Professional Documents

Culture Documents

Application of Inventory Material Management Techniques in Construction Project

Application of Inventory Material Management Techniques in Construction Project

Uploaded by

John AjishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Inventory Material Management Techniques in Construction Project

Application of Inventory Material Management Techniques in Construction Project

Uploaded by

John AjishCopyright:

Available Formats

APPLICATION OF INVENTORY MATERIAL MANAGEMENT

TECHNIQUES IN CONSTRUCTION PROJECT

ABSTRACT:

Construction materials consists more than 50% of the total cost of the

project. Efficient materials management plays a key role in the successful

completion of the project within estimated cost and time. In this research paper

written to explore current practice of material management to construction project

and Inventory control techniques such as ABC classification and EOQ analysis are

performed to maintain the inventory in an optimum level and S curve Analysis

performed to compare the Actual work performed cost and budgeted cost of work

performed using Microsoft project software. By applying inventory control

techniques such as ABC classification and EOQ analysis the stock out problems of

some A-class materials can be avoided. After the application of ABC and EOQ

analysis, the total cost of inventory will be reduced.

INTRODUCTION

The construction sector represents one of the most dynamic and complex

industrial environments. In developing countries like India, construction industry

plays a most important role in development and economic growth of the country.

Successful completion of projects requires all resources to be effectively managed.

Materials are the major element in any construction project. Construction material

constitutes a major cost component in any construction project. The total cost of

material may be 50-60% of the total project cost.

Material management is an approach for planning, organizing, and

controlling all those activities principally concerned with the flow of materials into

an organization. The goal of material management is to ensure that the materials

are available at their point of use when needed hence, efficient procurement of

material represents a key role in the successful completion of the work. [II]

Materials management is a critical component of the construction industry.

As such, organizations need to understand the effects of proper materials

management techniques on the effectiveness of project execution. Properly

implemented materials management techniques can achieve the timely flow of

materials and equipment to the jobsite, and thus facilitate improved work face

planning, increased labor productivity, better schedules, and lower project costs.

OBJECTIVE OF MATERIAL MANAGEMENT

There are two types of objective of material management.

1) Primary Objective

Low prices

Reduction in inventory cost and high inventory turnover ratio

Maintaining the flow of production.

Maintaining Consistency of quality

Cordial relationship with suppliers

Good record keeping protects the purchase and stores from charge of

corruption.

Development of personnel in the material department

2) Secondary Objectives

Promotion of Standardization with suppliers

Development of reciprocal relations with customers

Committees to decide on economic make or buy decisions

Objective of the Study

To study the conventional Practices of material management at Construction

site.

Comparison of planned and actual cost of construction material using S

Curve Analysis with the help of Microsoft Project Software.

Apply inventory control technique so as to minimize the total cost of

inventory.

RESEARCH METHODOLOGY

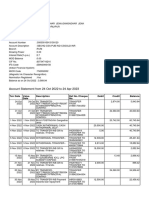

ABC Analysis

The ABC analysis classifies the material item based on the Annual Usage

Value of items in order to determine its priority among plenty of material items.

The ABC analysis is used to identifying material items that has a highest impact on

overall inventory cost. In this method materials divided into three Groups. I.e. A, B

and C Group. The grouping of all materials used in Construction into materials (A

Class ) which require the highest attention , materials (B Class) which require

medium attention and materials (C Class) which require the least attention such

that the control mechanism be focused on selective class of materials.

Methodology Adopted for ABC analysis:

1. List all the materials items used in the project along with unit price and quantity

consumed annually.

2. Compute the Annual Usage Value (AUV) of each material item.

3. Arrange the items in the descending order of AUV and compute the cumulative

percentage units consumed and cumulative percentage of AUV for each item.

(Appendix C)

4. Graph is plotted between cumulative percentages of unit’s vs. cumulative

percentages of items.

