Professional Documents

Culture Documents

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

Uploaded by

Anggara KusumaCopyright:

Available Formats

You might also like

- Austin Cars From 1932Document103 pagesAustin Cars From 1932Chris ThorleyNo ratings yet

- ATLAS COPCO New - Troubleshooting - GuideDocument245 pagesATLAS COPCO New - Troubleshooting - GuideBruce Li100% (11)

- Elite 100 & 300 - Technical Reference Manual - (Secure) - BGX701-234-R01Document60 pagesElite 100 & 300 - Technical Reference Manual - (Secure) - BGX701-234-R01Anggara Kusuma75% (20)

- Antenna DvorDocument27 pagesAntenna DvorRhonny AlbertoNo ratings yet

- KP308.V1.0 Controller Operation Manual 2nd VersionDocument28 pagesKP308.V1.0 Controller Operation Manual 2nd Versiontonielhage100% (7)

- Elite 100 and 300 QIG - Secure - BGX701-208-R01 - Curved PDFDocument2 pagesElite 100 and 300 QIG - Secure - BGX701-208-R01 - Curved PDFAnggara Kusuma0% (1)

- Eastron SDM630MCT-Lora Series User Manual V1Document2 pagesEastron SDM630MCT-Lora Series User Manual V1Luiz Fernando AlvesNo ratings yet

- Eastron SDM630MCT-RJ User-Manual 2020Document2 pagesEastron SDM630MCT-RJ User-Manual 2020Marco Lo GueNo ratings yet

- 409 M Quick User GuideDocument2 pages409 M Quick User GuidePuneet BachalNo ratings yet

- Man 000008Document2 pagesMan 000008Angelo CotradoNo ratings yet

- Hfem 3400ctcom MTDocument24 pagesHfem 3400ctcom MTAnonymous yugocxnNo ratings yet

- Operation and PC and APP Instruction For Digital Control Constant Voltage Constant Current Power Supply Without Power PartDocument17 pagesOperation and PC and APP Instruction For Digital Control Constant Voltage Constant Current Power Supply Without Power PartCONG TRAN NGOCNo ratings yet

- DC30D Configuration and Instructions Ver1.0Document8 pagesDC30D Configuration and Instructions Ver1.0JaimeCoello100% (2)

- Network Analyser Network Analyser: MPR60S / MPR60S-MPR60S / MPR60SDocument4 pagesNetwork Analyser Network Analyser: MPR60S / MPR60S-MPR60S / MPR60SSarmad KhanNo ratings yet

- SLC Cube 3+: User'S ManualDocument16 pagesSLC Cube 3+: User'S ManualJose CaceresNo ratings yet

- 116 UserDocument4 pages116 UserWinston diaz valeraNo ratings yet

- Eaton-IQ200X-Electronic Power Meter-User Manual-EN-USDocument2 pagesEaton-IQ200X-Electronic Power Meter-User Manual-EN-USAlan leví TeleguarioNo ratings yet

- 116 UserDocument4 pages116 UserMohamed Yahya100% (1)

- 7SR224 - Argus Technical Manual Chapter 2 Settings App 2 R4 3Document134 pages7SR224 - Argus Technical Manual Chapter 2 Settings App 2 R4 3Gerald GribelNo ratings yet

- Distance/force: Series Touch Screen Quick Start User'S GuideDocument2 pagesDistance/force: Series Touch Screen Quick Start User'S GuideanthonyMNo ratings yet

- Eastron SDM630MCT V2 User Manual 2016 V4.8Document26 pagesEastron SDM630MCT V2 User Manual 2016 V4.8Asif KhanNo ratings yet

- Toubleshoot FR-E700Document5 pagesToubleshoot FR-E700SilentXNo ratings yet

- Numerical Residual Voltage - Neutral Displacement RelayDocument4 pagesNumerical Residual Voltage - Neutral Displacement RelaySumit SinghNo ratings yet

- Ats-Plc Manual SDocument58 pagesAts-Plc Manual SOrlando VeladoNo ratings yet

- Connections, Displays and Operating Elements: G F MN HDocument10 pagesConnections, Displays and Operating Elements: G F MN HdogasanchesNo ratings yet

- Altistart 48 - Руководство по программированию - ENGDocument41 pagesAltistart 48 - Руководство по программированию - ENGZhiger Fox SaurambayevNo ratings yet

- DSP-10 ManualDocument2 pagesDSP-10 ManualIvan EspinosaNo ratings yet

- Guide 100 412 175 2000xea Quick Start Rev 05 en 5283264Document2 pagesGuide 100 412 175 2000xea Quick Start Rev 05 en 5283264martin JeongNo ratings yet

- GW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualDocument18 pagesGW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualSlobodan NocajNo ratings yet

- DataKom 409 - INSTEDocument7 pagesDataKom 409 - INSTEKhaleel KhanNo ratings yet

- Ninglu NMEA Simulator PDFDocument17 pagesNinglu NMEA Simulator PDFtariktunadNo ratings yet

- PM135 Quick Start Manual: Win A Tablet!Document4 pagesPM135 Quick Start Manual: Win A Tablet!Vũ MinhNo ratings yet

- Power MeterDocument23 pagesPower MeterDaniel WongNo ratings yet

- Elmeasure Accl Accl300 Programming GuideDocument2 pagesElmeasure Accl Accl300 Programming GuideaymaanfkNo ratings yet

- Flow ControllerDocument2 pagesFlow ControlleraniketNo ratings yet

- Elmeasure Multifunction Meter Multifunctionlcd Programming GuideDocument2 pagesElmeasure Multifunction Meter Multifunctionlcd Programming GuideP.p. Arul IlancheeranNo ratings yet

- DPS300Document2 pagesDPS300RicardoNo ratings yet

- HP 4155a GuideDocument18 pagesHP 4155a Guide전자전기컴퓨터공학과/조정익No ratings yet

- UT94 - Quick - User - Guide Masibus IsolatorDocument2 pagesUT94 - Quick - User - Guide Masibus IsolatorShigilNo ratings yet

