Professional Documents

Culture Documents

External Chamber For Level Measurement With Inserted Sensors Model BZG

External Chamber For Level Measurement With Inserted Sensors Model BZG

Uploaded by

Zenon KociubaCopyright:

Available Formats

You might also like

- Subsection BDocument251 pagesSubsection Bsafeer ahmad100% (1)

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- Cyanide and Ricin Homemade PDFDocument7 pagesCyanide and Ricin Homemade PDFСергей ЯрмолаNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- Bypass Level Indicator With Magnetic Display Model BNA: ApplicationsDocument19 pagesBypass Level Indicator With Magnetic Display Model BNA: ApplicationsEyuNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- Familyoverview LBR-SicWave g505156 enDocument4 pagesFamilyoverview LBR-SicWave g505156 enTien LoiNo ratings yet

- Technical DrawingDocument6 pagesTechnical DrawingRosyad AminNo ratings yet

- BombasDocument8 pagesBombasDiego Fernando GaviriaNo ratings yet

- PS01Document11 pagesPS01Sherry HenryNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- Explosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetDocument4 pagesExplosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetachmadinNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Extended Diaphragm SealDocument2 pagesExtended Diaphragm SealShankar PediredlaNo ratings yet

- Bav04 eDocument2 pagesBav04 eYipeng Lex ChuNo ratings yet

- Level Switch NS 64/NS 100 ..-AM: FluidcontrolDocument4 pagesLevel Switch NS 64/NS 100 ..-AM: FluidcontrolAmar KevricNo ratings yet

- Technical Data Sheet Ecotrol Control Valve TD - 6HDocument6 pagesTechnical Data Sheet Ecotrol Control Valve TD - 6HFrancisco SanchezNo ratings yet

- ICO4SDocument12 pagesICO4SGopinath SekarNo ratings yet

- Technical Bulletin: ArgusDocument11 pagesTechnical Bulletin: ArgusTerry wei shengNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- Type Zlic Brand SihiDocument8 pagesType Zlic Brand SihiArdi 4791No ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- Alfa Laval Alfacond 400 - enDocument2 pagesAlfa Laval Alfacond 400 - enAjayNo ratings yet

- Walvoil Comando SD6DLS7 2019Document101 pagesWalvoil Comando SD6DLS7 2019Istenio Cassiano NetoNo ratings yet

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerNo ratings yet

- Volute Casing Pumps: SupernovaDocument9 pagesVolute Casing Pumps: SupernovaP. Ernesto C. GutierrezNo ratings yet

- Alfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332Document3 pagesAlfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332apri andi setyawanNo ratings yet

- General Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42Document4 pagesGeneral Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42HolicsNo ratings yet

- 2p - en - Bfs 20 o Bfs 20 OlDocument2 pages2p - en - Bfs 20 o Bfs 20 OlMukesh Kumar JhaNo ratings yet

- Sanimagnum Rotary SprayDocument3 pagesSanimagnum Rotary Sprayeder.flavioparraNo ratings yet

- CPE-CENTER-LINE-RS-TD-EN-A4-2021_03_01-webDocument48 pagesCPE-CENTER-LINE-RS-TD-EN-A4-2021_03_01-webluan_apereiraNo ratings yet

- LPG - Pump CatalogueDocument19 pagesLPG - Pump CataloguepomaukNo ratings yet

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Document4 pages2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanNo ratings yet

- Model 3201 Liquid Level Controller: FeaturesDocument8 pagesModel 3201 Liquid Level Controller: Featuresio1_roNo ratings yet

- Metalwork 02a 32 125mmboreDocument20 pagesMetalwork 02a 32 125mmboreTeguh Ariefia GunawanNo ratings yet

- Pan Cake Diaphragm Seal 1Document2 pagesPan Cake Diaphragm Seal 1Shankar PediredlaNo ratings yet

- General Specifications: Y/17B6 Pneumatic Buoyancy TransmitterDocument3 pagesGeneral Specifications: Y/17B6 Pneumatic Buoyancy Transmitterمحمد امين التشغيل الآليNo ratings yet

- Sterling PumpeDocument20 pagesSterling PumpesrdzaNo ratings yet

- ICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDocument12 pagesICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDur MuhammadNo ratings yet

- Datasheet NovarotorDocument3 pagesDatasheet NovarotorSalimNo ratings yet

- Astm A106Document5 pagesAstm A106Andy SetyawanNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- PSV 6r8 Api - 526lDocument1 pagePSV 6r8 Api - 526lIoana PopescuNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloNo ratings yet

- 330 00 GB 1102Document12 pages330 00 GB 1102Sergio Gaete CovarrubiasNo ratings yet

- Boa-S PN6 DN40Document14 pagesBoa-S PN6 DN40melaNo ratings yet

- ZLKDocument10 pagesZLKHunter NoVaNo ratings yet

- Applications: Pressure Transmitter For Applications in Hazardous Areas 08/2015Document2 pagesApplications: Pressure Transmitter For Applications in Hazardous Areas 08/2015Pablo QuirogaNo ratings yet

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 pagesPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaNo ratings yet

- NH DIN Dual Indication Fuse Links: Class GG/GL, 690vac, 2 To 800 Amps, Sizes 000 To 4 NH SeriesDocument9 pagesNH DIN Dual Indication Fuse Links: Class GG/GL, 690vac, 2 To 800 Amps, Sizes 000 To 4 NH SeriesSantiago BoloquiNo ratings yet

- RAGL - GS - GS 01R01B08-00E-E - Ed14 - Pub01042020Document10 pagesRAGL - GS - GS 01R01B08-00E-E - Ed14 - Pub01042020calibracionNo ratings yet

- ICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledDocument3 pagesICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledUntoro Adi NugrohoNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 pagesProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiNo ratings yet

- BB4-Catalogue 2015Document11 pagesBB4-Catalogue 2015nima hasanzadehNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- Tank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Document8 pagesTank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Mauricio Ariel H. OrellanaNo ratings yet

- Especificaciones MesskoDocument8 pagesEspecificaciones MesskoviejoluisNo ratings yet

- Arhead Manual (English)Document15 pagesArhead Manual (English)DeMen NguyenNo ratings yet

- HP Dreamcolor Z27X Display: User GuideDocument80 pagesHP Dreamcolor Z27X Display: User GuideZenon KociubaNo ratings yet

- GU Catalogue FoldSlide For PVC and Timber WP00073 01 18 enDocument148 pagesGU Catalogue FoldSlide For PVC and Timber WP00073 01 18 enZenon KociubaNo ratings yet

- Risk-Based Inspection Study and Its Contribution To Optimize T&I Expenditure at JNGLF PlantDocument11 pagesRisk-Based Inspection Study and Its Contribution To Optimize T&I Expenditure at JNGLF PlantZenon KociubaNo ratings yet

- UOP R-334 CCR Platforming CatalystDocument1 pageUOP R-334 CCR Platforming CatalystZenon KociubaNo ratings yet

- Erosion Corrosion of Parallel Feed Water Discharge Lines at The Loviisa Vver 440Document11 pagesErosion Corrosion of Parallel Feed Water Discharge Lines at The Loviisa Vver 440Zenon KociubaNo ratings yet

- Integrity Operating Windows ShellDocument28 pagesIntegrity Operating Windows ShellZenon KociubaNo ratings yet

- Development of A Material Databook For Api STD 530Document10 pagesDevelopment of A Material Databook For Api STD 530Zenon Kociuba100% (1)

- Appendix 1 List of Participants: Minutes of EFC WP15 Corrosion in The Refinery Industry 8 April 2014Document92 pagesAppendix 1 List of Participants: Minutes of EFC WP15 Corrosion in The Refinery Industry 8 April 2014Zenon KociubaNo ratings yet

- A New Model For Reliability Centered Mai PDFDocument9 pagesA New Model For Reliability Centered Mai PDFZenon KociubaNo ratings yet

- Objectives: Khalid Humaid Al-HasaniDocument13 pagesObjectives: Khalid Humaid Al-HasaniZenon KociubaNo ratings yet

- Vulnerable To Brittle FractureDocument7 pagesVulnerable To Brittle FractureZenon KociubaNo ratings yet

- SCI Current Document Status - Fall 2014 FinalDocument5 pagesSCI Current Document Status - Fall 2014 FinalZenon KociubaNo ratings yet

- API TR 971 Injection Point Outline2Document7 pagesAPI TR 971 Injection Point Outline2Zenon KociubaNo ratings yet

- Us 20100036866Document22 pagesUs 20100036866Zenon KociubaNo ratings yet

- Del 67Document2 pagesDel 67Zenon KociubaNo ratings yet

- XIV Paper 38Document11 pagesXIV Paper 38Zenon KociubaNo ratings yet

- Coin-Cell Battery: Back To Contents PageDocument2 pagesCoin-Cell Battery: Back To Contents PageZenon KociubaNo ratings yet

- Notice:: in The Microsoft in The Microsoft Windows XP Operating System, Click StartDocument3 pagesNotice:: in The Microsoft in The Microsoft Windows XP Operating System, Click StartZenon KociubaNo ratings yet

- Troubleshooting-Data: Component: From: To: Condition: Value Measured: PicDocument2 pagesTroubleshooting-Data: Component: From: To: Condition: Value Measured: PicZenon KociubaNo ratings yet

- Solvent Product List (Metal Complex Solvent Dyes)Document3 pagesSolvent Product List (Metal Complex Solvent Dyes)Camilo DominguezNo ratings yet

- Solberg Ebook 00010 Web PDFDocument434 pagesSolberg Ebook 00010 Web PDFToretta AdrianNo ratings yet

- Water Treatment TechnologyDocument10 pagesWater Treatment TechnologynickNo ratings yet

- PNO52 245 71687 v1 ENDocument8 pagesPNO52 245 71687 v1 ENjtcool74100% (1)

- 560 000 TS M 296aDocument29 pages560 000 TS M 296awesqui100% (1)

- GB Grade ASP-2030Document2 pagesGB Grade ASP-2030Nabeel AliNo ratings yet

- Adler Brochure Layout (Lo Res)Document40 pagesAdler Brochure Layout (Lo Res)Chris DresdenNo ratings yet

- Catalogo Machuelos Threading Tools To Jis StandardDocument68 pagesCatalogo Machuelos Threading Tools To Jis StandardnabilahanakhairunnidaNo ratings yet

- Castrol Molub-Alloy 823 FM-tdsDocument3 pagesCastrol Molub-Alloy 823 FM-tdsCleiton Luiz CordeiroNo ratings yet

- The Welding Journal 1958 6Document161 pagesThe Welding Journal 1958 6Alexey100% (1)

- Qualitative AnalysisDocument23 pagesQualitative AnalysisLiana JalilNo ratings yet

- Bedroom ElevationDocument1 pageBedroom ElevationkeshavNo ratings yet

- Cell Holder ABSDocument2 pagesCell Holder ABSRachit RanjanNo ratings yet

- Class 7 Science Notes Chapter 3 Fibre To FabricDocument7 pagesClass 7 Science Notes Chapter 3 Fibre To FabricImran UL HAQNo ratings yet

- Semisolid ExcipientsDocument18 pagesSemisolid Excipientsmohamedibrahim.a1No ratings yet

