Professional Documents

Culture Documents

BHA (m3) : Surface CP

BHA (m3) : Surface CP

Uploaded by

Laureat NgomaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHA (m3) : Surface CP

BHA (m3) : Surface CP

Uploaded by

Laureat NgomaCopyright:

Available Formats

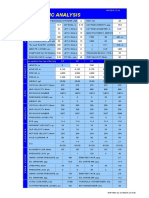

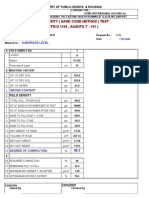

DAILY MUD REPORT 6 Date 19-Jun-2017 No.

Depth [ m ] 270

Well Name KEWB-02 Spud Date 14-Jun-2017 Interval [ in ] 12 1/4

Field / Block Kanga Country / Region Congo / Kouilou

Operator Company : MIN Customer Representative: Mr coman Activity: Tripping

Contractor : L Rig Name L 9 Contractor Representative: Mud Engineers : UVM

BHA CASING VOLUME [ m3 ] RIG PUMPS & CIRCULATING DATA

Bit Size 12 1/4 CSG OD [in]ID [in] Shoe @ Annular Volume 17.3 Pump 2 1 Flow Rate [ L/min ]

Make From SMITH CP 20 19 9 String Volume 1.2 Model UPET UPET 930

Type Tricone Surface 13 3/8 12 1/2 63 Hole Volume 18.5 Liner Size 5 6 Pressure [ psi ]

Jets Open Active pit 44.6 L / Stroke 11.13 13.2 90

Pipe OD [in] ID [in] Length[m] Total Circulating 63.1 Efficiency 98% Annular Velocity [ m/min ]

DP Reserve 30.1 Bottom up [ min ] 18.6 Minimum 42

DP 4 1/2 3 186 Previous Volume 80.0 Surace to Surface [ min ] 19.89 Maximum 41

HWDP 6 1/2 3 1/4 47 Addition Volume 40.0 Total Circulating [ min ] 67.8

DC 6 3/4 2 7/8 37 MD [m] TVD [m] Inclination Losses 26.9 B/U Stroke 1586 ECD @ CSG [SG]

SURVEY

DC Actual Volume 93.1 S to S Stroke 1696 ECD @ Bottom [SG]

FLUID PROPERTIES SPUD MUD LITHOLOGY: limestone

Sample From FL Pit FL Pit FL Pit Program MUD TREATMENT & COMMENTS:

Time Sample Taken 11H30 18h00 20h30 While drilling @ 237 m, lost 20 m3 in the formation, Spot 4 m3 of LCM ( CaCO3 Coarse = 30 kg / m3 + CaCO3 Medium =

Flowline / Suction Pit Temperature °C Bentonite 30 kg/m3 + Nut Plug fine = 25 kg / m3 + STEELSEAL = 21 kg/m3) & POOH to 122 m. Mixing more mud for surface pit

level, RIH back to bottom & while circulating losses reduced to 2 m3 / h till no more losses when drilling to 255 m. Total

Depth - M.D. m 243 267 50

daily formation losses 26,9 m3.

Depth - T.V.D. m 243 267 50

Weight sg / ppg 1.09 9.1 1.10 9.2 1.05 1.10

Fann 600 / 300 rpm @ 50 °C 50 38 48 37 48 37

Fann 200 / 100 rpm @ 50 °C 35 30 33 29 27 22

Fann 60 / 30 rpm @ 50 °C

Fann 6 / 3 rpm @ 50 °C 20 16 18 15 17 15 15

Marsh Viscosity sec/L @ °C 70 65 63 70 110

Apparent Viscosity cp @ 50 °C 25 24 24 RIG OPERATIONS & COMMENTS:

Plastic Viscosity cp @ 50 °C 12 11 11 10 12 Drilling formation from 229 m to 237 m, observed 20 m3 mud losses POOH to 202 m & flow check 10 min. Spot 3 m3 of