- MPR63 A2925 Rev6 v1.78 EngDocument4 pagesMPR63 A2925 Rev6 v1.78 EngEsat SÖNMEZNo ratings yet

- Epm 4ac enDocument2 pagesEpm 4ac enFarrukh MajeedNo ratings yet

- Electronic Digital Thermometer With Maximum / Minimum Temperature LogDocument2 pagesElectronic Digital Thermometer With Maximum / Minimum Temperature LogHoàngViệtAnhNo ratings yet

- PM135 QuickstartDocument4 pagesPM135 QuickstartNguyen Danh HuyNo ratings yet

- JT DPS5015 ManualDocument8 pagesJT DPS5015 ManualLuis CansinoNo ratings yet

- DPS5015-Digital Control Power Supply Instruction 1217Document6 pagesDPS5015-Digital Control Power Supply Instruction 1217Giordano De StefanisNo ratings yet

- Transformer Turn Ratio Test SetDocument15 pagesTransformer Turn Ratio Test SetYoussef EzatNo ratings yet

- Programming Guide - Power Factor Conroller: 1. FeaturesDocument5 pagesProgramming Guide - Power Factor Conroller: 1. Featureskhan leNo ratings yet

- TensionRite® Belt Frequency MeterDocument31 pagesTensionRite® Belt Frequency MeterWilson Muñoz ArayaNo ratings yet

- CM3022 How To Set UpDocument4 pagesCM3022 How To Set UptasneemengsolNo ratings yet

- EL Meaure MeterDocument40 pagesEL Meaure MeterRangasamyNo ratings yet

- SDM630MV CT Modbus Manual - GoodMeasure StoreDocument21 pagesSDM630MV CT Modbus Manual - GoodMeasure StoreKunanon JaitrongNo ratings yet

- Network Analyser Network Analyser: MPR63-MPR63Document4 pagesNetwork Analyser Network Analyser: MPR63-MPR63Anonymous X0NBULtOqdNo ratings yet

- 6000/8000 Platform Quick Card Optical Spectrum Analysis With The Osa: Alarms Set UpDocument2 pages6000/8000 Platform Quick Card Optical Spectrum Analysis With The Osa: Alarms Set UpGaurav SainiNo ratings yet

- Operating Manual Eine+ DC DPM 48x96 Rev GDocument26 pagesOperating Manual Eine+ DC DPM 48x96 Rev GVAJIRAVEL NAGALINGAMNo ratings yet

- Evario Instructions 1.0Document6 pagesEvario Instructions 1.0simonwood003No ratings yet

- Manual Dixell x120Document4 pagesManual Dixell x120Alejandro AlomotoNo ratings yet

- PQM-702 - 703 - 710 - 711 QuickStart v1.01 ENDocument2 pagesPQM-702 - 703 - 710 - 711 QuickStart v1.01 ENtaufiq nurNo ratings yet

- Manual Eocr 3ezDocument5 pagesManual Eocr 3ezsunilatiipm100% (1)

- Man Dro NV 20 300m OpeDocument24 pagesMan Dro NV 20 300m OpeFabianeNo ratings yet

- Manual Microprogel TC 323: KontaktinformationDocument10 pagesManual Microprogel TC 323: Kontaktinformationsyed maroof aliNo ratings yet

- Potenciometro EsteirasDocument2 pagesPotenciometro EsteirasNeri Machado CarrielNo ratings yet

- TEC System NT538 - JUN-2004Document15 pagesTEC System NT538 - JUN-2004Raul quispe quispeNo ratings yet

- User Manual Achook-1080, G726A, UM0084 - LatestDocument24 pagesUser Manual Achook-1080, G726A, UM0084 - Latestprajith555No ratings yet

- SMARTRAIL X835 Protocol: WWW - Smartprocess.co - UkDocument14 pagesSMARTRAIL X835 Protocol: WWW - Smartprocess.co - UkAnggara KusumaNo ratings yet

- IEEE 754 ConverterDocument2 pagesIEEE 754 ConverterAnggara KusumaNo ratings yet

- TC3 Modbus RTU: ManualDocument36 pagesTC3 Modbus RTU: ManualAnggara KusumaNo ratings yet

- Mk6N Factsheet EnglishDocument2 pagesMk6N Factsheet EnglishAlfia RochmanNo ratings yet

- Introducing Sepam - R1Document51 pagesIntroducing Sepam - R1Anggara KusumaNo ratings yet

- Nonlinear Curve Fitting: "Why Fit in When You Were Born To Stand Out?" - Dr. SeussDocument65 pagesNonlinear Curve Fitting: "Why Fit in When You Were Born To Stand Out?" - Dr. Seussomarkhaled200321No ratings yet

- Balancing Chemical Equations HTML Guide - enDocument2 pagesBalancing Chemical Equations HTML Guide - enMiguel ApazaNo ratings yet

- HVAC FundamentalDocument192 pagesHVAC FundamentalMyo Kyaw Kyaw100% (1)

- Fujitsu VRF Seria V, Manual TehnicDocument477 pagesFujitsu VRF Seria V, Manual TehnicOnutu Lohengrin100% (2)

- Yaskawa Academy 2016 EDocument56 pagesYaskawa Academy 2016 Ejmorenoh103100% (1)

- Connections and SchemaDocument7 pagesConnections and SchemaKukuh WidodoNo ratings yet

- DIY Smart Phone Microscope Biology Performance TaskDocument3 pagesDIY Smart Phone Microscope Biology Performance TaskArvie QuijanoNo ratings yet

- Efficientfi: Towards Large-Scale Lightweight Wifi Sensing Via Csi CompressionDocument10 pagesEfficientfi: Towards Large-Scale Lightweight Wifi Sensing Via Csi CompressionJohnNo ratings yet

- Hero Project Kedar BBADocument49 pagesHero Project Kedar BBAVinod HeggannaNo ratings yet

