Professional Documents

Culture Documents

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Uploaded by

M. ShaatCopyright:

Available Formats

You might also like

- TB Woods XFC Series Datasheet1 177469416 PDFDocument36 pagesTB Woods XFC Series Datasheet1 177469416 PDFRamon LilloNo ratings yet

- IEEE Standard Letter Symbols For Quantities Used in Electrical Science and Electrical EngineeringDocument40 pagesIEEE Standard Letter Symbols For Quantities Used in Electrical Science and Electrical Engineeringstanculeanu100% (2)

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- UPS Three Single Phase IST7Document1 pageUPS Three Single Phase IST7Bassem MouelhiNo ratings yet

- Monofasico East TorreDocument2 pagesMonofasico East Torreomar zaquinaulaNo ratings yet

- IP 31 Series Online UPS: Technical SpecificationsDocument1 pageIP 31 Series Online UPS: Technical SpecificationsAbdelwhab Elsafty100% (1)

- Rx5a FumanDocument7 pagesRx5a FumanOrlando CastroNo ratings yet

- Proportional Relief Valve: PRP-10W-X-Y-Z-B1Document1 pageProportional Relief Valve: PRP-10W-X-Y-Z-B1Michał A.No ratings yet

- User'S Manual: 1 - Installation 2 - Technical SpecificationsDocument8 pagesUser'S Manual: 1 - Installation 2 - Technical SpecificationsGopal HegdeNo ratings yet

- G6kva 10kva G4Document1 pageG6kva 10kva G4Adrian DeoancaNo ratings yet

- Tesdq5V0: Small Signal Product Taiwan SemiconductorDocument4 pagesTesdq5V0: Small Signal Product Taiwan Semiconductorn tanevarNo ratings yet

- SR802 Series - I13-523740 PDFDocument5 pagesSR802 Series - I13-523740 PDFJohn PerzyloNo ratings yet

- W 38 × H 42 MM Twin Analog Timers: ATS8W / ATS11W SeriesDocument2 pagesW 38 × H 42 MM Twin Analog Timers: ATS8W / ATS11W SeriesHendra WiratamaNo ratings yet

- Avr Kutay Selecton GenericosDocument1 pageAvr Kutay Selecton GenericosGONZALONo ratings yet

- GM8804C 2Document1 pageGM8804C 2www.surebekeleNo ratings yet

- HDF 2415 DDocument2 pagesHDF 2415 Dศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- Avr Yanan Tc321 (P)Document1 pageAvr Yanan Tc321 (P)lilireneNo ratings yet

- Ower Mplifiers: Rem-S Series-Power AmplifiersDocument4 pagesOwer Mplifiers: Rem-S Series-Power AmplifiersМаксым КовальськыйNo ratings yet

- JAL33 MTEK Series 6-30 kVA PDFDocument1 pageJAL33 MTEK Series 6-30 kVA PDFEdward Alejandro Giraldo GallónNo ratings yet

- Chromium RTSeries BrochureDocument5 pagesChromium RTSeries BrochureZein CassamoNo ratings yet

- Operating Instructions: Digital Clamp Meter Model DSA600TRMSDocument9 pagesOperating Instructions: Digital Clamp Meter Model DSA600TRMSchuks blessingNo ratings yet

- Photomultiplier TubeDocument2 pagesPhotomultiplier TubecuentadosngrokNo ratings yet

- RLD-134A Catalog PageDocument2 pagesRLD-134A Catalog PageGiang TrườngNo ratings yet

- Precision Low Drift 2.048 V/2.5 V/4.096 V/ 5.0 V SOT-23 Reference With ShutdownDocument17 pagesPrecision Low Drift 2.048 V/2.5 V/4.096 V/ 5.0 V SOT-23 Reference With ShutdownbezasamiNo ratings yet

- Avr Yanan Tc341 (P)Document1 pageAvr Yanan Tc341 (P)lilireneNo ratings yet

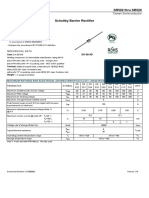

- SR502 Thru SR520: Creat by ArtDocument4 pagesSR502 Thru SR520: Creat by ArtbekowiczNo ratings yet

- Sa15b45 EpacDocument1 pageSa15b45 EpacBINOY DASNo ratings yet

- Sa15b63 EpacDocument1 pageSa15b63 EpacBINOY DASNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Document9 pagesObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)GermánNo ratings yet

- IRF530stmicroelectronics cd00000699-1204277 PDFDocument9 pagesIRF530stmicroelectronics cd00000699-1204277 PDFGermánNo ratings yet

- CATALOGO UPS COMPUTER POWER Modelo VRN 1.5, 3 KVA (RACKMOUNT)Document4 pagesCATALOGO UPS COMPUTER POWER Modelo VRN 1.5, 3 KVA (RACKMOUNT)RJ Jonathan RizzoNo ratings yet