Yield Point lb/100ft2 @ 50 °C 26 26 26 25 35 LCM pill flow check ok, continue POOH to 122 m flow check 30 min well static. Mixing surface mud while circulating &

Gel 10 sec / 10 min lb/100ft2 @ 50 °C 23 26 21 24 18 22 reciprocate string, RIH to 237 m, ream wash down @ 237 m & drilling formation from from 229 m to 270 m w/ 930 lpm - 90

psi - 50rpm. POOH from 270 m to 217 m, flow check ok No losses, freely no drags. RIH wash down @ 270 m, circulate

Gel 30 min lb/100ft2 @ 50 °C

hole clean flow check ok, & POOH from 270 m to 180 m No losses freely No drags.

LSR YP (Yeld Stress) lb/100ft2

lb/100ft2 @ 50 °C 12 12 13

SAR*100 (Shape Ratio) @ 50 °C 55 53 65

n/K - / lb*secn/100ft2 @ 50 °C 0.40 3.22 0.38 3.56 0.38 3.56

API Filtrate mL/30 min @ -10 °C

HTHP Filtrate mL/30 min @ ## °C

Cake (API / HTHP) 32nd in 2.0 2.0 2.0

Lubricant (Oil) % by Vol.

Water % by Vol. 96.0 96.0 96.0

Ret. Solids (Uncorrected Solids) % by Vol. 4.0 4.0 4.0

Corrected Solids % by Vol. 4.0 4.0

Avg. Sp. Gravity of Corr. Solids kg/L 2.96 3.21 INVENTORY & MATERIAL CONSUMPTION [ Unit ] COST [ USD ]

HGS ( Barite ) % by Vol. / ppb 1.5 21 2.0 29 Products Unit Start Return Receive Used End Daily Section Cumulative

Low Gravity Solids % by Vol. / ppb 2.5 20 2.0 16 Bentonite 1 MT 3 2 1 648.7 1,621.7 3,243.3

Sand Content % by Vol. Soda Ash 25 kg 2 2 - 279.7

Bentonite Equivalent (M.B.T.) kg/m3 / ppb 65.0 22.8 65.0 22.8 65.0 22.8 BARAZAN D 25 kg 13 2 11 143.2 286.4 429.6

Drilled Solids % by Vol. / ppb 0.7 7 0.2 2 Sodium Bicarbo 25 kg 32 32 206.0 206.0

pH Meter Strip 10.0 9.5 9.5 9 9.5 KCl 1 MT 8 8 - -

Alkalinity Mud Pom mL H2SO4 0.1N 1.0 1.0 1.0 BARABUF 25 kg 17 2 15 96 240.0 240.0

Alk. Filtrate Pf / Mf mL H2SO4 0.02N 0.1 0.3 0.1 0.3 0.1 0.3 N - DRILL HT 25 kg 50 50 - -

Lime content kg/m3 / ppb 0.7 0.2 0.7 0.2 0.7 0.2 CaCO3 Medium 1 MT 4 4 310.1 310.1

-

Cl whole mud g/L 1300 1300 1300 CaCO3 Coarse 1 MT 1 1 401.0 401.0

-

Cl whole mud ppm 1284585 1284585 1284585 STEELSEAL 25 kg 12 6 6 466 853.8 853.8

+

K g/L Caustic Soda(MI) 25 kg - 48.0

K+ ppm Citric Acid 25 kg 20 20 - -

KCl % by Wt. / kg/m3 Glutaraldehyde 25 kg 2 2 - -

NaCl g/L GEM GP 1000 L 1 1 - -

Ca++ mg/L TORQ TRIM II 185 kg 2 2 - -

Total Hardness as Ca++ mg/L 380 370 380 EZ SPOT 55 gal 2 2 - -

B.H.C.T. °C MgCl2 (MI) 1 MT 7 7 - -

Emulsion stability 20 volt CaCl2 (MI) 1 MT 1 1 - -

Cl- Brine CaCl2 ppm / mg/l Safecarb (MI) 500 kg 1 1 - -

Bentonite (MI) 50 lbs 7 7 - -

CaCl2 Brine g/l Nut plug F (MI) 15 8 7 336 336.0 336.0

% CaCl2 - -

OWR 18 - -

19 - -

- -

20 - -

Cloud Point Temperature °C Daily Products Total Daily Mud Cumulative Products

Avaglyco % by Vol. Daily Personal Section Products Cumulative Mud

Avaglyco In / Out Solution % by Vol. Daily Lab Section Pers / Eq.