- EnglishDocument76 pagesEnglishTak ProNo ratings yet

- Animals by Walt WhitmanDocument2 pagesAnimals by Walt Whitmanyashna gadiaNo ratings yet

- BB SESSION - ME132P Lecture 3A LINKAGESDocument32 pagesBB SESSION - ME132P Lecture 3A LINKAGESkris garciaNo ratings yet

- ANTARA Mobile Phone Portal (Angl. Qzyk)Document27 pagesANTARA Mobile Phone Portal (Angl. Qzyk)Shekina_YanaNo ratings yet

- MSL Clutch & P P 1-2-13Document3 pagesMSL Clutch & P P 1-2-13Abhishek SinghNo ratings yet

- RRL DamsDocument7 pagesRRL DamsJamesNo ratings yet

- Aegis Basics of MES WhitepaperDocument19 pagesAegis Basics of MES Whitepaperg_325899365100% (1)

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- Makati City Ordinance No. 2003-095Document12 pagesMakati City Ordinance No. 2003-095KNo ratings yet

- WS01 Slopes Samantha SarahDocument7 pagesWS01 Slopes Samantha SarahSAMANTHA SARAH PURBANo ratings yet

- Flame Tests and Atomic SpectraDocument3 pagesFlame Tests and Atomic SpectraImmanuel LashleyNo ratings yet

- Design, Fabrication & Testing of A Vertical Axis Wind Turbine With Wind de EctorsDocument61 pagesDesign, Fabrication & Testing of A Vertical Axis Wind Turbine With Wind de EctorsGautham NNo ratings yet

- Technical Rider Alcatraz Sound-Light Requirements PDFDocument3 pagesTechnical Rider Alcatraz Sound-Light Requirements PDFvijesh sutharNo ratings yet

- Will and Going To WSDocument3 pagesWill and Going To WSKatia Belen CARDENAS ROJASNo ratings yet

- Clinical MedicineDocument18 pagesClinical MedicineRishikesh AsthanaNo ratings yet

- Coolmay HMI User ManualDocument2 pagesCoolmay HMI User Manualspotlight studiosNo ratings yet

- 121: Buckwell Farm, Usk, Monmouthshire. Desk Based AssessmentDocument20 pages121: Buckwell Farm, Usk, Monmouthshire. Desk Based AssessmentAPAC LtdNo ratings yet

- Daewoo Doosan Forklift g420f Fe LP Engine Service ManualDocument23 pagesDaewoo Doosan Forklift g420f Fe LP Engine Service Manualjerryroberts051291ixe100% (29)

- The Three Types of Rocks!: Learning ObjectivesDocument2 pagesThe Three Types of Rocks!: Learning ObjectivesJekim Novo LumbaNo ratings yet

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

Uploaded by

Anggara KusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical Systems

Uploaded by

Anggara KusumaCopyright:

Available Formats

3.1 Voltage and Current 4 Set Up 4.

4 Supply System

The unit has a default setting of 3 Phase 4 Wire (3P4W).

Each successive press of the button selects a new parameter: Use this section to set the type of electrical system.

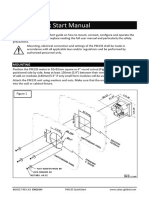

To enter set up mode, hold the button for 3 seconds,

until the password screen appears.

Use the and

Phase to neutral voltages. The set up is password- buttons to select the menu

User Manual

protected so you must option. The screen will

enter the correct password show the current setting.

2016 v1.0 (default ‘1000’) before

processing.

SMARTRAIL X835-MID Hold the button to

Current on each phase.

DIN Rail Smart Energy Meter for Single and If an incorrect password enter the menu option, the

Three Phase Electrical Systems is entered, the display will current selection will flash.

show:

1 Introduction PASS Err (Error)

This document provides operating, maintenance and Phase to neutral voltage Use the and

installation instructions. This unit measures and displays THD%. To exit the set up menu, hold the for 3 seconds, the buttons to select the

the characteristics of Single Phase Two Wire (1P2W), Three measurement screen will display. required option.

Phase Three Wire (3P3W) and Three Phase Four Wire (3P4W)

networks. The measuring parameters include Voltage (V),

Current (A), Frequency (Hz), Power (kW/KVA/KVAr), Power 4.1 Set up Entry Methods Hold the button to confirm your adjustment. Hold the

Factor (PF), Imported, Exported and Total Energy (kWh/kVArh). button for 3 seconds to exit the set up menu.

The unit also measures Maximum Demand Current and Power, Current THD% for each Some menu items, such as Password and CT, require a

this is measured over preset periods of up to 60 minutes. phase. four-digit number entry while others, such as supply system, 4.5 CT Configuration

require selection from a number of menu options.

The CT options set the Secondary Current (CT2 5A or 1A) of

This particular model accommodates 1A or 5A Current the Current Transformer (CT) that are used with the meter.

Transformers and can be configured to work with a wide range

of CTs. It also comes with a complete comms capability with 4.1.1 Menu Option Selection

built in Pulse and RS485 Modbus RTU outputs, configuration 3.2 Frequency and Power Factor and Demand Use the and

is password protected. 1. Use the and buttons to scroll through the

Each successive press of the button selects a new range: different options of the set up menu. buttons to select the menu

option. The screen will

This unit can be powered from a separate auxiliary supply (AC

2. Hold the button for 3 seconds to confirm your show the current setting.

or DC). Alternatively, it can be powered from the monitored

selection.

supply by linking the voltage reference and neutral reference in

to terminals 5 & 6 (Please refer to wiring diagram). Frequency and Power 3. If an item flashes, then it can be adjusted by the and

Factor (total). buttons. Secondary CT Setting:

Hold the button to

1.1 Unit Characteristics 4. Having selected an option from the current layer, hold the set the CT secondary

button for 3 seconds to confirm your selection. option: 5A (default) or 1A.

The SMARTRAIL X835 can measure and display:

5. Having completed a parameter setting, hold the

• Phase to Neutral Voltage and THD% (Total Harmonic

Power Factor of each button for 3 seconds to return to a higher menu level.