- Tps 54160Document50 pagesTps 54160csclzNo ratings yet

- Marine: On-Board With ConfidenceDocument4 pagesMarine: On-Board With Confidenceabduallah muhammadNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Manual EA20S CaterpillarDocument3 pagesManual EA20S CaterpillarHernán Peñafiel ReaNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Dse704 4120 Data Sheet Us PDFDocument2 pagesDse704 4120 Data Sheet Us PDFzakki ahmadNo ratings yet

- Knight Series: 1KVA-10KVADocument3 pagesKnight Series: 1KVA-10KVAAntónio BarrosNo ratings yet

- Hybrid InverterDocument1 pageHybrid InverterDiego EspinosaNo ratings yet

- FG1000BV 90daDocument4 pagesFG1000BV 90dapietisc pietiscNo ratings yet

- Circuito en Fuente TV LCD Mustek N3856VGDocument13 pagesCircuito en Fuente TV LCD Mustek N3856VGAntonio ChavezNo ratings yet

- GTA202AS36 R1.pdf ALTERNADOR DE FINNINGDocument1 pageGTA202AS36 R1.pdf ALTERNADOR DE FINNINGDANIEL CUELLARNo ratings yet

- Emo 85 MDocument1 pageEmo 85 MGustavo AghinoniNo ratings yet

- EA08A ManualDocument6 pagesEA08A ManualDavid MoyaNo ratings yet

- TRI002U321TLN0Document5 pagesTRI002U321TLN0iker.sanchez.aNo ratings yet

- WT Micro Temperature Controller CatalogueDocument7 pagesWT Micro Temperature Controller CataloguepngchanhNo ratings yet

- Tps 54240Document48 pagesTps 54240Maria KhanNo ratings yet

- GTP-Series 10-40KVA CatalogueDocument2 pagesGTP-Series 10-40KVA CatalogueAgung PermanaNo ratings yet

- SPC1 Series: FeaturesDocument6 pagesSPC1 Series: FeaturesMin ZayarNo ratings yet

- T-49C-CA MOD2 Operational ManualDocument52 pagesT-49C-CA MOD2 Operational ManualVolodymyr PotapovNo ratings yet

- SM Tachometer & Line Speed Meter: DIN 24x48 / 72x72 / 96x48Document4 pagesSM Tachometer & Line Speed Meter: DIN 24x48 / 72x72 / 96x48nehalNo ratings yet

- Patanjali Solar Corporate ProfileDocument29 pagesPatanjali Solar Corporate ProfileDigitalsolar NoidaNo ratings yet

- Ups Lyonn Ult KVTDocument2 pagesUps Lyonn Ult KVTDivision EnergiaNo ratings yet

- Tap Position Indicator Tc-02: FeaturesDocument1 pageTap Position Indicator Tc-02: Featuresss subramanyamNo ratings yet

- Eg3002 Comparison Table enDocument1 pageEg3002 Comparison Table enاحمد الشمريNo ratings yet

- mt4w DV 40 - ImDocument1 pagemt4w DV 40 - ImJavier VillelaNo ratings yet

- xc6420 SeriesDocument27 pagesxc6420 SeriesFarid MubarokNo ratings yet

- Features Descriptio: Lt1213/Lt1214 28Mhz, 12V/ S, Single Supply Dual and Quad Precision Op AmpsDocument20 pagesFeatures Descriptio: Lt1213/Lt1214 28Mhz, 12V/ S, Single Supply Dual and Quad Precision Op AmpshamedNo ratings yet

- Ultra: Starting With QualityDocument2 pagesUltra: Starting With Qualityabduallah muhammadNo ratings yet

- V585me42 LFDocument2 pagesV585me42 LFashfaqNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- CT410-CT450S (50 HZ)Document3 pagesCT410-CT450S (50 HZ)M. ShaatNo ratings yet

- CT575 CT635S (KTA19 60Hz)Document3 pagesCT575 CT635S (KTA19 60Hz)M. ShaatNo ratings yet

- CT425 CT460S (QSG12 60Hz)Document3 pagesCT425 CT460S (QSG12 60Hz)M. ShaatNo ratings yet

- 1500 Series Turbo Exhaust Elbow and Oil Supply ChangeDocument2 pages1500 Series Turbo Exhaust Elbow and Oil Supply ChangeM. ShaatNo ratings yet

- New DP200 and DP210 Fuel Injection Pump Spring Gen202E1Document1 pageNew DP200 and DP210 Fuel Injection Pump Spring Gen202E1M. ShaatNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Data SheetDocument2 pagesData SheetM. ShaatNo ratings yet

- 1006DTAG2 Launch BulletinDocument4 pages1006DTAG2 Launch BulletinM. ShaatNo ratings yet

- Fault Code SpreadsheetBTPDocument2 pagesFault Code SpreadsheetBTPM. Shaat100% (1)

- J1939 Engine Monitoring and Control PortDocument3 pagesJ1939 Engine Monitoring and Control PortM. ShaatNo ratings yet

