Professional Documents

Culture Documents

Predicting Reservoir Fluid Phase and Volumetric Behavior From Samples Contaminated With Oil Based Mud

Predicting Reservoir Fluid Phase and Volumetric Behavior From Samples Contaminated With Oil Based Mud

Uploaded by

JesseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Predicting Reservoir Fluid Phase and Volumetric Behavior From Samples Contaminated With Oil Based Mud

Predicting Reservoir Fluid Phase and Volumetric Behavior From Samples Contaminated With Oil Based Mud

Uploaded by

JesseCopyright:

Available Formats

Predicting Reservoir Fluid Phase and

Volumetric Behavior From Samples

Contaminated With Oil-Based Mud

F. Gozalpour, SPE, A. Danesh, SPE, D.-H. Tehrani, SPE, A.C. Todd, SPE, and B. Tohidi, SPE, Heriot-Watt U.

Summary EOS

The impact of sample contamination with oil-based mud filtrate on EOSs are used extensively to simulate the volumetric behavior and

phase behavior and properties of different types of reservoir fluids, phase equilibrium of petroleum reservoir fluids. Among different

including gas condensate and volatile oil, has been investigated. types of EOSs, cubic EOSs have enjoyed considerable success in

Two simple methods are used to determine the uncontaminated modeling because they are simple and give reliable results in phase

fluid composition from contaminated samples. The capability of equilibrium calculations. Two EOSs, the Valderrama1 modifica-

the methods is demonstrated against highly contaminated samples. tion of the Patel-Teja (VPT) EOS and a modified Peng-Robinson2

An equation-of-state (EOS)-based method also has been devel- (mPR) EOS, were used in this study to perform phase equilibrium

oped to predict the phase and volumetric properties of the retrieved calculations. All binary interaction parameters (BIP) in the mixing

composition. The method determines the required parameters of rule were set to zero, and the temperature dependency of the

the EOS for the uncontaminated fluid using the developed phase- attractive term was used as the tuning parameter to fit the mea-

behavior models from contaminated-sample data. The method has sured data.3

been examined against experimental data of different types of Extended compositional analyses (up to C20+) of fluids were

reservoir fluids with successful results. used in phase equilibrium calculations. The required critical prop-

Introduction erties of petroleum fractions to calculate parameters of EOS were

Accurate reservoir fluid composition and properties are essential determined by perturbation expansion correlations.4 The required

for reservoir management and development. Reliable reservoir boiling-point temperatures were calculated from the Riazi-

fluid samples are therefore required; however, major challenges Daubert5 correlation using the molecular weight and specific grav-

can render the fluid analysis limited in value. The reservoir fluid ity of petroleum fractions. The Lee-Kesler6 correlation was used to

samples for pressure/volume/temperature (PVT) tests can be col- calculate the accentric factor of compounds.

lected by bottomhole and/or surface sampling techniques as ap-

propriate. During the drilling process, owing to overbalance pres- Contaminated Reservoir Fluids

sure in the mud column, mud filtrate invades the formation. If an Hydrocarbon-based fluids (natural or synthetic oils) are generally

oil-based mud is used in the drilling, it can cause major difficulties used in oil-based drilling muds. Because these fluids are soluble in

in collecting high-quality formation fluid samples. Because the the reservoir fluid, they can render the fluid analysis limited in

filtrate of oil-based drilling mud is miscible with the formation value. Determination of the original fluid composition from the

fluid, it could significantly alter the composition and phase behav- analysis of a contaminated sample is feasible, but isolating the

ior of the reservoir fluid. Even the presence of a small amount of properties of the reservoir fluid free from contamination is not

oil-based filtrate in the collected sample could significantly affect easily accomplished. Despite the recent improvements in sampling

the PVT properties of the formation fluid. reservoir fluids,7,8 obtaining a contamination-free formation fluid

Oil-based mud is used widely in the petroleum industry. Con- is a major challenge, particularly in openhole wells. Therefore,

tamination with oil-based mud filtrate could affect reservoir fluid modeling techniques are required, along with the laboratory stud-

properties such as saturation pressure, formation volume factor, ies, to determine the composition and PVT properties of the un-

gas/liquid ratio, and stock-tank liquid density. Because collecting contaminated fluid.

a reservoir fluid sample is expensive, and accurate reservoir fluid We have demonstrated, as have other investigators,9,10 that an

properties are needed in reservoir development, it is highly desir- exponential relationship exists between the concentration of com-

able to determine accurate composition and phase behavior for the ponents in the C8+ portion of real reservoir fluids and the corre-

reservoir fluid from contaminated samples. sponding molecular weights. For example, if the molar concentra-

This study investigates the impact of sample contamination tion of single carbon number groups is plotted against their mo-

with oil-based mud filtrates on composition and phase behavior lecular weights, it will give a straight line on a semilogarithmic

properties of different types of reservoir fluids, including volatile scale. Based on this feature of natural fluids, two methods have

oil and gas condensate samples. The samples were purposely con- been developed in this study to retrieve the original composition of

taminated with a known amount of oil-based mud filtrates in the reservoir fluid from contaminated samples. The composition of the

laboratory. The methods developed in this study were then applied C8+ portion of contaminated sample is plotted against molecular

to determine the original composition of the reservoir fluid from weight on a semilogarithmic scale. The plotted data will show a

contaminated samples. The phase behavior of the contaminated departure from the line over the range affected by the contaminants

samples was also investigated by performing constant composition (see Fig. 1). The concentrations of the contaminants are then

expansion (CCE) tests at reservoir and surface conditions. The skimmed from the semilog straight line, presumed to be valid for

measured experimental data were used to tune EOSs by adjusting the uncontaminated reservoir fluid. The fitted line is used to de-

their parameters. The determined parameters of EOS tuned to the termine the composition of the uncontaminated fluid.

contaminated samples were used to calculate the parameters of The above method, referred to as the Skimming method, gives

EOS for the uncontaminated sample. a reliable composition of the uncontaminated fluid if the contami-

nant comprises a limited hydrocarbon range. MacMillan et al.11

developed a similar method. They fitted a gamma distribution

function to the composition of the C7+ portion of contaminated oil

Copyright © 2002 Society of Petroleum Engineers

samples, excluding the composition of contaminants from the data-

This paper (SPE 78130) was revised for publication from paper SPE 56747, first presented fitting procedure.

at the 1999 SPE Annual Technical Conference and Exhibition, Houston, 3–6 October.

Original manuscript received for review 28 July 2000. Revised manuscript received 14

In the second method, called the Subtraction method, a known

February 2002. Paper peer approved 21 February 2002. amount of drilling fluid with known composition is subtracted

June 2002 SPE Reservoir Evaluation & Engineering 197

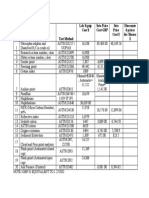

10 TABLE 1ÑCOMPOSITION AND PHYSICAL

PROPERTIES OF BASE OIL DMF-1

SCN Group Wt% Mol% Molecular Weight*

C11s 0.03 0.05 147

Composition, wt% C12s 0.12 0.17 161

C13s 1.37 1.75 175

1

C14s 11.38 13.38 190

C15s 25.46 27.60 206

C16s 20.01 20.13 222

Uncontaminated Region

Contaminated Region

C17s 17.87 16.84 237

C18s 10.41 9.26 251

C19s 6.44 5.47 263

C20s 3.26 2.65 275

0.1

100 200 300 400 500

Molecular Weight C21s 1.72 1.32 291

C22s 0.94 0.70 300

Fig. 1—Contaminated dead condensate LTB with base oil

DMF-1, C10–C30. C23s 0.54 0.39 312

C24s 0.25 0.17 324

from that of the contaminated sample. The C8+ portion of the

resultant composition is then used to fit an exponential distribution

C25s 0.10 0.07 337

function. The procedure is repeated for different levels of drilling C26s 0.04 0.03 349

fluid subtracted from the contaminated sample. The composition C27s 0.03 0.02 360

that gives the best fit to the exponential distribution function is

treated as the retrieved original reservoir fluid composition. This

C28s 0.02 0.01 372

approach can retrieve the original composition reliably even when C29s 0.01 0.01 382

the mud filtrate is composed of a wide range of natural hydrocar- C30+ < 0.01

bon components.