Distortion) of all Phases

phase. Set the CT Ratio Value:

• Line Frequency 6. On completion of all setting-up, hold the button for 3 Hold the button to

seconds, the measurement screen will then be restored. enter the CT Ratio setting

• Current, Maximum Demand Current and Current THD% of

all Phases screen. The range is from

0001 to 9999.

• Power, Maximum Power Demand and Power Factor

4.1.2 Number Entry Procedure

• Imported, Exported & Total Active Energy

Maximum Power Demand. When setting up the unit, some screens require the entering The CT Rate is the CT Primary divided by the CT Secondary.

• Imported, Exported & Total Reactive Energy

of a number. In particular, on entry to the setting up section, a For Example: 200/5A Current Transformers - 200÷5=40, so the

password must be entered. Digits are set individually, from left CT Rate would be 0040 and the CT2 would be 5.

The unit has a Password-Protected set up menu for:

• Changing the Password

to right. The procedure is as follows: On the MID Version, you can only program

• System Configuration - 1P2W, 3P3W, 3P4W. 1. The current digit to be set flashes and then can be adjusted the CT Rate ONCE.

using the and buttons.

Maximum Current

• Demand Interval Time

Demand.

4.5.1 CT Reversal

• Reset for Demand Measurements 2. Press the button to more right to the next digit.

If the CT connections are incorrectly wired, they can be

• Pulsed Output Duration 3. After setting the last digit, hold the button for 3 reversed through the “Set System Continued” menu:

seconds to save your selection.

1.2 Current Transformer Primary Current 3.3 Power

Use the and

buttons to select the

This unit requires configuring to operate with the appropriate 4.2 Change Password menu option. Hold the

Each successive press of the button select a new range:

curren transformer(s), the optional secondary currents are button to view the

1A or 5A. It is programmed by inputting the ratio (CT Primary sub-menu.

divided by the CT Secondary). It can be used on primary

currents up to 6000A. Instantaneous Active Use the and

Power in kW. to choose the change This screen will display,

On the MID Version, you can only program password option. you can change “Forward”

to “Reverse” on each

the CT Rate ONCE. individual CT connection.

1.3 RS485 Serial – Modbus RTU Instantaneous Reactive Hold the button to

Power in kVAr. enter the set up menu. The Hold the button to

This unit is compatible with remote monitoring through RS485 confirm your adjustment.

first digit will start flashing.

Modbus RTU. Set-up screens are provided for configuring the You can then move on to

RS485 port. Refers to section 4.8. IB or IC using the and

buttons.

1.4 Pulsed Outputs Use and to set

Instantaneous Volt-Amps the first digit and press Hold the button for 3 seconds to exit the set up menu.

The SMARTRAIL X835 has Two Pulsed Outputs that can be in KVA. to move right. The

set for active (kWh) or reactive (kVArh) energy. Terminals 11 & next digit will flash. 4.6 PT

12 have a fixed output of 3200imp/kWh. Terminals 9 & 10 are The PT option sets the Secondary Voltage (PT2 100-500V) of the

configurable within the setup menu. Voltage Transformer (PT) that may be connected to the meter.

Repeat the procedure for Use the and

2 Start Up Screens

Total kW, kVArh, kVA.

the remaining three digits. buttons to select the menu

option. The screen will

show the current setting.

The default value is 400V.

The first screen lights

up all display segments 3.4 Energy Measurements After setting the last digit,

and can be used as a Hold the button to Secondary PT Setting:

display check. Each successive press of the button selects a new range: save your selection. Hold the button to

set the PT secondary

option: 100-500V.

The second screen Imported active energy Hold the button for 3 seconds to exit the set up menu.

indicates the firmware in kWh.

installed in the unit and Set the PT Ratio Value:

Hold the button to

its build number. 4.3 DIT (Demand Integration Time) enter the PT Ratio setting

screen. The range is from

This sets the period (in minutes) in which the Current and

0001 to 9999.

Power readings are integrated for maximum demand

Exported active energy measurement. The options are off; 5; 10; 15; 30 or 60 minutes.

The interface performs a in kWh.

self-test and indicates the The PT Rate is the PT Primary divided by the PT Secondary.

result if the test passes. For Example: Voltage Transformer - 11000÷110=100, so the

Use the and PT Rate would be 0100 and the PT2 would be 110.

buttons to select the menu

option. The screen will 4.7 Pulsed Output

*After a short delay, the screen will display active show the current setting.

Imported reactive energy Use this section to configure the Pulsed Output Type.

energy measurements.

in kVArh. Units: kVArh (default); kWh.

3 Measurements Hold the button to Use the and

enter the menu option, the buttons to select the menu

The buttons operate as follows: current selection will flash. option. The screen will

Exported reactive energy show the current setting.

Selects the Voltage and Current display in kVArh.

screens. In Set-up Mode, this is the

“Left” (press) or “Escape” (hold 3sec)

button. Use the and

buttons to select the Hold the button to

required option. enter the menu option, the

Select the Frequency and Power factor

current selection will flash.

display screens. In Set-up Mode, this is Total active energy in kWh.

the “Up” (press) button.

Select the Power display screens. Use the and

Hold the button to buttons to select the

In Set-up Mode, this is the

confirm the selection. required option. Hold the

“Down” (press) button.

Total reactive energy in button to confirm the

kVArh. selection.

Select the Energy display screens.

In Set-up mode, this is the Hold the button for 3 seconds to exit the set up menu.

“Right” (press) or “Enter” (hold 3sec) Hold the button for 3 seconds to exit the set up menu.

button.

Please note the register is 9999999.9 display over two lines.

4.7.1 Pulse Rate 4.8.3 Parity 5.3 Accuracy 6 Dimensions

You can configure the number of pulses to relate to a defined • Voltage 0·5% of range maximum

amount of Total Energy.

• Current 0·5% of nominal

Use the and

Please note there are limitations that need to be factored in buttons to select the menu • Frequency 0·2% of mid-frequency

when setting the pulsed output. This is based upon the relay option. The screen will

output only being able to pulse 2 times per second. • Power factor 1% of unity (0.01)

show the current setting.