- JSW CementDocument32 pagesJSW CementChandra SekarNo ratings yet

- Sika® Viscocrete®-3006 Es: Product Data SheetDocument2 pagesSika® Viscocrete®-3006 Es: Product Data SheetShihab AhamedNo ratings yet

- Sealants: Caulking Is ADocument12 pagesSealants: Caulking Is ASheeza ShaanNo ratings yet

- BD ND Angle of Repose PDFDocument4 pagesBD ND Angle of Repose PDFDilnesa EjiguNo ratings yet

- EA448 Lab 5 Sieve Analysis ProcedureDocument8 pagesEA448 Lab 5 Sieve Analysis ProcedureEllz LahCe Gimotea BaluyutNo ratings yet

- Diptico Diesel WmoDocument2 pagesDiptico Diesel WmoSanchez Martinez Hugo De Dios100% (1)

- CommercialComplete NFPA 285 BrochureDocument8 pagesCommercialComplete NFPA 285 BrochureMehmet OzdenNo ratings yet

- TCD Maintenance Blg. BoqDocument14 pagesTCD Maintenance Blg. BoqMikuNo ratings yet

- Belzona ProductsDocument174 pagesBelzona Productsrao abdul bariNo ratings yet

- Enzymes Mechanism of Enzyme ActionDocument8 pagesEnzymes Mechanism of Enzyme Actionkl42c4300No ratings yet

- Hydrogen Effects in High Strength SteelsDocument36 pagesHydrogen Effects in High Strength SteelsNattapong PongbootNo ratings yet

- Detail of Mesh-1 Detail of Mesh-2Document1 pageDetail of Mesh-1 Detail of Mesh-2Saurabh PandeyNo ratings yet

- Axolotl PrintpatternDocument6 pagesAxolotl PrintpatternGeorgina Heredia100% (3)

External Chamber For Level Measurement With Inserted Sensors Model BZG

External Chamber For Level Measurement With Inserted Sensors Model BZG

Uploaded by

Zenon KociubaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

External Chamber For Level Measurement With Inserted Sensors Model BZG

External Chamber For Level Measurement With Inserted Sensors Model BZG

Uploaded by

Zenon KociubaCopyright:

Available Formats

Level

External chamber

For level measurement with inserted sensors

Model BZG

WIKA data sheet LM 11.01

Applications

■■ Level detection for almost all liquid media

■■ Individual design and corrosion-resistant materials make

the products suitable for a broad range of applications

■■ Chemical industry, petrochemical industry, oil and natural

gas extraction (on- and offshore), shipbuilding, machine

building, power generating equipment, power plants

Special features

■■ Process- and procedure-specific production

■■ Operating limits:

- Operating temperature: T = -196 ... +450 °C

- Operating pressure: P = Vacuum up to 400 bar

■■ Wide variety of different process connections and materials

■■ Mounting of level sensors and guided wave radars

possible as an option

Description

The external chamber model BZG consists of an external

chamber vessel that is mounted laterally to a vessel using

at least 2 process connections (flange, thread or weld stub).

Through this type of arrangement, the level in the external

chamber corresponds to the level in the vessel.

External chamber, model BZG

The level is measured by a measuring instrument inserted

additionally in the external chamber, for example model FLR

or FLS, or by a guided wave radar.

WIKA data sheet LM 11.01 ∙ 03/2019 Page 1 of 11

Data sheets showing similar products and accessories:

Bypass level indicator; model BNA; see data sheet LM 10.01

Level sensor with reed measuring chain; model FLR; see data sheet LM 20.02

Float switches for the process industry; model FLS; see data sheet LM 30.01

Model overview

Model Description Materials Max. operating Max. operating

pressure in bar temperature in °C

BZG-S Standard version Stainless steel 1.4571 (316Ti) 64 bar -196 ... +450 °C

Stainless steel 1.4401/1.4404 (316/316L) 64 bar -196 ... +450 °C

BZG-H High-pressure version Stainless steel 1.4571 (316Ti) 400 bar -196 ... +450 °C

Stainless steel 1.4401/1.4404 (316/316L) 400 bar -196 ... +450 °C

BZG-K Steel version Steel 1.0345/1.0460 250 bar -10 ... +400 °C

Steel 1.5415 (16Mo3) 250 bar -10 ... +400 °C

A105/A106 Gr. B 255 bar -29 ... +400 °C

A350 LF2/A333 Gr. 6 255 bar -46 ... +425 °C

BZG-X Special material version Stainless steel 6Mo 1.4547 (UNS S31254) 250 bar -29 ... +400 °C

Stainless steel 1.4306 (304L) 41 bar -196 ... +450 °C

Duplex 1.4462 (UNS S31803) 430 bar -40 ... +300 °C

Super Duplex 1.4410 (UNS S3850) 430 bar -40 ... +300 °C

Titanium 3.7035 (grade 2) 78 bar -60 ... +300 °C

Hastelloy C276 (2.4819) 430 bar -196 ... +500 °C

Other materials on request

Design codes available

■■ AD2000

■■ ASME B31.3

■■ NORSOK

■■ EN 13445

CE classification

Model PED CE PED module used

BZG-S00, BZG-H00, BZG-X00, BZG-K00 - - -

BZG-SA1, BZG-HA1, BZG-XA1, BZG-KA1 x x Module A

BZG-SA2, BZG-HA2, BZG-XA2, BZG-KA2 x x Module A2

BZG-SBC, BZG-HBC, BZG-XBC, BZG-KBC x x Module B + C2

BZG-SBD, BZG-HBD, BZG-XBD, BZG-KBD x x Module B + D

BZG-SGE, BZG-HGE, BZG-XGE, BZG-KGE x x Module G

Approvals

Logo Description Country

EU declaration of conformity European Union

Pressure equipment directive (option)

EAC Eurasian Economic Community

Pressure equipment directive

No. RU D-DE.MJU62.B.02027

Approvals and certificates, see website

WIKA data sheet LM 11.01 ∙ 03/2019 Page 2 of 11

External chamber, standard version

Model BZG-S

External chamber and process connections made of stainless steel

X = ... Specifications

Chamber end top Flange

■■ DIN EN 1092-1 DN 50 ... DN 100,

PN 6 ... PN 63

■■ DIN DN 50 ... DN 100, PN 6 ... PN 64

T = ...

