Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

71 viewsAttachment1 - Vav Quality Procedures: Vavline

Attachment1 - Vav Quality Procedures: Vavline

Uploaded by

lupi1) The document lists 32 quality procedures for various phases of an associated gas gathering project, including procedures for quality control, supplier pre-qualification, material handling, fabrication, calibration of equipment, non-conformances, management reviews, and commissioning.

2) The procedures provide guidance on training, document control, procurement, inspections, material issues, welding, painting, hydrotesting, and ensuring conformance to standards.

3) Following these procedures helps ensure quality delivery of the project in terms of schedule and cost.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Communication Procedure: Prepared By: AHR Manager Reviewed By: Top Approved By: Top Date Issued For UseDocument3 pagesCommunication Procedure: Prepared By: AHR Manager Reviewed By: Top Approved By: Top Date Issued For Uselupi100% (6)

- Dimensional Control ProcedureDocument22 pagesDimensional Control Proceduresilitonga3388100% (3)

- Attachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedDocument3 pagesAttachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedlupiNo ratings yet

- GAS-QCP-CIV-001 Excavation & Backfilling FoundationDocument10 pagesGAS-QCP-CIV-001 Excavation & Backfilling FoundationRafeeq Ur RahmanNo ratings yet

- NFS-DHA-E-TC-05 - Testing of Earthing and LPSDocument25 pagesNFS-DHA-E-TC-05 - Testing of Earthing and LPSirshadNo ratings yet

- MS For MV Cable Pulling ProcedureDocument10 pagesMS For MV Cable Pulling Procedurekbldam100% (2)

- Ms For MV Cable Pulling ProcedureDocument11 pagesMs For MV Cable Pulling ProcedureFaris Abandeh100% (1)

- SOP SRC QC 03 - QC Inspection ProcedureDocument9 pagesSOP SRC QC 03 - QC Inspection ProcedureDHANEESH VELLILAPULLINo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Project MGMNT FuctionsDocument3 pagesProject MGMNT FuctionsmorpheusneoNo ratings yet

- QCP Installation of Ahu FahuDocument7 pagesQCP Installation of Ahu FahuThulani DlaminiNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Practical Guidelines For Qualifying Purified Vvjater SystemsDocument6 pagesPractical Guidelines For Qualifying Purified Vvjater SystemsMiguel Egas LoorNo ratings yet

- NSH-SAOMPP-CMS-PI-004-tie in WorksDocument11 pagesNSH-SAOMPP-CMS-PI-004-tie in WorksNeil JavierNo ratings yet

- E201 1005 Valve ServicesDocument12 pagesE201 1005 Valve ServicesSouljah KhifferNo ratings yet

- PM Project Quality Plan 8-7-2012Document27 pagesPM Project Quality Plan 8-7-2012XozanNo ratings yet

- Project Inspection and Test Plan (Clamp)Document12 pagesProject Inspection and Test Plan (Clamp)Mohd KhaidirNo ratings yet

- Method Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQDocument13 pagesMethod Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQAzree Mohd Noor100% (3)

- Method Statement Procedure: Revision LogDocument20 pagesMethod Statement Procedure: Revision LogJoyce GordonioNo ratings yet

- Commissioning Vs Testing - Designing BuildingsDocument4 pagesCommissioning Vs Testing - Designing BuildingsharoldwilsonfranciscoNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- 1.MS Start Up & Comm of Fuel Oil PumpDocument11 pages1.MS Start Up & Comm of Fuel Oil Pump721917114 47No ratings yet

- Inspection and Test Personnel Qualification ProcedureDocument9 pagesInspection and Test Personnel Qualification ProcedureDindo QuintanNo ratings yet

- 4.3.2 Example - Assure Quality, v1.0.1Document1 page4.3.2 Example - Assure Quality, v1.0.1bakbakNo ratings yet

- 1.MS HVAC Ducts and Accessories (26 11 2011)Document12 pages1.MS HVAC Ducts and Accessories (26 11 2011)721917114 47No ratings yet