You might also like

- Project Estimating and Cost ManagementFrom EverandProject Estimating and Cost ManagementRating: 4.5 out of 5 stars4.5/5 (12)

- Marketing Project On ITC CompanyDocument59 pagesMarketing Project On ITC CompanyAkshay Jadhav80% (5)

- MBA 620 Week 3 HW SolutionsDocument5 pagesMBA 620 Week 3 HW SolutionsphoebeNo ratings yet

- Export Import Bank of India WWW - Edutap.co - inDocument6 pagesExport Import Bank of India WWW - Edutap.co - injashuramuNo ratings yet

- Framework - Tiny Asset EnginesDocument4 pagesFramework - Tiny Asset EnginesGishka GileNo ratings yet

- Kraft CaseDocument4 pagesKraft Casesamas7480No ratings yet

- CSEC POB June 2013 P032Document7 pagesCSEC POB June 2013 P032Richelle HUSBANDSNo ratings yet

- Study of Material Management Techniques On Construction ProjectDocument6 pagesStudy of Material Management Techniques On Construction ProjectIrfan AwanNo ratings yet

- Application of Inventory MaterialDocument7 pagesApplication of Inventory MaterialMohamed WayrahNo ratings yet

- A Literature Review On Analysis of Lean Concept in Construction Industry PDFDocument3 pagesA Literature Review On Analysis of Lean Concept in Construction Industry PDFAdicto AsereNo ratings yet

- Construction Material Management On Project SitesDocument5 pagesConstruction Material Management On Project SitesArathi KrishnaNo ratings yet

- Construction Material Management Through Inventory CONTROL TECHNIQUESDocument5 pagesConstruction Material Management Through Inventory CONTROL TECHNIQUESMohamed WayrahNo ratings yet

- JOURNAL Udaya ChangedDocument17 pagesJOURNAL Udaya ChangedUdaya JebishaNo ratings yet

- A Material Management in Construction Project Using Inventory Management SystemDocument17 pagesA Material Management in Construction Project Using Inventory Management SystemkjsdkjadNo ratings yet

- Imp RPPR PDFDocument15 pagesImp RPPR PDFRahul KumarNo ratings yet

- Review PaperDocument5 pagesReview PaperRohan C PrajapatiNo ratings yet

- Chapter One 1.1 Background of The StudyDocument46 pagesChapter One 1.1 Background of The StudyBarnabas UdehNo ratings yet

- A Critical Analysis of MaterialDocument10 pagesA Critical Analysis of MaterialMohamed WayrahNo ratings yet

- 5 - 6075402364573976110-MMPC 09Document12 pages5 - 6075402364573976110-MMPC 09B4BINONo ratings yet

- A Study of Inventory Management System in Construction IndustryDocument8 pagesA Study of Inventory Management System in Construction IndustryInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Lecture Notes Cons Mat Magt EditedDocument82 pagesLecture Notes Cons Mat Magt EditedSolomon Tekle100% (3)

- Cost Control in Residential Construction: Pavankumar Mohan Korke, Prof. Dr. A. B. More, Prof. Ganesh P JaradDocument13 pagesCost Control in Residential Construction: Pavankumar Mohan Korke, Prof. Dr. A. B. More, Prof. Ganesh P Jarad123kashmirNo ratings yet

- A Critical Literature Review On Application of Value Engineering in Building Construction ProjectDocument4 pagesA Critical Literature Review On Application of Value Engineering in Building Construction ProjectjayNo ratings yet

- ABC & S Curve in CivilDocument11 pagesABC & S Curve in CivilRaja AdityaNo ratings yet

- Project Report On Materials ManagementDocument13 pagesProject Report On Materials ManagementMd Nasimul HossainNo ratings yet

- Site Mgmt. CourseDocument17 pagesSite Mgmt. CoursesmshaidrNo ratings yet

- Construction Materials and SpecificationsDocument7 pagesConstruction Materials and SpecificationsSoumya SarangiNo ratings yet

