Professional Documents

Culture Documents

DMT300 Fast Track R21 PDF

DMT300 Fast Track R21 PDF

Uploaded by

ZeigtCopyright:

Available Formats

You might also like

- Raj Bawa (Editor) - Advances in Clinical Immunology, Medical Microbiology, COVID-19, And Big Data_ Immunology, Microbiology, Biostatistics, And Big Data (Current Issues in Medicine, 2)-Jenny StanfordDocument930 pagesRaj Bawa (Editor) - Advances in Clinical Immunology, Medical Microbiology, COVID-19, And Big Data_ Immunology, Microbiology, Biostatistics, And Big Data (Current Issues in Medicine, 2)-Jenny Stanfordkaf micrNo ratings yet

- Manual final-FWG10-1Document36 pagesManual final-FWG10-1Leonid LeonovNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Chime Sog Thig Part 1 - Shenphen Dawa RinpocheDocument45 pagesChime Sog Thig Part 1 - Shenphen Dawa Rinpochesusco100% (4)

- Sea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXDocument38 pagesSea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXMNo ratings yet

- Erie 2401S Installation Service ManualDocument44 pagesErie 2401S Installation Service ManualGreg Reyneke100% (1)

- Mam Ky02sDocument34 pagesMam Ky02sTaufan Justvands67% (3)

- AP CALCULUS BC - MC - Related RatesDocument4 pagesAP CALCULUS BC - MC - Related RatesShannon BurtonNo ratings yet

- Retention in Complete DentureDocument53 pagesRetention in Complete DentureVikas Aggarwal67% (3)

- Samsung DW ManualDocument28 pagesSamsung DW ManualtimmboNo ratings yet

- AQE-SMO-I301-CP: Washroom and Plumbing SolutionsDocument12 pagesAQE-SMO-I301-CP: Washroom and Plumbing SolutionsRahmat KhanNo ratings yet

- CW-3000 Industrial Chiller User ManualDocument12 pagesCW-3000 Industrial Chiller User ManualPARTHIBAN RETECHNo ratings yet

- At13 Samsung Laundry Wf317 Fast Track r22012 02 07Document7 pagesAt13 Samsung Laundry Wf317 Fast Track r22012 02 07bigfatbob44100% (1)

- WA400PJHD Fast-Track 2Document7 pagesWA400PJHD Fast-Track 2Ashton TyreeNo ratings yet

- FLOWSERVE MSX MantenimientoDocument2 pagesFLOWSERVE MSX MantenimientoMarco CastroNo ratings yet

- Instruction Manual: Laboratory Equipment Pty LTD PH: 02 9560 2811 - Fax: 02 9560 6131Document32 pagesInstruction Manual: Laboratory Equipment Pty LTD PH: 02 9560 2811 - Fax: 02 9560 6131afiaNo ratings yet

- Water Softeners Residential 6700XTR Upflow Valve Softeners US ManualDocument12 pagesWater Softeners Residential 6700XTR Upflow Valve Softeners US ManualPromagEnviro.comNo ratings yet

- 1150 Handbook v1641207997627Document44 pages1150 Handbook v1641207997627cerengolcurNo ratings yet

- Dv338agw Xaa Dv407 Fast Track r6Document8 pagesDv338agw Xaa Dv407 Fast Track r6arjr51No ratings yet

- ##Samsung Laundry TrainingDocument80 pages##Samsung Laundry Trainingdreamyson1983100% (10)

- CW-3000 Manual - 20211119150533Document7 pagesCW-3000 Manual - 20211119150533Malick SyNo ratings yet

- AQT-56 Manual PDFDocument20 pagesAQT-56 Manual PDFFiorella BravoNo ratings yet

- Water Softeners Residential 6700XTR Downflow Valve Softeners US ManualDocument12 pagesWater Softeners Residential 6700XTR Downflow Valve Softeners US ManualPromagEnviro.comNo ratings yet

- Manual de Instruccion Vap 10sDocument20 pagesManual de Instruccion Vap 10sCeleynes RTNo ratings yet

- Vapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsDocument14 pagesVapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsVirginia MartelliNo ratings yet

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicNo ratings yet

- TC02 DigitalDocument17 pagesTC02 DigitalNebojsa CekicNo ratings yet

- Dishdrawer 605: Service Summary and Fault Code DescriptionsDocument8 pagesDishdrawer 605: Service Summary and Fault Code DescriptionsmentmentoneNo ratings yet

- Fleck 5800 LXT & SXT Downflow/Upflow: Service ManualDocument26 pagesFleck 5800 LXT & SXT Downflow/Upflow: Service ManualJean-Paul IstaceNo ratings yet

- STERILIZERDocument22 pagesSTERILIZERGeorgi100% (1)

- RoMatik160-210-420 Operating-Instructions INT enDocument6 pagesRoMatik160-210-420 Operating-Instructions INT enPearceNo ratings yet

- BEU-399E - 3D TRASAR Cooling Water - Light Industrial ApplicationsDocument4 pagesBEU-399E - 3D TRASAR Cooling Water - Light Industrial Applicationscouplesousse23No ratings yet