Measured molecular weight = 232 (± 1%); measured density (15.5¼C) = 812 ( ± 1) kg/m3.

In this study, two base oils, known as DMF-1 and DMF-3, have * Generalized single carbon number (SCN) physical properties.12

been used to investigate the effect of contamination on the com-

position and phase behavior of different types of reservoir fluids.

DMF-3 is a linear alpha olefin (LAO) drilling fluid composed of

69 mol% C14 (tetradecene) and 31 mol% C16 (hexadecene). The

the Skimming method in determining the level of contamination.

base oil DMF-1 consisted of a wide range of petroleum fractions,

The predicted level of contamination by the Skimming method

and its compositional analysis revealed a distribution of C11 to C30.

(18.5%) can be a good initial estimate for the iterative process of

Because DMF-1 is similar to a real reservoir hydrocarbon mixture,

the Subtraction method. With this initial guess, 18.5 wt% mud

determination of its contamination level is more demanding in

filtrate DMF-1 was subtracted from the contaminated composition

comparison to DMF-3. The original and contaminated samples

of LTB. The resultant composition was normalized, and the C10+

were analyzed by gas chromatography (GC) in this study. Tables

1 and 2 show the concentration of constituents of DMF-1 and portion was used to fit an exponential distribution function. The

DMF-3, respectively. R2, or the quality of fit, was 0.9619. By adjusting the amount of

subtracted mud filtrate slightly, the optimum level of contamina-

Retrieving Original Fluid Composition. The capability of the tion was found to be 16.4% by weight, with R2⳱0.9701 for the

developed methods in retrieving the uncontaminated composition best fit. The AAD% of the retrieved composition by the Sub-

was examined for a large number of samples. The results are traction method was 3.3; the composition is also presented in Ta-

summarized in Table 3. An example of applying the methods to a ble 4. It should be noted that the mud filtrate composition is re-

deliberately contaminated dead condensate is presented. The com- quired when the Subtraction method is used for the decontamina-

position of a dead condensate (LTB) was measured in the labora- tion process.

tory before experimentally contaminating it with 16.9 wt% oil-

based drilling fluid DMF-1. The gravimetric compositions of the Volatile-Oil LRA. Fluid LRA was a real, volatile reservoir oil

contaminated sample, along with GC analyses of the original and with bubblepoint pressure values of 4,965 and 4,550 psia at the

contaminated samples, are given in Table 4. The two developed reservoir (100°C) and separator (37.8°C) temperatures, respec-

methods, the Skimming and the Subtraction methods, were applied tively. The LRA was used to carry out CCE tests at reservoir and

to the measured composition of the contaminated dead condensate separator conditions.

to determine the composition of the uncontaminated fluid. The LRA was purposely contaminated with DMF-3 in the

The weight fraction of C10–C30 of the contaminated dead con- range of 5 to 20% on a volumetric basis at 6,000 psia and 100°C.

The composition of the original and contaminated samples is pre-

densate is plotted against the molecular weight on a semilogarith-

sented in Table 5. The contaminated samples were subjected to

mic scale in Fig. 1. It shows a departure from the linear trend over

CCE tests at the reservoir and separator temperatures in the labo-

the range affected by the contaminants. Excluding the contaminant

components from the contaminated composition, an exponential

distribution function (linear on a semilogarithmic scale) was then

fitted to the rest of the components. The calculated level of con- TABLE 2ÑCOMPOSITION AND PHYSICAL PROPERTIES

tamination for the contaminated dead condensate, using the Skim- OF BASE OIL DMF-3

ming method, is 18.5% (by weight). The retrieved (contamination-

free) composition of condensate LTB using the Skimming method

Component Wt% Mol% Molecular Weight

is also given in Table 4. The average absolute percentage deviation Tetradecene 66.10 69.02 196.4

(AAD%) of the retrieved composition is 7.3. Hexadecene 33.90 30.98 224.4

Because the contaminant DMF-1 comprises a wide range of Measured molecular weight = 218 (± 1%); measured density (15.5¼C) = 817 (± 1) kg/m3.

petroleum fractions, the Subtraction method is more suitable than

198 June 2002 SPE Reservoir Evaluation & Engineering

TABLE 3—RESULTS OF APPLYING THE SKIMMING AND SUBTRACTION METHODS

TO VARIOUS CONTAMINATED SAMPLES

Level of Contamination

AAD% of Retrieved

Calculated Composition

Fluid Contaminant Actual Skimming Subtraction Skimming Subtraction

a

LTA DMF-3 5.1 4.8 — 1.3 —

LTA DMF-3 10.0 9.8 — 1.3 —

LTA DMF-3 1.1 0.0 — 2.5 —

LTA DMF-3 7.3 6.9 — 1.2 —

LTA DMF-3 2.5 1.9 — 1.3 —

b

LTB DMF-1 16.9 18.5 16.4 7.3 3.3

c

LRA DMF-3 5.1 4.7 4.8 0.7 0.4

LRA DMF-3 10.0 9.6 9.6 0.7 0.6

LRA DMF-3 20.0 19.7 19.7 0.7 0.6

d

GCB-1 DMF-3 5.0 4.7 4.9 0.3 0.0

GCB-1 DMF-3 15.0 14.9 15.1 0.3 0.2

GCB-1 DMF-3 30.0 30.0 30.1 0.4 0.2

d

GCB-2 DMF-3 20.0 20.3 20.1 0.5 0.0

GCB-2 DMF-3 40.0 40.2 40.1 0.5 0.1

GCB-2 DMF-3 49.0 49.1 49.0 0.6 0.1

GCB-2 DMF-3 55.0 55.1 55.1 0.5 0.1

d

GCB-2 DMF-1 15.0 14.2 14.4 4.4 0.5

GCB-2 DMF-1 30.0 29.3 29.6 4.5 0.6

GCB-2 DMF-1 46.0 45.5 45.4 5.5 1.4

GCB-2 DMF-1 50.0 49.6 49.6 4.9 0.9

GCB-2 DMF-1 56.0 55.6 55.8 4.7 0.7

GCB-2 DMF-1 70.0 69.7 69.9 5.3 0.8

(a) Level of contamination based on volume of sample.

(b) Level of contamination based on weight of sample.

(c) Level of contamination based on volume of single-phase sample at 6,000 psia and 100ºC.