■■ ANSI B 16.5 2" ... 4",

class 150 ... 600

■■ Threaded bushing G / NPT 3/4" ... 2"

Chamber end bottom Flange connection or pipe cap

■■ Drain plug

■■ Drain valve

■■ Drain flange

Options see page 9

M = ...

Process connections 2 x lateral (options see page 10)

Flange

■■ DIN EN 1092-1 DN 10 ... DN 100,

PN 6 ... PN 63

■■ DIN DN 10 ... DN 100, PN 6 ... PN 64

■■ ANSI B 16.5 ½" ... 4",

class 150 ... 600

Weld stub ½" ... 1"

Threaded bushing G / NPT ½" ... 1"

U = ...

Threaded nipple G / NPT ½" ... 1"

Centre-to-centre ≥ 150 ... ≤ 6,000 mm

distance (larger distances on request)

Material ■■ Stainless steel 1.4571 (316Ti)

Z = ...

■■ Stainless steel 1.4401/1.4404

X2 (316/316L)

Max. nominal pressure 64 bar

Temperature range

Y

■■ Stainless steel 1.4571 -120 … +400 °C

(316Ti)

■■ Stainless steel -196 … +450 °C

1.4401/1.4404

0° / 12.00

270° / 9.00 90° / 3.00 (316/316L)

Option with vent

180° / 6.00

Special versions on request

Chamber dimensions

Dimensions in mm Stainless steel 1.4571 (316Ti) Stainless steel 1.4401/1.4404 (316/316L)

60.3 x 2 x x

60.3 x 2.77 x x

88.9 x 2 x x

88.9 x 3.05 x

114.3 x 2.6 x

114.3 x 3.05 x

WIKA data sheet LM 11.01 ∙ 03/2019 Page 3 of 11

External chamber, high-pressure version

Model BZG-H

External chamber and process connections made of stainless steel

X = ... Specifications

Chamber end top Flange

■■ DIN EN 1092-1 DN 50 ... DN 100,

PN 100 ... PN 400

■■ DIN DN 50 ... DN 100,

T = ...

PN 100 ... PN 400

■■ ANSI B 16.5 2" ... 4",

class 600 ... 2,500

■■ Threaded bushing G / NPT 3/4" ... 2"

Chamber end bottom Flange connection or pipe cap

■■ Drain plug

■■ Drain valve

■■ Drain flange

Options see page 9

M = ...

Process connections 2 x lateral (options see page 10)

Flange

■■ DIN EN 1092-1 DN 10 ... DN 100,

PN 100 ... PN 400

■■ DIN DN 10 ... DN 100,

PN 100 ... PN 400

■■ ANSI B 16.5 ½" ... 4",

class 600 ... 2,500

Weld stub ½" ... 1"

U = ...

Threaded bushing G / NPT ½" ... 1"

Threaded nipple G / NPT ½" ... 1"

Centre-to-centre ≥ 150 ... ≤ 6,000 mm

Z = ...

distance (larger distances on request)

Material ■■ Stainless steel 1.4571 (316Ti)

X2

■■ Stainless steel 1.4401/1.4404

(316/316L)

Y

Max. nominal pressure 400 bar

Temperature range

■■ Stainless steel 1.4571 -120 … +400 °C

0° / 12.00

(316Ti)

■■ Stainless steel -196 … +450 °C

270° / 9.00 90° / 3.00

Option with vent 1.4401/1.4404

180° / 6.00

(316/316L)

Special versions on request

Chamber dimensions

Dimensions in mm Stainless steel 1.4571 (316Ti) Stainless steel 1.4401/1.4404 (316/316L)

60.3 x 3.91 x x

60.3 x 5.54 x

60.3 x 8 x

60.3 x 8.74 x

88.9 x 4.5 x

88.9 x 5.49 x

88.9 x 7.62 x x

88.9 x 11 x

88.9 x 11.13 x

114.3 x 4 x

114.3 x 6.02 x

114.3 x 7.1 x

114.3 x 8.56 x

114.3 x 11.13 x

WIKA data sheet LM 11.01 ∙ 03/2019 Page 4 of 11

External chamber, steel version

Model BZG-K

External chamber and process connections made of steel

X = ... Specifications

Chamber end top Flange

■■ DIN EN 1092-1 DN 50 ... DN 100,

PN 16 ... PN 400

■■ DIN DN 50 ... DN 100,

T = ...

PN 16 ... PN 400

■■ ANSI B 16.5 2" ... 4",

class 150 ... 2,500

Chamber end bottom Flange connection or pipe cap

■■ Drain plug

■■ Drain valve

■■ Drain flange

Options see page 9

Process connections 2 x lateral (options see page 10)

M = ...

Flange

■■ DIN EN 1092-1 DN 10 ... DN 50,

PN 16 ... PN 400

■■ DIN DN 10 ... DN 50, PN 16 ... PN 400

■■ ANSI B 16.5 ½" ... 4",

class 150 ... 2,500

Weld stub ½" ... 1"

Threaded bushing G / NPT ½" ... 1"

Threaded nipple G / NPT ½" ... 1"

U = ...