- MODEL 00SRO365 Thru 00SRO1095 Commercial Reverse Osmosis: Operation & Maintenance ManualDocument26 pagesMODEL 00SRO365 Thru 00SRO1095 Commercial Reverse Osmosis: Operation & Maintenance ManualGuevara AnaNo ratings yet

- G-tek-GT-U1-Manual-Dish washerDocument9 pagesG-tek-GT-U1-Manual-Dish washerMYINT WAINo ratings yet

- Sensor Activated Fire Extinguishing (S.A.F.E.) System: Design and InnovationDocument12 pagesSensor Activated Fire Extinguishing (S.A.F.E.) System: Design and InnovationKleiver LaraNo ratings yet

- Descongelador de Plasma Manual de Servicio GE2006-CeDocument29 pagesDescongelador de Plasma Manual de Servicio GE2006-CeMike Sanchez100% (1)

- Thoracic Pump User ManualDocument28 pagesThoracic Pump User ManualAnonymous Wpc3YdNo ratings yet

- User Manual Diode Laser-TST SusanDocument20 pagesUser Manual Diode Laser-TST SusanGiantBongNo ratings yet

- Instruction Manual for F.W.G (X SERIES) 一式R1 (2015.1217)Document80 pagesInstruction Manual for F.W.G (X SERIES) 一式R1 (2015.1217)2533 9564No ratings yet

- Fast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaDocument7 pagesFast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaFaffNo ratings yet

- Fast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRDocument7 pagesFast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRZeigtNo ratings yet

- S.A.F.E. Ph7 Coin R4Document10 pagesS.A.F.E. Ph7 Coin R4naokito AkemiNo ratings yet

- Baxter Flo-Gard3 Infusion Pump - Service GuidelineDocument2 pagesBaxter Flo-Gard3 Infusion Pump - Service Guidelineamerico.villarrealNo ratings yet

- Trufrost If 20 Ice Flaker With Self Contained Bin 20 Kgs 24 HrsDocument8 pagesTrufrost If 20 Ice Flaker With Self Contained Bin 20 Kgs 24 Hrshamba AllahNo ratings yet

- 6 Installation System RefDocument48 pages6 Installation System Refcengiz kutukcuNo ratings yet

- Fleck 5600Sxt Upflow: Service ManualDocument28 pagesFleck 5600Sxt Upflow: Service ManualdewaNo ratings yet

- Dosing Pump Operational ManualDocument12 pagesDosing Pump Operational Manualalex_alexutzuuNo ratings yet

- Curtis Gem 120a ManualDocument12 pagesCurtis Gem 120a ManualBWNo ratings yet

- Dfs-Manual-2 13 15Document37 pagesDfs-Manual-2 13 15Enderson RamosNo ratings yet

- Ultrasonic Mist MakerDocument5 pagesUltrasonic Mist MakerDoni indra sukmanaNo ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- TLL13X Fozmula Liquid Level Sensor Data 8-6-33R2Document1 pageTLL13X Fozmula Liquid Level Sensor Data 8-6-33R2moisesNo ratings yet

- Triton Shower ManualDocument24 pagesTriton Shower ManualAmanda KinsellaNo ratings yet

- User Manual: FOR Soniclean Digital Benchtop Ultrasonic CleanersDocument12 pagesUser Manual: FOR Soniclean Digital Benchtop Ultrasonic Cleanersغزوان عماد الدين الحسينيNo ratings yet

- Ameritrol Electronic Thermal Flow SensorDocument2 pagesAmeritrol Electronic Thermal Flow SensorJavier AffifNo ratings yet

- Retrotec Field CalDocument15 pagesRetrotec Field CalMarkNo ratings yet

- SAT-S0260W - Service ManualDocument45 pagesSAT-S0260W - Service ManualTin Cậy Kỹ Thuật100% (1)

- Operation and Maintenance ManualDocument22 pagesOperation and Maintenance ManualKiki HendraNo ratings yet

- Cla FiltersDocument22 pagesCla FiltersAce Dynamics IndiaNo ratings yet

- Soft TROUBLE SHOOTING & PMPDocument10 pagesSoft TROUBLE SHOOTING & PMPLaur IriNo ratings yet

- Adiabatic ManualDocument6 pagesAdiabatic ManualWidawan Nurardi ArnantoNo ratings yet

- HT64-132 OWS Final Drawings150525Document24 pagesHT64-132 OWS Final Drawings150525jamukanak padNo ratings yet

- Operating Manual: High-Pressure CleanersDocument44 pagesOperating Manual: High-Pressure CleanersPierre LangevinNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- HAIER Combo WDHWD1600 HWD1600 SERVICE MANUALDocument28 pagesHAIER Combo WDHWD1600 HWD1600 SERVICE MANUALZeigt100% (1)

- Fast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRDocument7 pagesFast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRZeigtNo ratings yet

- DW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFDocument14 pagesDW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFZeigtNo ratings yet

- Service Manual Dishwashers Type: DW70Document33 pagesService Manual Dishwashers Type: DW70ZeigtNo ratings yet