- Studer Innotec SADocument56 pagesStuder Innotec SAM. ShaatNo ratings yet

- Nsets H25-33VDocument1 pageNsets H25-33VM. ShaatNo ratings yet

- ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning YstemDocument2 pagesECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning YstemM. ShaatNo ratings yet

- DSTATCOM ControlDocument5 pagesDSTATCOM ControlabsalnabiNo ratings yet

- Electric PotentialDocument24 pagesElectric PotentialRalph Francis AguilarNo ratings yet

- PhotoVoltaic General CatalogDocument20 pagesPhotoVoltaic General CatalogBernardo Andrés GilardoniNo ratings yet

- Nema MG 1-2011Document643 pagesNema MG 1-2011Nelson Escalona RNo ratings yet

- Leak RCPAU Preamp Rev 1Document5 pagesLeak RCPAU Preamp Rev 1elveramNo ratings yet

- Nine-Phase Armature Windings Design, Test and Harmonic AnalysisDocument5 pagesNine-Phase Armature Windings Design, Test and Harmonic Analysiszuriman anthonyNo ratings yet

- Imaging Science Laboratory Manual 2021: NameDocument30 pagesImaging Science Laboratory Manual 2021: NameRabab ZaidiNo ratings yet

- Circuits & Layout: N. Weste D. HarrisDocument50 pagesCircuits & Layout: N. Weste D. HarrisSiam HasanNo ratings yet

- 4c X 10 Technical Data SheetDocument2 pages4c X 10 Technical Data SheetPrabhakaran ChandrasekaranNo ratings yet

- Electrical Machines - I: Electric Circuit TheoryDocument22 pagesElectrical Machines - I: Electric Circuit TheoryPradeep SinglaNo ratings yet

- PN JunctionDocument7 pagesPN JunctionChannabasavagouda BNo ratings yet

- Co Project: Edge Avoiding Robot USING 8051 MicrocontrollerDocument14 pagesCo Project: Edge Avoiding Robot USING 8051 MicrocontrollerJuthik BVNo ratings yet

- Aim: - To Study No Load and Blocked Rotor Test of Three Phase ImDocument5 pagesAim: - To Study No Load and Blocked Rotor Test of Three Phase ImSubhash KumarNo ratings yet

- How Do You Set System Gain Structure?: by Chuck McgregorDocument13 pagesHow Do You Set System Gain Structure?: by Chuck McgregorklepkojNo ratings yet

- Válvula Proporcional KTG4V3Document33 pagesVálvula Proporcional KTG4V3Nkma BorgesNo ratings yet

- 12 20 (24) KV HXLP DSTA - Pdic01114Document2 pages12 20 (24) KV HXLP DSTA - Pdic01114Luis MurilloNo ratings yet

- Available Relay ModelsDocument25 pagesAvailable Relay ModelsashokdixitNo ratings yet

- E474007 PDFDocument6 pagesE474007 PDFany tasnimNo ratings yet

- Implementation of Security Door Lock System For Shopping MallDocument17 pagesImplementation of Security Door Lock System For Shopping MallNyi Lin NyoNo ratings yet

- DTnotiDocument49 pagesDTnotiokman17No ratings yet

- mc9 BrochureDocument8 pagesmc9 BrochureturricanNo ratings yet

- Especificaciones Condensadoras - Rxyq5-54pay1, Payl, Ptl-DaikinDocument458 pagesEspecificaciones Condensadoras - Rxyq5-54pay1, Payl, Ptl-DaikinJorge L Ramirez100% (1)

- Cables For EE342 CourseDocument7 pagesCables For EE342 Coursemahmab70No ratings yet

- JA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelDocument2 pagesJA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelVictor OliveiraNo ratings yet

- Electrochemistry: Brady and Senese 5th EditionDocument50 pagesElectrochemistry: Brady and Senese 5th Editionatiqa rumaisya100% (1)

- World-Class Synchronous Alternators: Totally Focused OnDocument13 pagesWorld-Class Synchronous Alternators: Totally Focused OnCris_eu09100% (1)

- Test-1: Self-Induction and R-L-circuit Multi Choice Single Correct (+3,-1)Document9 pagesTest-1: Self-Induction and R-L-circuit Multi Choice Single Correct (+3,-1)Nil KamalNo ratings yet

- 53Document5 pages53djahid abdullohNo ratings yet

- Hrrs 5Kv and 10Kv Series High Resistance, 5kV and 10kV Decade Substituter User and Service ManualDocument18 pagesHrrs 5Kv and 10Kv Series High Resistance, 5kV and 10kV Decade Substituter User and Service Manualb4tipibeNo ratings yet

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Uploaded by

M. ShaatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Generator Frequency Sensing Speed Control Unit: Specifications Wiring