(d) Level of contamination based on volume of liquid dropped out at stock tank (STLV).

ratory. The measured data are illustrated in Tables 6 and 7 for the tuned to the measured liquid fraction values of the original fluid

CCE tests at 100 and 37.8°C, respectively. The measured liquid are also shown in Fig. 3. It shows that the predicted liquid fractions

fraction values of the original, 5, 10, and 20% contaminated are in agreement with the experimental values, particularly at pres-

samples (by volume) are plotted against pressure at 100°C in sures lower than 3,500 psia. Approaching the bubblepoint pres-

Fig. 2. The experimental results show that contamination with the sure, the predicted liquid fractions deviate slightly from measured

oil-based mud filtrate has decreased the bubblepoint pressure, experimental ones. However, the predicted liquid fractions, using

whereas it has increased the liquid fraction at all subsequent pres- the retrieved compositions, match the tuned results of the original

sures. For example, a 20% contamination by volume could reduce fluid. Therefore, the deviation in predicting the liquid fraction of

the bubblepoint pressure of the system by as much as 22% at the original fluid at pressures close to the bubblepoint is caused by

reservoir conditions. An mPR EOS with no binary interaction the inability of the EOS to give a perfect match to the experimental

parameters was individually tuned to the measured experimental data of the original fluid.

data of the original, 5, 10, and 20% contaminated samples, using The deviation in predicting the bubblepoint pressure of the

the temperature dependency of the attractive term of the compo- original LRA, applying the tuned mPR EOS to contaminated

nents in the liquid phase as the regression variable.3 The tuning samples, increases with the level of contamination. For example,

results are also depicted in Fig. 2. It can be seen that the tuned EOS when using the tuned mPR EOS to experimental data of the 20%

predictions are in agreement with the experimental data. contaminated sample, the bubblepoint pressure of the original fluid

The developed methods (Skimming and Subtraction) were ap- was determined within 3.5% error. This results from the tuning of

plied to the composition of contaminated samples to retrieve the the EOS because the retrieved compositions at different contami-

composition of the original volatile-oil LRA. Both methods re- nation levels were very similar to those of the original composi-

trieved the original composition with a deviation within the error tion. As an example, the mPR EOS had been tuned to the experi-

bands of fluid analysis. The retrieved composition is also given in mental data of the 20% contaminated sample, which behaved like

Table 5. a low-volatile mixture. Removing the contaminants, the decon-

The EOS models tuned to the experimental data of 5, 10, and taminated sample behaved like a high-volatile oil. The parameters

20% contaminated samples were used to predict the phase behav- tuned to the experimental data of the low-volatile oil are not nec-

ior of the original reservoir fluid at reservoir conditions, using the essarily valid for a high-volatile oil system. Hence, when using the

retrieved composition from fluids with different contamination adjusted EOS to predict the phase behavior and volumetric prop-

levels. The predicted results are compared with those of the ex- erties of the original reservoir fluid, the predictions can be affected

perimentally measured values in Fig. 3. The results of the EOS by the extent of EOS tuning.

June 2002 SPE Reservoir Evaluation & Engineering 199

An investigation of the developed phase behavior models for of the contaminated samples to the zero level of contamination, the

contaminated samples revealed that the correction factors of the predicted phase behavior of the original fluid is given in Fig. 7.

attractive term in EOS, determined by tuning the model to the The improvement is quite clear when compared to the use of the

contaminated data, changed linearly with the contamination level tuned VPT EOS to 20% contaminated samples in Fig. 6. It should

(Fig. 4). Hence, the correction factor of the attractive term for the be noted that although the proposed method adjusts the parameter

original fluid could be determined by extrapolating the values for of the fluid model at any contamination level, it becomes less

contaminated samples to the zero contamination level. It was also reliable when the amount of base oil (mud filtrate) in the collected

observed that when using the specific gravity of the plus fraction sample exceeds the reservoir oil.

(C7+) as a regression variable to match the measured phase behav- Gas condensate samples are more sensitive to contamination

ior of contaminated samples, the tuned value varied linearly with with oil-based mud filtrates in comparison to oil samples. A high

the level of contamination.13 The results of the model with the level of contamination can change gas condensate samples to

derived correction term using the above extrapolating technique oil systems.

and the retrieved composition are shown in Fig. 5. Note the im-

provement, in comparison with the results shown in Fig. 3. Gas Condensate GCB-1. Gas condensate GCB-1 was prepared in

The contamination of the volatile-oil LRA with the DMF-3 was this laboratory by blending separator liquid and vapor samples in

also investigated at separator conditions. The original, 5, and 20% the ratio of field gas/liquid ratio (GLR). The composition of origi-

(by volume) contaminated samples were used to perform CCE nal gas condensate is given in Table 8. To investigate the effect of

tests at 37.8°C in the laboratory. Contamination of the LRA with contamination on phase behavior and volumetric properties of res-

5% (volume) oil-based mud filtrate at this temperature reduced the ervoir fluids, three batches of gas condensate GCB-1 were experi-

bubblepoint pressure by 6.8%. The VPT1 EOS was individually

mentally contaminated with 5, 15, and 30% base oil DMF-3. The

tuned to the experimental data of the original and contaminated

gravimetric composition of the contaminated samples is also pre-

samples, using the temperature dependency of the attractive term

sented in Table 8. The level of contamination was based on the

of components in the liquid phase as the regression variable. The

volume of liquid dropped out in the stock tank at laboratory con-

tuned models were then applied to predict the phase behavior of

the original fluid at 37.8°C. The results are shown in Fig. 6. The ditions (STLV). The contaminated samples, as well as the original

tuning results of EOS, using the original composition, are also one, were used to carry out CCE tests at the reservoir (100°C) and

given in Fig. 6. The same deviation in predicting the bubblepoint separator (37.8°C) temperatures. The original (uncontaminated)

pressure of the original composition, which was observed at gas condensate GCB-1 behaved like a medium-rich gas condensate

100°C, can also be seen in Fig. 6. Using the model with its pa- with a dewpoint pressure of 5,525 psia and a maximum liquid

rameters, determined by extrapolating the correction to parameters fraction of 13.0% at the reservoir temperature (100°C).

Contamination with DMF-3 had a large effect on the dewpoint

pressure and the maximum liquid fraction of the system. A 30%

TABLE 4ÑRETRIEVED, ORIGINAL, AND CONTAMINATED STLV contamination reduced the dewpoint pressure by 9% at

COMPOSITION (WT%) OF DEAD CONDENSATE LTB reservoir conditions. However, it almost doubled the maximum

WITH DRILLING FLUID DMF-1 liquid fraction of the system at 100°C. The modified mPR EOS

was individually tuned to the experimental data of the original and

Contaminated Retrieved the contaminated samples, with reasonable results. The measured

and predicted phase behavior of the original and contaminated

Original Gravimetric GC Analysis Skimming Subtraction samples of the GCB-1 at 100°C are plotted in Fig. 8.

C8sÐ 22.99 19.10 19.11 23.48 22.87 The EOSs tuned to the experimental data of contaminated

samples were applied individually to the retrieved composition to

C9s 9.30 7.72 7.43 9.11 8.89

determine the phase behavior and volumetric properties of the

C10s 7.45 6.19 6.15 7.54 7.35 uncontaminated fluid. The results are depicted in Fig. 9 for the

C11s 5.85 4.86 4.93 6.05 5.90 mPR EOS at 100°C. Fig. 9 shows that the deviation in predicting

C12s 4.80 4.00 4.03 4.94 4.80 the dewpoint pressure and volumetric behavior of the uncontami-

nated fluid, using the tuned mPR EOS with contaminated samples,

C13s 5.83 5.18 5.48 4.99 6.29 increases with an increase in the contamination level. The devia-

C14s 4.94 6.31 6.70 4.54 5.78 tion is caused by the unreliability of the model, particularly that of

C15s 4.37 7.35 7.44 4.01 3.90 the 30% contaminated sample; the retrieved composition matches

the original one perfectly. Using the mPR EOS with its parameter,

C16s 3.29 6.25 5.98 3.67 3.23 determined by extrapolating the tuning parameters of the contami-

C17s 2.72 5.24 4.43 3.31 1.79 nated samples to the zero level of contamination, the predicted

C18s 3.35 4.83 4.76 2.92 3.65 phase behavior of the original fluid at 100°C is illustrated in Fig.

