Professional Documents

Culture Documents

ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning Ystem

ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning Ystem

Uploaded by

M. ShaatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning Ystem

ECC328 Generator Frequency Sensing Speed Control Unit: Ngine Overning Ystem

Uploaded by

M. ShaatCopyright:

Available Formats

ENGINE ECC328

G OVERNORS

GOVERNING Generator Frequency Sensing

A MERICA

SYSTEM Speed Control Unit

C ORP. ®

• Isochronous Operation • Rugged Hard Potted Design

• No Magnetic Speed Pick-Up Required • Gain And Stability Adjustments

• For Genset Only/Max 260 VAC • Lower System Cost

INTRODUCTION

The ECC328 speed control unit is an electronic device de-

signed to control engine speed with precise response to tran-

sient engine loads changes. The closed loop speed control,

when connected to a proportional actuator and supplied with

a speed signal/ frequency from the main AC generator, will

control a wide variety of engines in an isochronous mode.

The speed signal input must be in the frequency range of

40 to 80 Hz.

The ECC328 is a hard potted module designed to operate

with high reliability in harsh environments. The adjustment

procedure is simple and easy.

Standard features include: protection against reversal of the

battery supply, accidental shorts in the actuator wiring, high

voltage transient on the DC and AC lines, and the loss of the

speed signal or battery supply.

The ECC328 is designed to be used for actuators with less

then 4.5 AMP’s Max current.

DESCRIPTION During engine cranking, the actuator should be fully ener-

gized and should move to the maximum fuel position. The

The generator’s frequency, when used as an engine speed actuator will remain in that state during engine cranking and

signal, can be either 50 or 60 Hz nominally. The minimum acceleration up to the operating speed. With the engine at

and maximum amplitude levels required to operate the a steady load, the actuator will be energized with sufficient

ECC328 are 1V AC to 260V AC. The generator’s residual current to maintain the governed speed set point.

voltage must reach 1V AC, so the loss of speed signal will

be defeated and allow the actuator to open the fuel valve The output circuit to the actuator provides a controlled switch-

to start the engine. Other than the Min and Max AC input ing current loop to the proportional actuator at a frequency

values, the control is insensitive to sine wave shape or the of about 200 Hz. This switching frequency is well beyond the

voltage levels from the generator. natural frequency response of the actuator, thus there is no

visible motion of the actuator due to this switching circuit.

When the speed signal is received by the controller, the Switching of the output transistor reduces internal power

signal is conditioned to operate the GAC proprietary speed dissipation and provides for efficient power control up to 5

sensor circuit. If the speed signal disappears for longer than Amps of continuous current at 25°C. A proportional actuator

approximately 0.2 seconds, the actuator output will be shut will respond to the average current to position the engine

off (loss of speed signal protection). When cranking the en- fuel control lever.

gine, the control unit will sense a very low frequency and

operate the actuator to start the engine. The ECC328 is compatible with ALN, ALR, 100, 103 GAC

actuators.

The internal summing circuit receives the speed signal and

combines it with the speed setting reference adjustment

along with the remote speed trim setting. The output of the

summing circuit is the input to the dynamics control circuits

of which the gain and stability adjustments are apart. These

control functions provide isochronous and stable perfor-

mance.

Governors America Corp., 720 Silver Street Agawam, MA 01001

phone: 413.786.5600 fax: 413.789.7736

www.governors-america.com

info@governors-america.com

1

DIAGRAM 1 SYSTEM WIRING/OUTLINE

4.67 [118.6]

3.95 [100.2]

AGAWAM, MA U.S.A.

SPEED GAIN

MADE IN

STABILITY

FREQ

2.50 [63.5]

TRIM

120/ BATTERY

STARTER 240V AC ACTUATOR

CRANK

+ _ 4.00 [101.6]

A B C D E F G H J

ENGINE SPEED CONTROL

PRODUCT PUBLICATION.

CAUTION

SERVICING, REFER TO

WHEN INSTALLING OR

COMPONENT

0.19 [ 4.8]

FREQ

TRIM

STARTER FUSE

15A

Starter Solenoid

Crank Post

(Small Post)

ACTUATOR

+

L-L

GENERATOR OR 12V

L-N BATTERY

-

L-L

OR

L-N

SPECIFICATIONS

PERFORMANCE RELIABILITY

Isochronous Operation…........................................................…… ±0.250% Vibration…………….............................................................5G, 20-500 Hz

Speed Range (unless stated in units specifications)………...……40 - 80 HZ Shock…...........................................................................…20G’s

Speed Drift with Temperature……....……………………………….....… ±1% Testing...........................100% Functional Testing before and after potting

Speed Trim (see units specifications)…...……………………….....… +/- 2 Hz

PHYSICAL

ENVIRONMENTAL Dimensions……………………………………… See Wiring Diagram (Fig. 1)