Uploaded by

M. ShaatCopyright:

Available Formats

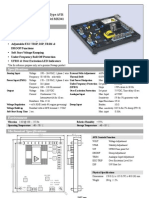

ECC328

Generator Frequency Sensing Speed Control Unit

1 SPECIFICATIONS 3 WIRING

PERFORMANCE

Isochronous Operation ± 0.25% FREQ

TRIM

Speed Range 40 - 80 Hz STARTER 120/ BATTERY

CRANK 240V AC ACTUATOR

Speed Drift with Temperature ±1%

+ _

Speed Trim ±2 Hz A B C D E F G H J

ENVIRONMENTAL

Ambient Temperature -40° to 85°C (-40 to 185°F)

FREQ

Relative Humidity up to 100% TRIM

STARTER FUSE

15A

INPUT / OUTPUT Starter Solenoid

Crank Post

Supply 12 VDC (8 - 15 VDC) Nominal (Small Post)

24 VDC (10 - 32 VDC) Nominal

+

Polarity Negative Ground (Case Isolated) L-L 12V

GENERATOR OR

Power Consumption <50mA + actuator current

L-N BATTERY

-

Maximum Actuator Current 4 Amps ACTUATOR

Generator Frequency Sensing Load on generator, 40K Ohms

L-L

Minimum sensing 1 VAC RMS OR

L-N

Maximum voltage 260 VAC

PHYSICAL

Dimension See Section 2

Weight 0.75 lb (0.34 kg)

TERMINAL DEFINITION NOTES

Mounting Any Position, Vertical Preferred

#16 AWG wire

RELIABILITY A Starter Crank

Vibration 5G, 20-500 Hz Starter solenoid crank post

Shock 20G Peak B&C Freq Trim Potentiometer input for frequency trim (small)

Testing 100% Functional Testing Should be connected to generator’s AC windings.

These connections can be line to line or line to neu-

D&E Generator

2

tral. Terminal E should be connected to the neutral if

INSTALLATION & OUTLINE DIAGRAM this connection is chosen.

#16 AWG wire recommended

Vertical orientation Mount in a cabinet, F&G Battery

allows for the drain- engine enclosure, or Terminal F is positive (+) and should be fused for

ing of fluids in moist sealed metal box. 15A

environments.

H&J Actuator #16 AWG wire recommended

Avoid Extreme Heat

4 STARTING THE ENGINE

Before starting the engine, check to ensure that the GAIN,

IMPORTANT

4.67 [118.6] STABILITY, and external SPEED TRIM controls are set to

3.95 [100.2]

their mid positions.

1. STARTING THE ENGINE: The ECC328 control is factory set to operate

at approximately 60 Hz generator frequency.

AGAWAM, MA U.S.A.

SPEED GAIN

MADE IN

STABILITY

2. Crank the engine with DC power applied to the governor system. The ac-

FREQ

TRIM

2.50 [63.5] tuator will energize (within 1.5 VDC of battery voltage) and force the fuel

STARTER

120/

240V AC

BATTERY

ACTUATOR

control to its maximum fuel position until the engine starts. The governor

CRANK

4.00 [101.6]

A B C D E

+

F

_

G H J

system should then control the engine at near rated speed.

ENGINE SPEED CONTROL

PRODUCT PUBLICATION.

CAUTION

SERVICING, REFER TO

WHEN INSTALLING OR

3. If the engine is unstable after starting, turn the GAIN and STABILITY pots

COMPONENT

ø 0.19 [4.8] CCW until the engine speed is stable. Section 5 details the procedure for

stability adjustment.

5 GOVERNOR SPEED SETTING

An overspeed shutdown device, independent of the governor The governed speed set point can be increased by the CW rotation of the

WARNING

system, should be provided to prevent loss of engine control SPEED adjustment. The remote speed adjustment (optional) can be used as

which may cause personal injury or equipment damage. Do not rely exclusively a FREQ TRIM control. The frequency range is 40 - 80 Hz. See diagram in

on the governor system electric actuator to prevent overspeed. A secondary section 3.

shutoff device, such as a fuel solenoid must be used.

ECC328 Speed Control Unit 10.27.15 PIB 1083 E

1 © 2015 Copyright All Rights Reserved

6 ADJUSTING FOR STABILITY INSTABILITY SYMPTOM PROBABLE CAUSE OF

ABNORMAL READING

nce the engine is running at operating speed and at no load, the following

O 1. Increasing the GAIN adjustment should

governor performance adjustment can be made to increase engine stability. reduce the instability but not totally cor-

PARAMETER ADJUSTMENT PROCEDURE rect it.

If this is the case, there is most likely a

1. Rotate the GAIN adjustment CW until instability develops. Erratic Engine problem with the engine itself.

Non-Periodic

Behavior Check for:

2. Then, gradually move the adjustment CCW until stability a. engine mis-firings

returns. b. an erratic fuel system

GAIN c. load changes on the generator set

3. Finally, move the adjustment 1/8 of a turn further CCW voltage regulator.

further to ensure stable performance.