- Used Water SES 7 Testing 12feb2016Document9 pagesUsed Water SES 7 Testing 12feb2016Mark BenjieNo ratings yet

- Equipment Installation ProcedureDocument15 pagesEquipment Installation ProcedureMOHAMEDNo ratings yet

- HSBSBDDocument97 pagesHSBSBDAnonymous uTmCat2QRNo ratings yet

- Panama Renewable Energy PVT LTD: Standard Operating ProcedureDocument3 pagesPanama Renewable Energy PVT LTD: Standard Operating ProcedureAradhya SinghNo ratings yet

- KON 8.2 QA PRO 0024 C1 Certification ProcedureDocument8 pagesKON 8.2 QA PRO 0024 C1 Certification ProcedureAlizamin SalmanovNo ratings yet

- Inspection Testing and Coordination Procedure - CMEDocument15 pagesInspection Testing and Coordination Procedure - CMEsanujNo ratings yet

- Kantas International Nigeria Limited: Generic Hydrotesting ProcedureDocument7 pagesKantas International Nigeria Limited: Generic Hydrotesting ProcedureGbenga MoboladeNo ratings yet

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

- Request For Ready Mix ConcreteDocument6 pagesRequest For Ready Mix Concretesarsan nedumkuzhiNo ratings yet

- ADP-263623-007 R0 Generator Synchronizing PanelsDocument23 pagesADP-263623-007 R0 Generator Synchronizing Panelssaithu09janNo ratings yet

- Testing OperationalDocument13 pagesTesting OperationalPuneet AroraNo ratings yet

- Test Plan Template 20Document15 pagesTest Plan Template 20Nicholas SandersNo ratings yet

- Form o - Quality AssuranceDocument93 pagesForm o - Quality AssuranceonutocsNo ratings yet

- 017-W005-2667 - ITP - PDA Test Rev C0Document3 pages017-W005-2667 - ITP - PDA Test Rev C0Mohammad Hadoumi SaldanNo ratings yet

- Work Instruction For Hydrostatic TestingDocument18 pagesWork Instruction For Hydrostatic TestingAlok SinghNo ratings yet

- 01 Method Statement For Pile Cap Foundations FindalDocument8 pages01 Method Statement For Pile Cap Foundations FindalazwanNo ratings yet

- M.S For Hydro TestDocument16 pagesM.S For Hydro TestjahaanNo ratings yet

- Attachment 13 - Handover ProcedureDocument24 pagesAttachment 13 - Handover ProcedureHayder JNo ratings yet

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (2)

- Qa-Qc PlanDocument16 pagesQa-Qc PlanPEng. Tech. Alvince Korero100% (1)

- 7665-Mos-0002-000 MechDocument28 pages7665-Mos-0002-000 MechRuel BuntogNo ratings yet

- 1.MS Fcu (07.7.2011)Document9 pages1.MS Fcu (07.7.2011)721917114 47No ratings yet

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- Quality Requirements For Sub ContractorDocument103 pagesQuality Requirements For Sub ContractorMohammed100% (1)

- QCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedDocument11 pagesQCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedRAMAKRISHNANo ratings yet

- Project Handoff ChecklistDocument3 pagesProject Handoff ChecklistJosé David Martínez CárcamoNo ratings yet

- 11 - Method of Statement For Stub Angle InstallationDocument10 pages11 - Method of Statement For Stub Angle InstallationiloveumakkahNo ratings yet

- W190-600-002 (1.1)Document76 pagesW190-600-002 (1.1)abidmehmod118No ratings yet

- PM High Rise Building ScheduleDocument27 pagesPM High Rise Building ScheduleXozanNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Site Visit ChecklistDocument2 pagesSite Visit ChecklistlupiNo ratings yet

- Deck Space Request Form-MainDocument1 pageDeck Space Request Form-MainlupiNo ratings yet

- Flange Weight Charts Asme B16.5Document7 pagesFlange Weight Charts Asme B16.5lupiNo ratings yet

