Professional Documents

Culture Documents

Planos-Separador-Trifasico Mena Paucar Ramirez PDF

Planos-Separador-Trifasico Mena Paucar Ramirez PDF

Uploaded by

Xavier VillegasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planos-Separador-Trifasico Mena Paucar Ramirez PDF

Planos-Separador-Trifasico Mena Paucar Ramirez PDF

Uploaded by

Xavier VillegasCopyright:

Available Formats

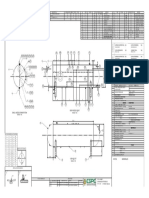

ITEM QUANTITY MATERIAL DESCRIPTION NORMALIZED IMPACT TEST PWHT NK SIZE RATING TYPE ORIENTATION SERVICE NK SIZE RATING

IMPACT TEST PWHT NK SIZE RATING TYPE ORIENTATION SERVICE NK SIZE RATING TYPE ORIENTATION SERVICE

1 2 A516-GR.70 SPHERICAL HEAD Ø39 '' N N N N1 10 '' NPT LEFT HEAD ENTRADA N16 2 '' NPT 57° VISOR DE NIVEL CRUDO

2 2 A36 LEG N N N N2 6 '' NPT 0° SALIDA DE GAS N17 2 '' NPT 119° VISOR DE NIVEL CRUDO

3 3 A516-GR.70 CILYNDER (5/16 '') N N N N3 4 '' NPT 180° SALIDA CRUDO N18 3 '' NPT 57° CONTROL NIVEL CRUDO

N4 4 '' NPT 180° SALIDA AGUA N19 2 '' NPT 48° INTERRUPTOR NIVEL

N5 2 '' NPT 180° DRENAJE N20 2 '' NPT 143° INTERRUPTOR NIVEL

N6 2 '' NPT 180° DRENAJE N21 2 '' NPT 143° INTERRUPTOR NIVEL

N7 2 '' NPT 0° DRENAJE N22 2 '' NPT 90° TRANSM. DE TEMPER.

N8 2 '' NPT 0° VALV. DE SEGURIDAD N23 2 '' NPT 90° INDICAD. DE TEMPER.

N9 2 '' NPT 0° VALV. DE SEGURIDAD N24 2 '' NPT 154° SAND JET

N10 2 '' NPT 0° SONDA DE INTERFASE N25 2 '' NPT 154° SAND JET

N11 2 '' NPT 0° INDICADOR DE PRESON N26 3 '' NPT RIGHT HEAD TRANSM. NIVEL CRUDO

N12 2 '' NPT 0° DISPONIBLE N27 3 '' NPT RIGHT HEAD TRANSM. NIVEL CRUDO

N13 2 '' NPT 57° VISOR DE NIVEL INTERF. N28 2 '' NPT 180° DRENAJE

N14 2 '' NPT 119° VISOR DE NIVEL INTERF. MH1 24 '' S. OUTLET 90° MANHOLE

N15 3 '' NPT 57° CONTROL NIVEL INTERF.

EXTERIOR

LIMPIEZA SUPERFICIAL: N/A CAPA INTERMEDIA: N/A

(Clean System) - (Intermediate coat) -

CAPA IMPRIMANTE: N/A ACABAD FINAL: N/A

MH1 N12 N10 N8 N7 N2 (Primer Coat) - (FINAL COAT) -

N23

2'' 24'' 2'' 2'' 2'' 2'' 6''

N12 N11 N10 N9 N8 N7 N2

LIMPIEZA SUPERFICIAL: N/A CAPA INTERMEDIA: N/A

INTERIOR

2'' 2'' 2'' 2'' 2'' 2'' 6''

S2 (Clean System) - (Intermediate coat) -

48° N19 D E F G H I J K L A

S2 S1

CAPA IMPRIMANTE: N/A ACABAD FINAL: N/A

H1

0° 2''

(Primer Coat) - (FINAL COAT) -

N26

57° N13 N15 N16 N18 N11 N9 N15 N16 3'' DESIGN DATA

2'' 3'' 2'' 3'' N1 2'' 2'' 3'' 2'' N19

S1 S1 10'' N13 2'' Design Pressure 75 Psig Serial No.

2'' Design Temperature 200 °F C. R. N. No.