- Study of Cost Control Techniques Used in Construction Industry PDFDocument7 pagesStudy of Cost Control Techniques Used in Construction Industry PDFJavier Estocalenko PeñaNo ratings yet

- Unit III - Materials ManagementDocument55 pagesUnit III - Materials ManagementSumiksh ManhasNo ratings yet

- Material Management in Construction IndustyDocument3 pagesMaterial Management in Construction IndustyadeolaodukoyaNo ratings yet

- Study of Cost Control On Construction Study of Cost Control On Construction Project Study of Cost Control On ConstructionDocument2 pagesStudy of Cost Control On Construction Study of Cost Control On Construction Project Study of Cost Control On ConstructionRohitGargNo ratings yet

- Manage Construction Costing System of ProjectsDocument53 pagesManage Construction Costing System of ProjectsYihun abrahamNo ratings yet

- Material ManagementDocument22 pagesMaterial ManagementDanica SolisNo ratings yet

- Material Schedule: Useful Tool For Effective Management of Building ProjectDocument13 pagesMaterial Schedule: Useful Tool For Effective Management of Building ProjectJunoir NentyNo ratings yet

- Unit 3.1 - Materials ManagementDocument58 pagesUnit 3.1 - Materials Managementlamao123No ratings yet

- Chapter 2 Material ManagementDocument10 pagesChapter 2 Material Managementtemesgen yohannesNo ratings yet

- Lecture Notes Cons Mat Magt Edited Final Rev 2012Document102 pagesLecture Notes Cons Mat Magt Edited Final Rev 2012Minichil YesmawNo ratings yet

- Analysis of Construction Materials Using Inventory Control TechniquesDocument8 pagesAnalysis of Construction Materials Using Inventory Control TechniquesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bba PM 4 BDocument20 pagesBba PM 4 BJyoti SinghNo ratings yet

- Analysis of Material Cost in Road ConstructionDocument8 pagesAnalysis of Material Cost in Road ConstructionMahesh JayawardanaNo ratings yet

- Module 4 PDFDocument31 pagesModule 4 PDFWCC2 channelNo ratings yet

- PCX - Report-KashidDocument8 pagesPCX - Report-KashidAshtashil BhambulkarNo ratings yet

- Inventory ListDocument15 pagesInventory ListRonak GorNo ratings yet

- An Analysis On Resource Planning, Cost Estimation and Tracking of Project by Earned Value ManagementDocument7 pagesAn Analysis On Resource Planning, Cost Estimation and Tracking of Project by Earned Value ManagementGanesh SppmNo ratings yet

- Notes For IDM 13-1Document19 pagesNotes For IDM 13-1Ankur AroraNo ratings yet

- Developing A Sample Web Application Model For Material ManagementDocument7 pagesDeveloping A Sample Web Application Model For Material ManagementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chapter - 7Document33 pagesChapter - 7Arifur Rahman MSquareNo ratings yet

- Analyzing Material Management Techniques On Construction ProjectDocument3 pagesAnalyzing Material Management Techniques On Construction ProjectSunny KapseNo ratings yet

- Application of ABC Analysis For Material Management of A Residential BuildingDocument7 pagesApplication of ABC Analysis For Material Management of A Residential BuildingJimmy O'TooleNo ratings yet

- Optimal Techniques For Cost Reduction and Control in Construction SitesDocument10 pagesOptimal Techniques For Cost Reduction and Control in Construction SitesAngelo VillalobosNo ratings yet

- Inventory Control SystemDocument11 pagesInventory Control SystemAbhinav SinghNo ratings yet

- Scope and Functons of Materials ManagementDocument5 pagesScope and Functons of Materials ManagementahmerkhateebNo ratings yet

- WK 7 Material ManagementDocument34 pagesWK 7 Material Managementitsbriskofficial05No ratings yet

- Material Management & ControlDocument146 pagesMaterial Management & Controlmatrixworld20No ratings yet