4. If instability persists, adjust the stability parameter. UNSATISFACTORY PERFORMANCE

1. Rotate the GAIN adjustment CW until instability develops. PROBABLE CAUSE OF

SYMPTOM NORMAL READING ABNORMAL READING

2. Then, gradually move the adjustment CCW until stability

STABILITY returns. 1. If actuator goes to full fuel,

then disconnect speed sens-

3. Finally, move the adjustment 1/8 of a turn further CCW Do Not Crank. Apply DC ing wires at Terminals D & E.

further to ensure stable performance. power to the governor If actuator is still at full fuel

1. the speed control

system. Generated

Normally, adjustments made at no load result in satisfactory per- unit is defective.

NOTE residual voltage must 2.

formance across the entire load range. GAIN readjustment might Engine be 10 volts or higher for If the actuator is at minimum

be required after load is applied to the engine, if a non-linearity exists in the fuel Overspeed this test. fuel position and there exists

control. A strip chart recorder or storage oscilloscope with appropriate elec- an erroneous position signal,

tronics can be used to measure generator frequency to further optimize the then check speed sensor

governor’s performance. 1. If the voltage reading is

2.0 to 3.0 VDC:

If instability cannot be corrected, or further performance improvements are re- 1. SPEED adjustment set

quired, refer to the Instability section under SYSTEM TROUBLESHOOTING above desired speed

(Section 7) Manually hold the engine 2. Defective speed control

at the desired running unit

7

speed. Measure the DC

TROUBLESHOOTING 2. voltage between Termi-

2. If voltage reading is > 3.0

nals H(-) & J(+) on the VDC then check for:

speed control unit. 1. Actuator binding

SYSTEM INOPERATIVE 2. Linkage binding

3. If the voltage reading is

If the engine governing system does not function, the fault may be determined

by performing the voltage tests described in Steps 1 through 4. Positive (+) and below 1.0 VDC:

1. Defective speed control

negative (-) refer to meter polarity. Should normal values be indicated during unit

troubleshooting steps, then the fault may be with the actuator or the wiring to

the actuator. Tests are performed with battery power on and the engine off, 1. Try to increase the GAIN

setting CW and also turn

except where noted. See actuator publication for testing procedure on the ac- the STABILITY CW as much

tuator. Overspeed during as possible without causing

1. Low GAIN setting

start up instability.

PROBABLE CAUSE OF 2.

STEP TERM. NORMAL READING Check the actuator for bind-

ABNORMAL READING

ing or friction.

1. DC battery power not

Battery Supply Voltage connected. Check for Measure the DC voltage 1. If the voltage is less than:

1 F(+) & G(-) (8-15 VDC for 12V) 2. blown fuse at the actuator. It should a. 7V for a 12V system, or

or (10-32 VDC for 24V) Low battery voltage be 0.8 to 1.5 VDC less b. 14V for a 24V system,

3. 1.

than the actual battery Then: Check or replace

Wiring error voltage but not less than battery.

Actuator does not 8 VDC.

Battery Voltage 1. Terminal (A) not connected energize fully

2 J(+) & H(-) less than 1.5 volt to starter solenoid properly 1. Actuator or battery wiring

(When cranking) Momentarily connect

terminals J and F. The in error

2.

Voltage present, but actu- 1. Actuator circuit open; mea- actuator should move to 2. Actuator or linkage binding

3 J(+) & H(-)

ator does not move sure actuator resistance the full fuel position. 3. Defective actuator

1. Generator residual voltage 1. If voltage measurement is

Engine stalls after

4 J(+) & H(-) too low or absent, check within 2 VDC of the battery

starting, 0 voltage

wiring to terminals D & E supply voltage level, then

fuel control is restricted from

INSTABILITY Measure the actuator reaching full fuel position,

Engine remains

output, Terminals J (+) possibly due to mechanical

below desired 1.

PROBABLE CAUSE OF & H (-) while running governor, carburetor spring,

INSTABILITY SYMPTOM governed speed

ABNORMAL READING under governor control. or linkage interference.

2.

1. Interference from powerful electri- SPEED adjustment set too

An irregularity of cal signals can be a cause. Turn off

Fast Periodic speed above 3Hz. battery chargers or other electrical low

(Usually a jitter) equipment to see if the symptom 1. Check wiring to Terminal A,

disappears. Turn speed pot CCW to make sure Terminal A is con-

1.

1. Adjustment of GAIN and STABIL- increase speed set point nected to the Terminal of the

Engine does not starter.

ITY usually cures most situations

start or stalls

by matching the speed control unit Measure VAC at 1. Low speed reference set point

dynamics. If instability persists: 2. terminals D and E while below engine idle speed.

An irregularity of 2. cranking.