Centre-to-centre ≥ 150 ... ≤ 6,000 mm

distance (larger distances on request)

Material ■■ Steel 1.0345/1.0460

Z = ...

■■ Steel 1.5415 (16Mo3)

X2

■■ Steel A105/A106 Gr.B

■■ Steel A350 LF2/A333 Gr. 6

Max. nominal pressure

Y

■■ Steel 1.0345/1.0460, 250 bar

1.5415 (16Mo3)

■■ Steel A105/A106 255 bar

0° / 12.00

Gr. B, A350 LF2/A333

Gr. 6

270° / 9.00 90° / 3.00

Option with vent Temperature range

180° / 6.00 ■■ Steel 1.0345/1.0460, -10 … +400 °C

1.5415 (16Mo3)

■■ Steel A105/A106 Gr. B -29 … +400 °C

■■ Steel A350 LF2/A333 -46 … +425 °C

Gr. 6

Special versions on request

Paintings on request

WIKA data sheet LM 11.01 ∙ 03/2019 Page 5 of 11

Chamber dimensions model BZG-K (made of steel)

Dimensions in mm Steel 1.0345/1.0460 Steel 1.5415 (16Mo3) Steel A105/A106 Steel A350 LF2/A333

Gr. B Gr. 6

60.3 x 3.6 x x

60.3 x 3.91 x x

60.3 x 4 x x

60.3 x 5.54 x x

60.3 x 5.6 x x

60.3 x 7.1 x x

60.3 x 8.74 x x

60.3 x 8.8 x x

60.3 x 11.07 x x

73 x 3.05 x x

73 x 5.16 x x

73 x 7.01 x x

73 x 9.53 x x

73 x 14.02 x x

76.1 x 3.6 x x

76.1 x 5.6 x x

76.1 x 7.1 x x

76.1 x 8 x x

76.1 x 10 x x

76.1 x 14.2 x

88.9 x 4 x x

88.9 x 5.49 x x

88.9 x 5.6 x x

88.9 x 7.62 x x

88.9 x 8 x x

88.9 x 8.8 x x

88.9 x 11 x x

88.9 x 11.13 x x

88.9 x 15.24 x x

88.9 x 16 x

114.3 x 4.5 x x

114.3 x 6.02 x x

114.3 x 6.3 x x

114.3 x 8.8 x x

114.3 x 11 x x

114.3 x 11.13 x x

114.3 x 13.49 x x

114.3 x 14.2 x x

114.3 x 17.12 x x

114.3 x 17.5 x

WIKA data sheet LM 11.01 ∙ 03/2019 Page 6 of 11

External chamber, special material version

Model BZG-X

External chamber and process connections made of austenitic and ferritic stainless steel

X = ... Specifications

Chamber end top Flange

■■ DIN EN 1092-1 DN 50 ... DN 100,

PN 63 ... PN 400

■■ DIN DN 50 ... DN 100,

T = ...

PN 64 ... PN 400

■■ ANSI B 16.5 2" ... 4",

class 600 ... 2,500

Chamber end bottom Flange connection or pipe cap

■■ Drain plug

■■ Drain valve

■■ Drain flange

Options see page 9

Process connections 2 x lateral (options see page 10)

M = ...

Flange

■■ DIN EN 1092-1 DN 10 ... DN 100,

PN 63 ... PN 400

■■ DIN DN 10 ... DN 100,

PN 64 ... PN 400

■■ ANSI B 16.5 ½" ... 4",

class 600 ... 2,500

Weld stub ½" ... 1"

Threaded bushing G / NPT ½" ... 1"

U = ...

Threaded nipple G / NPT ½" ... 1"

Centre-to-centre distance ≥ 150 ... ≤ 6,000 mm

(larger distances on request)

Z = ...

Material ■■ Stainless steel 6Mo 1.4547

X2

(UNS S31254)

■■ Stainless steel Duplex 1.4462

(UNS S31803)

■■ Stainless steel Super Duplex

Y

1.4410 (UNS S32750)

Max. nominal pressure 258 bar

0° / 12.00

Temperature range

■■ Stainless steel 6Mo -196 … +450 °C

270° / 9.00 90° / 3.00

Option with vent 1.4547

180° / 6.00 ■■ Stainless steel Duplex -40 … +300 °C

1.4462

■■ Stainless steel Super -40 … +300 °C

Duplex 1.4410

Special versions on request

Chamber dimensions

Dimensions in mm Stainless steel 6Mo Stainless steel Duplex Stainless steel Super Duplex

1.4547 (UNS S31254) 1.4462 (UNS S31803) 1.4410 (UNS S32750)

60.3 x 2.77 x x x

60.3 x 3.91 x x x

60.3 x 5.54 x x x

88.9 x 3.05 x x x

114.3 x 3.05 x x x

WIKA data sheet LM 11.01 ∙ 03/2019 Page 7 of 11

External chamber, special material version

Model BZG-X

External chamber and process connections made of stainless steel / titanium / Hastelloy

X = ... Specifications

Chamber end top Flange

■■ DIN EN 1092-1 DN 50 ... DN 100,

PN 6 ... PN 400

■■ DIN DN 50 ... DN 100,

T = ...

PN 6 ... PN 400

■■ ANSI B 16.5 2" ... 4",

class 150 ... 2,500

Chamber end bottom Flange connection or pipe cap

■■ Drain plug

■■ Drain valve

■■ Drain flange

Options see page 9

Process connections 2 x lateral (options see page 10)

M = ...