• Active power (W) ±1% of range maximum

For example, If the CT is set to 500/5A on a Single Phase

network this would generate (500Ax230V=115,000 / 1000) • Reactive power (VAr) ±1% of range maximum

115kWh which is 31W per second. A setting of 10IMP/kWh • Apparent power (VA) ±1% of range maximum

(10 pulses per kWH) would generate 3 pulses per second. Hold the button to

enter the menu option, the • Active energy (Wh) Class 1 IEC 62053-21

This will exceed the 2 pulse per second limitation.

current selection will flash. • Reactive energy (VARh) ±1% of range maximum

Pulse settings: 1 Pulse per: 10W (0.01) / 100W (0.1) /

• Total harmonic distortion 1% up to 31st harmonic

1000W/1kWh (1) / 10kWh (10) / 100kWh (100) /1000kWh

(1000) • Response time to step input 1s, typical, to >99% of

Use the and final reading, at 50 Hz.

buttons to select the

required option.

Range: None (default), Odd

Use the and

or Even.

5.4 Auxiliary Supply

buttons to select the menu

option. The screen will Two-way fixed connector with 2.5mm² stranded wire

7 Installation

show the current setting. On completion of the entry procedure, hold the button capacity. 85-275V AC 50/60Hz ±10% or 120-380V DC ±20%.

for 3 seconds until the selection stops flashing. Consumption <2W 10VA.

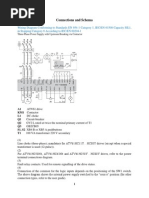

7.1 Single phase two wires

Hold the button to 4.8.4 Stop bits 5.5 Interfaces for External Monitoring

enter the menu option, the

current selection will flash. Three interfaces are provided:

• RS485 communication channel that can be programmed

Use the and 1 2 B A

for Modbus RTU protocol

buttons to select the menu

Use the and buttons to choose the desired pulse option. The screen will • Relay output indicating real-time measured energy.

rate. To save the new setting, hold the button for 3 show the current setting. (configurable)

seconds until the selection stops flashing.

• Pulse output 3200IMP/kWh (not configurable) 9 10 11 12 13 14 15 16 17 18 19 20

The Modbus configuration (baud rate etc.) and the pulse

4.7.2 Pulse Duration relay output assignments (kW/kVArh) are configured through

Hold the button to

The energy monitored can be active or reactive and the pulse the set-up screens.

enter the menu option, the

width can be selected as 200, 100 or 60mS. current selection will flash.

5.5.1 Pulse Output

Opto-coupler with potential free SPST-NO Contact

Use the and Use the and (Contact rating 5-27V DC / Max current input: Imin 2mA and

buttons to select the menu buttons to select the Imax 27mA DC). The pulse output can be set to generate

option. The screen will required option. pulses to represent kWh or kVArh.

show the current setting. Range: 1 (default) or 2. 1 2 3 4 5 6 7 8

Rate can be set to generate 1 pulse per:

0.01 = 10 Wh/VArh L N L N

0.1 = 100 Wh/VArh

On completion of the entry procedure, hold the button

1 = 1 kWh/kVArh

Hold the button to for 3 seconds until the selection stops flashing.

10 = 10 kWh/kVArh

enter the menu option, the 100 = 100 kWh/kVArh

current selection will flash. L1

4.9 CLR Pulse width 200/100/60 mS.

The meter provides a function to reset the maximum demand

Use the and buttons to choose the desired pulse value of current and power.

rate. To save the new setting, hold the button for 3

5.5.2 RS485 Output for Modbus RTU N

seconds until the selection stops flashing. For Modbus RTU, the following RS485 communication

Use the and parameters can be configured from the set-up menu: 7.2 Three phase three wires

buttons to select the menu

4.8 Communication option. The screen will

Baud rate: 2400, 4800, 9600, 19200, 38400

show the current setting. Parity: none (default) / odd / even

The RS485 port can be used for communication using

Modbus RTU Protocol. To configure the Modbus settings, Stop bits: 1 or 2

such as Address and Baud Rate, this is also done within the

Password-protected set up menu. RS485 Network Address: 3 digit number

1 -2 001-247

B A 1 2 B A

Hold the button to

Modbus Word order Hi/Lo byte order is set automatically to

™

enter the menu option, the

4.8.1 RS485 Address current selection will flash.

normal or reverse. It cannot be configured from the

set-up menu.

9 10 11 12 13 14 15 16 17 18 19 20 9 10 11 12 13 14 15 16 17 18 19 20

Use the and

Hold the button to confirm the setting and press to 5.6 Reference Conditions of Influence

return to the main set up menu.

buttons to select the menu Quantities

option. The screen will

show the current setting. Influence Quantities are variables that affect measurement

errors to a minor degree. Accuracy is verified under nominal

5 Specifications value (within the specified tolerance) of these conditions.

• Ambient temperature 23°C ±1°C

Hold the button to 5.1 Measured Parameters

set the meter Address. • Input waveform 50 or 60Hz ±2%

Range: 001(default) to 247. The unit can monitor and display the following parameters • Input waveform 1 2Sinusoidal

3 4 (distortion

5 6 7 8 1 2 3 4 5 6 7 8

of a Single Phase Two Wire (1P2W), Three Phase Three Wire factor < 0·005)

(3P3W) or Three Phase Four Wire (3P4W) system. L N L N L N L N

• Auxiliary supply voltage Nominal ±1%

• Auxiliary supply frequency Nominal ±1%

Hold the button to

5.1.1 Voltage and Current

• Auxiliary supply waveform (if AC) Sinusoidal (distortion

confirm the selection. L1 factor < 0·05) L1

• Phase to Neutral Voltages 100-289V AC

(not for 3P3W supplies). • Magnetic field of external origin Terrestrial flux L2

• Phase to Phase Voltages 173-500V AC L3

Use the and buttons to choose the necessary (3 Phase supplies only). N

number, then press the button to move along to the next

• Percentage Total Voltage Harmonic Distortion (V %THD) for 5.7 Environment

number. To save the new setting, hold the button for 3

each Phase to Neutral (not for 3P3W supplies).

