Curves, CAD Drawings and Other Technical InformationDocument3 pagesOrdering Information: Download TC Curves, CAD Drawings and Other Technical InformationErnesto DeRoNo ratings yet

- Plumbing Hangers SupportsDocument27 pagesPlumbing Hangers Supportsronaldbhall1755No ratings yet

- Numbers Writing in TamilDocument3 pagesNumbers Writing in TamilkalpanaNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshNo ratings yet

- Price Fitting PVCDocument10 pagesPrice Fitting PVCtjiangtjiangsNo ratings yet

- CI2400 BS2400 Product DataDocument6 pagesCI2400 BS2400 Product DataDaniel BrownNo ratings yet

- (Based On Table 1, Chapter 9) : Maximum Number of Conductors or Fixture Wires in Electrical Metallic Tubing (EMT)Document5 pages(Based On Table 1, Chapter 9) : Maximum Number of Conductors or Fixture Wires in Electrical Metallic Tubing (EMT)j de santisNo ratings yet

- 8t TM Tadano Ts-75mlDocument8 pages8t TM Tadano Ts-75mlEugene NortjeNo ratings yet

- Greutate Proprie Placa 1000 Greutate 850 Proprie Perete: Placa Zidarie NR - Crt. Aria Suma L Zid. H Zid. SumaDocument9 pagesGreutate Proprie Placa 1000 Greutate 850 Proprie Perete: Placa Zidarie NR - Crt. Aria Suma L Zid. H Zid. SumaDaniel PanciuNo ratings yet

- PC800-8 Arm & BucketDocument4 pagesPC800-8 Arm & BucketRyan Abubakar Obili PakayaNo ratings yet

- Pipe SizeDocument2 pagesPipe SizeKrishna PATELNo ratings yet

- Ramill Tech Toolkit 3Document9 pagesRamill Tech Toolkit 3moddysNo ratings yet

- All in OneDocument26 pagesAll in OneRamandaNo ratings yet

- 5.1 Accessories Pe PN12,5 & PN 16 02 Jan 2018Document4 pages5.1 Accessories Pe PN12,5 & PN 16 02 Jan 2018Dannyadja RahardjoNo ratings yet

- Studding Outlet DimensionDocument2 pagesStudding Outlet DimensionpandiangvNo ratings yet

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDocument2 pagesTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartRuben GutierrezNo ratings yet

- Portland Bolt - ATSM SAEDocument1 pagePortland Bolt - ATSM SAEMinhddNo ratings yet

- Anv 295HDocument1 pageAnv 295HsaurabhsubhuNo ratings yet

- TB Woods Taper Lock Bushings CatalogoDocument10 pagesTB Woods Taper Lock Bushings Catalogofelipe ugarteNo ratings yet

- Daftar Harga: Fitting 8 - 17 (PN 10) Dan 10 - 21 8) Vinilon 02 2018Document4 pagesDaftar Harga: Fitting 8 - 17 (PN 10) Dan 10 - 21 8) Vinilon 02 2018Dannyadja RahardjoNo ratings yet

- Annex C TablesDocument60 pagesAnnex C TablesMohamad SannanNo ratings yet

- Market Survey Respond - SampleDocument1 pageMarket Survey Respond - Samplemuhammad ghazaliNo ratings yet

- SS SUB 175 v01Document1 pageSS SUB 175 v01mcohen LCINo ratings yet

- Flow Duration Curve Chart Title: Month Discharge (M 3/s) Discharge in Descending OrderDocument4 pagesFlow Duration Curve Chart Title: Month Discharge (M 3/s) Discharge in Descending OrderOsama JamilNo ratings yet

- Denah Tangga 1 SKALA 1:50 Denah Tangga 2 SKALA 1:50Document1 pageDenah Tangga 1 SKALA 1:50 Denah Tangga 2 SKALA 1:50yohanes karuniawanNo ratings yet