■■ Stainless steel 1.4306 Flange

(304L), titanium 3.7035, ■■ DIN EN 1092-1 DN 10 ... DN 100,

PN 6 ... PN 63

■■ DIN DN 10 ... DN 100,

PN 6 ... PN 64

■■ ANSI B 16.5 ½" ... 4",

class 150 ... 600

■■ Hastelloy C276 (2.4819) Flange

■■ DIN EN 1092-1 DN 10 ... DN 100,

U = ...

PN 6 ... PN 160

■■ DIN DN 10 ... DN 100,

PN 6 ... PN 160

■■ ANSI B 16.5 ½" ... 4",

Z = ...

class 150 ... 900

X2

Centre-to-centre distance ≥ 150 ... ≤ 6,000 mm

(larger distances on request)

Material ■■ Stainless steel 1.4306 (304L)

Y

■■ Titanium 3.7035

■■ Hastelloy C276 (2.4819)

0° / 12.00 Max. nominal pressure

■■ Stainless steel 1.4306 41.4 bar

(304L)

270° / 9.00 90° / 3.00

Option with vent

180° / 6.00 ■■ Titanium 3.7035 64 bar

■■ Hastelloy C276 (2.4819) 160 bar

Temperature range

■■ Stainless steel 1.4306 -196 ... +450 °C

(304L)

■■ Titanium 3.7035 -10 ... +300 °C

■■ Hastelloy C276 (2.4819) -196 ... +500 °C

Special versions on request

Chamber dimensions

Dimensions in mm Titanium 3.7035 Hastelloy C276 (2.4819) Stainless steel 1.4306 (304L)

60.3 x 2 x

60.3 x 2.77 x x x

60.3 x 3.91 x

88.9 x 3.05 x

114.3 x 3.05 x

WIKA data sheet LM 11.01 ∙ 03/2019 Page 8 of 11

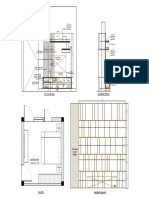

Options for chamber ends

Chamber end top (examples)

Flange connection Threaded connection

Vent (examples)

Weld stub Vent plug G / NPT ½ Flange connection

Chamber end bottom (examples)

Pipe cap without drain Pipe cap with drain plug Flange connection

G / NPT ½"

Pipe cap with drain flange Pipe cap with drain valve

Other options on request

WIKA data sheet LM 11.01 ∙ 03/2019 Page 9 of 11

Options for process connection

Process connection (examples)

Welding neck flange Blind flange Threaded coupling GN ... Threaded coupling GM ... Weld stub S ...

(Male thread) (Female thread)

Complete instrument (examples)

Vertical flange connection (top) Vertical flange connection (top) Vertical threaded connection (top)

Process connections 2 x lateral Process connections 1 x lateral Process connections 2 x lateral

Pipe cap with vertical drain flange (bottom) Vertical flange connection (bottom) Pipe cap with vertical drain plug

(bottom)

Other connections on request

WIKA data sheet LM 11.01 ∙ 03/2019 Page 10 of 11

Selectable tests

■■ Hydrostatic pressure test

■■ X-ray testing (RT)

■■ Dye penetrant test (PT)

■■ Visual testing (VT)

■■ Positive material identification test (PMI)

Other tests on request

Ordering information

Model / Material / Process specifications (operating temperature and pressure) / Process connection / Centre-to-centre

distance M ...

Detailed information on sensors (reed chain and magnetostrictive) can be found in the following data sheets:

■■ Level sensor, magnetostrictive high-resolution measuring principle; model FLM; see data sheet LM 20.01

■■ Level sensor, with reed measuring chain; model FLR; see data sheet LM 20.02

© 02/2015 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet LM 11.01 ∙ 03/2019 Page 11 of 11

03/2019 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Subsection BDocument251 pagesSubsection Bsafeer ahmad100% (1)

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- Cyanide and Ricin Homemade PDFDocument7 pagesCyanide and Ricin Homemade PDFСергей ЯрмолаNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- Bypass Level Indicator With Magnetic Display Model BNA: ApplicationsDocument19 pagesBypass Level Indicator With Magnetic Display Model BNA: ApplicationsEyuNo ratings yet

- DFS (GS 06p01y01-E-E - 008)Document30 pagesDFS (GS 06p01y01-E-E - 008)tetioNo ratings yet

- Familyoverview LBR-SicWave g505156 enDocument4 pagesFamilyoverview LBR-SicWave g505156 enTien LoiNo ratings yet

- Technical DrawingDocument6 pagesTechnical DrawingRosyad AminNo ratings yet

- BombasDocument8 pagesBombasDiego Fernando GaviriaNo ratings yet

- PS01Document11 pagesPS01Sherry HenryNo ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- Explosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetDocument4 pagesExplosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetachmadinNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Extended Diaphragm SealDocument2 pagesExtended Diaphragm SealShankar PediredlaNo ratings yet

- Bav04 eDocument2 pagesBav04 eYipeng Lex ChuNo ratings yet

- Level Switch NS 64/NS 100 ..-AM: FluidcontrolDocument4 pagesLevel Switch NS 64/NS 100 ..-AM: FluidcontrolAmar KevricNo ratings yet

- Technical Data Sheet Ecotrol Control Valve TD - 6HDocument6 pagesTechnical Data Sheet Ecotrol Control Valve TD - 6HFrancisco SanchezNo ratings yet

- ICO4SDocument12 pagesICO4SGopinath SekarNo ratings yet

- Technical Bulletin: ArgusDocument11 pagesTechnical Bulletin: ArgusTerry wei shengNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- Type Zlic Brand SihiDocument8 pagesType Zlic Brand SihiArdi 4791No ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- Alfa Laval Alfacond 400 - enDocument2 pagesAlfa Laval Alfacond 400 - enAjayNo ratings yet