seconds until the selection stops flashing. • Operating temperature -25°C to +55°C* 7.3 Three phase four wires

• Percentage Total Voltage Harmonic Distortion (V% THD)

between Phases (3 Phase supplies only). • Storage temperature -40°C to +70°C*

4.8.2 Baud Rate • Current %THD for each Phase. • Relative humidity 0 to 95%,

non-condensing

• Altitude Up to 3000m

5.1.2 Power factor and Frequency and

1 2 B A 1 2 B A

1 2 B A

Use the and • Warm up time 1 minute

buttons to select the menu

Max. Demand

• Vibration 10Hz to 50Hz, IEC

option. The screen will

• Frequency in Hz 60068-2-6, 2g

show the current setting. 9 10 11 12 13 14 15 16 17 18 19 20 9 10 11 12 13 14 15 16 17 18 19 20 9 10 11 12 13 14 15 16 17 18 19 20

• Instantaneous power: • Shock 30g in 3 planes

• Power 0-3600 MW

*Maximum operating and storage temperatures are in the

• Reactive power 0-3600 MVAr

context of typical daily and seasonal variation.

Hold the button to

• Volt-amps 0-3600 MVA

enter the menu option, the

current selection will flash. • Maximum Demand Power since last reset

• Power factor

5.8 Mechanics

• Maximum Neutral Demand Current, since the last reset (for • DIN rail dimensions 72 x 94.5 mm (WxH)

Three Phase supplies only) per DIN 43880

Use the and • Mounting DIN rail (DIN 43880)

buttons to select the

required option.

5.1.3 Energy Measurements 1 2 3 4 5 6 • 7Sealing

8 1 2IP51

3 indoor

4 5 6 7 8 1 2 3 4 5 6 7 8

L N L N

L N • LMaterial

N Self-extinguishing

L N UL

L N

• Imported/Exported active energy 0 to 9999999.9 kWh

94 V-0

On completion of the entry procedure, hold the button to • Imported/Exported reactive energy 0 to 9999999.9 kVArh

confirm the setting. • Total active energy 0 to 9999999.9 kWh 5.9 Declaration of Conformity

• Total reactive energy 0 to

L19999999.9 kVArh L1 L1

We, Smart Process & Control LTD, declare under our sole L2

L2

responsibility as the manufacturer that the poly phase

L3 meter “SMARTRAIL X835-MID”

multifunction electrical energy L3

5.2 Measured Inputs N correspond to the production model described in the EC-type N

examination certificate and to the requirements of the Directive

Voltage inputs through 4-way fixed connector with 2.5mm²

2004/22/EC EC type examination certificate number 0120/

stranded wire capacity. Single Phase Two Wire (1P2W), Three

SGS0150. Identifcation number of the NB 0120.

Phase Three Wire (3P3W) or Three Phase Four Wire (3P4W)

unbalanced. Line frequency measured from L1 Voltage

or L3 Voltage. Three current inputs (six physical terminals) with

2.5mm² stranded wire capacity for connection of external CTs.

Nominal rated input current 5A or 1A AC RMS.

Smart Process & Control LTD

01268 773 422 | www.smartprocess.co.uk | Specifications are subject to change without notice

You might also like

- Austin Cars From 1932Document103 pagesAustin Cars From 1932Chris ThorleyNo ratings yet

- ATLAS COPCO New - Troubleshooting - GuideDocument245 pagesATLAS COPCO New - Troubleshooting - GuideBruce Li100% (11)

- Elite 100 & 300 - Technical Reference Manual - (Secure) - BGX701-234-R01Document60 pagesElite 100 & 300 - Technical Reference Manual - (Secure) - BGX701-234-R01Anggara Kusuma75% (20)

- Antenna DvorDocument27 pagesAntenna DvorRhonny AlbertoNo ratings yet

- KP308.V1.0 Controller Operation Manual 2nd VersionDocument28 pagesKP308.V1.0 Controller Operation Manual 2nd Versiontonielhage100% (7)

- Elite 100 and 300 QIG - Secure - BGX701-208-R01 - Curved PDFDocument2 pagesElite 100 and 300 QIG - Secure - BGX701-208-R01 - Curved PDFAnggara Kusuma0% (1)

- Eastron SDM630MCT-Lora Series User Manual V1Document2 pagesEastron SDM630MCT-Lora Series User Manual V1Luiz Fernando AlvesNo ratings yet

- Eastron SDM630MCT-RJ User-Manual 2020Document2 pagesEastron SDM630MCT-RJ User-Manual 2020Marco Lo GueNo ratings yet

- 409 M Quick User GuideDocument2 pages409 M Quick User GuidePuneet BachalNo ratings yet

- Man 000008Document2 pagesMan 000008Angelo CotradoNo ratings yet

- Hfem 3400ctcom MTDocument24 pagesHfem 3400ctcom MTAnonymous yugocxnNo ratings yet

- Operation and PC and APP Instruction For Digital Control Constant Voltage Constant Current Power Supply Without Power PartDocument17 pagesOperation and PC and APP Instruction For Digital Control Constant Voltage Constant Current Power Supply Without Power PartCONG TRAN NGOCNo ratings yet

- DC30D Configuration and Instructions Ver1.0Document8 pagesDC30D Configuration and Instructions Ver1.0JaimeCoello100% (2)

- Network Analyser Network Analyser: MPR60S / MPR60S-MPR60S / MPR60SDocument4 pagesNetwork Analyser Network Analyser: MPR60S / MPR60S-MPR60S / MPR60SSarmad KhanNo ratings yet

- SLC Cube 3+: User'S ManualDocument16 pagesSLC Cube 3+: User'S ManualJose CaceresNo ratings yet