- 24in Built in Electronic 5995293536 Update PDFDocument65 pages24in Built in Electronic 5995293536 Update PDFZeigtNo ratings yet

- dw20 Asko DishwasherDocument46 pagesdw20 Asko DishwasherZeigt100% (1)

- dw95 Asko DishwasherDocument18 pagesdw95 Asko DishwasherZeigtNo ratings yet

- Rfg298aa Samsung Refrigerator PDFDocument133 pagesRfg298aa Samsung Refrigerator PDFZeigtNo ratings yet

- DMT400 Fast Track R21 PDFDocument6 pagesDMT400 Fast Track R21 PDFZeigtNo ratings yet

- Alpm 39201Document128 pagesAlpm 39201ZeigtNo ratings yet

- Corticosteroids: Dr.R.Prameela, Assistant Professor of Pharmacology, GMC, SrikakulamDocument64 pagesCorticosteroids: Dr.R.Prameela, Assistant Professor of Pharmacology, GMC, SrikakulamRamadi PrameelaNo ratings yet

- Research On:: Department of English Language Faculty of Arts University of KordofanDocument49 pagesResearch On:: Department of English Language Faculty of Arts University of KordofanMr DragonNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- Prezantimi - Pristina International Airport-AjDocument61 pagesPrezantimi - Pristina International Airport-AjPerparim ShapiNo ratings yet

- Rob - Report 41+508 - 01.02.2016Document13 pagesRob - Report 41+508 - 01.02.2016vivekNo ratings yet

- Letter of Undertaking Letter Seggregation in ChargeDocument1 pageLetter of Undertaking Letter Seggregation in ChargeSijin SivankuttyNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Basic Waste Management Training After Revision (Compatibility Mode)Document64 pagesBasic Waste Management Training After Revision (Compatibility Mode)Gangsar LukmanjayaNo ratings yet

- A Guide To Crane and DerricksDocument222 pagesA Guide To Crane and Derricksrafaqat hussainNo ratings yet

- 2010AnalMethMicrowave AssisteddigestioninclosedvesselsDocument6 pages2010AnalMethMicrowave AssisteddigestioninclosedvesselsMuchlas AkbarNo ratings yet

- Brother Sewing Machine S7250aDocument88 pagesBrother Sewing Machine S7250aDavid Andres Ducuara MayorgaNo ratings yet

- CDS57006 Bosch LSU 4.9 Sensor PDFDocument4 pagesCDS57006 Bosch LSU 4.9 Sensor PDFAnonymous K3FaYFlNo ratings yet

- Zuku Visual Flashnotes Distemper ExtendedDocument4 pagesZuku Visual Flashnotes Distemper ExtendedShubham HarishNo ratings yet

- Checklist For Visa Application Tourism and Visit To Family / FriendsDocument4 pagesChecklist For Visa Application Tourism and Visit To Family / FriendsBepdjNo ratings yet

- STPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: SulitDocument14 pagesSTPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: Sulitrevathy varatharajahNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- Physiology Past PapersDocument11 pagesPhysiology Past PapersIrfan Haider FaniNo ratings yet

- औषधे मिक्स प्रमाणDocument11 pagesऔषधे मिक्स प्रमाणShivam PatilNo ratings yet

- Cable, Conductor and Conduit - Fr.enDocument14 pagesCable, Conductor and Conduit - Fr.eneuge sylNo ratings yet

- CourseDocument2 pagesCourseRNo ratings yet

- Conditioner Portatil Sams ClubDocument5 pagesConditioner Portatil Sams ClubJuan Carlos RodriguezNo ratings yet

- Nebosh International Diploma ID1Document6 pagesNebosh International Diploma ID1Haltebaye Djim RahmNo ratings yet

- Resistance Training: FW01 Physical Activities Toward Health and Fitness 1Document7 pagesResistance Training: FW01 Physical Activities Toward Health and Fitness 1Jerome SadulloNo ratings yet

- Acp CBC 1Document52 pagesAcp CBC 1Danny R. SalvadorNo ratings yet

DMT300 Fast Track R21 PDF

DMT300 Fast Track R21 PDF

Uploaded by

ZeigtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DMT300 Fast Track R21 PDF

DMT300 Fast Track R21 PDF

Uploaded by

ZeigtCopyright:

Available Formats

Fast Track Troubleshooting

IMPORTANT SAFETY NOTICE – “For Technicians Only” This service data sheet is

intended for use by persons having electrical, electronic, and mechanical experience

Models: and knowledge at a level generally considered acceptable in the appliance repair trade.

DMT300RFB/XAA Any attempt to repair a major appliance may result in personal injury and property

DMT300RFS/XAA damage. The manufacturer or seller cannot be responsible, nor assume any liability for

DMT300RFW/XAA injury or damage of any kind arising from the use of this data sheet.

Publication # tsDMT300RF Revision Date 03/21/2011

Which Detergent Ingredients Give Best Dishwasher Performance

Detergent with a separate rinse additive in the dispenser gives better drying performance.

For tough baked on soils an Enzyme detergent is better at hydration of the food soils.