- Walvoil Comando SD6DLS7 2019Document101 pagesWalvoil Comando SD6DLS7 2019Istenio Cassiano NetoNo ratings yet

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerNo ratings yet

- Volute Casing Pumps: SupernovaDocument9 pagesVolute Casing Pumps: SupernovaP. Ernesto C. GutierrezNo ratings yet

- Alfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332Document3 pagesAlfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332apri andi setyawanNo ratings yet

- General Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42Document4 pagesGeneral Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42HolicsNo ratings yet

- 2p - en - Bfs 20 o Bfs 20 OlDocument2 pages2p - en - Bfs 20 o Bfs 20 OlMukesh Kumar JhaNo ratings yet

- Sanimagnum Rotary SprayDocument3 pagesSanimagnum Rotary Sprayeder.flavioparraNo ratings yet

- CPE-CENTER-LINE-RS-TD-EN-A4-2021_03_01-webDocument48 pagesCPE-CENTER-LINE-RS-TD-EN-A4-2021_03_01-webluan_apereiraNo ratings yet

- LPG - Pump CatalogueDocument19 pagesLPG - Pump CataloguepomaukNo ratings yet

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Document4 pages2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanNo ratings yet

- Model 3201 Liquid Level Controller: FeaturesDocument8 pagesModel 3201 Liquid Level Controller: Featuresio1_roNo ratings yet

- Metalwork 02a 32 125mmboreDocument20 pagesMetalwork 02a 32 125mmboreTeguh Ariefia GunawanNo ratings yet

- Pan Cake Diaphragm Seal 1Document2 pagesPan Cake Diaphragm Seal 1Shankar PediredlaNo ratings yet

- General Specifications: Y/17B6 Pneumatic Buoyancy TransmitterDocument3 pagesGeneral Specifications: Y/17B6 Pneumatic Buoyancy Transmitterمحمد امين التشغيل الآليNo ratings yet

- Sterling PumpeDocument20 pagesSterling PumpesrdzaNo ratings yet

- ICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDocument12 pagesICO4S 2/2, 3/2 or 5/2 Poppet Valves Electromagnetic Actuated, Directly ControlledDur MuhammadNo ratings yet

- Datasheet NovarotorDocument3 pagesDatasheet NovarotorSalimNo ratings yet

- Astm A106Document5 pagesAstm A106Andy SetyawanNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- PSV 6r8 Api - 526lDocument1 pagePSV 6r8 Api - 526lIoana PopescuNo ratings yet

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterDocument4 pagesSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloNo ratings yet

- 330 00 GB 1102Document12 pages330 00 GB 1102Sergio Gaete CovarrubiasNo ratings yet

- Boa-S PN6 DN40Document14 pagesBoa-S PN6 DN40melaNo ratings yet

- ZLKDocument10 pagesZLKHunter NoVaNo ratings yet

- Applications: Pressure Transmitter For Applications in Hazardous Areas 08/2015Document2 pagesApplications: Pressure Transmitter For Applications in Hazardous Areas 08/2015Pablo QuirogaNo ratings yet

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 pagesPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaNo ratings yet

- NH DIN Dual Indication Fuse Links: Class GG/GL, 690vac, 2 To 800 Amps, Sizes 000 To 4 NH SeriesDocument9 pagesNH DIN Dual Indication Fuse Links: Class GG/GL, 690vac, 2 To 800 Amps, Sizes 000 To 4 NH SeriesSantiago BoloquiNo ratings yet

- RAGL - GS - GS 01R01B08-00E-E - Ed14 - Pub01042020Document10 pagesRAGL - GS - GS 01R01B08-00E-E - Ed14 - Pub01042020calibracionNo ratings yet

- ICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledDocument3 pagesICO3S 350B Hydraulic Valve Electromagnetically Actuated, Directly ControlledUntoro Adi NugrohoNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Process Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VDocument6 pagesProcess Measurement and Control: Enraf Small Volume Prover Specifications Worksheet Rev VadjiNo ratings yet

- BB4-Catalogue 2015Document11 pagesBB4-Catalogue 2015nima hasanzadehNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- Tank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Document8 pagesTank Top Return Line Filter Pi 5000 Nominal Size 160 1000 According To Din 24550Mauricio Ariel H. OrellanaNo ratings yet

- Especificaciones MesskoDocument8 pagesEspecificaciones MesskoviejoluisNo ratings yet

- Arhead Manual (English)Document15 pagesArhead Manual (English)DeMen NguyenNo ratings yet

- HP Dreamcolor Z27X Display: User GuideDocument80 pagesHP Dreamcolor Z27X Display: User GuideZenon KociubaNo ratings yet

- GU Catalogue FoldSlide For PVC and Timber WP00073 01 18 enDocument148 pagesGU Catalogue FoldSlide For PVC and Timber WP00073 01 18 enZenon KociubaNo ratings yet

- Risk-Based Inspection Study and Its Contribution To Optimize T&I Expenditure at JNGLF PlantDocument11 pagesRisk-Based Inspection Study and Its Contribution To Optimize T&I Expenditure at JNGLF PlantZenon KociubaNo ratings yet

- UOP R-334 CCR Platforming CatalystDocument1 pageUOP R-334 CCR Platforming CatalystZenon KociubaNo ratings yet

- Erosion Corrosion of Parallel Feed Water Discharge Lines at The Loviisa Vver 440Document11 pagesErosion Corrosion of Parallel Feed Water Discharge Lines at The Loviisa Vver 440Zenon KociubaNo ratings yet

- Integrity Operating Windows ShellDocument28 pagesIntegrity Operating Windows ShellZenon KociubaNo ratings yet

- Development of A Material Databook For Api STD 530Document10 pagesDevelopment of A Material Databook For Api STD 530Zenon Kociuba100% (1)

