Professional Documents

Culture Documents

Horizontal Directional Drill Rig Plant Pre-Acceptance Checklist

Horizontal Directional Drill Rig Plant Pre-Acceptance Checklist

Uploaded by

EdiPrawiraSimanjuntakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizontal Directional Drill Rig Plant Pre-Acceptance Checklist

Horizontal Directional Drill Rig Plant Pre-Acceptance Checklist

Uploaded by

EdiPrawiraSimanjuntakCopyright:

Available Formats

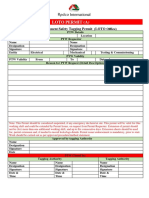

HORIZONTAL DIRECTIONAL DRILL RIG PLANT PRE-

ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs: Comcare/ State registration No Expire date:

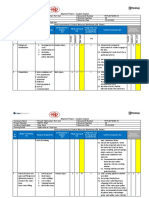

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Verif Check Requirement Verify Chec Requirement

y k

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged

Revision No: 1 Document Number: JH-FRM-PAE-001-62 Page 1 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

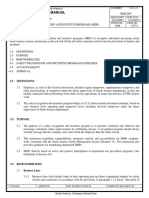

Verify Check Engine

Engine Mountings

HORIZONTAL DIRECTIONAL DRILL RIG PLANT PRE- Engine Guarding

Exhaust Guarding

ACCEPTANCE CHECKLIST Oil Leaks/check levels

Coolant Leaks/check levels

Coolant System

Vee Belt Condition

Air Cleaner System

Battery Condition / Mounting

Verif Verify Check Undercarriage

Verify Check Work platform Check Environmental

y Tracks complete and undamaged

Platform free from dirt Clean, free of organic materials (mud, dirt,

Levers / Controls Operational weeds or seeds) prior to arrival Idlers / Rollers

Access and Egress Engine baffling or noise reduction equipment Drivers free from leaks

Warning devices and other lights fitted as per manufacturers specifications Tracks drive Sprockets.

(flashing, head, tail, etc) are Smoke from internal combustion engines Articulation (slew) bearings and

appropriate for the environment in should not be visible for more than ten seconds retainers

which plant is being used. (check

Verify Check Warning signs and devices

environment noise criteria particularly if Instructions: Verify Box to be ticked by Owner / Supplier /

working out of hours) Operator prior to arrival onsite. Check Box to be ticked after Warning Signs - DANGER – BEWARE

Sun protection available over operator OVERHEAD WIRES &

visual inspection by the project

UNDERGROUND SERVICES

Verify Check Drilling Components

Warning Signs - Seat belts must be

Support Frame worn

Drill rod changer operational Warning Signs - NOISE WARNING

Hydraulic Rams operational SIGNAGE

Drill gauges fitted are legible

Emergency stops where fitted

operable (eg. Deadman switches)

Delivery Line, Hoses & Connections

(check for excessive, wear, leaks and

creep)

PLANT OWNER / OCCUPIER PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is being I certify that I have verified that the described plant has met the inspection criteria stipulated within this

serviced and maintained in accordance with the manufacturer’s specifications checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date: Name: Signature: Date:

Revision No: 1 Document Number: JH-FRM-PAE-001-62 Page 2 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

You might also like

- Kursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDocument163 pagesKursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDurga SreetharanNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Document9 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Delta akathehuskyNo ratings yet

- Capital SAR 5,000,000 Fully Paid C.R. No. 2051002660 P.O. Box 31770 Al Khobar 31952 Kingdom of Saudi Arabia Tel.: (+966) 13 882 8737 Fax: (+966) 13 882 4131Document8 pagesCapital SAR 5,000,000 Fully Paid C.R. No. 2051002660 P.O. Box 31770 Al Khobar 31952 Kingdom of Saudi Arabia Tel.: (+966) 13 882 8737 Fax: (+966) 13 882 4131Abu UmarNo ratings yet

- Key Project Resoures SDN BHDDocument2 pagesKey Project Resoures SDN BHDIkhmal IsmayatimNo ratings yet

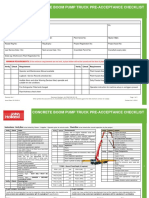

- Boom Placer ChecklistDocument3 pagesBoom Placer ChecklistAlves Edattukaran100% (3)

- Online Vendor Registration Declaration LetterDocument1 pageOnline Vendor Registration Declaration Letteramr ahmed0% (1)

- MOS-09-Generator Set Installation-Rev-0 (05, Jan)Document42 pagesMOS-09-Generator Set Installation-Rev-0 (05, Jan)Muhammad IrfanNo ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- 0006 - 030-Traffic and Vehicle SafetyDocument20 pages0006 - 030-Traffic and Vehicle SafetyFrancis VinojNo ratings yet

- Environment ProtectionDocument7 pagesEnvironment ProtectionPhilip YapNo ratings yet

- Job Explanation MeetingDocument26 pagesJob Explanation Meetingjp2udhayaNo ratings yet