10. It shows that using the developed method, the predicted phase

C19s 3.35 3.78 4.13 2.67 3.67 behaviors of the retrieved compositions are in close agreement

C20s 2.11 2.28 2.28 2.27 2.09 with those of the measured values, and they match the tuned results

C21s 1.87 1.82 1.85 1.99 1.88 of the original composition. This illustrates the capability and re-

liability of the method developed in this study to determine the

C22s 1.77 1.62 1.65 1.78 1.79

phase behavior of the original fluid from contaminated samples.

C23s 1.60 1.41 1.43 1.67 1.60 The presented extrapolating technique will not be applicable when

C24s 1.34 1.15 1.18 1.53 1.36 contamination changes an originally uncontaminated gas conden-

C25s 1.24 1.05 1.07 1.31 1.26 sate sample to an oil system.*

The EOS that requires the least tuning should be used to model

C26s 1.15 0.97 0.98 1.20 1.16 the phase behavior of contaminated samples. The VPT EOS was

C27s 1.05 0.88 0.89 1.09 1.06 also tuned to the contaminated samples at 100°C. In this case, the

C28s 0.92 0.77 0.79 0.97 0.94 models needed very little tuning to match the measured experi-

mental data. Therefore, the VPT EOS tuned to the contaminated

C29s 0.84 0.70 0.71 0.87 0.85 samples could reliably predict the phase behavior of the original

C30s 0.77 0.64 0.68 0.83 0.81

C31+ 7.10 5.90 5.92 7.26 7.08

Total 100.00 100.00 100.00 100.00 100.00 * Gozalpour et al.: “Contamination of Gas Condensate Samples With Oil-Based Drilling

Fluid.”

200 June 2002 SPE Reservoir Evaluation & Engineering

TABLE 5—MOLAR COMPOSITION OF ORIGINAL, CONTAMINATED, AND RETRIEVED

VOLATILE-OIL LRA, FROM SAMPLES CONTAMINATED WITH BASE OIL DMF-3

5% Contamination* 20% Contamination*

Component Original Gravimetric GC Analysis Gravimetric GC Analysis Retrieved

C1 55.90 54.74 54.04 50.96 51.35 55.85

C2 9.88 9.68 9.55 9.01 8.76 9.87

C3 5.67 5.56 5.49 5.17 4.98 5.66

iC4 1.18 1.16 1.14 1.08 1.07 1.18

nC4 2.03 1.99 1.94 1.85 1.78 2.03

iC5 1.10 1.08 1.08 1.00 1.01 1.10

nC5 1.92 1.88 1.87 1.75 1.65 1.92

C6s 1.54 1.51 1.49 1.40 1.36 1.54

C7s 2.16 2.12 2.30 1.97 1.83 2.16

C8s 2.69 2.64 2.70 2.45 2.47 2.69

C9s 1.99 1.95 1.96 1.81 1.75 1.99

C10s 1.70 1.67 1.66 1.55 1.53 1.70

C11s 1.30 1.27 1.24 1.19 1.18 1.30

C12s 0.95 0.93 1.07 0.87 0.93 0.95

C13s 1.22 1.20 1.00 1.11 1.05 1.22

C14s 0.86 2.24 2.16 6.87 7.56 0.91

C15s 0.87 0.85 0.99 0.79 0.81 0.87

C16s 0.68 1.29 1.31 3.36 3.48 0.70

C17s 0.50 0.49 0.71 0.46 0.42 0.50

C18s 0.57 0.56 0.66 0.52 0.51 0.57

C19s 0.60 0.59 0.59 0.55 0.50 0.60

C20+ 4.69 4.60 5.05 4.28 4.02 4.69

Properties of the Original Volatile-Oil LRA

Molecular weight = 65.2

Bubblepoint pressure at 100ºC = 4,965 psia

Bubblepoint pressure at 37.8ºC = 4,550 psia

*Level of contamination based on volume of sample at 6,000 psia and 100ºC.

TABLE 6—CCE TEST OF VOLATILE-OIL LRA, ORIGINAL, AND CONTAMINATED SAMPLES

WITH DMF-3 AT 100ºC (CONTAMINATION BASED ON VOLUME AT 6,000 PSIA AND 100ºC)

Original 5% Contamination 10% Contamination 20% Contamination

Liquid Liquid Liquid Liquid

Pressure Fraction Pressure Fraction Pressure Fraction Pressure Fraction

(psia) (Vliq/Vtotal) (psia) (Vliq/Vtotal) (psia) (Vliq/Vtotal) (psia) (Vliq/Vtotal)

Pb=4,965 100.00 Pb=4,630 100.00 Pb =4,355 100.00 Pb =3,850 100.00

4,500 85.81 4,000 83.56 3,600 81.96 3,000 80.32

4,300 81.45 2,000 46.28 3,400 78.08 2,000 57.85

4,100 78.24 3,200 74.33 1,200 36.07

3,800 73.83 3,000 70.55

3,500 69.13 2,500 60.63

3,000 61.37 2,000 49.89

2,500 52.71 1,200 30.37

2,000 42.75

1,200 25.40

June 2002 SPE Reservoir Evaluation & Engineering 201

100

TABLE 7ÑCCE TEST OF VOLATILE-OIL LRA, ORIGINAL,

AND CONTAMINATED SAMPLES WITH DMF-3 AT 37.8¼C

Liquid Fraction ( liq/ total), percentage

(CONTAMINATION BASED ON VOLUME

AT 6,000 PSIA AND 100¼C)

80

Original 5% Contamination 20% Contamination

Liquid Liquid Liquid

Pressure Fraction Pressure Fraction Pressure Fraction

V V

(psia) (Vliq/Vtotal) (psia) (Vliq/Vtotal) (psia) (Vliq/Vtotal)

60

Pb =4,550 100.00 Pb =4,241 100.00 Pb =3,408 100.00

Experimental, Original

Experimental, 5% Contaminated

4,250 93.94 4,000 96.24 3,000 94.06 40 Experimental, 10% Contaminated

Experimental, 20% Contaminated

4,000 90.36 3,800 92.94 2,500 84.29 EOS, Tuned

3,000 77.70 3,500 89.03 2,000 72.33 20

2,000 60.91 3,000 80.87 1,500 58.61 1,000 2,000 3,000

Pressure, psia

4,000 5,000

2,000 61.81 1,000 40.45

1,500 49.23 Fig. 2—Measured and predicted phase behavior of volatile-oil

LRA, contaminated with 5, 10, and 20% (volumetric) DMF-3,

1,250 40.08 mPR EOS, 100°C.

100 0.000

100

Liquid Fraction ( liq/ total), percentage

Correction to Alpha Parameter (F)

90

80 –0.005

80

4,000 4,250 4,500 4,750 5,000

V V

60 –0.010

Experimental, Original

Tuned EOS, Original

40 Retrieved, 5%

–0.015

Retrieved, 10%

Retrieved, 20%

20

–0.020

1,000 2,000 3,000 4,000 5,000

0 5 10 15 20 25

Pressure, psia

Level of Contamination, vol%

Fig. 3—Predicted phase behavior of the original volatile-oil

Fig. 4—Correction to the alpha parameter of supercritical com-

LRA, using the retrieved composition and EOS tuned to con-

ponents in the liquid phase, volatile-oil LRA at 100°C, mPR EOS,

taminated samples, mPR EOS, 100°C.

[F=alpha(tuned)/alpha(std)–1].

100 100

Experimental, Original

Liquid Fraction ( liq/ total), percentage

Liquid Fraction ( liq/ total), percentage

Experimental, Original

Tuned, Original

90 Tuned EOS, Original

Retrieved, Adjusted EOS

80 Retrieved, 5%

Retrieved, 20%

80

V V

V V

60

70

40

60

20 50

1,000 2,000 3,000 4,000 5,000 1,000 2,000 3,000 4,000 5,000

Pressure, psia Pressure, psia

Fig. 5—Predicted liquid fraction of the uncontaminated volatile- Fig. 6—Predicted phase behavior of the original volatile-oil

oil LRA, using EOS with adjusted tuned parameter and retrieved LRA, using EOS tuned to contaminated samples and retrieved

composition, mPR EOS, 100°C. composition, VPT EOS, 37.8°C.