- 116 UserDocument4 pages116 UserWinston diaz valeraNo ratings yet

- Eaton-IQ200X-Electronic Power Meter-User Manual-EN-USDocument2 pagesEaton-IQ200X-Electronic Power Meter-User Manual-EN-USAlan leví TeleguarioNo ratings yet

- 116 UserDocument4 pages116 UserMohamed Yahya100% (1)

- 7SR224 - Argus Technical Manual Chapter 2 Settings App 2 R4 3Document134 pages7SR224 - Argus Technical Manual Chapter 2 Settings App 2 R4 3Gerald GribelNo ratings yet

- Distance/force: Series Touch Screen Quick Start User'S GuideDocument2 pagesDistance/force: Series Touch Screen Quick Start User'S GuideanthonyMNo ratings yet

- Eastron SDM630MCT V2 User Manual 2016 V4.8Document26 pagesEastron SDM630MCT V2 User Manual 2016 V4.8Asif KhanNo ratings yet

- Toubleshoot FR-E700Document5 pagesToubleshoot FR-E700SilentXNo ratings yet

- Numerical Residual Voltage - Neutral Displacement RelayDocument4 pagesNumerical Residual Voltage - Neutral Displacement RelaySumit SinghNo ratings yet

- Ats-Plc Manual SDocument58 pagesAts-Plc Manual SOrlando VeladoNo ratings yet

- Connections, Displays and Operating Elements: G F MN HDocument10 pagesConnections, Displays and Operating Elements: G F MN HdogasanchesNo ratings yet

- Altistart 48 - Руководство по программированию - ENGDocument41 pagesAltistart 48 - Руководство по программированию - ENGZhiger Fox SaurambayevNo ratings yet

- DSP-10 ManualDocument2 pagesDSP-10 ManualIvan EspinosaNo ratings yet

- Guide 100 412 175 2000xea Quick Start Rev 05 en 5283264Document2 pagesGuide 100 412 175 2000xea Quick Start Rev 05 en 5283264martin JeongNo ratings yet

- GW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualDocument18 pagesGW621/GW626/GW631/GW636 Multifunctional Pulse Meter Instruction ManualSlobodan NocajNo ratings yet

- DataKom 409 - INSTEDocument7 pagesDataKom 409 - INSTEKhaleel KhanNo ratings yet

- Ninglu NMEA Simulator PDFDocument17 pagesNinglu NMEA Simulator PDFtariktunadNo ratings yet

- PM135 Quick Start Manual: Win A Tablet!Document4 pagesPM135 Quick Start Manual: Win A Tablet!Vũ MinhNo ratings yet

- Power MeterDocument23 pagesPower MeterDaniel WongNo ratings yet

- Elmeasure Accl Accl300 Programming GuideDocument2 pagesElmeasure Accl Accl300 Programming GuideaymaanfkNo ratings yet

- Flow ControllerDocument2 pagesFlow ControlleraniketNo ratings yet

- Elmeasure Multifunction Meter Multifunctionlcd Programming GuideDocument2 pagesElmeasure Multifunction Meter Multifunctionlcd Programming GuideP.p. Arul IlancheeranNo ratings yet

- DPS300Document2 pagesDPS300RicardoNo ratings yet

- HP 4155a GuideDocument18 pagesHP 4155a Guide전자전기컴퓨터공학과/조정익No ratings yet

- UT94 - Quick - User - Guide Masibus IsolatorDocument2 pagesUT94 - Quick - User - Guide Masibus IsolatorShigilNo ratings yet

- MPR63 A2925 Rev6 v1.78 EngDocument4 pagesMPR63 A2925 Rev6 v1.78 EngEsat SÖNMEZNo ratings yet

- Epm 4ac enDocument2 pagesEpm 4ac enFarrukh MajeedNo ratings yet

- Electronic Digital Thermometer With Maximum / Minimum Temperature LogDocument2 pagesElectronic Digital Thermometer With Maximum / Minimum Temperature LogHoàngViệtAnhNo ratings yet

- PM135 QuickstartDocument4 pagesPM135 QuickstartNguyen Danh HuyNo ratings yet

- JT DPS5015 ManualDocument8 pagesJT DPS5015 ManualLuis CansinoNo ratings yet

- DPS5015-Digital Control Power Supply Instruction 1217Document6 pagesDPS5015-Digital Control Power Supply Instruction 1217Giordano De StefanisNo ratings yet

- Transformer Turn Ratio Test SetDocument15 pagesTransformer Turn Ratio Test SetYoussef EzatNo ratings yet

- Programming Guide - Power Factor Conroller: 1. FeaturesDocument5 pagesProgramming Guide - Power Factor Conroller: 1. Featureskhan leNo ratings yet

- TensionRite® Belt Frequency MeterDocument31 pagesTensionRite® Belt Frequency MeterWilson Muñoz ArayaNo ratings yet

- CM3022 How To Set UpDocument4 pagesCM3022 How To Set UptasneemengsolNo ratings yet

- EL Meaure MeterDocument40 pagesEL Meaure MeterRangasamyNo ratings yet

- SDM630MV CT Modbus Manual - GoodMeasure StoreDocument21 pagesSDM630MV CT Modbus Manual - GoodMeasure StoreKunanon JaitrongNo ratings yet

- Network Analyser Network Analyser: MPR63-MPR63Document4 pagesNetwork Analyser Network Analyser: MPR63-MPR63Anonymous X0NBULtOqdNo ratings yet

- 6000/8000 Platform Quick Card Optical Spectrum Analysis With The Osa: Alarms Set UpDocument2 pages6000/8000 Platform Quick Card Optical Spectrum Analysis With The Osa: Alarms Set UpGaurav SainiNo ratings yet

- Operating Manual Eine+ DC DPM 48x96 Rev GDocument26 pagesOperating Manual Eine+ DC DPM 48x96 Rev GVAJIRAVEL NAGALINGAMNo ratings yet

- Evario Instructions 1.0Document6 pagesEvario Instructions 1.0simonwood003No ratings yet

- Manual Dixell x120Document4 pagesManual Dixell x120Alejandro AlomotoNo ratings yet