- Appendix 1 List of Participants: Minutes of EFC WP15 Corrosion in The Refinery Industry 8 April 2014Document92 pagesAppendix 1 List of Participants: Minutes of EFC WP15 Corrosion in The Refinery Industry 8 April 2014Zenon KociubaNo ratings yet

- A New Model For Reliability Centered Mai PDFDocument9 pagesA New Model For Reliability Centered Mai PDFZenon KociubaNo ratings yet

- Objectives: Khalid Humaid Al-HasaniDocument13 pagesObjectives: Khalid Humaid Al-HasaniZenon KociubaNo ratings yet

- Vulnerable To Brittle FractureDocument7 pagesVulnerable To Brittle FractureZenon KociubaNo ratings yet

- SCI Current Document Status - Fall 2014 FinalDocument5 pagesSCI Current Document Status - Fall 2014 FinalZenon KociubaNo ratings yet

- API TR 971 Injection Point Outline2Document7 pagesAPI TR 971 Injection Point Outline2Zenon KociubaNo ratings yet

- Us 20100036866Document22 pagesUs 20100036866Zenon KociubaNo ratings yet

- Del 67Document2 pagesDel 67Zenon KociubaNo ratings yet

- XIV Paper 38Document11 pagesXIV Paper 38Zenon KociubaNo ratings yet

- Coin-Cell Battery: Back To Contents PageDocument2 pagesCoin-Cell Battery: Back To Contents PageZenon KociubaNo ratings yet

- Notice:: in The Microsoft in The Microsoft Windows XP Operating System, Click StartDocument3 pagesNotice:: in The Microsoft in The Microsoft Windows XP Operating System, Click StartZenon KociubaNo ratings yet

- Troubleshooting-Data: Component: From: To: Condition: Value Measured: PicDocument2 pagesTroubleshooting-Data: Component: From: To: Condition: Value Measured: PicZenon KociubaNo ratings yet

- Solvent Product List (Metal Complex Solvent Dyes)Document3 pagesSolvent Product List (Metal Complex Solvent Dyes)Camilo DominguezNo ratings yet

- Solberg Ebook 00010 Web PDFDocument434 pagesSolberg Ebook 00010 Web PDFToretta AdrianNo ratings yet

- Water Treatment TechnologyDocument10 pagesWater Treatment TechnologynickNo ratings yet

- PNO52 245 71687 v1 ENDocument8 pagesPNO52 245 71687 v1 ENjtcool74100% (1)

- 560 000 TS M 296aDocument29 pages560 000 TS M 296awesqui100% (1)

- GB Grade ASP-2030Document2 pagesGB Grade ASP-2030Nabeel AliNo ratings yet

- Adler Brochure Layout (Lo Res)Document40 pagesAdler Brochure Layout (Lo Res)Chris DresdenNo ratings yet

- Catalogo Machuelos Threading Tools To Jis StandardDocument68 pagesCatalogo Machuelos Threading Tools To Jis StandardnabilahanakhairunnidaNo ratings yet

- Castrol Molub-Alloy 823 FM-tdsDocument3 pagesCastrol Molub-Alloy 823 FM-tdsCleiton Luiz CordeiroNo ratings yet

- The Welding Journal 1958 6Document161 pagesThe Welding Journal 1958 6Alexey100% (1)

- Qualitative AnalysisDocument23 pagesQualitative AnalysisLiana JalilNo ratings yet

- Bedroom ElevationDocument1 pageBedroom ElevationkeshavNo ratings yet

- Cell Holder ABSDocument2 pagesCell Holder ABSRachit RanjanNo ratings yet

- Class 7 Science Notes Chapter 3 Fibre To FabricDocument7 pagesClass 7 Science Notes Chapter 3 Fibre To FabricImran UL HAQNo ratings yet

- Semisolid ExcipientsDocument18 pagesSemisolid Excipientsmohamedibrahim.a1No ratings yet

- JSW CementDocument32 pagesJSW CementChandra SekarNo ratings yet

- Sika® Viscocrete®-3006 Es: Product Data SheetDocument2 pagesSika® Viscocrete®-3006 Es: Product Data SheetShihab AhamedNo ratings yet

- Sealants: Caulking Is ADocument12 pagesSealants: Caulking Is ASheeza ShaanNo ratings yet

- BD ND Angle of Repose PDFDocument4 pagesBD ND Angle of Repose PDFDilnesa EjiguNo ratings yet

- EA448 Lab 5 Sieve Analysis ProcedureDocument8 pagesEA448 Lab 5 Sieve Analysis ProcedureEllz LahCe Gimotea BaluyutNo ratings yet

- Diptico Diesel WmoDocument2 pagesDiptico Diesel WmoSanchez Martinez Hugo De Dios100% (1)

- CommercialComplete NFPA 285 BrochureDocument8 pagesCommercialComplete NFPA 285 BrochureMehmet OzdenNo ratings yet

- TCD Maintenance Blg. BoqDocument14 pagesTCD Maintenance Blg. BoqMikuNo ratings yet

- Belzona ProductsDocument174 pagesBelzona Productsrao abdul bariNo ratings yet

- Enzymes Mechanism of Enzyme ActionDocument8 pagesEnzymes Mechanism of Enzyme Actionkl42c4300No ratings yet

- Hydrogen Effects in High Strength SteelsDocument36 pagesHydrogen Effects in High Strength SteelsNattapong PongbootNo ratings yet

- Detail of Mesh-1 Detail of Mesh-2Document1 pageDetail of Mesh-1 Detail of Mesh-2Saurabh PandeyNo ratings yet

- Axolotl PrintpatternDocument6 pagesAxolotl PrintpatternGeorgina Heredia100% (3)