202 June 2002 SPE Reservoir Evaluation & Engineering

100

TABLE 8ÑMOLAR COMPOSITION OF ORIGINAL,

Experimental, Original

Liquid Fraction ( liq/ total), percentage

CONTAMINATED, AND RETRIEVED GAS CONDENSATE

Tuned EOS, Original GCB-1, FROM SAMPLES CONTAMINATED

90

Retrieved, Adjusted EOS WITH BASE OIL DMF-1

Contaminated* Samples

V V 80 (Gravimetric)

Component Original 5% 15% 30% Retrieved

70

C1 71.99 71.81 71.43 70.66 71.98

C2 11.81 11.77 11.71 11.58 11.81

60 C3 4.76 4.75 4.72 4.67 4.76

iC4 0.81 0.81 0.80 0.79 0.81

50 nC4 1.72 1.72 1.71 1.69 1.72

1,000 2,000 3,000 4,000 5,000

iC5 0.62 0.62 0.62 0.61 0.62

Pressure, psia

nC5 0.78 0.78 0.77 0.77 0.78

Fig. 7—Predicted liquid fraction of the uncontaminated volatile- C6s 0.90 0.90 0.89 0.88 0.90

oil LRA, using EOS with adjusted tuned parameter and retrieved C7s 1.36 1.36 1.35 1.33 1.36

composition, VPT EOS, 37.8°C.

C8s 1.32 1.32 1.31 1.30 1.32

C9s 0.73 0.73 0.72 0.72 0.73

C10s 0.54 0.54 0.54 0.53 0.54

C11s 0.40 0.40 0.40 0.39 0.40

30 C12s 0.31 0.31 0.31 0.30 0.31

C13s 0.27 0.27 0.27 0.26 0.27

0% Contam., Exp.

Liquid Fraction ( liq/ total), percentage

0% Contam., EOS

5% Contam., Exp.

5% Contam., EOS C14s 0.27 0.43 0.80 1.55 0.27

15% Contam., Exp. C15s 0.23 0.23 0.23 0.23 0.23

20

C16s 0.18 0.25 0.42 0.75 0.19

15% Contam., EOS

30% Contam., Exp.

C17s 0.14 0.14 0.14 0.14 0.14

V V

30% Contam., EOS

C18s 0.14 0.14 0.14 0.14 0.14

10 C19s 0.12 0.12 0.12 0.12 0.12

C20+ 0.60 0.60 0.60 0.59 0.60

*Level of contamination based on the volume of liquid dropped out in the

stock tank (STLV).

0

0 1,000 2,000 3,000 4,000 5,000 6,000

Pressure, psia

fluid at reservoir conditions without having to adjust its param-

eters, as shown in Fig. 11.

The phase behavior and volumetric properties of the original

Fig. 8—Effect of contamination with DMF-3 on phase behavior and contaminated samples of GCB-1 with the DMF-3 also were

of gas condensate GCB-1, contamination based on volume of

liquid in stock tank, mPR EOS, 100°C.

investigated at separator conditions. Fig. 12 shows the results of

using the mPR EOS tuned to contaminated samples to predict the

phase behavior of the original composition at 37.8°C. As expected,

the mPR EOS tuned to the 30% contaminated sample is not reli-

15

15

Liquid Fraction ( liq/ total), percentage

Liquid Fraction ( liq/ total), percentage

10

10

V V

V V

5

5 Original, Experimental

Original, Experimental

Retrieved, 5%

Retrieved, 15% Original, Tuned EOS

Retrieved, 30% Retrieved, Adjusted EOS

0 0

0 1,000 2,000 3,000 4,000 5,000 6,000 0 1,000 2,000 3,000 4,000 5,000 6,000

Pressure, psia Pressure, psia

Fig. 9—Predicted liquid fraction of the uncontaminated gas con- Fig. 10—Predicted liquid fraction of the uncontaminated gas

densate GCB-1, using EOS tuned to contaminated samples and condensate GCB-1, using EOS with adjusted tuned parameter

retrieved composition, mPR EOS, 100°C. and retrieved composition, mPR EOS, 100°C.

June 2002 SPE Reservoir Evaluation & Engineering 203

15

25

Liquid Fraction ( liq/ total), percentage

Liquid Fraction ( liq/ total), percentage

20

10

15

V V

V V

10

5

Original, Experimental

Original, Experimental

Retrieved, 5% 5 Retrieved, 5%

Retrieved, 15% Retrieved, 30%

0 0

0 1,000 2,000 3,000 4,000 5,000 6,000 1,000 2,000 3,000 4,000 5,000 6,000

Pressure, psia Pressure, psia

Fig. 11—Predicted liquid fraction of the uncontaminated gas Fig. 12—Predicted liquid fraction of the uncontaminated gas

condensate GCB-1, using EOS tuned to contaminated samples condensate GCB-1, using EOS tuned to contaminated samples

and retrieved composition, VPT EOS, 100°C. and retrieved composition, mPR EOS, 37.8°C.

able in predicting the phase behavior of the original fluid. Using 3. The EOS tuned to the experimental data of contaminated

the same approach, the predicted liquid fractions and the dewpoint samples, along with the retrieved composition, can be used to

pressure of the retrieved composition are given in Fig. 13. Note a reasonably predict the phase behavior of the uncontaminated oil

perfect match to the predicted results by the model tuned to ex- samples. However, the predicted results for gas condensate

perimental data of the uncontaminated sample. samples could be erroneous.

4. The temperature-dependency parameter of an EOS, used as the

regression variable, tuned to match the data of contaminated

Conclusions samples varied linearly with the level of contamination. There-

The impact of contamination with oil-based mud filtrates on com- fore, the required EOS parameters for the uncontaminated fluid

position and phase behavior of different types of reservoir fluids, can be determined by extrapolating the line to the zero level

including volatile oil and gas condensate samples, has been inves- of contamination.

tigated. Two methods have been developed to retrieve the original 5. Applying the determined parameters to the EOS, the developed

fluid composition from contaminated samples. EOSs have been model can accurately predict the phase behavior and volumetric

tuned to the experimental data of contaminated samples. The pa- properties of the uncontaminated fluid.

rameters of the tuned EOS have been adjusted to develop a phase 6. The method developed to determine the parameters of EOS for

behavior model for the uncontaminated sample. The following the uncontaminated fluid is general, and it can be applied to any

conclusions can be drawn based on the results of this work: EOS. This was successfully applied to the mPR and VPT EOSs

1. Using the linearity of concentration of single-carbon groups in this study.

(molecular weight, semi-logarithmic plot), two methods (Skim-

ming and Subtraction) have been developed to determine the Acknowledgments

original composition from contaminated samples. The experiments were performed by K. Malcolm and K. Bell, with

2. The Skimming and Subtraction methods can reliably predict the support from A. Reid. We gratefully acknowledge the sponsors of

level of contamination and the composition of uncontaminated this study: the U.K. Dept. of Trade and Industry, BP Exploration

fluid from contaminated samples. However, the Subtraction Co. Ltd., Edinburgh Petroleum Services (EPS) Ltd., Elf (UK) Ltd.,

method is preferred if the contaminant comprises of a wide Marathon International (GB) Ltd., Mobil (North Sea) Ltd., Oil

range of petroleum fractions. Phase Sampling Ltd., Phillips Petroleum Co. (UK) Ltd., Shell UK

Exploration and Production Ltd., and Statoil AS. Some of the fluid

samples used in this study were donated by Statoil AS and BP

25 Exploration Co. Ltd.

References

Liquid Fraction ( liq/ total), percentage

20

1. Valderrama, J.O.: “A Generalised Patel-Teja Equation of State for

Polar and Non-polar Fluids and Their Mixtures,” J. Chem. Eng. Japan

(1990) 23, No.1, 87.