- 13 Construction of Blower LineDocument7 pages13 Construction of Blower LinePangky AbasoloNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- Form-05 Contract Kick-Off MeetingDocument11 pagesForm-05 Contract Kick-Off MeetingMohammad GouseNo ratings yet

- Blasting Safety Toolbox Complete PDFDocument30 pagesBlasting Safety Toolbox Complete PDFHSE Health Safety EnvironmentNo ratings yet

- Hazard Identification PlanDocument36 pagesHazard Identification PlanLawrenceNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- 0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)Document5 pages0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)baseet gazaliNo ratings yet

- SNC - Lavalin: To Whom It May ConcernDocument29 pagesSNC - Lavalin: To Whom It May ConcernDeshwa Saravanan33% (3)

- Aqib Javed CV and DocumentsDocument15 pagesAqib Javed CV and DocumentsSher DilNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbMAZHARUL100% (1)

- TKS Noc2Document3 pagesTKS Noc2dubai eyeNo ratings yet

- Weekly - Safety - Highlights - October - 2021 - Week #4 (HUGRS)Document2 pagesWeekly - Safety - Highlights - October - 2021 - Week #4 (HUGRS)Zeeshan AbbasiNo ratings yet

- General Instruction Manual: Gas Testing Using Portable Gas MonitorsDocument11 pagesGeneral Instruction Manual: Gas Testing Using Portable Gas Monitorskhrayzie bhoneNo ratings yet

- PTW LOTO Permit To Work (A) DetailsDocument4 pagesPTW LOTO Permit To Work (A) DetailsZaki AziziNo ratings yet

- API 570 CertificateDocument1 pageAPI 570 Certificateamalhaj2013No ratings yet

- Risk Assessment FormDocument2 pagesRisk Assessment FormMeng Hwi KorNo ratings yet

- Marker Post Installation JSADocument10 pagesMarker Post Installation JSAShahid BhattiNo ratings yet

- Hope Certificate - IOSH-11654Document1 pageHope Certificate - IOSH-11654Muhammad ImranNo ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- Chemical Cleaning of 11TK30 (TANK) Rev-00Document2 pagesChemical Cleaning of 11TK30 (TANK) Rev-00Syed Ahmed manzoorNo ratings yet

- Omdb Ils 30 Rwy30lDocument1 pageOmdb Ils 30 Rwy30lItsIlaiNo ratings yet

- Assad Ullah Jan: ObjectiveDocument6 pagesAssad Ullah Jan: ObjectiveManda Khel Apna DesNo ratings yet

- Sample Construction Risk Assessment 3.13.55 PMDocument4 pagesSample Construction Risk Assessment 3.13.55 PMEmmanuelNo ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- Coshh FuelDocument3 pagesCoshh FuelDaniel Hernandez CalderonNo ratings yet

- 3.material Lifting & TransportationDocument5 pages3.material Lifting & TransportationZubair Ahmed KhaskheliNo ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- GU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1Document190 pagesGU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1hridya dasNo ratings yet

- 10.26.2020 20-030 Blasting ActivityDocument5 pages10.26.2020 20-030 Blasting ActivityPangky AbasoloNo ratings yet

- 51.0 - Powered Lift Trucks v3.0 EnglishDocument18 pages51.0 - Powered Lift Trucks v3.0 EnglishNoor Muddassir KhanNo ratings yet

- JSA FabricationDocument3 pagesJSA FabricationSwaroop Cherry100% (1)

- GESTS - Industrial Risk & Environment Management - October 2020 PDFDocument2 pagesGESTS - Industrial Risk & Environment Management - October 2020 PDFEurl GestsNo ratings yet

- Ako AcknowledgmentDocument1 pageAko Acknowledgmentclaude stanton0% (1)

- MPT RaDocument9 pagesMPT RaHassanNo ratings yet

- Job Safety Analysis FormDocument3 pagesJob Safety Analysis FormDamalieNo ratings yet

- RA For Erection of Precast Elemenets For BOP Ref. No 3761800008-R-01-C-E-69047 - ADocument33 pagesRA For Erection of Precast Elemenets For BOP Ref. No 3761800008-R-01-C-E-69047 - ARAMY ABOU AL DAHABNo ratings yet

- TCF & Civil Works - JSADocument42 pagesTCF & Civil Works - JSASiraj Mohamed IkbalNo ratings yet

- F.hse.07 Work PermitDocument4 pagesF.hse.07 Work PermitMOJIBNo ratings yet

- Risk Assessment For LIFTINGDocument5 pagesRisk Assessment For LIFTINGsak388036No ratings yet

- Emergency Responce Plan For Gulf CryoDocument22 pagesEmergency Responce Plan For Gulf CryoHabib ur rahman0% (1)

- Interview PreparationDocument10 pagesInterview Preparationosama ShahzadNo ratings yet