- Impact of Materials Management Practices in The Nigerian B Construction IndustryDocument10 pagesImpact of Materials Management Practices in The Nigerian B Construction IndustryMohamed WayrahNo ratings yet

- Jaabe2204152cm Proof HiDocument27 pagesJaabe2204152cm Proof HiKarina LópezNo ratings yet

- Waste Management in Construction (2012) : Ref: Build0034Document3 pagesWaste Management in Construction (2012) : Ref: Build0034Mahendra KumaraNo ratings yet

- PRE572 OgbeideDocument22 pagesPRE572 OgbeideChukwudi DesmondNo ratings yet

- Construction Materials, Stores and Inventory Control and Technology ManagementDocument10 pagesConstruction Materials, Stores and Inventory Control and Technology ManagementAnushka PatilNo ratings yet

- ReengineeringDocument10 pagesReengineeringmansoor.sendanNo ratings yet

- Lecture 10 Cost Estimation in Project ManagementDocument21 pagesLecture 10 Cost Estimation in Project Managementtanya sharmaNo ratings yet

- Material Delivery ScheduleDocument20 pagesMaterial Delivery ScheduleBarnabas UdehNo ratings yet

- S. Jannet Lydia P. Thanga VarshiniDocument10 pagesS. Jannet Lydia P. Thanga VarshiniThanga VarshiniNo ratings yet

- Dhayan PDFDocument50 pagesDhayan PDFJohn AjishNo ratings yet

- Experimental Study On Strength Properties of Concrete With Addition of Tamarind Kernal Powder As An AdditiveDocument24 pagesExperimental Study On Strength Properties of Concrete With Addition of Tamarind Kernal Powder As An AdditiveJohn AjishNo ratings yet

- DAYAN Bonafide 12Document11 pagesDAYAN Bonafide 12John AjishNo ratings yet

- Electromagnetic Braking SystemDocument18 pagesElectromagnetic Braking SystemJohn AjishNo ratings yet

- PGE0133Document2 pagesPGE0133John AjishNo ratings yet

- Endocrain Systm Question 1 ST DayDocument15 pagesEndocrain Systm Question 1 ST DayJohn AjishNo ratings yet

- PGE0112Document3 pagesPGE0112John AjishNo ratings yet

- PGE0123Document2 pagesPGE0123John AjishNo ratings yet

- PGE0114Document1 pagePGE0114John AjishNo ratings yet

- Full DetailsDocument61 pagesFull DetailsJohn AjishNo ratings yet

- Syllabus Banking PDFDocument3 pagesSyllabus Banking PDFJohn AjishNo ratings yet

- Optimization of Renewable Energy and Energy Storage Capacity With The Hierarchical Control Strategy of ESSDocument17 pagesOptimization of Renewable Energy and Energy Storage Capacity With The Hierarchical Control Strategy of ESSJohn AjishNo ratings yet

- Insurance PDFDocument2 pagesInsurance PDFJohn AjishNo ratings yet

- Analysis of Key Factors Affecting The Variation of Labour Productivity in Construction ProjectsDocument9 pagesAnalysis of Key Factors Affecting The Variation of Labour Productivity in Construction ProjectsJohn AjishNo ratings yet

- Optimization and Analysis of A Tilting Mechanism For A Narrow Tilting Car To Increase The Maximum Speed in CurvesDocument23 pagesOptimization and Analysis of A Tilting Mechanism For A Narrow Tilting Car To Increase The Maximum Speed in CurvesJohn AjishNo ratings yet

- FINALDocument34 pagesFINALJohn AjishNo ratings yet

- Application Details - Railway Recruitment Board PDFDocument3 pagesApplication Details - Railway Recruitment Board PDFJohn AjishNo ratings yet

- REVIEWDocument13 pagesREVIEWJohn AjishNo ratings yet

- Electric Vehicle Charging Station With An Energy Storage Stage For Split-Dc Bus Voltage BalancingDocument3 pagesElectric Vehicle Charging Station With An Energy Storage Stage For Split-Dc Bus Voltage BalancingJohn AjishNo ratings yet