15

2. Gozalpour, F. et al.: “Rapid and Robust Phase Equilibrium Calculation

V V

to Model Fluids in Reservoir and Surface Processing,” Chem. Eng. Res.

10

& Des., Trans. IChemE (July 1998) 76(a), 594.

3. Gozalpour, F. et al.: “Integrated Phase Behavior Modeling of Fluids in

Original, Experimental

Reservoir-Surface Processes Using Equation of State,” paper SPE/DOE

5 39630 presented at the 1998 SPE/DOE Improved Oil Recovery Sym-

Original, Tuned EOS

posium, Tulsa, 19–22 April.

Retrieved, Adjusted EOS

4. Twu, C.H.: “An Internally Consistent Correlation for Predicting the

0 Critical Properties and Molecular Weights of Petroleum and Coal-Tar

1,000 2,000 3,000 4,000 5,000 6,000 Liquids,” Fluid Phase Equilibria (1984) 16, No. 2, 137.

Pressure, psia 5. Riazi, M.R. and Daubert, T.E.: “Characterization Parameters for Pe-

troleum Fractions,” Ind. Eng. Chem. Res. (1987) 26, No. 4, 755.

Fig. 13—Predicted liquid fraction of the uncontaminated gas 6. Lee, B.I. and Kesler, M.G.: “A Generalized Thermodynamic Correla-

condensate GCB-1, using EOS with adjusted tuned parameter tion Based on Three-parameter Corresponding States,” AIChE J.

and retrieved composition, mPR EOS, 37.8°C. (1975) 21, No. 3, 510.

204 June 2002 SPE Reservoir Evaluation & Engineering

7. Morris, C.W. et al.: “Using Optical Fluid Analysis To Evaluate Down- search interests include phase behavior modeling of volatile

hole Fluid Sample Contamination,” paper SPE 50603 presented at the oils and gas condensates, HP/HT fluids, contamination of res-

1998 SPE European Petroleum Conference, The Hague, 20–22 Octo- ervoir fluids with oil-based drilling fluid, and gas-injection pro-

ber. cesses. He holds a BS degree in chemical engineering, an MS

degree in reservoir engineering from Tehran U., and a PhD

8. Akram, A.H., Fitzpatrick, A.J., and Halford, F.R.: “A Model to Predict

degree in petroleum engineering from Heriot-Watt U. Ali

Wireline Formation Tester Sample Contamination,” paper SPE 48959 Danesh is a professor in the Dept. of Petroleum Engineering at

prepared for presentation at the 1998 SPE Annual Technical Confer- Heriot-Watt U. His research interests include reservoir fluids and

ence and Exhibition, New Orleans, 27–30 September. hydrocarbon recovery mechanisms, and he teaches courses

9. Katz, D.L.: “Overview of Phase Behavior in Oil and Gas Production,” on fluids phase behavior and gas condensate reservoirs. He is

JPT (June 1983) 1205. the author of the book PVT and Phase Behaviour of Petroleum

10. Pedersen, K., Thomassen, P., and Fredenslund, A.: “Phase Equilibria Reservoir Fluids (1998). Danesh holds a BS degree in petroleum

engineering from the Abadan Inst. of Technology (AIT), Iran,

and Separation Processes,” Report SEP 8207, Inst. of Kemiteknik,

and a PhD degree in chemical engineering from Manchester

Denmark Tekniske Højskole (July 1982). U., U.K. Dabir H. Tehrani is an honorary professor of petroleum

11. MacMillan, D.J., Ginley, G.M., and Dembicki, H. Jr.: “How to Obtain engineering at Heriot-Watt U. He joined the oil industry (Iran) in

Reservoir Fluid Properties from an Oil Sample Contaminated with 1957, working in different positions up to Petroleum Engineering

Synthetic Drilling Mud,” paper SPE 38852 presented at the 1997 SPE Manager (1978) and Reservoir Engineering Manager (1983–91)

Annual Technical Conference and Exhibition, San Antonio, Texas, 5–8 with Britoil and BP Exploration. Previously, he taught part-time

October. at AIT (Iran) and Heriot-Watt U. (1983–92). He joined Heriot-Watt

U. full-time as a research consultant after retiring from BP in

12. Whitson, C.H.: “Characterizing Hydrocarbon Plus Fractions,” SPEJ

1991. Tehrani holds a BS degree in mathematics from Tehran U.

(August 1983) 683 and a postgraduate diploma in petroleum engineering from

13. “Reservoir Fluid Studies,” 1996–1999 Programme, Report No. PVT/ Birmingham U., U.K. Adrian C. Todd is a professor and former

99/2, Progress Report, Dept. of Petroleum Eng., Heriot-Watt U., Ed- chairman of the Dept. of Petroleum Engineering at Heriot-Watt

inburgh, U.K. (July 1999). U. He joined the department in 1972 and has been involved in

research of oilfield scale, phase behavior of reservoir fluids,

water injection, and hydrates. Todd holds BS and PhD degrees

in chemical engineering from Loughborough U. of Technology,

SI Metric Conversion Factors U.K. Bahman Tohidi is a reader in the Dept. of Petroleum Engi-

neering at Heriot-Watt U. He joined the National Iranian Oil Co.

°F (°F - 32)/1.8 ⳱ °C

(NIOC) in 1984, where he worked as an instructor and produc-

psi × 6.894757 E+00 ⳱ kPa tion engineer for 7 years. He joined Heriot-Watt U. in 1991. His

research interests include gas hydrates, PVT and phase behav-

ior, and properties of reservoir fluids and production technol-

Fathollah Gozalpour is a senior researcher in the Dept. of Pe- ogy. Tohidi holds a BS degree in chemical engineering from AIT

troleum Engineering at Heriot-Watt U. in Edinburgh, U.K. His re- and a PhD degree in petroleum engineering from Heriot-Watt U.

June 2002 SPE Reservoir Evaluation & Engineering 205

You might also like

- Iso 17025 - Corrective Action Request Form (Completed)Document1 pageIso 17025 - Corrective Action Request Form (Completed)Jesse100% (1)

- Iso 17025 - Corrective Action Request Form (Completed)Document1 pageIso 17025 - Corrective Action Request Form (Completed)JesseNo ratings yet

- WeatherfordLabs Reservoir Fluid AnalysisDocument7 pagesWeatherfordLabs Reservoir Fluid AnalysisJesseNo ratings yet

- Res Eng Ch14 Parts 1-12Document37 pagesRes Eng Ch14 Parts 1-12AiwarikiaarNo ratings yet

- SPE-195039-MS Compositional Modeling and Calibration of ASP Carbonate CorefloodsDocument19 pagesSPE-195039-MS Compositional Modeling and Calibration of ASP Carbonate CorefloodsMohamed CHIKHAOUINo ratings yet

- Loreal IndiaDocument36 pagesLoreal IndiaDeepakNo ratings yet

- Paper 1Document8 pagesPaper 1WALDO DAVID SILVA SANCHEZNo ratings yet

- Spe143612 Singh OMVDocument12 pagesSpe143612 Singh OMVSeftianaNo ratings yet

- Spe 172359 MSDocument12 pagesSpe 172359 MSamramazon88No ratings yet

- Lee 1996Document9 pagesLee 1996marianapereagarciaNo ratings yet

- Laboratory and Theoretical InvestigationDocument14 pagesLaboratory and Theoretical InvestigationlidiNo ratings yet

