Professional Documents

Culture Documents

Anchor Chain Stud

Anchor Chain Stud

Uploaded by

Antonios BachtisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor Chain Stud

Anchor Chain Stud

Uploaded by

Antonios BachtisCopyright:

Available Formats

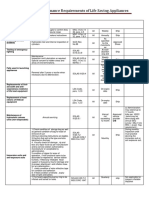

No.

79

4. The Looseness of Studs in Anchor Chain Cable

No.

4.1 During the Special Survey Hull (SSH) when the anchor chains are ranged, gauged and

79 examined, there should be no looseness of studs within links of the anchor cable. Where

(cont) loose studs exist, the affected cable should be replaced, or where considered feasible,

welded in accordance with the procedure specification below.

4.2 Loose studs in anchors cable found prior to the Special Survey may be permitted,

subject to the following criteria:

Maximum Axial Stud movement – 3% of cable diameter

Maximum Lateral Stud movement – 5% of cable diameter

Maximum gap between Link and Stud – 3mm

4.3 Where studs are missing from the anchor cable, the lengths of affected cable should be

replaced.

5. The Securing by Welding of Chain Cable Studs in Service

5.1 Where it is proposed to secure loose anchor cable studs by welding, the proposal for

repair is to be submitted to the Surveyor for evaluation and approval. The approval will be

based on the conditions of the link to be repaired and of remaining links (see para. A1.6

Permissible Weardown of Stud Link Chain Cable for Bower Anchors in UR A1).

5.2 Any such repairs should be carried out in a clean environment as far as practicable.

The attachment of earthing straps to cable links should be specially considered prior to

welding.

6. Welding Procedure Specification

6.1 Welds are to be made in accordance with a qualified and approved welding procedure

and accepted by the Surveyor.

6.2 Welding consumables used are to be approved with grading 3 or 3Y. For Grades 1 and

2 chain cables consumables should have low hydrogen grading H15 or better and for Grade

3 chain cables a very low hydrogen grading of H5 or better.

6.3 A preheating temperature suitable to limit hardness and to prevent the risk of cold

cracks is to be applied. In general the following applies:

- Grade 1 and 2: 100°C

- Grade 3: 175°C

6.4 The welding practice and the welding parameters are to be selected to permit a large

single weld deposit to be made. A temper bead at the stud side is allowed and may be

advisable depending on the link grade.

6.5 After welding, links should be wrapped to allow a slow cooling.

Page 2 of 10 IACS Rec. 2003/Rev.1 2014

No.79

Anchor Chain Link and Shackles

No. Typical Measurements

79 1) Anchor chain calibration – location of the chain link measurements and wearing limits

(cont)

D1 = average of measured diameter (mm) = d1 d 2 2

d1 and d2 measured diameters of the chain link in the area of maximum wear

D1≥0,88 DO

DO = original diameter (mm)

2) Loose stud of anchor chain links location of the measurements

a) Maximum lateral stud movements

≤ 0,05 Do where DO = original diameter (mm)

DO

DO = original

diameter (mm)

Page 7 of 10 IACS Rec. 2003/Rev.1 2014

No.79

b) Maximum axial stud movements

No.

79

(cont)

DO

≤ 0,03 Do

DO = original

diameter (mm)

c) Maximum gap between Link and Stud

≤ 3 mm

Page 8 of 10 IACS Rec. 2003/Rev.1 2014

You might also like

- T ISS PX01 Instruction Manual Rev.01Document9 pagesT ISS PX01 Instruction Manual Rev.01Louis Marino100% (1)

- Navy and Broken White Geometric Thesis Defense PresentationDocument20 pagesNavy and Broken White Geometric Thesis Defense PresentationRemuel Arellano100% (1)

- SOLAS Training Manual PDFDocument52 pagesSOLAS Training Manual PDFRajapradeepNo ratings yet

- JX-2 Operation and Maintenance ManualDocument14 pagesJX-2 Operation and Maintenance ManualKunpeng Zhou100% (1)