VOL. ACCOUNTING Daily Section Cumul. PIT Vol Fluid M.W. SOLIDS CONTROL Run Hrs. Screens New Screens

3 3

[m ] Volume Volume Volume REVIEW [ m ] Type [ sg ] EQUIPMENT Daily Sect. [ API Designation No. ] Usage (API)

Vol. Mud Built S. Traps 9 Spud Mud 1.10 Shaker 1 24 111.0 70 - 70

Vol. added products 2.0 5.0 9.0 Degaser 14 Spud Mud 1.10 Shaker 2 24 111.0 70 - 70

Vol. Used Base Oil Desilter 14 Spud Mud 1.10

Vol. water 38.0 81.0 151.0 Pit - 2 A 8 Spud Mud 1.09

Gain from formation Pit - 2 B 0 Spud Mud 1.05 Desander

Vol. Received Pit - 3 A 15 Spud Mud 1.10 Desilter Flow rate m3/h rpm MW in MW out SG solids lost m3/h

Vol. Returned Pit - 3 B 13 Spud Mud 1.06 Centrifuge 1 Brandt 12 24.0

SCE Losses 18.1 40.0 Slug 1 LCM 1.18 Centrifuge 2 Brandt

Evaporation Trip tank 1 Spud Mud 1.10 RIG TIME BREAKDOWN

Pit residual ACTIVITY DURATION ACTIVITY DURATION ACTIVITY DURATION

Left in Hole Drilling 12 Cement job Circulating 5.5

Formation 26.9 26.9 26.9 Tripping 6.5 Cut casing Rig Service

Others R / U & M/U Cut & Slip

You might also like

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj Mk100% (2)

- 13 Secunda - Oil of Egg - UnknownDocument3 pages13 Secunda - Oil of Egg - UnknownJohnny jonesNo ratings yet

- Pipe Sizing Calculation DumaiDocument39 pagesPipe Sizing Calculation DumaiKemas Muhandis M.100% (3)

- Bio Gas Excel Calculation SheetDocument5 pagesBio Gas Excel Calculation SheetsrivarmaNo ratings yet

- 2 Phase Flow Pressure Drop Calc Suresh1Document6 pages2 Phase Flow Pressure Drop Calc Suresh1NKNo ratings yet

- Module 2: Polymer Reactions Step-Growth Polymerization KineticsDocument35 pagesModule 2: Polymer Reactions Step-Growth Polymerization KineticsYu An Shih100% (1)

- 112 DMR Ark-19 DSTDocument2 pages112 DMR Ark-19 DSTB fattahiNo ratings yet

- Synthetic-Based Mud Report No.10: Ongc 20-Feb-22Document4 pagesSynthetic-Based Mud Report No.10: Ongc 20-Feb-22ongcchemist gd chitraNo ratings yet

- Hydraulic Calc by VassDocument1 pageHydraulic Calc by VassKyzak K. KeorkNo ratings yet

- DMR FgchyuihducDocument2 pagesDMR FgchyuihducB fattahiNo ratings yet

- Zone 9 Dewats DesignDocument8 pagesZone 9 Dewats Designengsamim.walizadaNo ratings yet

- Daily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Document5 pagesDaily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Tahir Iqbal. Kharpa RehanNo ratings yet

- Hydraulic Calculations MudpumpDocument1 pageHydraulic Calculations MudpumpSudish BhatNo ratings yet

- Zone 18 Dewats DesignDocument8 pagesZone 18 Dewats Designengsamim.walizadaNo ratings yet

- Zone 11 Dewats DesignDocument8 pagesZone 11 Dewats Designengsamim.walizadaNo ratings yet