- New Modified Black-Oil PVT Correlations For Gas Condensate and Volatile Oil Fluids - SPE-102240-MS-PDocument6 pagesNew Modified Black-Oil PVT Correlations For Gas Condensate and Volatile Oil Fluids - SPE-102240-MS-PvinomarkyNo ratings yet

- Ratnakar, Phase Behavior Experiments and PVT Modeling of DME-brine-crudeDocument14 pagesRatnakar, Phase Behavior Experiments and PVT Modeling of DME-brine-crudeAllah BakhshNo ratings yet

- SURFACTANTDocument15 pagesSURFACTANTRachel PanjaitanNo ratings yet

- SPE-187453-MS Assessing Single EOS Predictability Using PVT Properties of A Wet-Gas Reservoir On A Compositional SimulatorDocument16 pagesSPE-187453-MS Assessing Single EOS Predictability Using PVT Properties of A Wet-Gas Reservoir On A Compositional SimulatorCarlos Alberto Torrico BorjaNo ratings yet

- GROOT, Representation of Phase Behavior and PVT Workflow For DME EnhancedDocument19 pagesGROOT, Representation of Phase Behavior and PVT Workflow For DME EnhancedAllah BakhshNo ratings yet

- Selection Method of Surfactants For Chemical Enhanced Oil RecoveryDocument8 pagesSelection Method of Surfactants For Chemical Enhanced Oil RecoveryAdhita MeryantoNo ratings yet

- PVT PaperDocument14 pagesPVT PaperIrvany PetitNo ratings yet

- Paper Black OilDocument20 pagesPaper Black OilFariz AdriansyahNo ratings yet

- Identification and Evaluation of High-Performance EOR SurfactantsDocument11 pagesIdentification and Evaluation of High-Performance EOR SurfactantsDavid LópezNo ratings yet

- EOS Tuning To Model Full Field Crude Oil Properties Using Multiple Well Fluid PVT AnalysisDocument10 pagesEOS Tuning To Model Full Field Crude Oil Properties Using Multiple Well Fluid PVT AnalysisSebastianDiazNo ratings yet

- Crude Oil Viscosity Data ModellingDocument19 pagesCrude Oil Viscosity Data ModellingOKORIENo ratings yet

- Instrucciones de Acceso A PlataformaDocument12 pagesInstrucciones de Acceso A PlataformafelixNo ratings yet

- SPE 56745 (1999) PVT ExpertDocument9 pagesSPE 56745 (1999) PVT ExpertPorfirio AguileraNo ratings yet

- A Single Well Tracer Test With Insitu Generated CO2 As Oil TracerDocument7 pagesA Single Well Tracer Test With Insitu Generated CO2 As Oil TracerLazuardhy Vozika FuturNo ratings yet

- Spe 103255 MS P (1) - PDFDocument9 pagesSpe 103255 MS P (1) - PDFGabriel EduardoNo ratings yet

- Review of PVT Correlations For Crude Oils: S. S. Ikiensikimama and O. OgbojaDocument7 pagesReview of PVT Correlations For Crude Oils: S. S. Ikiensikimama and O. Ogbojajules junior cheudeuNo ratings yet

- A Method To Determine K Values and From Laboratory Data and Its ApplicationsDocument16 pagesA Method To Determine K Values and From Laboratory Data and Its ApplicationsHector PeñaNo ratings yet

- Descriptive Statistical Analysis of Experimental Data For WettabiDocument20 pagesDescriptive Statistical Analysis of Experimental Data For WettabiEnggela LarwuyNo ratings yet

- El-Banbi, Sayyouh, Nassar.-Modified Black Oil PVT Properties Correlations For Volatile Oil and Gas Condensate ReservoirsDocument19 pagesEl-Banbi, Sayyouh, Nassar.-Modified Black Oil PVT Properties Correlations For Volatile Oil and Gas Condensate ReservoirsSergio FloresNo ratings yet

- Case Studies Downhole Fluid AnalyserDocument2 pagesCase Studies Downhole Fluid Analysergeoahamza85No ratings yet

- SPE-10127 Bashbush J.L. A Method To Determine K-Values From Laboratory Data and Its ApplicationsDocument16 pagesSPE-10127 Bashbush J.L. A Method To Determine K-Values From Laboratory Data and Its Applicationsjohndo3No ratings yet

- SPE94211 MonitoringPVTTuning 4244061 01Document9 pagesSPE94211 MonitoringPVTTuning 4244061 01krimoNo ratings yet

- Rheology of Drilling Fluids: Comparison Between Rotational Viscometer and RheometerDocument7 pagesRheology of Drilling Fluids: Comparison Between Rotational Viscometer and RheometershyamalNo ratings yet

- SPE-107803-Carito Comp SimDocument14 pagesSPE-107803-Carito Comp SimWilmer CuicasNo ratings yet

- Jia 2017Document24 pagesJia 2017Kelly Jhoanna JimenezNo ratings yet

- A Method For Characterization of BitumenDocument9 pagesA Method For Characterization of Bitumenzakiyah irfin100% (1)

- Rigorous Modeling of Solution Gasoil Ratios For A Wide Ranges of Reservoir Fluid Properties 2157 7463 1000308Document7 pagesRigorous Modeling of Solution Gasoil Ratios For A Wide Ranges of Reservoir Fluid Properties 2157 7463 1000308UmarNo ratings yet

- Masoud Riazi, Abdolah Golkari: ArticleinfoDocument9 pagesMasoud Riazi, Abdolah Golkari: ArticleinfoSahib QafarsoyNo ratings yet

- Prediction of CO2 MMPDocument16 pagesPrediction of CO2 MMPArie IrNo ratings yet

- Prediction of Cloud Points of BiodieselDocument6 pagesPrediction of Cloud Points of BiodieselRene Juan Gino Garcia MadariagaNo ratings yet

- 1 s2.0 S016773222201251X MainDocument15 pages1 s2.0 S016773222201251X MainSebastián RodríguezNo ratings yet

- Spe 183640 PaDocument17 pagesSpe 183640 PaDavid SantanderNo ratings yet

- SPE 91483 Evaluation of A Depleted Gas-Condensate Reservoir For Gas StorageDocument6 pagesSPE 91483 Evaluation of A Depleted Gas-Condensate Reservoir For Gas StoragemsmsoftNo ratings yet

- Sca 9703Document10 pagesSca 9703Rosa K Chang HNo ratings yet

- Anand Et Al., 2012 (Petrophysics)Document16 pagesAnand Et Al., 2012 (Petrophysics)Leticia SakaiNo ratings yet

- Chemical Dehydration Correlations BetweeDocument7 pagesChemical Dehydration Correlations BetweeMaximiliano MackeviciusNo ratings yet

- Spe/Doe: Lumped-Component Characterization of Crude Oils For Compositional SimulationDocument23 pagesSpe/Doe: Lumped-Component Characterization of Crude Oils For Compositional Simulationpedro aguilarNo ratings yet

- Interacción Surfactante-Polímero Sobre Las Propiedades Interfaciales de Una SustanciaDocument9 pagesInteracción Surfactante-Polímero Sobre Las Propiedades Interfaciales de Una SustanciaJesus BcNo ratings yet

- Colloids and Surfaces A: Contents Lists Available atDocument9 pagesColloids and Surfaces A: Contents Lists Available atAnderson Widmer Morales VillarrealNo ratings yet

- SPE 102564 The Effect of Wettability On Oil Recovery of Alkaline/Surfactant/P Olymer FloodingDocument8 pagesSPE 102564 The Effect of Wettability On Oil Recovery of Alkaline/Surfactant/P Olymer FloodingClyde San VicenteNo ratings yet