For staining such as tomato, coffee and tea, a detergent with Chlorine bleach will work on the stains much better than

an Enzyme based detergent.

Now that phosphate content in dishwasher detergent has plummeted to 0.5 percent from as high as 8.7 percent, condi-

tioned (soft) water is even more critical. The reduction of phosphates may cause spots and film on dishes that can form

when the minerals and food bits combine during the wash.

It is important to test water hardness for washability complaints.

SUPPORT INFORMATION

Training — Plus One

http://my.plus1solutions.net/clientPortals/samsung/

Help — GSPN http://service.samsungportal.com/

Samsung Product Support TV

http://support-us.samsung.com/spstv/howto.jsp

Customer information videos and chat programs

Programs for Fridges, Laundry, Ranges & D/W

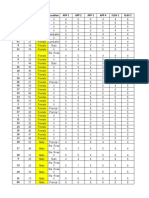

Dishwasher Cycle Chart — Air Vent Dry System

# tsDMT300RF RevB 03/21/2011 1

# tsDMT300RF RevB 03/21/2011 2

CN302 CN803 Key Driver

1-6 Power Relay Driver (Blk-Org) CN01 CN1 PBA Power Main PCB 10-11 5vdc

2-6 Heater Relay Driver (Red-Org) 1 120vac L1 (Wht)

4-Trubidity Receiver (Yel) 3 120vac N (Blk)

5-Trubidity Transmitter (Brn)

7-6 5vdc (Pnk-Org)

8-Rinse Aid Sensor (Gry)

9-6 12vdc (Wht-Org) (Pwr On)

9-6 6vdc (Wht-Org) (Pwr Off)

CN301

1-Low Water Sensor

3-Overflow Sensor

5-Water Counter

6-Leakage Sensor

8-Thermistor

9– 12vdc

10-Door Check Receiver

Components

CN201

Component Voltage Ω

1-(CN101-1) Wash Mtr (Red-Wht) 120vac (Ω test to Yel on Disp)

Water Valve 120vac 1.2 KΩ 2-(CN101-1) Fan Mtr (S/Blu-Wht) 120vac (Ω test to Yel on Disp)

5-(CN101-1) Disp Wax Mtr (Wht-Wht) 120vac (Ω test to Yel on Disp)

Drain Pump 120vac 37Ω-42Ω 7-(CN101-1) Inlet Valve (Brn-Wht) 120vac (Ω test to Yel on Disp)

Heater 120vac 13Ω 8-(CN101-1) Drain Pump (Org-Wht) 120vac

Fan Mtr 120vac 1.8kΩ

Disp Wax Mtr 120vac 2.3KΩ

Thermal Actuator 1.45kΩ

Circulation Mtr 120vac 21.5Ω

Thermistor

Temp. Resistance Temp.

Resistance (kΩ)

(ºF) (kΩ) (ºF)

125.78 41 26.065 104

98.323 50 21.385 113

77.454 59 17.599 122

61.465 68 14.579 131

49.12 77 12.14 140

39.517 86 10.159 149

31.996 95 8.542 158

# tsDMT300RF RevB 03/21/2011 3

Leaking Code

Moisture creates resistance between the pins. ALWAYS

clean the area below the pins after troubleshooting.

Check Pump Ass’y for proper twist lock.

Condensation may form on the tray from uninsulated

outside walls or large hole in the floor to a cold basement.

Check Drain Hose for cut or small hole.

Check all components mounted to the sump for any

leakage.

Detergent Door Not Opening

1. Never overfill the dispenser compartment with powder or liquid, only go below or up to fill line.

2. If there is residue around the dispenser door area. Previously undispensed, partially dispensed, or door stuck close

issue) clean it with mild soap & water. The residue can foul the mating latch.

3. If the customer uses ―tablets‖ or some self contained type of soap tab, make sure it is fully seated and the door does

not ‗sandwich‘ it shut.

4. Make sure that in the rack nearest to the dispenser door when the door is shut, is not obstructing the opening of the

dispenser with some protruding utensil.

Testing The Detergent Door and Dispenser

1. Disconnect wires from disp. & close detergent door.

2. Connect Fused cheater cord and apply 120vac

3. In approximately 40 seconds the wax motor will open the door.

4. Remove power, allow wax motor to return.

5. Restore power to wax motor, in approximately 40 seconds the rinse aid will

be activated. Remove power.