- WHS 2016 Working at Heights SWMSDocument14 pagesWHS 2016 Working at Heights SWMSlupiNo ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- Safety Data SheetDocument12 pagesSafety Data SheetlupiNo ratings yet

- VAV Manpower HistogramDocument1 pageVAV Manpower HistogramlupiNo ratings yet

- Attachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedDocument3 pagesAttachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedlupiNo ratings yet

- VAVLINE-Vessel Intervention-IRM Method StatementDocument18 pagesVAVLINE-Vessel Intervention-IRM Method StatementlupiNo ratings yet

- Excel Practice - ExcelRDocument150 pagesExcel Practice - ExcelRNihal JadhavNo ratings yet

- Work Measurement For Process Improvement in The Car Seat Polyurethane Injection Manufacturing LineDocument2 pagesWork Measurement For Process Improvement in The Car Seat Polyurethane Injection Manufacturing LineAli abbasNo ratings yet

- Final Draft Terms of Reference NewDocument14 pagesFinal Draft Terms of Reference NewIES-GATEWizNo ratings yet

- Business Plan 2Document9 pagesBusiness Plan 2KhaiiiNo ratings yet

- Chapter - Strategy Implementation MCQDocument11 pagesChapter - Strategy Implementation MCQgamergeeeNo ratings yet

- Bac+Reso+No +20+series+of+2017Document2 pagesBac+Reso+No +20+series+of+2017Vee VirayNo ratings yet

- PAPER AKUNTANSI BIAYA - Nathaniel Christianto Gosti (2111061)Document9 pagesPAPER AKUNTANSI BIAYA - Nathaniel Christianto Gosti (2111061)Geraldo AlexisNo ratings yet

- Chrome Daily Report On 29 December, 2021Document8 pagesChrome Daily Report On 29 December, 2021Kanishka DharNo ratings yet

- The Lore Talent Management Maturity ModelDocument5 pagesThe Lore Talent Management Maturity ModelabhishekforeanandNo ratings yet

- 1st Sem 2021-BPOPS Accomplishment ReportDocument29 pages1st Sem 2021-BPOPS Accomplishment ReportBarangay PoblacionNo ratings yet

- CA Chap 4Document13 pagesCA Chap 4massoud ahadiNo ratings yet

- Q2 Applied Econ M2Document4 pagesQ2 Applied Econ M2christine abilaNo ratings yet

- Understanding Quality - H01Document4 pagesUnderstanding Quality - H01Yhanne BlancoNo ratings yet

- C6 - Sales and Operations Planning - Capacity Planning and Aggregate Production Planning RSVDocument74 pagesC6 - Sales and Operations Planning - Capacity Planning and Aggregate Production Planning RSVphuckhang33203No ratings yet

- EM2301. Practical Class 5.2Document5 pagesEM2301. Practical Class 5.2luu duongNo ratings yet

- Case Studies 1Document4 pagesCase Studies 1Anse RoythomasNo ratings yet

- Organizing Function of ManagementDocument4 pagesOrganizing Function of Managementrinky_trivedi100% (1)

- Partnership Accounts QnADocument30 pagesPartnership Accounts QnARakesh JaiswalNo ratings yet

- FIDIC and The Standard Form ContractsDocument108 pagesFIDIC and The Standard Form Contractsstormwater.selmyNo ratings yet

- RJR-581 Web Notice Tender No.28-2022-To-33-2022Document2 pagesRJR-581 Web Notice Tender No.28-2022-To-33-2022ABCDNo ratings yet

- Chapter 5Document7 pagesChapter 5ERICKA MAE NATONo ratings yet

- Jekyll and HydeDocument3 pagesJekyll and HydeSIMON BUSISANo ratings yet

- 2020 Innovation Report InsightsDocument30 pages2020 Innovation Report InsightsjaneNo ratings yet

- Schroders Announces New Leadership in Asia Pacific: News ReleaseDocument3 pagesSchroders Announces New Leadership in Asia Pacific: News ReleaseLaura ParkaNo ratings yet