Slow Periodic speed below 3Hz. Check:

(Sometimes severe) a. The fuel system linkage for bind- If unsuccessful in solving instability, contact GAC for assistance.

ing high friction, or poor linkage. NOTE

GAC@governors-america.com or call: +1 413-233-1888

b. Poor fuel mixture or bad ignition

timing

ECC328 Speed Control Unit 10.27.15 PIB 1083 E

2 © 2015 Copyright All Rights Reserved

You might also like

- TB Woods XFC Series Datasheet1 177469416 PDFDocument36 pagesTB Woods XFC Series Datasheet1 177469416 PDFRamon LilloNo ratings yet

- IEEE Standard Letter Symbols For Quantities Used in Electrical Science and Electrical EngineeringDocument40 pagesIEEE Standard Letter Symbols For Quantities Used in Electrical Science and Electrical Engineeringstanculeanu100% (2)

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- UPS Three Single Phase IST7Document1 pageUPS Three Single Phase IST7Bassem MouelhiNo ratings yet

- Monofasico East TorreDocument2 pagesMonofasico East Torreomar zaquinaulaNo ratings yet

- IP 31 Series Online UPS: Technical SpecificationsDocument1 pageIP 31 Series Online UPS: Technical SpecificationsAbdelwhab Elsafty100% (1)

- Rx5a FumanDocument7 pagesRx5a FumanOrlando CastroNo ratings yet

- Proportional Relief Valve: PRP-10W-X-Y-Z-B1Document1 pageProportional Relief Valve: PRP-10W-X-Y-Z-B1Michał A.No ratings yet

- User'S Manual: 1 - Installation 2 - Technical SpecificationsDocument8 pagesUser'S Manual: 1 - Installation 2 - Technical SpecificationsGopal HegdeNo ratings yet

- G6kva 10kva G4Document1 pageG6kva 10kva G4Adrian DeoancaNo ratings yet

- Tesdq5V0: Small Signal Product Taiwan SemiconductorDocument4 pagesTesdq5V0: Small Signal Product Taiwan Semiconductorn tanevarNo ratings yet

- SR802 Series - I13-523740 PDFDocument5 pagesSR802 Series - I13-523740 PDFJohn PerzyloNo ratings yet

- W 38 × H 42 MM Twin Analog Timers: ATS8W / ATS11W SeriesDocument2 pagesW 38 × H 42 MM Twin Analog Timers: ATS8W / ATS11W SeriesHendra WiratamaNo ratings yet

- Avr Kutay Selecton GenericosDocument1 pageAvr Kutay Selecton GenericosGONZALONo ratings yet

- GM8804C 2Document1 pageGM8804C 2www.surebekeleNo ratings yet

- HDF 2415 DDocument2 pagesHDF 2415 Dศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- Avr Yanan Tc321 (P)Document1 pageAvr Yanan Tc321 (P)lilireneNo ratings yet

- Ower Mplifiers: Rem-S Series-Power AmplifiersDocument4 pagesOwer Mplifiers: Rem-S Series-Power AmplifiersМаксым КовальськыйNo ratings yet

- JAL33 MTEK Series 6-30 kVA PDFDocument1 pageJAL33 MTEK Series 6-30 kVA PDFEdward Alejandro Giraldo GallónNo ratings yet

- Chromium RTSeries BrochureDocument5 pagesChromium RTSeries BrochureZein CassamoNo ratings yet

- Operating Instructions: Digital Clamp Meter Model DSA600TRMSDocument9 pagesOperating Instructions: Digital Clamp Meter Model DSA600TRMSchuks blessingNo ratings yet

- Photomultiplier TubeDocument2 pagesPhotomultiplier TubecuentadosngrokNo ratings yet

- RLD-134A Catalog PageDocument2 pagesRLD-134A Catalog PageGiang TrườngNo ratings yet

- Precision Low Drift 2.048 V/2.5 V/4.096 V/ 5.0 V SOT-23 Reference With ShutdownDocument17 pagesPrecision Low Drift 2.048 V/2.5 V/4.096 V/ 5.0 V SOT-23 Reference With ShutdownbezasamiNo ratings yet

- Avr Yanan Tc341 (P)Document1 pageAvr Yanan Tc341 (P)lilireneNo ratings yet

- SR502 Thru SR520: Creat by ArtDocument4 pagesSR502 Thru SR520: Creat by ArtbekowiczNo ratings yet

- Sa15b45 EpacDocument1 pageSa15b45 EpacBINOY DASNo ratings yet

- Sa15b63 EpacDocument1 pageSa15b63 EpacBINOY DASNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)Document9 pagesObsolete Product(s) - Obsolete Product(s) Obsolete Product(s) - Obsolete Product(s)GermánNo ratings yet

- IRF530stmicroelectronics cd00000699-1204277 PDFDocument9 pagesIRF530stmicroelectronics cd00000699-1204277 PDFGermánNo ratings yet

- CATALOGO UPS COMPUTER POWER Modelo VRN 1.5, 3 KVA (RACKMOUNT)Document4 pagesCATALOGO UPS COMPUTER POWER Modelo VRN 1.5, 3 KVA (RACKMOUNT)RJ Jonathan RizzoNo ratings yet