6. Close detergent door to repeat test

Leaking and Poor

Washability—Check

for split wash arms

# tsDMT300RF RevB 03/21/2011 4

CODE Meaning Occurring condition Expected causes

SYMBOL

Temp When 0.2V or below, or 4.5V or above is Thermistor not connected, Possible

Sensor maintained for over 3 seconds defect : Thermistor , Main PBA

error

Heater When the temperature change is 4℃ or Htr terminal not connected

error less within the first 10 minutes after the Possible defect : Main Wire-

heating starts Harness, Htr , Htr Relay, Main PBA

High When the temperature of the Thermistor Water supply temp of 80℃ or above

temp is 80℃ or above for more than 3 sec- Possible defect : Thermistor , Main

error. onds PBA

Low- When Low Level is detected to cause Low Level Sensor terminal not con-

level Error even after the water supply re- nected, Possible defect : Low Level

water sumes after Low Level is detected for Sensor , Main PBA

error the 1st time

Water 1. When the pulse of 100 or less is de- Alien particles within water supply

supply tected even 1 minute after the water sup- valve

error ply Water supply valve terminal not con-

2. When flow meter pulse is 5 or less 5 nected

seconds after the water supply starts Possible defect : Main PB, Water

3. When the water supply does not oc- supply valve , Flow Meter

cur 5 minutes after the water supply

starts

High When 80℃ or above is detected during Water supply temperature of 80℃ or

temp water supply above

Water Possible defect : Thermistor, Main

error PBA

Drain When OFF status of Low Level S/W is Alien particles clogging mater drain

error not detected within 3 minutes during the hose

drain. Drain valve terminal not connected

Possible defect : Drain pump, Low

Level Sensor , Main PBA

Over- When overflow detection AD data is 4.0V Particles within water supply valve

level or below for 3 seconds Case Sensor part leakage, Possible

water (When leakage sensor detects 4.0V or defect : Flow Meter, Main PBA

error below for 1 sec during water supply)

Leak- When leakage sensor detects 4.5V or Possible defect : Base part hose

age er- below for 1 seconds connection , Sump and Tub assem-

ror bly, Drain Pump assembly , Main

PBA

Button When the button is pressed continu- Possible defect : Sub PBA, Main

error ously for over 30 seconds PBA

Door When door is open in washing period. Door is not close properly.

open Possible defect : Door lock switch,

warning Main PBA

# tsDMT300RF RevB 03/21/2011 5

Press the ‗Heavy‘ + ‗Delicate‘ + ‗Power‘ buttons at the same time for two seconds to enter Service Inspection Mode.

All LEDs are displayed for the first two seconds and then Software-Ver. It will be indicated Binary Code using ‗Wash +

Dry + Clean + Child Lock‘ LED.

You can change the mode by pressing the Normal button once more. If press the Normal button in any mode, mode will

be changed to next mode.

If ‗Heavy + Quick‘ LED, ‗Heavy‘ LED or ‗Heavy + Delicate + Quick‘ LED error occur, enter the Service Inspection Mode

after resolving problem.

Service Inspection Mode is described in the following table. When you activate this inspection mode, the door must be

closed.

Mod Display Related Parts Symptoms Note

e (LED Blinking)

No.1 'Quick' LED Inlet Valve Water Supply If Door is open, 'Delicate' + 'Quick' LED will blink.

Flow Meter Error Water is supplying af ter low level S/W is detected. If low level S/W is high, Draining at f irst.

Low Level If water is not supplied, Water Supply Error ('Quick' LED) will blink.

Sensor Low Level Water

Error When water level is low af ter water is supplied, Low Level Water Error ('Normal' + 'Heavy'

+ 'Quick' LED) will blink.

'Normal' + When Turbidity problem is detected af ter water is supplied, 'Normal' + 'Heavy' + 'Delicate'

'Heavy' + LED will blink.

'Delicate' LED If all f unctions in this mode are completed, 'Wash' LED will blink.

No.2 'Delicate' Circulation A nozzle does If Low Level S/W is detected bef ore Circulation Motor is operating, 'Sanitize' LED will blink.

LED Motor not inject water.

No.3 'Delicate' + Circulation Heater Error If Low Level S/W is detected bef ore Circulation Motor is operating, 'Sanitize' LED will blink.

'Quick' LED Motor Circulation Motor and Heater will be operated.

Heater When the temperature is 60℃ or above, the heater is turned of f and 'Wash' LED will blink.

Thermistor

If Heater or Thermistor have problems, the Heater Error (‗Heavy‘ + Delicate‘ LED) will blink.

Dispenser will operate during 2 minutes and 10 seconds only one time.

No.4 'Heavy' + Fan Motor The Fan Motor Operate Vent Motor and check whether Rinse aid is f illed.

'Quick' LED Dispensor does not work. If there is not rinse in Dispenser, Rinse Ref illed light is ON.

No.5 'Heavy' + Overf low Over level water Water is supplied until Over Level Water Error ('Heavy' + 'Quick' LED) is blinked.

'Delicate' Sensor error If Over Level Water Error occurs, overf low sensor is OK.

LED

No.6 'Heavy' + Drain Pump Drain Error Drain pump will work until low level is detected.

'Delicate' + Low Level If Low level is not detected af ter 60 seconds, Drain Error ('Delicate' LED) will blink.

'Quick' LED Sensor

No.7 'Normal' + Inlet Valve Operate each operating part when the button is pressed. (See the below)

'Quick' LED Circulation When the 'Quick' button is pressed, it toggles between Inlet Valve On ('Quick' LED On) ->

Motor Of f ('Quick' LED Of f ).