- WEEK 3 Models and Frameworks For Total Quality ManagementDocument14 pagesWEEK 3 Models and Frameworks For Total Quality Managementuser 123No ratings yet

- Strategi Pemasaran Benih Padi Pada UD Tani Sejati Di Kecamatan Blahbatuh Kabupaten GianyarDocument10 pagesStrategi Pemasaran Benih Padi Pada UD Tani Sejati Di Kecamatan Blahbatuh Kabupaten GianyarAnastasya EmbongbulanNo ratings yet

- cp146 Trustees Powers and Duties Consultation PDFDocument192 pagescp146 Trustees Powers and Duties Consultation PDFAkhomioto OsarodionNo ratings yet

- Unbelievable Business Strategy Notes by BARDDocument12 pagesUnbelievable Business Strategy Notes by BARDkeremNo ratings yet

- Period End Processing - Summary The Following Outlines:: PayablesDocument3 pagesPeriod End Processing - Summary The Following Outlines:: Payablesbritesprite2000No ratings yet

- Total Productive Maintenance by Ankur KumarDocument25 pagesTotal Productive Maintenance by Ankur Kumarsembalap29No ratings yet

Attachment1 - Vav Quality Procedures: Vavline

Attachment1 - Vav Quality Procedures: Vavline

Uploaded by

lupi0 ratings0% found this document useful (0 votes)

71 views3 pages1) The document lists 32 quality procedures for various phases of an associated gas gathering project, including procedures for quality control, supplier pre-qualification, material handling, fabrication, calibration of equipment, non-conformances, management reviews, and commissioning.

2) The procedures provide guidance on training, document control, procurement, inspections, material issues, welding, painting, hydrotesting, and ensuring conformance to standards.

3) Following these procedures helps ensure quality delivery of the project in terms of schedule and cost.

Original Description:

Original Title

VAV QMS Procedure

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document lists 32 quality procedures for various phases of an associated gas gathering project, including procedures for quality control, supplier pre-qualification, material handling, fabrication, calibration of equipment, non-conformances, management reviews, and commissioning.

2) The procedures provide guidance on training, document control, procurement, inspections, material issues, welding, painting, hydrotesting, and ensuring conformance to standards.

3) Following these procedures helps ensure quality delivery of the project in terms of schedule and cost.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

71 views3 pagesAttachment1 - Vav Quality Procedures: Vavline

Attachment1 - Vav Quality Procedures: Vavline

Uploaded by

lupi1) The document lists 32 quality procedures for various phases of an associated gas gathering project, including procedures for quality control, supplier pre-qualification, material handling, fabrication, calibration of equipment, non-conformances, management reviews, and commissioning.

2) The procedures provide guidance on training, document control, procurement, inspections, material issues, welding, painting, hydrotesting, and ensuring conformance to standards.

3) Following these procedures helps ensure quality delivery of the project in terms of schedule and cost.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

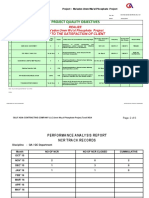

DOC.

NO VAV/SOP/016

VAVLINE REVISED 01/10/2020 REV. NO 01

ISSUED 26/09/2020

PROJECT TITLE: OPERATIONS AND MAINTENANCE OF ASSOCIATED GAS GATHERING

DOCUMENT TITLE: QUALITY PROCEDURE

ATTACHME NT 1 – VAV QUALITY PROCE DURE S

The following table lists some relevant procedures:

Procedures Reference Objective Phase Application

in project

1 CONTROL & ISSUANCE OF QMS VAV/QMS/002 For Control of Key Engineering

MANUAL & PROCEDURES project management

2 QA/QC TRAINING & VAV /QMS/003 For QAQC training Engineering

QUALIFICATION guidance

3 DRAWING CONTROL VAV /QMS/004 To control the Use of All project phases

Drawings for the

project

4 PRE-QUALIFICATION OF VAV /QMS/005 For selection of Before project

SUPPLIERS Suppliers commencement

5 PROCUREMENT CONTROL VAV /QMS/006 For control during During

procurement activities procurement

for the project phase of the

project

6 RECEIVING, INSPECTION & VAV /QMS/007 For control and All project phases

STORAGE assurance of procured

materials for the project

to ensured they are in

compliance with

specification and

standards and MTO

7 MATERIAL ISSUE CONTROL VAV /QMS/008 For control of materials During workshop

released for the project prefabrication and

site installation

phase of the

project.