- Datema CatalogueDocument91 pagesDatema CatalogueRostyslav Stavytskyi50% (2)

- DigiMoorX7 Software IntroductionDocument24 pagesDigiMoorX7 Software IntroductionSachin SikkaNo ratings yet

- ENG'G-11 Hydrostatic Test Procedures (Cargo Hoses)Document4 pagesENG'G-11 Hydrostatic Test Procedures (Cargo Hoses)ramon c. macarandangNo ratings yet

- Linethrower 250 Pains WessexDocument2 pagesLinethrower 250 Pains WessexAntonio Clas100% (2)

- Anchoring Poster For BridgeDocument1 pageAnchoring Poster For BridgeSachin SikkaNo ratings yet

- Navigat 3000 Operational Manual PDFDocument228 pagesNavigat 3000 Operational Manual PDFspongeboboNo ratings yet

- Life-Saving Appliances Including LSA Code 2017Document8 pagesLife-Saving Appliances Including LSA Code 2017fajee_faridNo ratings yet

- General Smart Manual PDFDocument62 pagesGeneral Smart Manual PDFGiurca FlorinNo ratings yet

- SurveysDocument3 pagesSurveysAndy James Roberts100% (1)

- COD Lab Report FullDocument9 pagesCOD Lab Report FullLutfi Amin67% (3)

- Experiment 5-Solar Ray CollectorDocument16 pagesExperiment 5-Solar Ray CollectorRazman Bijan100% (1)

- Instruction Manual WARTSILLADocument458 pagesInstruction Manual WARTSILLAEmilio Portela100% (7)

- IACS Rec - 79Document10 pagesIACS Rec - 79tyuNo ratings yet

- 3060 - E - 012 - Pilotstar D Typ Ap02-S01Document166 pages3060 - E - 012 - Pilotstar D Typ Ap02-S01Gary GouveiaNo ratings yet

- Annual Summary of Notices To Mariners What Is NP247Document2 pagesAnnual Summary of Notices To Mariners What Is NP247Kunal SinghNo ratings yet

- SCANJET General Instruction SC 45TW PDFDocument40 pagesSCANJET General Instruction SC 45TW PDFpescarra-1No ratings yet

- AVCS JRC JAN701B-901B-2000 NavStickDocument13 pagesAVCS JRC JAN701B-901B-2000 NavSticksrinu1984100% (1)

- Anchor Chain Stud RepairsDocument1 pageAnchor Chain Stud RepairsAnkush GuptaNo ratings yet

- SIRE 2.0 - Instructions For Uploading PhotograDocument32 pagesSIRE 2.0 - Instructions For Uploading PhotograErdem CihanNo ratings yet

- GX 8000 Tips and CautionsDocument11 pagesGX 8000 Tips and CautionsalexanderNo ratings yet

- Rec 10 Rev 5Document28 pagesRec 10 Rev 5Kenan YILDIRIMÇAKARNo ratings yet

- A044 - Actions When Unable To Heave Up AnchorDocument4 pagesA044 - Actions When Unable To Heave Up Anchoranatoliy100% (2)

- Allowable Thickness Diminution For Hull StructuresDocument13 pagesAllowable Thickness Diminution For Hull Structuresjstoute100% (1)

- Maintenance ChartDocument2 pagesMaintenance Chartrabi4457100% (1)

- Weekly Test and InspectionDocument5 pagesWeekly Test and InspectionBehendu Perera100% (1)

- What Is Abort Point and How You Can Use It For Safe NavigationDocument16 pagesWhat Is Abort Point and How You Can Use It For Safe NavigationKunal Singh100% (1)

- Anchor Chain Cable PDFDocument19 pagesAnchor Chain Cable PDFKoldo Gómez AlzibarNo ratings yet

- How To Know The Worst Case of Damage StabilityDocument34 pagesHow To Know The Worst Case of Damage StabilityJeet Singh0% (1)

- ENV-09A - Fuel Change-Over Procedure Rev 0Document15 pagesENV-09A - Fuel Change-Over Procedure Rev 0Filip NikolevskiNo ratings yet