Ambient Temperature...................................... -40° to 185°F (-40 to +85C) Weight…………………………………………………........…0.75 lb (0.34 kg)

Relative Humidity……………………………………........…………up to 100% Mounting................................……………………………………Any Position

INPUT POWER

DC Supply…..................................................12V DC (8 - 15 VDC) Nominal

............................................................(24 VDC available as special order)

Polarity........................................................Negative Ground (case isolated)

Power Consumption.........................................<50 mA + Actuator Current

Maximum Actuator Current..............................................................5 Amps

Generator Frequency Sensing........................Load on generator, 40K OHMS

...................................................................Minimum sensing 1 VAC RMS

...........................................................................Maximum voltage 260 VAC

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

2 PTI1083 B

You might also like

- CW673CDocument10 pagesCW673CDiego Idrovo Villavicencio100% (1)

- 454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesDocument12 pages454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesVicente Orbegoso RodriguezNo ratings yet

- Ec5000 6-09 PDFDocument5 pagesEc5000 6-09 PDFAnonymous M0OEZEKoGiNo ratings yet

- Manual Regulador de Velocidade Gac Esd 5111Document2 pagesManual Regulador de Velocidade Gac Esd 5111Paulo Alves100% (2)

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- 1006-6TA Spec SheetDocument2 pages1006-6TA Spec SheetM. ShaatNo ratings yet

- Speed Control GAC ESD5500Document8 pagesSpeed Control GAC ESD5500Manuel Otero80% (5)

- Ngine Overning Ystems: Generator Frequency Sensing Speed Control UnitDocument6 pagesNgine Overning Ystems: Generator Frequency Sensing Speed Control Unitjuan narvaezNo ratings yet

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDocument7 pagesEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNo ratings yet

- Warning: ESD5100 Series Speed Control UnitDocument6 pagesWarning: ESD5100 Series Speed Control Unitinstrumentacion.hsrNo ratings yet

- Ambac Ec 5010 ManualDocument2 pagesAmbac Ec 5010 ManualGonzalo DominguezNo ratings yet

- I Pues D 1000 Series Data SheetDocument3 pagesI Pues D 1000 Series Data Sheetkhaled kamelNo ratings yet

- 0181830sby (1) Gereac GasolinaDocument4 pages0181830sby (1) Gereac GasolinaRobertoHerediaJacoboNo ratings yet

- Energy SavingDocument50 pagesEnergy SavingKuna MarndiNo ratings yet

- ESD-5550/5570 Series - Speed Control Unit: Technical InformationDocument12 pagesESD-5550/5570 Series - Speed Control Unit: Technical InformationCarlos Molina100% (1)

- ESG2002 Controller PDFDocument15 pagesESG2002 Controller PDFAung Mh100% (1)

- WWW - Servorepair.ca: Scroll Down To View Your Document!Document62 pagesWWW - Servorepair.ca: Scroll Down To View Your Document!TranNo ratings yet

- Ec5000 1Document2 pagesEc5000 1Bruno MarianoNo ratings yet

- Warning: ESD5200 Series Speed Control UnitDocument6 pagesWarning: ESD5200 Series Speed Control UnitAnas BasarahNo ratings yet

- Manual Regulador de Velocidade Gac Esd 5111 PDFDocument2 pagesManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- Electronic Governor CatalogDocument26 pagesElectronic Governor CatalogAung Mh100% (1)

- .Qpmvnpank": - ,,JL - I Ivv/I IviDocument61 pages.Qpmvnpank": - ,,JL - I Ivv/I IviHoangvinh DuongNo ratings yet

- Pti1000 Esd5100 SeriesDocument2 pagesPti1000 Esd5100 SeriesRamon Thales DomeniconiNo ratings yet

- ESD-5500E Series: Analogue Speed GovernorsDocument4 pagesESD-5500E Series: Analogue Speed GovernorsVasil Stoianov100% (1)

- Esd-5200 DS en 03.2011 V1.0Document4 pagesEsd-5200 DS en 03.2011 V1.0BryanLeonardoOspinoReinaNo ratings yet

- 3 PHASE/1500RPM: Image For Illustrative Purposes Only.Document2 pages3 PHASE/1500RPM: Image For Illustrative Purposes Only.Anamta KhanNo ratings yet

- ts300 Mosa PDFDocument50 pagests300 Mosa PDFzanioNo ratings yet

- Esd5500E Series Speed Control Tlnit: WarningDocument5 pagesEsd5500E Series Speed Control Tlnit: WarningKarla HolandaNo ratings yet

- Carrier Technical SpecificationDocument2 pagesCarrier Technical Specificationkatrina.chongNo ratings yet

- Reg. Velocidade GAC ESD 5550 5570Document8 pagesReg. Velocidade GAC ESD 5550 5570thyagoenerg100% (1)