8 FABRICATION & PROCESS VAV /QMS/009 For control of all During Site

CONTROL (PAINTING, fabrication and process installation and

WORKSHOP PREFABRICATION, related activities workshop

NDT, HYDROTEST, PAINTING prefabrication

PROCEDURES, ITP, WPS AND phase of the

PQR ETC) project.

10 CALIBRATION & CONTROL OF VAV /QMS/011 For control of During all phase

MEASURING & TEST calibration of of the project and

EQUIPMENT measuring, sensing and at six months

test equipment to be interval after first

DOC. NO VAV/SOP/016

VAVLINE REVISED 01/10/2020 REV. NO 01

ISSUED 26/09/2020

PROJECT TITLE: OPERATIONS AND MAINTENANCE OF ASSOCIATED GAS GATHERING

use

DOCUMENT TITLE: QUALITY PROCEDURE of

deployed for the project every sensing or

measuring

equipment in the

project

11 FIELD CHANGE REQUEST VAV /QMS/012 For control and Engineering, Site

implementation of works and As-

requests and variations Built

from the main project

scope.

13 DOCUMENT CONTROL & VAV /QMS/014 For control of use of All Phase of the

RECORDS the entire project project

generated documents,

records and drawings

by individuals and

parties involved in the

project

17 NON-CONFORMANCES VAV /QMS/018 For Quality Assurance All PHASEs of

and Control throughout the project

the project life

21 MANAGEMENT REVIEWS VAV/QMS/022 For key managerial All phase of the

decision as regards the project

project execution and

performance

25 PROJECT QUALITY PLAN VAV /QMS/026 To set out the standards All phase of the

to be implemented project

throughout the project

life for a quality

delivery in terms of

schedule and cost

26 PROJECT EXECUTION PLAN VAV/QMS/027 To set out the various All phase of the

plans from the project project

management

department that will be

incidental to a timely

and successful

execution of the project

28 COMMISSIONING PROCEDURE VAV /QMS/029 To serve as a To be hugely

complimentary implemented

document to all during the

applicable total GS for commissioning

DOC. NO VAV/SOP/016

VAVLINE REVISED 01/10/2020 REV. NO 01

ISSUED 26/09/2020

PROJECT TITLE: OPERATIONS AND MAINTENANCE OF ASSOCIATED GAS GATHERING

DOCUMENT TITLE: QUALITY PROCEDURE

commissioning phase of the

project.

29 WELDING INSPECTION TEST VAV/QMS/030 To ensure conformance Before and after

PLAN to standard welding

30 PAINTING INSPECTION TEST VAV/QMS/031 To ensure conformance Before and after

PLAN to standard painting

31 HYDROTEST PLAN VAV/QMS/032 To serve as a plan During hydrotest

during hydrotest

32 WELDING PROCEDURE VAV/QMS/031 To ensure welding is During shop and

carried out according to field welding

approved WPS. phases

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Communication Procedure: Prepared By: AHR Manager Reviewed By: Top Approved By: Top Date Issued For UseDocument3 pagesCommunication Procedure: Prepared By: AHR Manager Reviewed By: Top Approved By: Top Date Issued For Uselupi100% (6)

- Dimensional Control ProcedureDocument22 pagesDimensional Control Proceduresilitonga3388100% (3)

- Attachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedDocument3 pagesAttachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedlupiNo ratings yet

- GAS-QCP-CIV-001 Excavation & Backfilling FoundationDocument10 pagesGAS-QCP-CIV-001 Excavation & Backfilling FoundationRafeeq Ur RahmanNo ratings yet