- LSFOchangeovercalculator tcm155-175156Document23 pagesLSFOchangeovercalculator tcm155-175156George PonparauNo ratings yet

- Annex - 3 Maintenance Requirements of Life Saving AppliancesDocument5 pagesAnnex - 3 Maintenance Requirements of Life Saving AppliancesTanker Bneider100% (2)

- RSV Indian River - Sea Vessels (New Rules)Document7 pagesRSV Indian River - Sea Vessels (New Rules)SAMKUMAR100% (2)

- Rocking Test For Deck Crane MN RaulíDocument1 pageRocking Test For Deck Crane MN RaulíAlexis Barnabás CollinsNo ratings yet

- LSA1Document103 pagesLSA1SIDDHARTH MOHANTY100% (1)

- Risk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43Document2 pagesRisk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43ARUN100% (2)

- LSA MaintenceDocument18 pagesLSA MaintencemavericksailorNo ratings yet

- Anchors & Anchor WorkDocument35 pagesAnchors & Anchor WorkJitin Kanwar100% (2)

- Dunnage CalculatorDocument3 pagesDunnage Calculator123456No ratings yet

- Oil Record Book Part IDocument21 pagesOil Record Book Part ISamarth Aryan Singh100% (1)

- 16 - FRAMO Submerged Cargo Pump - Pressure Testing RoutineDocument6 pages16 - FRAMO Submerged Cargo Pump - Pressure Testing RoutineMomchil DimitrovNo ratings yet

- Annual Summary of Admiralty Notices To MarinersDocument3 pagesAnnual Summary of Admiralty Notices To Marinersss_tayade100% (1)

- Operator'S Manual: Voyage Data Recorder (VDR)Document48 pagesOperator'S Manual: Voyage Data Recorder (VDR)Edwin NyangeNo ratings yet

- COLREG Consolidated 2018Document62 pagesCOLREG Consolidated 2018RiswanNo ratings yet

- Steering Gear Regulations-LloydsDocument15 pagesSteering Gear Regulations-Lloydsd_damn100% (1)

- ECDISDocument513 pagesECDISPaul Lucian VentelNo ratings yet

- Lugless Shackle and Other Different Type of Shackle Used in Anchor. Lugless ShackleDocument4 pagesLugless Shackle and Other Different Type of Shackle Used in Anchor. Lugless ShacklekenNo ratings yet

- Consilium: Gas Detector Salwico ST400Document2 pagesConsilium: Gas Detector Salwico ST400SEDNANo ratings yet

- Tanker Familiarization CourseDocument135 pagesTanker Familiarization CoursePavlin Koev100% (2)

- LifeboatDocument6 pagesLifeboatvanmaika9960No ratings yet

- 190-ECDIS JRC JAN-7201S-9201S Instruct Manual Reference 27-7-2020Document350 pages190-ECDIS JRC JAN-7201S-9201S Instruct Manual Reference 27-7-2020dorgNo ratings yet

- Fonar - Fuel Oil Non-Availability ReportDocument4 pagesFonar - Fuel Oil Non-Availability ReportJagmohan SinghNo ratings yet

- ST 703 09 Life Saving AppliancesDocument76 pagesST 703 09 Life Saving AppliancesJaya SankerNo ratings yet

- ESP CodeDocument7 pagesESP CodeAkash KandwalNo ratings yet

- Register of Materials Handling Equipment-AMSA357Document10 pagesRegister of Materials Handling Equipment-AMSA357SudheerRawatNo ratings yet

- Hydraulic Top BracingDocument8 pagesHydraulic Top BracingAnonymous alQXB11EgQNo ratings yet

- RadarDocument305 pagesRadarNi Ck100% (1)