- Calcul Coalescer L-LDocument4 pagesCalcul Coalescer L-LChitu Ionut-LaurentiuNo ratings yet

- Zone 13 Dewats DesignDocument8 pagesZone 13 Dewats Designengsamim.walizadaNo ratings yet

- 12 - Hydraulic Calculations & MudpumpDocument1 page12 - Hydraulic Calculations & MudpumpJunaid MateenNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- JcjciiciciciDocument4 pagesJcjciiciciciyacineNo ratings yet

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 pageSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025No ratings yet

- 005 CompactionDocument30 pages005 CompactionJolayemi Emmanuel OlatayoNo ratings yet

- JcjciiciciciDocument4 pagesJcjciiciciciyacineNo ratings yet

- Pump Head Calculation - Waste Water PumpDocument8 pagesPump Head Calculation - Waste Water PumpChoon Zhe ShyiNo ratings yet

- Hdca 1971 M WVD 270 GPM Corralillo 3035Document5 pagesHdca 1971 M WVD 270 GPM Corralillo 3035Jesus HernandezNo ratings yet

- KMC HydraulicDocument1 pageKMC HydraulicHunterNo ratings yet

- JgcickckxjwhwhxhpDocument4 pagesJgcickckxjwhwhxhpyacineNo ratings yet

- 11 Hydraulics & Well Control Calculations - QuartzDocument29 pages11 Hydraulics & Well Control Calculations - QuartzRebarNo ratings yet

- NJHXKCJWGXDocument4 pagesNJHXKCJWGXyacineNo ratings yet

- KfigigigigigDocument4 pagesKfigigigigigyacineNo ratings yet

- GRP PipeDocument6 pagesGRP Pipezshehadeh0% (1)

- HWYH-1178 Mud Report - 7530073 - 01Document5 pagesHWYH-1178 Mud Report - 7530073 - 01KHALEDFEKAIRNo ratings yet

- Dresser G100 Rotary Meter: Baker Hughes, A GE CompanyDocument1 pageDresser G100 Rotary Meter: Baker Hughes, A GE CompanyAndrea Pamela León AlgarañazNo ratings yet

- SUMP PIT CALC Hyde Park 11Document2 pagesSUMP PIT CALC Hyde Park 11MohammedRiyadNo ratings yet

- Cement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated TempsDocument3 pagesCement Plug: Hole Size CSG Size Bottom of Plug Length of Plug Estimated Tempsislam atifNo ratings yet

- LhdjcigoohogDocument4 pagesLhdjcigoohogyacineNo ratings yet

- Calculation Hdpe 24 InchDocument5 pagesCalculation Hdpe 24 InchBachtiar Ramadhan100% (1)

- 23mse015 Slender ColumnDocument2 pages23mse015 Slender Column19CEF082 SHANMATHY SNo ratings yet

- Clear Water From Industrial Waste Water: 80m3/hr, 80mDocument9 pagesClear Water From Industrial Waste Water: 80m3/hr, 80mSameera RanasingheNo ratings yet

- Pipeline CalculationDocument11 pagesPipeline CalculationBibowei JohnNo ratings yet

- Fermentation Broth: Pump and Line Calculation SheetDocument12 pagesFermentation Broth: Pump and Line Calculation Sheetagung gunandarNo ratings yet

- Active Pressure Calculation For The Shoring Plate: New Bridge Centre, BLK 336, Smith Street #06-305, SINGAPORE 050336Document13 pagesActive Pressure Calculation For The Shoring Plate: New Bridge Centre, BLK 336, Smith Street #06-305, SINGAPORE 050336ThaungMyintNo ratings yet

- Pumping DistanceDrawdownDocument16 pagesPumping DistanceDrawdownJuan MendozaNo ratings yet

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- GRP Pipe Calculation: Ft/secDocument6 pagesGRP Pipe Calculation: Ft/secمعتصم منورNo ratings yet

- Cantilever Slab (Modified)Document4 pagesCantilever Slab (Modified)WRay TanNo ratings yet