- Generac Stand ByeDocument5 pagesGenerac Stand ByeMiguel Angel Pavon CarbonellNo ratings yet

- ADD 103 Series PTI2045ADocument4 pagesADD 103 Series PTI2045ALeonardo LimbergerNo ratings yet

- What Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputDocument5 pagesWhat Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputpostNo ratings yet

- 9000 Series and Cruisecommand Product Brochure: Marine Propulsion SystemsDocument6 pages9000 Series and Cruisecommand Product Brochure: Marine Propulsion SystemsBoris ZhilkinNo ratings yet

- actiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingDocument9 pagesactiVAR - Performance in Mitigating Voltage Sags Associated With Motor StartingbansalrNo ratings yet

- FX1000 enDocument2 pagesFX1000 endao trong nghiaNo ratings yet

- GOB EG1065x Manual en PDFDocument8 pagesGOB EG1065x Manual en PDFRonaldCarrasquelNo ratings yet

- Pib1010 Esc63c SeriesDocument4 pagesPib1010 Esc63c Serieszakie8008No ratings yet

- ENGINE DATA SHEET 275 KW 6R1600G70SDocument4 pagesENGINE DATA SHEET 275 KW 6R1600G70SAngel RiosNo ratings yet

- Problems Often Occur Because of The Words We Use To Describe A ProjectDocument83 pagesProblems Often Occur Because of The Words We Use To Describe A ProjectThanigaivelu SubrmanianNo ratings yet

- 41 2os01Document8 pages41 2os01Miguel Angel RodriguezNo ratings yet

- Sigma-SD Spindle 002Document8 pagesSigma-SD Spindle 002Edimilson RodriguesNo ratings yet

- 2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFDocument13 pages2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFSamir KhanNo ratings yet

- Speed Control MotorDocument32 pagesSpeed Control MotorMASOUD0% (1)

- Series: Compact Vector Control AC Variable Frequency DrivesDocument24 pagesSeries: Compact Vector Control AC Variable Frequency DrivesTahir HusainNo ratings yet

- Flyer L1000E PDFDocument2 pagesFlyer L1000E PDFOliver07 ValenzuelaNo ratings yet

- 4500e DC Motor Controller InstructionsDocument1 page4500e DC Motor Controller InstructionsKalyani GangulianNo ratings yet

- Esd2400 Series: Ngine Overning YstemsDocument6 pagesEsd2400 Series: Ngine Overning YstemsAnas BasarahNo ratings yet

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Document2 pagesPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNo ratings yet

- Air Charge-Air Cooling: Diesel Engine-Generator SetDocument4 pagesAir Charge-Air Cooling: Diesel Engine-Generator SetredaNo ratings yet

- 701a DSCDocument4 pages701a DSCLiv SeguraNo ratings yet

- Sx460 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsDocument4 pagesSx460 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsJose PirulliNo ratings yet

- Pti2080a, AtbDocument4 pagesPti2080a, AtbrepelindNo ratings yet

- Apecs 70-101 11/13/03 11:10 AM Page 76Document2 pagesApecs 70-101 11/13/03 11:10 AM Page 76gregorioNo ratings yet

- 0186720SBY-B Core Power HSB Model 005837-0Document4 pages0186720SBY-B Core Power HSB Model 005837-0apelectricNo ratings yet

- What Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputDocument5 pagesWhat Is A Servo Stabilizer?: Single Phase Input & Single Phase OutputHerman SalimNo ratings yet

- Kirloskar: Diesel Generating SetsDocument4 pagesKirloskar: Diesel Generating Setsnam phạmNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- CT410-CT450S (50 HZ)Document3 pagesCT410-CT450S (50 HZ)M. ShaatNo ratings yet

- CT575 CT635S (KTA19 60Hz)Document3 pagesCT575 CT635S (KTA19 60Hz)M. ShaatNo ratings yet

- CT425 CT460S (QSG12 60Hz)Document3 pagesCT425 CT460S (QSG12 60Hz)M. ShaatNo ratings yet

- 1500 Series Turbo Exhaust Elbow and Oil Supply ChangeDocument2 pages1500 Series Turbo Exhaust Elbow and Oil Supply ChangeM. ShaatNo ratings yet

- New DP200 and DP210 Fuel Injection Pump Spring Gen202E1Document1 pageNew DP200 and DP210 Fuel Injection Pump Spring Gen202E1M. ShaatNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Data SheetDocument2 pagesData SheetM. ShaatNo ratings yet

- 1006DTAG2 Launch BulletinDocument4 pages1006DTAG2 Launch BulletinM. ShaatNo ratings yet

- Fault Code SpreadsheetBTPDocument2 pagesFault Code SpreadsheetBTPM. Shaat100% (1)