- GIL-ORGN-MGM-G-102-01 Storage, Handling and Disposal of Hazardous Waste PDFDocument8 pagesGIL-ORGN-MGM-G-102-01 Storage, Handling and Disposal of Hazardous Waste PDFRajarathinam1235463No ratings yet

- Contents:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument4 pagesContents:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualSAQIB100% (1)

- Daily JSA - Excavation and Soil CollectionDocument4 pagesDaily JSA - Excavation and Soil Collectionshoaib akhtarNo ratings yet

- Daily Crane Checklist Naw English and ArabicDocument2 pagesDaily Crane Checklist Naw English and ArabicmejbahNo ratings yet

- G.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018Document12 pagesG.I. 7 026 Crane and Heavy Equipment Incident and Investigation - 2018hasnainkhattakNo ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- The Rediscovered Benjamin Graham Lectures From 1946 - 47Document73 pagesThe Rediscovered Benjamin Graham Lectures From 1946 - 47Ludger MoraesNo ratings yet

- Soundproof GeneratorDocument1 pageSoundproof Generatorprasadi.ariyadasaNo ratings yet

- DX DiagDocument33 pagesDX DiagAnonymous DZdfuToZQBNo ratings yet

- ShrsDocument16 pagesShrsKevin Patel100% (1)

- Criminal ProcedureDocument42 pagesCriminal ProcedurePearl Joy Mijares100% (3)

- Paging RRRDocument153 pagesPaging RRRMark EmakhuNo ratings yet

- People Vs GozoDocument2 pagesPeople Vs GozoTeresa Cardinoza100% (1)

- Soni Penal Information PDFDocument290 pagesSoni Penal Information PDFAnarsinh Solanki100% (1)

- PGD500Document3 pagesPGD500m370550647No ratings yet

- Chapter 6 CompleteDocument30 pagesChapter 6 Completeduniya t vNo ratings yet

- Eat That Frog BookDocument14 pagesEat That Frog BookDivyanshu JoshiNo ratings yet

- Knight Who Wouldn T Fight Extract 1528597Document6 pagesKnight Who Wouldn T Fight Extract 1528597Ionela CiudinNo ratings yet

- (Digest) Ang Yu Asuncion vs. CA, 238 Scra 602 (FCD)Document2 pages(Digest) Ang Yu Asuncion vs. CA, 238 Scra 602 (FCD)RexNo ratings yet

- 4th Computer Hardware ServicingDocument25 pages4th Computer Hardware ServicingShabby Gay Malala TroganiNo ratings yet

- ELCOMA Diractory 2021 2022Document28 pagesELCOMA Diractory 2021 2022Neeraj KumarNo ratings yet

- Alliances MergedDocument87 pagesAlliances MergedSiddhant SinghNo ratings yet

- Portfolio Channel BeginnersDocument9 pagesPortfolio Channel BeginnersFerenc BárándiNo ratings yet

- Question 1. Calculate Covariance and Correlation Between Below Two Columns A and B?Document5 pagesQuestion 1. Calculate Covariance and Correlation Between Below Two Columns A and B?navdeepNo ratings yet

- No Fees Required For The Filing, Evaluation and Approval of CSHPDocument3 pagesNo Fees Required For The Filing, Evaluation and Approval of CSHPJai C. SantosNo ratings yet

- Aniket ResumeDocument2 pagesAniket ResumeKunal ChaudharyNo ratings yet

- Full Answers For Level 2 Accounting Learning Work BookDocument80 pagesFull Answers For Level 2 Accounting Learning Work BookSerki Love Setki LiveNo ratings yet

- Impact of Marketing Strategy On Profitability: Chapter One 1.1 Background of The StudyDocument7 pagesImpact of Marketing Strategy On Profitability: Chapter One 1.1 Background of The StudyMegha Jain BhandariNo ratings yet

- CounterACT Switch Commands in Use by The Switch Plugin v8.9.4Document798 pagesCounterACT Switch Commands in Use by The Switch Plugin v8.9.4Thiên HoàngNo ratings yet

- ItineraryDocument1 pageItineraryZul HardinataNo ratings yet

- BSC ITDocument34 pagesBSC ITUmesh ChandraNo ratings yet

- Frostpunk Kickstarter Deluxe Board Game With Frostlander Expansion (S15) - EbayDocument1 pageFrostpunk Kickstarter Deluxe Board Game With Frostlander Expansion (S15) - Ebayno thanksNo ratings yet

- Body Wash and CareDocument2 pagesBody Wash and CareBeautyTalkNo ratings yet

- Halton Design Guide enDocument54 pagesHalton Design Guide enimtiyaz94No ratings yet

- Business Agreement: Between M/S METROPOLIS HEALTHCARE LIMITED, Having Its RegisteredDocument4 pagesBusiness Agreement: Between M/S METROPOLIS HEALTHCARE LIMITED, Having Its RegisterednimeshnarnaNo ratings yet

- DevOps Syllabus CloudZenixDocument10 pagesDevOps Syllabus CloudZenixVamsi RamuNo ratings yet