- Immersion SuitsDocument8 pagesImmersion SuitsBeyza AlacagözNo ratings yet

- Tanktrader BV: Technical Specification For 20' X 8' X 8'6" Iso Icc Type Tank Container For Bulk Bitumen (Un T3 Code)Document9 pagesTanktrader BV: Technical Specification For 20' X 8' X 8'6" Iso Icc Type Tank Container For Bulk Bitumen (Un T3 Code)Nauman AliNo ratings yet

- Oral Preparation Watch Keeper Deck Mates: Question and Answer GuidelinesFrom EverandOral Preparation Watch Keeper Deck Mates: Question and Answer GuidelinesRating: 5 out of 5 stars5/5 (1)

- Surface Hardening enDocument20 pagesSurface Hardening enanhntran4850No ratings yet

- O M Manual For Nuaire NU-619 Dual Access Animal Transfer Station 1411065332Document27 pagesO M Manual For Nuaire NU-619 Dual Access Animal Transfer Station 1411065332Edgar Ignacio Mendoza GarcíaNo ratings yet

- Electromagnetic FlowmeterDocument15 pagesElectromagnetic Flowmeteramer_arauf100% (1)

- Features: Narrow Pitch Connectors (0.4mm Pitch)Document11 pagesFeatures: Narrow Pitch Connectors (0.4mm Pitch)Jhonn arcilaNo ratings yet

- John Deere Components WorksDocument1 pageJohn Deere Components WorksDouglas PardosiNo ratings yet

- Maxim Is Ing The Reuse and Recycling of Clothes and TextilesDocument128 pagesMaxim Is Ing The Reuse and Recycling of Clothes and TextilesTom TommorelloNo ratings yet

- Progressive Cavity PumpDocument6 pagesProgressive Cavity Pumpmohanned salahNo ratings yet

- Processing of Edible Oil (Palm Oil)Document33 pagesProcessing of Edible Oil (Palm Oil)Salihah AbdullahNo ratings yet

- E 391 Manual 1Document6 pagesE 391 Manual 1naruto akatcyNo ratings yet

- Pipe Conveyor SystemDocument6 pagesPipe Conveyor Systemsurajit81100% (2)

- Equivalencia - AC, Aleados, Inox, Fundiciones, Aleaciones de Cu y Otros 1 PDFDocument73 pagesEquivalencia - AC, Aleados, Inox, Fundiciones, Aleaciones de Cu y Otros 1 PDFjarv7910No ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- Drying Time RecorderDocument1 pageDrying Time RecorderJohn McLovenNo ratings yet

- In Plane Arch Buckling Ofnetwork Arch BridgesDocument11 pagesIn Plane Arch Buckling Ofnetwork Arch BridgesJuan Pablo Lopez CarrascoNo ratings yet

- Technical Design Guide For FRP Composite Products and Parts: Techniques & TechnologiesDocument25 pagesTechnical Design Guide For FRP Composite Products and Parts: Techniques & TechnologiesvikasNo ratings yet

- Walworth PressureSealDocument20 pagesWalworth PressureSealtxlucky80No ratings yet

- Boq Reinforcement DPT Casa de CangguDocument1 pageBoq Reinforcement DPT Casa de CangguoxiNo ratings yet

- PDS FF IODocument9 pagesPDS FF IODaniel GarciaNo ratings yet

- 002 - Gen5700 - 000 - PD2 - 01 2Document1 page002 - Gen5700 - 000 - PD2 - 01 2HermanNo ratings yet

- Door SheetDocument5 pagesDoor SheetShanmuga Navaneethan100% (1)

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- Vickers Counterbalance Valve CBV 10Document2 pagesVickers Counterbalance Valve CBV 10rafarodrig6No ratings yet

- Rheocrete CNI - ASTM G 109 - ScannedDocument17 pagesRheocrete CNI - ASTM G 109 - ScannedsunilbauchkarNo ratings yet

- Battery Unit ServicingDocument8 pagesBattery Unit ServicingLeonardo Alfonso Carcamo CarreñoNo ratings yet

- Is 4925Document14 pagesIs 4925Naveen MatNo ratings yet

- 08 PawDocument30 pages08 PawAnupam KushwahaNo ratings yet