A1

S2 Corrosion Allowance 1/8 '' Location ECUADOR

Test Pressure ASME Code ASME VII-DIVISION 1

270° 90° N22 N23 MH1 Radiographic Level RT-1 Shell Thick 5/16 ''

2'' 2'' 24'' Stress Reliet Head thick 5/16 ''

F1

N22

E1

N14 N17

2'' 2'' 2'' VESSEL DATA

1 ITEM No:

N24 2 SERVICE: SEPARADOR TRIFÁSICO DE CRUDO

D1

119° N14 N17 2'' N20

N25 3 SPECIF.: ASME SEC VII DIV 1 UG:27,36,37 - ASME B16.5

C1

2'' 2'' 2''

2''

4 OPER. PRESSURE ABOVE

B 5 LIQUID LEVEL

G1

180° B1

143° N20

6 INT: 75 Psig

N21 DESIGN PRESSURE

C 7 Ext: ATM.

S2 2'' 2'' N27

3'' 8 MAX. DESIGN TEMPERATURE:

9 OPERATING CONDITIONS:

10 PRESSURE RATING:

M N O P Q R S T V

154° N24 N25 U 11 MAX. OPER. TEMPERATURE:

2'' 2''

12 DESIGN CONDITIONS

N28 N6 N15 N21 N4 N5 N3

2'' 2'' 3'' 2'' 4'' 2'' 4'' 13 CODE.: ASME SEC VII DIV 1

N28 N6 N4 N5 N3 14 SPECIFIC GRAVITY: Del tipo de crudo

2'' 2'' 4'' 2'' 4''

N18 15 MIN. DESIGN METAL TEMPERATURE:

3'' 16

VIEW NOZZLE @ 90° WIND DATA:

SHELL NOZZLE ORIENTATION SCALE 1:30 17 SISMIC ZONE:

SCALE 1:30 18 RADIOGRAPHIC LEVEL: FULLY RADIOGRAPHED

19 JOINT EFFICIENCY.

20 SHELL CIRCUNFERENTIAL:

6705.6 21 SHELLNLONGITUDINAL:

22 TYPE OF HEADS: HEMISPHERICAL

1 23 CORROSION ALLOWENCE: 1/8 ''

24 TEST HIDROSTATIC

25 MATERIALS

26 MATERIAL SHELL: SA-516 Gr. 70

1

27 MATERIAL HEADS: SA-516 Gr. 70

28 MATERIAL SUPPORTS: SA-516 Gr. 70

990.6

29 MATERIAL FLANGES:

30 MATERIAL NOZZLES:

31 STUD BOLTS: N

32 --

495.3

33 GASKETS

34 OTHER

35 ESTIMATED WEIGHT

ORIENTACIÓN GENERAL 36 FABRICATION:

838.2

3 37 TEST:

0° 38 OPERATING:

39 ESTIMATED CAPACITY:

990.6 431.8

270° 90°

VIEW @ 270° 2 NOTAS GENERALES

2

SCALE 1:30

180°

DETALLES DE SOLDADURA

S1 S2

NOTAS GENERALES REVISIONES

DATA SHEET:

DESCRIPCIÓN FECHA DIBUJADO POR REVISO APRUEBO

60°

SEPARADOR TRIFÁSICO

13/01/18 MENA-PAUCAR-RAMIREZ ING. BYRON GUERRERO

78'' OD - 22' Entre Costuras

14/01/18 MENA-PAUCAR-RAMIREZ ING. BYRON GUERRERO

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- BioPsychoSocial JongsmaDocument4 pagesBioPsychoSocial Jongsmarredmond100% (2)

- Promeco Extruder System PES Briquetting MachineDocument2 pagesPromeco Extruder System PES Briquetting MachineXavier VillegasNo ratings yet

- Catalogo Generale Promeco2Document52 pagesCatalogo Generale Promeco2Xavier VillegasNo ratings yet

- Plano-General Mena Paucar RamirezDocument1 pagePlano-General Mena Paucar RamirezXavier VillegasNo ratings yet

- Ejer Cici Op Roy EctoDocument5 pagesEjer Cici Op Roy EctoXavier VillegasNo ratings yet

- Department of Energy Sciences and Mechanics: a σ σ σ K a σ N=50000Document2 pagesDepartment of Energy Sciences and Mechanics: a σ σ σ K a σ N=50000Xavier VillegasNo ratings yet