- NFS-DHA-E-TC-05 - Testing of Earthing and LPSDocument25 pagesNFS-DHA-E-TC-05 - Testing of Earthing and LPSirshadNo ratings yet

- MS For MV Cable Pulling ProcedureDocument10 pagesMS For MV Cable Pulling Procedurekbldam100% (2)

- Ms For MV Cable Pulling ProcedureDocument11 pagesMs For MV Cable Pulling ProcedureFaris Abandeh100% (1)

- SOP SRC QC 03 - QC Inspection ProcedureDocument9 pagesSOP SRC QC 03 - QC Inspection ProcedureDHANEESH VELLILAPULLINo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Project MGMNT FuctionsDocument3 pagesProject MGMNT FuctionsmorpheusneoNo ratings yet

- QCP Installation of Ahu FahuDocument7 pagesQCP Installation of Ahu FahuThulani DlaminiNo ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Practical Guidelines For Qualifying Purified Vvjater SystemsDocument6 pagesPractical Guidelines For Qualifying Purified Vvjater SystemsMiguel Egas LoorNo ratings yet

- NSH-SAOMPP-CMS-PI-004-tie in WorksDocument11 pagesNSH-SAOMPP-CMS-PI-004-tie in WorksNeil JavierNo ratings yet

- E201 1005 Valve ServicesDocument12 pagesE201 1005 Valve ServicesSouljah KhifferNo ratings yet

- PM Project Quality Plan 8-7-2012Document27 pagesPM Project Quality Plan 8-7-2012XozanNo ratings yet

- Project Inspection and Test Plan (Clamp)Document12 pagesProject Inspection and Test Plan (Clamp)Mohd KhaidirNo ratings yet

- Method Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQDocument13 pagesMethod Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQAzree Mohd Noor100% (3)

- Method Statement Procedure: Revision LogDocument20 pagesMethod Statement Procedure: Revision LogJoyce GordonioNo ratings yet

- Commissioning Vs Testing - Designing BuildingsDocument4 pagesCommissioning Vs Testing - Designing BuildingsharoldwilsonfranciscoNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Management System Manual: Title Doc. No. ProcessDocument2 pagesManagement System Manual: Title Doc. No. ProcessZina CabreraNo ratings yet

- 1.MS Start Up & Comm of Fuel Oil PumpDocument11 pages1.MS Start Up & Comm of Fuel Oil Pump721917114 47No ratings yet

- Inspection and Test Personnel Qualification ProcedureDocument9 pagesInspection and Test Personnel Qualification ProcedureDindo QuintanNo ratings yet

- 4.3.2 Example - Assure Quality, v1.0.1Document1 page4.3.2 Example - Assure Quality, v1.0.1bakbakNo ratings yet

- 1.MS HVAC Ducts and Accessories (26 11 2011)Document12 pages1.MS HVAC Ducts and Accessories (26 11 2011)721917114 47No ratings yet

- Used Water SES 7 Testing 12feb2016Document9 pagesUsed Water SES 7 Testing 12feb2016Mark BenjieNo ratings yet

- Equipment Installation ProcedureDocument15 pagesEquipment Installation ProcedureMOHAMEDNo ratings yet

- HSBSBDDocument97 pagesHSBSBDAnonymous uTmCat2QRNo ratings yet

- Panama Renewable Energy PVT LTD: Standard Operating ProcedureDocument3 pagesPanama Renewable Energy PVT LTD: Standard Operating ProcedureAradhya SinghNo ratings yet

- KON 8.2 QA PRO 0024 C1 Certification ProcedureDocument8 pagesKON 8.2 QA PRO 0024 C1 Certification ProcedureAlizamin SalmanovNo ratings yet

- Inspection Testing and Coordination Procedure - CMEDocument15 pagesInspection Testing and Coordination Procedure - CMEsanujNo ratings yet

- Kantas International Nigeria Limited: Generic Hydrotesting ProcedureDocument7 pagesKantas International Nigeria Limited: Generic Hydrotesting ProcedureGbenga MoboladeNo ratings yet