Fan Motor When ‗Heavy' button is pressed, it works Circulation Motor On ('Heavy' LED On) -> Of f

Drain Pump ('Heavy' LED Of f ) -> Fan Motor On ('Heavy' LED On) -> Of f ('Heavy' LED Of f ), Drain

Heater Pump On ('Heavy' LED On) -> Of f ('Heavy' LED Of f )

When 'Delicate' button is pressed, it woks Heater On ('Delicate' LED On during 2 seconds).

When a dif f erent button is pressed during individual operation of the operating part,

operating part is stopped and the applicable operation f or the pressed button‘s f unction will

start.

# tsDMT300RF RevB 03/21/2011 6

You might also like

- Raj Bawa (Editor) - Advances in Clinical Immunology, Medical Microbiology, COVID-19, And Big Data_ Immunology, Microbiology, Biostatistics, And Big Data (Current Issues in Medicine, 2)-Jenny StanfordDocument930 pagesRaj Bawa (Editor) - Advances in Clinical Immunology, Medical Microbiology, COVID-19, And Big Data_ Immunology, Microbiology, Biostatistics, And Big Data (Current Issues in Medicine, 2)-Jenny Stanfordkaf micrNo ratings yet

- Manual final-FWG10-1Document36 pagesManual final-FWG10-1Leonid LeonovNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Chime Sog Thig Part 1 - Shenphen Dawa RinpocheDocument45 pagesChime Sog Thig Part 1 - Shenphen Dawa Rinpochesusco100% (4)

- Sea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXDocument38 pagesSea Breeze Mini-Split Troubleshooting Guide 9A23YGX, 12A23YGX, 12A23ZGX 18A23ZGX 9H43YCX, 12H43YCX 12H43ZGX, 18H43ZGX 24H43ZCX, 24A43ZCXMNo ratings yet

- Erie 2401S Installation Service ManualDocument44 pagesErie 2401S Installation Service ManualGreg Reyneke100% (1)

- Mam Ky02sDocument34 pagesMam Ky02sTaufan Justvands67% (3)

- AP CALCULUS BC - MC - Related RatesDocument4 pagesAP CALCULUS BC - MC - Related RatesShannon BurtonNo ratings yet

- Retention in Complete DentureDocument53 pagesRetention in Complete DentureVikas Aggarwal67% (3)

- Samsung DW ManualDocument28 pagesSamsung DW ManualtimmboNo ratings yet

- AQE-SMO-I301-CP: Washroom and Plumbing SolutionsDocument12 pagesAQE-SMO-I301-CP: Washroom and Plumbing SolutionsRahmat KhanNo ratings yet

- CW-3000 Industrial Chiller User ManualDocument12 pagesCW-3000 Industrial Chiller User ManualPARTHIBAN RETECHNo ratings yet

- At13 Samsung Laundry Wf317 Fast Track r22012 02 07Document7 pagesAt13 Samsung Laundry Wf317 Fast Track r22012 02 07bigfatbob44100% (1)

- WA400PJHD Fast-Track 2Document7 pagesWA400PJHD Fast-Track 2Ashton TyreeNo ratings yet

- FLOWSERVE MSX MantenimientoDocument2 pagesFLOWSERVE MSX MantenimientoMarco CastroNo ratings yet

- Instruction Manual: Laboratory Equipment Pty LTD PH: 02 9560 2811 - Fax: 02 9560 6131Document32 pagesInstruction Manual: Laboratory Equipment Pty LTD PH: 02 9560 2811 - Fax: 02 9560 6131afiaNo ratings yet

- Water Softeners Residential 6700XTR Upflow Valve Softeners US ManualDocument12 pagesWater Softeners Residential 6700XTR Upflow Valve Softeners US ManualPromagEnviro.comNo ratings yet

- 1150 Handbook v1641207997627Document44 pages1150 Handbook v1641207997627cerengolcurNo ratings yet

- Dv338agw Xaa Dv407 Fast Track r6Document8 pagesDv338agw Xaa Dv407 Fast Track r6arjr51No ratings yet

- ##Samsung Laundry TrainingDocument80 pages##Samsung Laundry Trainingdreamyson1983100% (10)

- CW-3000 Manual - 20211119150533Document7 pagesCW-3000 Manual - 20211119150533Malick SyNo ratings yet

- AQT-56 Manual PDFDocument20 pagesAQT-56 Manual PDFFiorella BravoNo ratings yet

- Water Softeners Residential 6700XTR Downflow Valve Softeners US ManualDocument12 pagesWater Softeners Residential 6700XTR Downflow Valve Softeners US ManualPromagEnviro.comNo ratings yet

- Manual de Instruccion Vap 10sDocument20 pagesManual de Instruccion Vap 10sCeleynes RTNo ratings yet

- Vapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsDocument14 pagesVapor-Flo Humidity Generator Operation and Maintenance: Thermal Product SolutionsVirginia MartelliNo ratings yet

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicNo ratings yet

- TC02 DigitalDocument17 pagesTC02 DigitalNebojsa CekicNo ratings yet

- Dishdrawer 605: Service Summary and Fault Code DescriptionsDocument8 pagesDishdrawer 605: Service Summary and Fault Code DescriptionsmentmentoneNo ratings yet