- 3.20 2 Tecnicas de Planeacion de La ProduccionDocument16 pages3.20 2 Tecnicas de Planeacion de La ProduccionXavier VillegasNo ratings yet

- Pic E10224Document1 pagePic E10224santosh KumarNo ratings yet

- Sa Pula, Sa PutiDocument84 pagesSa Pula, Sa PutiLuvina Amor Belarma0% (2)

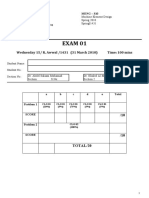

- Meng 310 Exam 01 Spring 2010Document4 pagesMeng 310 Exam 01 Spring 2010Abdulrahman AlzahraniNo ratings yet

- Wolfram Von Eschenbach - ParzivalDocument324 pagesWolfram Von Eschenbach - ParzivalStanley Castro100% (1)

- Unit I (Magnetic Field and Circuits - Electromagnetic Force and Torque)Document43 pagesUnit I (Magnetic Field and Circuits - Electromagnetic Force and Torque)UpasnaNo ratings yet

- Phi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisingDocument47 pagesPhi Theta Kappa Sued by HonorSociety - Org Lawsuit Details 2024 False AdvertisinghonorsocietyorgNo ratings yet

- Tugas Uas Miss LennyDocument8 pagesTugas Uas Miss LennyZiyan Khoirun hakimNo ratings yet

- In Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CDocument2 pagesIn Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CAma GavNo ratings yet

- The GiantDocument4 pagesThe GiantBug BeeNo ratings yet

- COD Testing in Environmental Laboratory of Environmental Engineering Diponegoro UniversityDocument10 pagesCOD Testing in Environmental Laboratory of Environmental Engineering Diponegoro UniversityTasha RifantiNo ratings yet

- 50 HaazinuDocument6 pages50 HaazinuTheodore James TurnerNo ratings yet

- Adobe Photoshop CS6 Exam SimulationDocument6 pagesAdobe Photoshop CS6 Exam SimulationMuhammad NadhirNo ratings yet

- StressesDocument19 pagesStressesAnonymous 3sHEQDNo ratings yet

- SSL Stripping Technique DHCP Snooping and ARP Spoofing InspectionDocument7 pagesSSL Stripping Technique DHCP Snooping and ARP Spoofing InspectionRMNo ratings yet

- A-SME Platinum Brochure (SST) 20180901 v1Document64 pagesA-SME Platinum Brochure (SST) 20180901 v1khamini dilly kannan100% (1)

- Porter's Five Forces Model of Competition-1Document14 pagesPorter's Five Forces Model of Competition-1Kanika RustagiNo ratings yet

- IMC 151 - PAIR AssignmentDocument37 pagesIMC 151 - PAIR Assignmentfarishaemylia40No ratings yet

- Gestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFDocument9 pagesGestational Diabetes Diet - What To Eat For A Healthy Pregnancy PDFJibin John JacksonNo ratings yet

- SPM Unit 4 Notes-1Document27 pagesSPM Unit 4 Notes-1Ibrahim GadliNo ratings yet

- 1 SM PDFDocument12 pages1 SM PDFElan Patria NusadiNo ratings yet

- Order Form Dedicated Internet Local: Customer InformationDocument5 pagesOrder Form Dedicated Internet Local: Customer InformationtejoajaaNo ratings yet

- Cabin Crew Prepare Take Off Webinar PresentationDocument23 pagesCabin Crew Prepare Take Off Webinar PresentationTakele KalebNo ratings yet

- Cultural Variations and Social Differences (Ethnicity)Document19 pagesCultural Variations and Social Differences (Ethnicity)Jomar TeofiloNo ratings yet

- SBARDocument2 pagesSBARNabiela Aswaty 2011125083No ratings yet

- SHRM PerspectivesDocument14 pagesSHRM PerspectivesNoman Ul Haq Siddiqui100% (2)

- Ec6004 Satellite Communication r2013Document2 pagesEc6004 Satellite Communication r2013Anonymous JnvCyu85No ratings yet

- Hypertensive Patients Knowledge, Self-Care ManagementDocument10 pagesHypertensive Patients Knowledge, Self-Care ManagementLilian ArthoNo ratings yet

- Lesson 1 - Traditions and Locations - The Filipino PoemDocument8 pagesLesson 1 - Traditions and Locations - The Filipino Poemdes oro100% (1)