- Spe 15835 PaDocument14 pagesSpe 15835 PaDavid SantanderNo ratings yet

- An Investigation Into Surfactant Flooding and Alkaline-Surfactant-Polymer Flooding For Enhancing Oil Recovery From Carbonate Reservoirs: Experimental Study and SimulationDocument13 pagesAn Investigation Into Surfactant Flooding and Alkaline-Surfactant-Polymer Flooding For Enhancing Oil Recovery From Carbonate Reservoirs: Experimental Study and SimulationNur InsaniNo ratings yet

- Jessen 2009Document13 pagesJessen 2009Franciani GoedertNo ratings yet

- SPE 182 - Robust Chemical EOR Modelling From Coreflood To Full Field Scale in A Brown Field, Offshore-Ghadami2016Document19 pagesSPE 182 - Robust Chemical EOR Modelling From Coreflood To Full Field Scale in A Brown Field, Offshore-Ghadami2016Elizabeth CanoNo ratings yet

- 1 s2.0 S0920410520302382 MainDocument8 pages1 s2.0 S0920410520302382 MainArunNo ratings yet

- Crude Oil/Brine Interfacial TensionsDocument12 pagesCrude Oil/Brine Interfacial TensionsRosa K Chang HNo ratings yet

- SPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsDocument11 pagesSPE-191947-MS Novel Eco-Friendly Cationic Surfactant For Improving Oil Recovery From Carbonate ReservoirsGabriel SNo ratings yet

- SPE-17685-MS CVD ValidationDocument10 pagesSPE-17685-MS CVD ValidationPorfirio AguileraNo ratings yet

- Phase Behaviour Modelling of NC98 FieldDocument8 pagesPhase Behaviour Modelling of NC98 FieldBashirNo ratings yet

- Spe 17685 MSDocument10 pagesSpe 17685 MSrarahahaNo ratings yet

- Biopolymer Plugging Effect Laboratorypressurized Pumping 2004Document1 pageBiopolymer Plugging Effect Laboratorypressurized Pumping 2004Meghna SharmaNo ratings yet

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- Petroleum Engineering: Principles, Calculations, and WorkflowsFrom EverandPetroleum Engineering: Principles, Calculations, and WorkflowsRating: 5 out of 5 stars5/5 (1)

- DHC 11 12 2021Document1 pageDHC 11 12 2021JesseNo ratings yet

- Section 3.a Civil (3) FOR BUILDING WORKDocument3 pagesSection 3.a Civil (3) FOR BUILDING WORKJesseNo ratings yet

- PVTsimHelp 20Document197 pagesPVTsimHelp 20JesseNo ratings yet

- Alto SaxophoneDocument9 pagesAlto SaxophoneJesse100% (2)

- DHC 09 04 2022.Document1 pageDHC 09 04 2022.JesseNo ratings yet

- Lab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $Document1 pageLab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $JesseNo ratings yet

- SPS - Technical Spec.Document2 pagesSPS - Technical Spec.JesseNo ratings yet

- Hydrates: by Sherry Oyagha 28 August, 2020Document45 pagesHydrates: by Sherry Oyagha 28 August, 2020JesseNo ratings yet

- General Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesDocument28 pagesGeneral Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesJesseNo ratings yet

- KDC HSE-IIPPManual v.2015Document156 pagesKDC HSE-IIPPManual v.2015JesseNo ratings yet

- Challenges During Operation and Shutdown of Waxy Crude PipelinesDocument13 pagesChallenges During Operation and Shutdown of Waxy Crude PipelinesJesseNo ratings yet

- Construction Quality Control Plan Draft - Rev0 - 27feb09Document24 pagesConstruction Quality Control Plan Draft - Rev0 - 27feb09JesseNo ratings yet

- Heptanes PlusDocument15 pagesHeptanes PlusJesseNo ratings yet

- III RD Maths I Preliminary Paper of HSCDocument2 pagesIII RD Maths I Preliminary Paper of HSCAMIN BUHARI ABDUL KHADERNo ratings yet

- Introduction To Computer NetworkingDocument28 pagesIntroduction To Computer NetworkingKendrewNo ratings yet

- Common Size Statement Analysis PDF Notes 1Document10 pagesCommon Size Statement Analysis PDF Notes 124.7upskill Lakshmi V0% (1)

- Chapter 10 Dealing With Uncertainty: General ProcedureDocument15 pagesChapter 10 Dealing With Uncertainty: General ProcedureHannan Mahmood TonmoyNo ratings yet

- Abita Brand GuideDocument7 pagesAbita Brand GuideGabriel Bedini de JesusNo ratings yet

- AHN Eafit Sarmiento 2011 Llanos Petroleum GeologyDocument177 pagesAHN Eafit Sarmiento 2011 Llanos Petroleum Geology2032086No ratings yet

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument61 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDarshan MakwanaNo ratings yet

- Presentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementDocument17 pagesPresentation On Loan Management-3 Problem/ Distressed Loans: Course Name: Bank Fund ManagementNafisa MonsurNo ratings yet

- Corporate Nvidia in BriefDocument2 pagesCorporate Nvidia in BriefakesplwebsiteNo ratings yet

- Starkville Dispatch Eedition 5-20-20 CORRDocument16 pagesStarkville Dispatch Eedition 5-20-20 CORRThe DispatchNo ratings yet

- اسئلة بروتوكولات الفصل الاولDocument21 pagesاسئلة بروتوكولات الفصل الاولرسول ابراهيم عبد علي رويعيNo ratings yet

- Maya, Aztec, and Inca Civilizations PDFDocument116 pagesMaya, Aztec, and Inca Civilizations PDFGabriel Medina100% (2)

- City Planning and Neighbourhood Design Case Studies1Document132 pagesCity Planning and Neighbourhood Design Case Studies1shinmiNo ratings yet

- T5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 616Document6 pagesT5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 6169/11 Document ArchiveNo ratings yet

- Business Case Part 1 - Phase 2 - Group 212053 - 17 FDocument14 pagesBusiness Case Part 1 - Phase 2 - Group 212053 - 17 Fkaren stefania hortua curzNo ratings yet

- Athletics Throwing EventsDocument8 pagesAthletics Throwing EventsJehan PugosaNo ratings yet

- Employee Background Verification SystemDocument5 pagesEmployee Background Verification SystemPayal ChauhanNo ratings yet

- RecursionDocument9 pagesRecursionMada BaskoroNo ratings yet

- Drivewindow BasicsDocument34 pagesDrivewindow BasicsYaa ShinNo ratings yet

- Talent AcquisitionDocument2 pagesTalent AcquisitionkiranNo ratings yet

- Factoring HandoutDocument2 pagesFactoring HandoutJordan SenkoNo ratings yet

- Boli Interne Vol I Partea 1Document454 pagesBoli Interne Vol I Partea 1Murariu Diana100% (2)

- Gammagard Us PiDocument4 pagesGammagard Us Pibmartindoyle6396No ratings yet

- Saarc - 25 Years of Regional Integration in South Asia: Tomislav DelinićDocument15 pagesSaarc - 25 Years of Regional Integration in South Asia: Tomislav DelinićGagandeep KaurNo ratings yet

- Sma Negeri 1 Kotabaru: I. Answer The Following Question!Document6 pagesSma Negeri 1 Kotabaru: I. Answer The Following Question!Dian MardhikaNo ratings yet

- FortiOS 7.0.1 CLI ReferenceDocument1,751 pagesFortiOS 7.0.1 CLI ReferenceMoacir Nunes NetoNo ratings yet

- Garmin Oregon 750Document6 pagesGarmin Oregon 750Rihit kumarNo ratings yet

- TesisDocument78 pagesTesisWidya SariNo ratings yet

- Depth of FocusDocument7 pagesDepth of FocusDr-Riya MondalNo ratings yet