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

- Request For Ready Mix ConcreteDocument6 pagesRequest For Ready Mix Concretesarsan nedumkuzhiNo ratings yet

- ADP-263623-007 R0 Generator Synchronizing PanelsDocument23 pagesADP-263623-007 R0 Generator Synchronizing Panelssaithu09janNo ratings yet

- Testing OperationalDocument13 pagesTesting OperationalPuneet AroraNo ratings yet

- Test Plan Template 20Document15 pagesTest Plan Template 20Nicholas SandersNo ratings yet

- Form o - Quality AssuranceDocument93 pagesForm o - Quality AssuranceonutocsNo ratings yet

- 017-W005-2667 - ITP - PDA Test Rev C0Document3 pages017-W005-2667 - ITP - PDA Test Rev C0Mohammad Hadoumi SaldanNo ratings yet

- Work Instruction For Hydrostatic TestingDocument18 pagesWork Instruction For Hydrostatic TestingAlok SinghNo ratings yet

- 01 Method Statement For Pile Cap Foundations FindalDocument8 pages01 Method Statement For Pile Cap Foundations FindalazwanNo ratings yet

- M.S For Hydro TestDocument16 pagesM.S For Hydro TestjahaanNo ratings yet

- Attachment 13 - Handover ProcedureDocument24 pagesAttachment 13 - Handover ProcedureHayder JNo ratings yet

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (2)

- Qa-Qc PlanDocument16 pagesQa-Qc PlanPEng. Tech. Alvince Korero100% (1)

- 7665-Mos-0002-000 MechDocument28 pages7665-Mos-0002-000 MechRuel BuntogNo ratings yet

- 1.MS Fcu (07.7.2011)Document9 pages1.MS Fcu (07.7.2011)721917114 47No ratings yet

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- Quality Requirements For Sub ContractorDocument103 pagesQuality Requirements For Sub ContractorMohammed100% (1)

- QCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedDocument11 pagesQCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedRAMAKRISHNANo ratings yet

- Project Handoff ChecklistDocument3 pagesProject Handoff ChecklistJosé David Martínez CárcamoNo ratings yet

- 11 - Method of Statement For Stub Angle InstallationDocument10 pages11 - Method of Statement For Stub Angle InstallationiloveumakkahNo ratings yet

- W190-600-002 (1.1)Document76 pagesW190-600-002 (1.1)abidmehmod118No ratings yet

- PM High Rise Building ScheduleDocument27 pagesPM High Rise Building ScheduleXozanNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Site Visit ChecklistDocument2 pagesSite Visit ChecklistlupiNo ratings yet

- Deck Space Request Form-MainDocument1 pageDeck Space Request Form-MainlupiNo ratings yet

- Flange Weight Charts Asme B16.5Document7 pagesFlange Weight Charts Asme B16.5lupiNo ratings yet

- WHS 2016 Working at Heights SWMSDocument14 pagesWHS 2016 Working at Heights SWMSlupiNo ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- Safety Data SheetDocument12 pagesSafety Data SheetlupiNo ratings yet

- VAV Manpower HistogramDocument1 pageVAV Manpower HistogramlupiNo ratings yet

- Attachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedDocument3 pagesAttachment1 - WNL Quality Procedures: Wilkriss Nigeria LimitedlupiNo ratings yet

- VAVLINE-Vessel Intervention-IRM Method StatementDocument18 pagesVAVLINE-Vessel Intervention-IRM Method StatementlupiNo ratings yet

- Excel Practice - ExcelRDocument150 pagesExcel Practice - ExcelRNihal JadhavNo ratings yet

- Work Measurement For Process Improvement in The Car Seat Polyurethane Injection Manufacturing LineDocument2 pagesWork Measurement For Process Improvement in The Car Seat Polyurethane Injection Manufacturing LineAli abbasNo ratings yet

- Final Draft Terms of Reference NewDocument14 pagesFinal Draft Terms of Reference NewIES-GATEWizNo ratings yet