- Fleck 5800 LXT & SXT Downflow/Upflow: Service ManualDocument26 pagesFleck 5800 LXT & SXT Downflow/Upflow: Service ManualJean-Paul IstaceNo ratings yet

- STERILIZERDocument22 pagesSTERILIZERGeorgi100% (1)

- RoMatik160-210-420 Operating-Instructions INT enDocument6 pagesRoMatik160-210-420 Operating-Instructions INT enPearceNo ratings yet

- BEU-399E - 3D TRASAR Cooling Water - Light Industrial ApplicationsDocument4 pagesBEU-399E - 3D TRASAR Cooling Water - Light Industrial Applicationscouplesousse23No ratings yet

- MODEL 00SRO365 Thru 00SRO1095 Commercial Reverse Osmosis: Operation & Maintenance ManualDocument26 pagesMODEL 00SRO365 Thru 00SRO1095 Commercial Reverse Osmosis: Operation & Maintenance ManualGuevara AnaNo ratings yet

- G-tek-GT-U1-Manual-Dish washerDocument9 pagesG-tek-GT-U1-Manual-Dish washerMYINT WAINo ratings yet

- Sensor Activated Fire Extinguishing (S.A.F.E.) System: Design and InnovationDocument12 pagesSensor Activated Fire Extinguishing (S.A.F.E.) System: Design and InnovationKleiver LaraNo ratings yet

- Descongelador de Plasma Manual de Servicio GE2006-CeDocument29 pagesDescongelador de Plasma Manual de Servicio GE2006-CeMike Sanchez100% (1)

- Thoracic Pump User ManualDocument28 pagesThoracic Pump User ManualAnonymous Wpc3YdNo ratings yet

- User Manual Diode Laser-TST SusanDocument20 pagesUser Manual Diode Laser-TST SusanGiantBongNo ratings yet

- Instruction Manual for F.W.G (X SERIES) 一式R1 (2015.1217)Document80 pagesInstruction Manual for F.W.G (X SERIES) 一式R1 (2015.1217)2533 9564No ratings yet

- Fast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaDocument7 pagesFast Track Troubleshooting: Model: WA456DR /AA BOM Models Wa456Drhdwr/Aa Wa456Drhdsu/AaFaffNo ratings yet

- Fast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRDocument7 pagesFast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRZeigtNo ratings yet

- S.A.F.E. Ph7 Coin R4Document10 pagesS.A.F.E. Ph7 Coin R4naokito AkemiNo ratings yet

- Baxter Flo-Gard3 Infusion Pump - Service GuidelineDocument2 pagesBaxter Flo-Gard3 Infusion Pump - Service Guidelineamerico.villarrealNo ratings yet

- Trufrost If 20 Ice Flaker With Self Contained Bin 20 Kgs 24 HrsDocument8 pagesTrufrost If 20 Ice Flaker With Self Contained Bin 20 Kgs 24 Hrshamba AllahNo ratings yet

- 6 Installation System RefDocument48 pages6 Installation System Refcengiz kutukcuNo ratings yet

- Fleck 5600Sxt Upflow: Service ManualDocument28 pagesFleck 5600Sxt Upflow: Service ManualdewaNo ratings yet

- Dosing Pump Operational ManualDocument12 pagesDosing Pump Operational Manualalex_alexutzuuNo ratings yet

- Curtis Gem 120a ManualDocument12 pagesCurtis Gem 120a ManualBWNo ratings yet

- Dfs-Manual-2 13 15Document37 pagesDfs-Manual-2 13 15Enderson RamosNo ratings yet

- Ultrasonic Mist MakerDocument5 pagesUltrasonic Mist MakerDoni indra sukmanaNo ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- TLL13X Fozmula Liquid Level Sensor Data 8-6-33R2Document1 pageTLL13X Fozmula Liquid Level Sensor Data 8-6-33R2moisesNo ratings yet

- Triton Shower ManualDocument24 pagesTriton Shower ManualAmanda KinsellaNo ratings yet

- User Manual: FOR Soniclean Digital Benchtop Ultrasonic CleanersDocument12 pagesUser Manual: FOR Soniclean Digital Benchtop Ultrasonic Cleanersغزوان عماد الدين الحسينيNo ratings yet

- Ameritrol Electronic Thermal Flow SensorDocument2 pagesAmeritrol Electronic Thermal Flow SensorJavier AffifNo ratings yet

- Retrotec Field CalDocument15 pagesRetrotec Field CalMarkNo ratings yet

- SAT-S0260W - Service ManualDocument45 pagesSAT-S0260W - Service ManualTin Cậy Kỹ Thuật100% (1)

- Operation and Maintenance ManualDocument22 pagesOperation and Maintenance ManualKiki HendraNo ratings yet

- Cla FiltersDocument22 pagesCla FiltersAce Dynamics IndiaNo ratings yet

- Soft TROUBLE SHOOTING & PMPDocument10 pagesSoft TROUBLE SHOOTING & PMPLaur IriNo ratings yet