- Tps 54160Document50 pagesTps 54160csclzNo ratings yet

- Marine: On-Board With ConfidenceDocument4 pagesMarine: On-Board With Confidenceabduallah muhammadNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Manual EA20S CaterpillarDocument3 pagesManual EA20S CaterpillarHernán Peñafiel ReaNo ratings yet

- Automotive Power Relay: Technical Data For Contact SideDocument3 pagesAutomotive Power Relay: Technical Data For Contact SideStuxnetNo ratings yet

- Dse704 4120 Data Sheet Us PDFDocument2 pagesDse704 4120 Data Sheet Us PDFzakki ahmadNo ratings yet

- Knight Series: 1KVA-10KVADocument3 pagesKnight Series: 1KVA-10KVAAntónio BarrosNo ratings yet

- Hybrid InverterDocument1 pageHybrid InverterDiego EspinosaNo ratings yet

- FG1000BV 90daDocument4 pagesFG1000BV 90dapietisc pietiscNo ratings yet

- Circuito en Fuente TV LCD Mustek N3856VGDocument13 pagesCircuito en Fuente TV LCD Mustek N3856VGAntonio ChavezNo ratings yet

- GTA202AS36 R1.pdf ALTERNADOR DE FINNINGDocument1 pageGTA202AS36 R1.pdf ALTERNADOR DE FINNINGDANIEL CUELLARNo ratings yet

- Emo 85 MDocument1 pageEmo 85 MGustavo AghinoniNo ratings yet

- EA08A ManualDocument6 pagesEA08A ManualDavid MoyaNo ratings yet

- TRI002U321TLN0Document5 pagesTRI002U321TLN0iker.sanchez.aNo ratings yet

- WT Micro Temperature Controller CatalogueDocument7 pagesWT Micro Temperature Controller CataloguepngchanhNo ratings yet

- Tps 54240Document48 pagesTps 54240Maria KhanNo ratings yet

- GTP-Series 10-40KVA CatalogueDocument2 pagesGTP-Series 10-40KVA CatalogueAgung PermanaNo ratings yet

- SPC1 Series: FeaturesDocument6 pagesSPC1 Series: FeaturesMin ZayarNo ratings yet

- T-49C-CA MOD2 Operational ManualDocument52 pagesT-49C-CA MOD2 Operational ManualVolodymyr PotapovNo ratings yet

- SM Tachometer & Line Speed Meter: DIN 24x48 / 72x72 / 96x48Document4 pagesSM Tachometer & Line Speed Meter: DIN 24x48 / 72x72 / 96x48nehalNo ratings yet

- Patanjali Solar Corporate ProfileDocument29 pagesPatanjali Solar Corporate ProfileDigitalsolar NoidaNo ratings yet

- Ups Lyonn Ult KVTDocument2 pagesUps Lyonn Ult KVTDivision EnergiaNo ratings yet

- Tap Position Indicator Tc-02: FeaturesDocument1 pageTap Position Indicator Tc-02: Featuresss subramanyamNo ratings yet

- Eg3002 Comparison Table enDocument1 pageEg3002 Comparison Table enاحمد الشمريNo ratings yet

- mt4w DV 40 - ImDocument1 pagemt4w DV 40 - ImJavier VillelaNo ratings yet

- xc6420 SeriesDocument27 pagesxc6420 SeriesFarid MubarokNo ratings yet

- Features Descriptio: Lt1213/Lt1214 28Mhz, 12V/ S, Single Supply Dual and Quad Precision Op AmpsDocument20 pagesFeatures Descriptio: Lt1213/Lt1214 28Mhz, 12V/ S, Single Supply Dual and Quad Precision Op AmpshamedNo ratings yet

- Ultra: Starting With QualityDocument2 pagesUltra: Starting With Qualityabduallah muhammadNo ratings yet

- V585me42 LFDocument2 pagesV585me42 LFashfaqNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- CT410-CT450S (50 HZ)Document3 pagesCT410-CT450S (50 HZ)M. ShaatNo ratings yet

- CT575 CT635S (KTA19 60Hz)Document3 pagesCT575 CT635S (KTA19 60Hz)M. ShaatNo ratings yet

- CT425 CT460S (QSG12 60Hz)Document3 pagesCT425 CT460S (QSG12 60Hz)M. ShaatNo ratings yet

- 1500 Series Turbo Exhaust Elbow and Oil Supply ChangeDocument2 pages1500 Series Turbo Exhaust Elbow and Oil Supply ChangeM. ShaatNo ratings yet

- New DP200 and DP210 Fuel Injection Pump Spring Gen202E1Document1 pageNew DP200 and DP210 Fuel Injection Pump Spring Gen202E1M. ShaatNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Data SheetDocument2 pagesData SheetM. ShaatNo ratings yet

- 1006DTAG2 Launch BulletinDocument4 pages1006DTAG2 Launch BulletinM. ShaatNo ratings yet