- Business Plan 2Document9 pagesBusiness Plan 2KhaiiiNo ratings yet

- Chapter - Strategy Implementation MCQDocument11 pagesChapter - Strategy Implementation MCQgamergeeeNo ratings yet

- Bac+Reso+No +20+series+of+2017Document2 pagesBac+Reso+No +20+series+of+2017Vee VirayNo ratings yet

- PAPER AKUNTANSI BIAYA - Nathaniel Christianto Gosti (2111061)Document9 pagesPAPER AKUNTANSI BIAYA - Nathaniel Christianto Gosti (2111061)Geraldo AlexisNo ratings yet

- Chrome Daily Report On 29 December, 2021Document8 pagesChrome Daily Report On 29 December, 2021Kanishka DharNo ratings yet

- The Lore Talent Management Maturity ModelDocument5 pagesThe Lore Talent Management Maturity ModelabhishekforeanandNo ratings yet

- 1st Sem 2021-BPOPS Accomplishment ReportDocument29 pages1st Sem 2021-BPOPS Accomplishment ReportBarangay PoblacionNo ratings yet

- CA Chap 4Document13 pagesCA Chap 4massoud ahadiNo ratings yet

- Q2 Applied Econ M2Document4 pagesQ2 Applied Econ M2christine abilaNo ratings yet

- Understanding Quality - H01Document4 pagesUnderstanding Quality - H01Yhanne BlancoNo ratings yet

- C6 - Sales and Operations Planning - Capacity Planning and Aggregate Production Planning RSVDocument74 pagesC6 - Sales and Operations Planning - Capacity Planning and Aggregate Production Planning RSVphuckhang33203No ratings yet

- EM2301. Practical Class 5.2Document5 pagesEM2301. Practical Class 5.2luu duongNo ratings yet

- Case Studies 1Document4 pagesCase Studies 1Anse RoythomasNo ratings yet

- Organizing Function of ManagementDocument4 pagesOrganizing Function of Managementrinky_trivedi100% (1)

- Partnership Accounts QnADocument30 pagesPartnership Accounts QnARakesh JaiswalNo ratings yet

- FIDIC and The Standard Form ContractsDocument108 pagesFIDIC and The Standard Form Contractsstormwater.selmyNo ratings yet

- RJR-581 Web Notice Tender No.28-2022-To-33-2022Document2 pagesRJR-581 Web Notice Tender No.28-2022-To-33-2022ABCDNo ratings yet

- Chapter 5Document7 pagesChapter 5ERICKA MAE NATONo ratings yet

- Jekyll and HydeDocument3 pagesJekyll and HydeSIMON BUSISANo ratings yet

- 2020 Innovation Report InsightsDocument30 pages2020 Innovation Report InsightsjaneNo ratings yet

- Schroders Announces New Leadership in Asia Pacific: News ReleaseDocument3 pagesSchroders Announces New Leadership in Asia Pacific: News ReleaseLaura ParkaNo ratings yet

- WEEK 3 Models and Frameworks For Total Quality ManagementDocument14 pagesWEEK 3 Models and Frameworks For Total Quality Managementuser 123No ratings yet

- Strategi Pemasaran Benih Padi Pada UD Tani Sejati Di Kecamatan Blahbatuh Kabupaten GianyarDocument10 pagesStrategi Pemasaran Benih Padi Pada UD Tani Sejati Di Kecamatan Blahbatuh Kabupaten GianyarAnastasya EmbongbulanNo ratings yet

- cp146 Trustees Powers and Duties Consultation PDFDocument192 pagescp146 Trustees Powers and Duties Consultation PDFAkhomioto OsarodionNo ratings yet

- Unbelievable Business Strategy Notes by BARDDocument12 pagesUnbelievable Business Strategy Notes by BARDkeremNo ratings yet

- Period End Processing - Summary The Following Outlines:: PayablesDocument3 pagesPeriod End Processing - Summary The Following Outlines:: Payablesbritesprite2000No ratings yet

- Total Productive Maintenance by Ankur KumarDocument25 pagesTotal Productive Maintenance by Ankur Kumarsembalap29No ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)