- Adiabatic ManualDocument6 pagesAdiabatic ManualWidawan Nurardi ArnantoNo ratings yet

- HT64-132 OWS Final Drawings150525Document24 pagesHT64-132 OWS Final Drawings150525jamukanak padNo ratings yet

- Operating Manual: High-Pressure CleanersDocument44 pagesOperating Manual: High-Pressure CleanersPierre LangevinNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- HAIER Combo WDHWD1600 HWD1600 SERVICE MANUALDocument28 pagesHAIER Combo WDHWD1600 HWD1600 SERVICE MANUALZeigt100% (1)

- Fast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRDocument7 pagesFast Track Troubleshooting: Models: DV350AEW DV350AGW DV350AER DV350AGRZeigtNo ratings yet

- DW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFDocument14 pagesDW-8888-02 Haier Dishwasher ESD20 Series Service Manual PDFZeigtNo ratings yet

- Service Manual Dishwashers Type: DW70Document33 pagesService Manual Dishwashers Type: DW70ZeigtNo ratings yet

- 24in Built in Electronic 5995293536 Update PDFDocument65 pages24in Built in Electronic 5995293536 Update PDFZeigtNo ratings yet

- dw20 Asko DishwasherDocument46 pagesdw20 Asko DishwasherZeigt100% (1)

- dw95 Asko DishwasherDocument18 pagesdw95 Asko DishwasherZeigtNo ratings yet

- Rfg298aa Samsung Refrigerator PDFDocument133 pagesRfg298aa Samsung Refrigerator PDFZeigtNo ratings yet

- DMT400 Fast Track R21 PDFDocument6 pagesDMT400 Fast Track R21 PDFZeigtNo ratings yet

- Alpm 39201Document128 pagesAlpm 39201ZeigtNo ratings yet

- Corticosteroids: Dr.R.Prameela, Assistant Professor of Pharmacology, GMC, SrikakulamDocument64 pagesCorticosteroids: Dr.R.Prameela, Assistant Professor of Pharmacology, GMC, SrikakulamRamadi PrameelaNo ratings yet

- Research On:: Department of English Language Faculty of Arts University of KordofanDocument49 pagesResearch On:: Department of English Language Faculty of Arts University of KordofanMr DragonNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- Prezantimi - Pristina International Airport-AjDocument61 pagesPrezantimi - Pristina International Airport-AjPerparim ShapiNo ratings yet

- Rob - Report 41+508 - 01.02.2016Document13 pagesRob - Report 41+508 - 01.02.2016vivekNo ratings yet

- Letter of Undertaking Letter Seggregation in ChargeDocument1 pageLetter of Undertaking Letter Seggregation in ChargeSijin SivankuttyNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Basic Waste Management Training After Revision (Compatibility Mode)Document64 pagesBasic Waste Management Training After Revision (Compatibility Mode)Gangsar LukmanjayaNo ratings yet

- A Guide To Crane and DerricksDocument222 pagesA Guide To Crane and Derricksrafaqat hussainNo ratings yet

- 2010AnalMethMicrowave AssisteddigestioninclosedvesselsDocument6 pages2010AnalMethMicrowave AssisteddigestioninclosedvesselsMuchlas AkbarNo ratings yet

- Brother Sewing Machine S7250aDocument88 pagesBrother Sewing Machine S7250aDavid Andres Ducuara MayorgaNo ratings yet

- CDS57006 Bosch LSU 4.9 Sensor PDFDocument4 pagesCDS57006 Bosch LSU 4.9 Sensor PDFAnonymous K3FaYFlNo ratings yet

- Zuku Visual Flashnotes Distemper ExtendedDocument4 pagesZuku Visual Flashnotes Distemper ExtendedShubham HarishNo ratings yet

- Checklist For Visa Application Tourism and Visit To Family / FriendsDocument4 pagesChecklist For Visa Application Tourism and Visit To Family / FriendsBepdjNo ratings yet

- STPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: SulitDocument14 pagesSTPM Biology 964/1 4 Oktober 2017 1 Hour 30 Minutes: Sulitrevathy varatharajahNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- Physiology Past PapersDocument11 pagesPhysiology Past PapersIrfan Haider FaniNo ratings yet

- औषधे मिक्स प्रमाणDocument11 pagesऔषधे मिक्स प्रमाणShivam PatilNo ratings yet

- Cable, Conductor and Conduit - Fr.enDocument14 pagesCable, Conductor and Conduit - Fr.eneuge sylNo ratings yet

- CourseDocument2 pagesCourseRNo ratings yet

- Conditioner Portatil Sams ClubDocument5 pagesConditioner Portatil Sams ClubJuan Carlos RodriguezNo ratings yet

- Nebosh International Diploma ID1Document6 pagesNebosh International Diploma ID1Haltebaye Djim RahmNo ratings yet

- Resistance Training: FW01 Physical Activities Toward Health and Fitness 1Document7 pagesResistance Training: FW01 Physical Activities Toward Health and Fitness 1Jerome SadulloNo ratings yet

- Acp CBC 1Document52 pagesAcp CBC 1Danny R. SalvadorNo ratings yet