- Fault Code SpreadsheetBTPDocument2 pagesFault Code SpreadsheetBTPM. Shaat100% (1)

- J1939 Engine Monitoring and Control PortDocument3 pagesJ1939 Engine Monitoring and Control PortM. ShaatNo ratings yet

- Studer Innotec SADocument56 pagesStuder Innotec SAM. ShaatNo ratings yet

- Nsets H25-33VDocument1 pageNsets H25-33VM. ShaatNo ratings yet

- ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning YstemDocument2 pagesECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning YstemM. ShaatNo ratings yet

- DSTATCOM ControlDocument5 pagesDSTATCOM ControlabsalnabiNo ratings yet

- Electric PotentialDocument24 pagesElectric PotentialRalph Francis AguilarNo ratings yet

- PhotoVoltaic General CatalogDocument20 pagesPhotoVoltaic General CatalogBernardo Andrés GilardoniNo ratings yet

- Nema MG 1-2011Document643 pagesNema MG 1-2011Nelson Escalona RNo ratings yet

- Leak RCPAU Preamp Rev 1Document5 pagesLeak RCPAU Preamp Rev 1elveramNo ratings yet

- Nine-Phase Armature Windings Design, Test and Harmonic AnalysisDocument5 pagesNine-Phase Armature Windings Design, Test and Harmonic Analysiszuriman anthonyNo ratings yet

- Imaging Science Laboratory Manual 2021: NameDocument30 pagesImaging Science Laboratory Manual 2021: NameRabab ZaidiNo ratings yet

- Circuits & Layout: N. Weste D. HarrisDocument50 pagesCircuits & Layout: N. Weste D. HarrisSiam HasanNo ratings yet

- 4c X 10 Technical Data SheetDocument2 pages4c X 10 Technical Data SheetPrabhakaran ChandrasekaranNo ratings yet

- Electrical Machines - I: Electric Circuit TheoryDocument22 pagesElectrical Machines - I: Electric Circuit TheoryPradeep SinglaNo ratings yet

- PN JunctionDocument7 pagesPN JunctionChannabasavagouda BNo ratings yet

- Co Project: Edge Avoiding Robot USING 8051 MicrocontrollerDocument14 pagesCo Project: Edge Avoiding Robot USING 8051 MicrocontrollerJuthik BVNo ratings yet

- Aim: - To Study No Load and Blocked Rotor Test of Three Phase ImDocument5 pagesAim: - To Study No Load and Blocked Rotor Test of Three Phase ImSubhash KumarNo ratings yet

- How Do You Set System Gain Structure?: by Chuck McgregorDocument13 pagesHow Do You Set System Gain Structure?: by Chuck McgregorklepkojNo ratings yet

- Válvula Proporcional KTG4V3Document33 pagesVálvula Proporcional KTG4V3Nkma BorgesNo ratings yet

- 12 20 (24) KV HXLP DSTA - Pdic01114Document2 pages12 20 (24) KV HXLP DSTA - Pdic01114Luis MurilloNo ratings yet

- Available Relay ModelsDocument25 pagesAvailable Relay ModelsashokdixitNo ratings yet

- E474007 PDFDocument6 pagesE474007 PDFany tasnimNo ratings yet

- Implementation of Security Door Lock System For Shopping MallDocument17 pagesImplementation of Security Door Lock System For Shopping MallNyi Lin NyoNo ratings yet

- DTnotiDocument49 pagesDTnotiokman17No ratings yet

- mc9 BrochureDocument8 pagesmc9 BrochureturricanNo ratings yet

- Especificaciones Condensadoras - Rxyq5-54pay1, Payl, Ptl-DaikinDocument458 pagesEspecificaciones Condensadoras - Rxyq5-54pay1, Payl, Ptl-DaikinJorge L Ramirez100% (1)

- Cables For EE342 CourseDocument7 pagesCables For EE342 Coursemahmab70No ratings yet

- JA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelDocument2 pagesJA Solar JAM5 (L) - 72-200 - SI (200W) Solar PanelVictor OliveiraNo ratings yet

- Electrochemistry: Brady and Senese 5th EditionDocument50 pagesElectrochemistry: Brady and Senese 5th Editionatiqa rumaisya100% (1)

- World-Class Synchronous Alternators: Totally Focused OnDocument13 pagesWorld-Class Synchronous Alternators: Totally Focused OnCris_eu09100% (1)

- Test-1: Self-Induction and R-L-circuit Multi Choice Single Correct (+3,-1)Document9 pagesTest-1: Self-Induction and R-L-circuit Multi Choice Single Correct (+3,-1)Nil KamalNo ratings yet

- 53Document5 pages53djahid abdullohNo ratings yet

- Hrrs 5Kv and 10Kv Series High Resistance, 5kV and 10kV Decade Substituter User and Service ManualDocument18 pagesHrrs 5Kv and 10Kv Series High Resistance, 5kV and 10kV Decade Substituter User and Service Manualb4tipibeNo ratings yet