- J1939 Engine Monitoring and Control PortDocument3 pagesJ1939 Engine Monitoring and Control PortM. ShaatNo ratings yet

- Studer Innotec SADocument56 pagesStuder Innotec SAM. ShaatNo ratings yet

- Nsets H25-33VDocument1 pageNsets H25-33VM. ShaatNo ratings yet

- Generator Frequency Sensing Speed Control Unit: Specifications WiringDocument2 pagesGenerator Frequency Sensing Speed Control Unit: Specifications WiringM. ShaatNo ratings yet

- Chapter 2 - Noise in Communication SystemDocument31 pagesChapter 2 - Noise in Communication SystemDavidNo ratings yet

- Radio TechnologyDocument70 pagesRadio TechnologyNikhitaWadhwaNo ratings yet

- Lab7 - Behavioral Modeling and Timing ConstraintsDocument6 pagesLab7 - Behavioral Modeling and Timing Constraintswert1a2No ratings yet

- ACM - Ds Standard Field Machine v2.0.4Document4 pagesACM - Ds Standard Field Machine v2.0.4s pradhanNo ratings yet

- PLC & SCADA Training ReportDocument44 pagesPLC & SCADA Training Reportneeraj meena100% (2)

- Ips 7.0" Hdmi LCD TFT Datasheet: RVT70HSHNWC00-BDocument17 pagesIps 7.0" Hdmi LCD TFT Datasheet: RVT70HSHNWC00-BC ONo ratings yet

- Guided Transmission MediaDocument23 pagesGuided Transmission MediaJoy PalNo ratings yet

- Case 1Document3 pagesCase 1ianiroy13No ratings yet

- FAS - Amps Models Gallery Qu 1.03Document21 pagesFAS - Amps Models Gallery Qu 1.03Michael IsbachNo ratings yet

- Custom Power DevicesDocument16 pagesCustom Power Devicessubhadip sadhukhanNo ratings yet

- 8086 Memory OrganizationDocument6 pages8086 Memory OrganizationManohar_3020No ratings yet

- Acs355 Manual Part 1 10 12 12 2244Document90 pagesAcs355 Manual Part 1 10 12 12 2244Nguyễn ĐứcNo ratings yet

- Cadence TutorialsDocument37 pagesCadence Tutorialsjohnisrael65No ratings yet

- Resolver Functional PrincipleDocument8 pagesResolver Functional PrincipleNick RivieraNo ratings yet

- MCQ On AnalogDocument10 pagesMCQ On AnalogJatin YadavNo ratings yet

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDocument2 pagesFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezNo ratings yet

- Disassembling A Computer's System UnitDocument3 pagesDisassembling A Computer's System UnitOrlando Ginson OcampoNo ratings yet

- 1MRK511149-UEN - TRM REC670 IEC 1pBDocument666 pages1MRK511149-UEN - TRM REC670 IEC 1pBJOSENo ratings yet

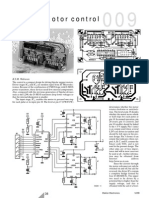

- Driver L297 + L6203Document2 pagesDriver L297 + L6203TatiiieleeeNo ratings yet

- Presentation ExtremeEXOSDocument31 pagesPresentation ExtremeEXOSPhan Trọng ĐứcNo ratings yet

- T1635h-6i, T1635H-6T, T1635H-6G T1650h-6i, T1650H-6T, T1650H-6GDocument13 pagesT1635h-6i, T1635H-6T, T1635H-6G T1650h-6i, T1650H-6T, T1650H-6Gemanuel viniciusNo ratings yet

- Test Report For Circuit Breaker: CustomerDocument6 pagesTest Report For Circuit Breaker: CustomerSubramaniam NPNo ratings yet

- Mobile Phone CloningDocument16 pagesMobile Phone CloningGloria HendersonNo ratings yet

- Electronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloDocument12 pagesElectronic Components, Packaging and Production: Leif Halbo and Per Ohlckers University of OsloengshimaaNo ratings yet

- Tutorial-3 AnsDocument6 pagesTutorial-3 AnsKawan LamaNo ratings yet

- 2.1 LedDocument5 pages2.1 LedFernando Reza CamposNo ratings yet

- AT89S52Document9 pagesAT89S52Aarthi GurunathanNo ratings yet

- 8-1017876 Tyco Informacion General Pedestal FTTXDocument4 pages8-1017876 Tyco Informacion General Pedestal FTTXRony ArguetaNo ratings yet

- Create New Project CodeVision AVR (Buzzer)Document6 pagesCreate New Project CodeVision AVR (Buzzer)calvinNo ratings yet

- Lutron TM-9017SD Data Sheet - 0Document2 pagesLutron TM-9017SD Data Sheet - 0Norberto Alonso Paez GuarnizoNo ratings yet