- TS-75ML: Total Rated LoadsDocument1 pageTS-75ML: Total Rated LoadsHiram LiraNo ratings yet

- Drilling Jar OP-J-002Document1 pageDrilling Jar OP-J-002Rene TorresNo ratings yet

- BridgeDocument12 pagesBridgekumarNo ratings yet

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocument3 pages88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNo ratings yet

- Pipe HangerDocument105 pagesPipe HangerYvan Nuñez EscobedoNo ratings yet

- NutsDocument1 pageNutsjoaquinNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- LS10 6clozeDocument1 pageLS10 6clozesinned68No ratings yet

- Diploma Intake 2022to2023 AdvertDocument1 pageDiploma Intake 2022to2023 AdvertLimbani SalleyNo ratings yet

- Chap 11Document3 pagesChap 11Flia Diaz ZunigaNo ratings yet

- Digital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualDocument2 pagesDigital Signal Processing Using Matlab Proakis 3rd Edition Solution ManualYasmin Yvonne De Chavez0% (4)

- 9702 s09 QP 4 PDFDocument24 pages9702 s09 QP 4 PDFPurplevision2003No ratings yet

- Literature Study Res.Document4 pagesLiterature Study Res.Areeb Ahmad100% (1)

- Lalon'S Bank Written Math:: Pipe and Cisterns Math Problems Part 1Document5 pagesLalon'S Bank Written Math:: Pipe and Cisterns Math Problems Part 1Zia UddinNo ratings yet

- Specifications Battery Chargers For Rail VehiclesDocument2 pagesSpecifications Battery Chargers For Rail VehiclesPirata ScribNo ratings yet

- 06 - Heights and DistancesDocument2 pages06 - Heights and DistancesRekha BhasinNo ratings yet

- How To Start A Candle BusinessDocument49 pagesHow To Start A Candle BusinessJessica Rodrigo100% (1)

- Automag Industries, Chennai: ISI StandardsDocument2 pagesAutomag Industries, Chennai: ISI Standardsnaga1501No ratings yet

- 04 Vikram Pawar Volume 3 Issue 2Document18 pages04 Vikram Pawar Volume 3 Issue 2Juwan JafferNo ratings yet

- Flash Notes SyndromesDocument8 pagesFlash Notes SyndromesschxzerrydawnNo ratings yet

- Compostable BagsDocument17 pagesCompostable Bagslucky jainNo ratings yet

- Saturn Quad QSDSSDocument1 pageSaturn Quad QSDSSniall.godleyNo ratings yet

- Measuring Place Attachment: Some Preliminary Results: October 1989Document8 pagesMeasuring Place Attachment: Some Preliminary Results: October 1989LathifahNo ratings yet

- Huawei FusionSolar Smart PV SolutionDocument32 pagesHuawei FusionSolar Smart PV SolutionJOGmzNo ratings yet

- XT0223S16128 Smart调试说明书 ENDocument81 pagesXT0223S16128 Smart调试说明书 ENBagwis100% (1)

- Chapter 03Document40 pagesChapter 03AC BañaresNo ratings yet

- Extreme Cold Weather (ECW) ClothingDocument7 pagesExtreme Cold Weather (ECW) ClothingSnowshadowNo ratings yet

- PROPOSALDocument62 pagesPROPOSALJam Dela CruzNo ratings yet

- Grade 10-EnglishDocument11 pagesGrade 10-EnglishlaiwelynNo ratings yet

- User'S Manual: Questions?Document32 pagesUser'S Manual: Questions?gorleanosNo ratings yet

- torque sensor |Unipulse CorporationDocument6 pagestorque sensor |Unipulse CorporationVerdy A. KoehuanNo ratings yet

- Astm D2563-94Document24 pagesAstm D2563-94Santiago AngelNo ratings yet

- Daftar Singkatan SMF JAntungDocument5 pagesDaftar Singkatan SMF JAntungBobby RahmantoNo ratings yet