- ABSTRACTDocument1 pageABSTRACTJohn AjishNo ratings yet

- Anandu PPT 1Document11 pagesAnandu PPT 1John AjishNo ratings yet

- Invoice 11Document1 pageInvoice 11John AjishNo ratings yet

- CERTIFICATEDocument1 pageCERTIFICATEJohn AjishNo ratings yet

- Tamil Nadu Veterinary and Animal Sciences University: For Office Use OnlyDocument2 pagesTamil Nadu Veterinary and Animal Sciences University: For Office Use OnlyJohn AjishNo ratings yet

- FVGGGGDocument173 pagesFVGGGGJohn AjishNo ratings yet

- Prelims: Subject Book Publis Her AuthorDocument4 pagesPrelims: Subject Book Publis Her AuthorJohn AjishNo ratings yet

- OIJPDocument1 pageOIJPJohn AjishNo ratings yet

- Option and FutureDocument28 pagesOption and Futuresunil_das95No ratings yet

- I LRD 3 L HF 78 W9 NBDWDocument3 pagesI LRD 3 L HF 78 W9 NBDWBIKRAM KUMAR BEHERANo ratings yet

- Resale Society NocDocument2 pagesResale Society NocVidhyesh GawasNo ratings yet

- School of Education: City College of TagaytayDocument3 pagesSchool of Education: City College of TagaytayAmparo Christine Recon-PanganibanNo ratings yet

- Deming'S 14 Points On Total Quality ManagementDocument19 pagesDeming'S 14 Points On Total Quality ManagementarulNo ratings yet

- Jihane Samrouth CVDocument1 pageJihane Samrouth CVsamroutjihaneNo ratings yet

- Production and Commerce What Is Commerce?Document4 pagesProduction and Commerce What Is Commerce?Agrippa MungaziNo ratings yet

- Go VermDocument15 pagesGo VermBoi Hot SauceNo ratings yet

- Introduction To Marketing ManagementDocument8 pagesIntroduction To Marketing ManagementVipul TripathiNo ratings yet

- AccuraCap PMSDocument35 pagesAccuraCap PMSAnkur100% (1)

- Hull: Options, Futures, and Other Derivatives, Tenth Edition Chapter 1: Introduction Multiple Choice Test BankDocument4 pagesHull: Options, Futures, and Other Derivatives, Tenth Edition Chapter 1: Introduction Multiple Choice Test BankKevin Molly KamrathNo ratings yet

- Internal Audit and Budget Department - Cash ReceiptsDocument13 pagesInternal Audit and Budget Department - Cash ReceiptsMarineth Monsanto100% (1)

- IJTIR Article 201504033Document6 pagesIJTIR Article 201504033hiba shujaatNo ratings yet

- EDE MicroDocument12 pagesEDE MicroNew EmailNo ratings yet

- Accounting 203 Chapter 12 TestDocument3 pagesAccounting 203 Chapter 12 TestAnbang XiaoNo ratings yet

- Family Business Management SyllabusDocument2 pagesFamily Business Management SyllabusnicsiehNo ratings yet

- BCP Lehman BrothersDocument8 pagesBCP Lehman BrothersVivek KumarNo ratings yet

- Chapter 20 - AnswerDocument4 pagesChapter 20 - AnsweragnesNo ratings yet

- Chapter 24Document20 pagesChapter 24Gelyn CruzNo ratings yet

- Term Paper OnDocument26 pagesTerm Paper OnMd. Nazmul IslamNo ratings yet

- Aarohan: Leadership Development Programme at Engineers India LimitedDocument19 pagesAarohan: Leadership Development Programme at Engineers India Limitedsandeep singhNo ratings yet

- Transition Guidance Chap 6Document44 pagesTransition Guidance Chap 6DoxCak3No ratings yet

- TBMC HealxDocument1 pageTBMC HealxElden Joy PecayoNo ratings yet