- PQM-702 - 703 - 710 - 711 QuickStart v1.01 ENDocument2 pagesPQM-702 - 703 - 710 - 711 QuickStart v1.01 ENtaufiq nurNo ratings yet

- Manual Eocr 3ezDocument5 pagesManual Eocr 3ezsunilatiipm100% (1)

- Man Dro NV 20 300m OpeDocument24 pagesMan Dro NV 20 300m OpeFabianeNo ratings yet

- Manual Microprogel TC 323: KontaktinformationDocument10 pagesManual Microprogel TC 323: Kontaktinformationsyed maroof aliNo ratings yet

- Potenciometro EsteirasDocument2 pagesPotenciometro EsteirasNeri Machado CarrielNo ratings yet

- TEC System NT538 - JUN-2004Document15 pagesTEC System NT538 - JUN-2004Raul quispe quispeNo ratings yet

- User Manual Achook-1080, G726A, UM0084 - LatestDocument24 pagesUser Manual Achook-1080, G726A, UM0084 - Latestprajith555No ratings yet

- SMARTRAIL X835 Protocol: WWW - Smartprocess.co - UkDocument14 pagesSMARTRAIL X835 Protocol: WWW - Smartprocess.co - UkAnggara KusumaNo ratings yet

- IEEE 754 ConverterDocument2 pagesIEEE 754 ConverterAnggara KusumaNo ratings yet

- TC3 Modbus RTU: ManualDocument36 pagesTC3 Modbus RTU: ManualAnggara KusumaNo ratings yet

- Mk6N Factsheet EnglishDocument2 pagesMk6N Factsheet EnglishAlfia RochmanNo ratings yet

- Introducing Sepam - R1Document51 pagesIntroducing Sepam - R1Anggara KusumaNo ratings yet

- Nonlinear Curve Fitting: "Why Fit in When You Were Born To Stand Out?" - Dr. SeussDocument65 pagesNonlinear Curve Fitting: "Why Fit in When You Were Born To Stand Out?" - Dr. Seussomarkhaled200321No ratings yet

- Balancing Chemical Equations HTML Guide - enDocument2 pagesBalancing Chemical Equations HTML Guide - enMiguel ApazaNo ratings yet

- HVAC FundamentalDocument192 pagesHVAC FundamentalMyo Kyaw Kyaw100% (1)

- Fujitsu VRF Seria V, Manual TehnicDocument477 pagesFujitsu VRF Seria V, Manual TehnicOnutu Lohengrin100% (2)

- Yaskawa Academy 2016 EDocument56 pagesYaskawa Academy 2016 Ejmorenoh103100% (1)

- Connections and SchemaDocument7 pagesConnections and SchemaKukuh WidodoNo ratings yet

- DIY Smart Phone Microscope Biology Performance TaskDocument3 pagesDIY Smart Phone Microscope Biology Performance TaskArvie QuijanoNo ratings yet

- Efficientfi: Towards Large-Scale Lightweight Wifi Sensing Via Csi CompressionDocument10 pagesEfficientfi: Towards Large-Scale Lightweight Wifi Sensing Via Csi CompressionJohnNo ratings yet

- Hero Project Kedar BBADocument49 pagesHero Project Kedar BBAVinod HeggannaNo ratings yet

- EnglishDocument76 pagesEnglishTak ProNo ratings yet

- Animals by Walt WhitmanDocument2 pagesAnimals by Walt Whitmanyashna gadiaNo ratings yet

- BB SESSION - ME132P Lecture 3A LINKAGESDocument32 pagesBB SESSION - ME132P Lecture 3A LINKAGESkris garciaNo ratings yet

- ANTARA Mobile Phone Portal (Angl. Qzyk)Document27 pagesANTARA Mobile Phone Portal (Angl. Qzyk)Shekina_YanaNo ratings yet

- MSL Clutch & P P 1-2-13Document3 pagesMSL Clutch & P P 1-2-13Abhishek SinghNo ratings yet

- RRL DamsDocument7 pagesRRL DamsJamesNo ratings yet

- Aegis Basics of MES WhitepaperDocument19 pagesAegis Basics of MES Whitepaperg_325899365100% (1)

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- Makati City Ordinance No. 2003-095Document12 pagesMakati City Ordinance No. 2003-095KNo ratings yet

- WS01 Slopes Samantha SarahDocument7 pagesWS01 Slopes Samantha SarahSAMANTHA SARAH PURBANo ratings yet

- Flame Tests and Atomic SpectraDocument3 pagesFlame Tests and Atomic SpectraImmanuel LashleyNo ratings yet

- Design, Fabrication & Testing of A Vertical Axis Wind Turbine With Wind de EctorsDocument61 pagesDesign, Fabrication & Testing of A Vertical Axis Wind Turbine With Wind de EctorsGautham NNo ratings yet

- Technical Rider Alcatraz Sound-Light Requirements PDFDocument3 pagesTechnical Rider Alcatraz Sound-Light Requirements PDFvijesh sutharNo ratings yet

- Will and Going To WSDocument3 pagesWill and Going To WSKatia Belen CARDENAS ROJASNo ratings yet

- Clinical MedicineDocument18 pagesClinical MedicineRishikesh AsthanaNo ratings yet

- Coolmay HMI User ManualDocument2 pagesCoolmay HMI User Manualspotlight studiosNo ratings yet

- 121: Buckwell Farm, Usk, Monmouthshire. Desk Based AssessmentDocument20 pages121: Buckwell Farm, Usk, Monmouthshire. Desk Based AssessmentAPAC LtdNo ratings yet

- Daewoo Doosan Forklift g420f Fe LP Engine Service ManualDocument23 pagesDaewoo Doosan Forklift g420f Fe LP Engine Service Manualjerryroberts051291ixe100% (29)

- The Three Types of Rocks!: Learning ObjectivesDocument2 pagesThe Three Types of Rocks!: Learning ObjectivesJekim Novo LumbaNo ratings yet