- Ship'S Particulars: Draft (MLD.) Density DWT Displacement TPC FWA T. Fresh Fresh Tropical Summer WinterDocument2 pagesShip'S Particulars: Draft (MLD.) Density DWT Displacement TPC FWA T. Fresh Fresh Tropical Summer WinterBarış ÖzturkNo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- Comet 5.0 Fiksasi RevisiDocument26 pagesComet 5.0 Fiksasi RevisiKhansa ArkhapNo ratings yet

- Field Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)Document5 pagesField Density (Sand Cone Method) Test (ASTM D 1556, AASHTO T - 191)m8877223No ratings yet

- Fire Water DemandDocument7 pagesFire Water DemandamolbagadeNo ratings yet

- A4 WellborePerformance SolutionsDocument2 pagesA4 WellborePerformance SolutionsVatsal ShahNo ratings yet

- HIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'Document1 pageHIDRAULICA MPJ9-08 24 - 11 - 17 - Hoyo 16'' at 550'alfonzitoNo ratings yet

- Lampiran Total CompanyDocument9 pagesLampiran Total CompanyDito Andi WNo ratings yet

- EC D-3 Charcoal Tower SizingDocument8 pagesEC D-3 Charcoal Tower SizingPrathmesh GujaratiNo ratings yet

- Design and Permissible LimitDocument34 pagesDesign and Permissible LimitMahendra PrasadNo ratings yet

- Morning Report 03 - 08 April 2012Document1 pageMorning Report 03 - 08 April 2012tolstoy potemkinNo ratings yet

- Common Oil Soak Pit - As Per BOTDocument93 pagesCommon Oil Soak Pit - As Per BOTzumanNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Understanding Membrane Distillation and Osmotic DistillationFrom EverandUnderstanding Membrane Distillation and Osmotic DistillationNo ratings yet

- CSR CatalogDocument52 pagesCSR CatalogHarvinder Singh100% (1)

- Nomenclature & IsomerismDocument19 pagesNomenclature & Isomerismkoli1417789No ratings yet

- Control ValvesDocument32 pagesControl ValvesParmeshwar Nath Tripathi100% (1)

- Oltec Coat 98 Fds Vers 8 - enDocument8 pagesOltec Coat 98 Fds Vers 8 - enGrégory EcalleNo ratings yet

- Chemical Reactions Science Presentation in Blue Light Blue Hand Drawn Style - 20230827 - 214710 - 0000Document16 pagesChemical Reactions Science Presentation in Blue Light Blue Hand Drawn Style - 20230827 - 214710 - 0000Criselda CarinoNo ratings yet

- Maf Accessories LTDDocument5 pagesMaf Accessories LTDMd. MominulNo ratings yet

- The Effects of Hydrogen On Some Constituents Elements in The Tarfaya Oil Shale Layers (Morocco)Document10 pagesThe Effects of Hydrogen On Some Constituents Elements in The Tarfaya Oil Shale Layers (Morocco)IJAR JOURNALNo ratings yet

- 01-Experiment-The Effect of PH On Food PreservativeDocument9 pages01-Experiment-The Effect of PH On Food Preservativejul.cotrimNo ratings yet

- Daftar Obat Look Alike Sound AlikeDocument2 pagesDaftar Obat Look Alike Sound AlikeAbil LaksonoNo ratings yet

- 7.3 7.5 WorksheetDocument2 pages7.3 7.5 Worksheettownsenr94No ratings yet

- FAO Emamectin Benzoate PDFDocument15 pagesFAO Emamectin Benzoate PDFmercuriusNo ratings yet

- Daftar Nama Pembimbimg Praktek Kerja Industri (Prakerin) TAHUN AJARAN 2020/2021Document2 pagesDaftar Nama Pembimbimg Praktek Kerja Industri (Prakerin) TAHUN AJARAN 2020/2021A Ming MingNo ratings yet

- BS 4479-7-1990Document12 pagesBS 4479-7-1990윤규섭No ratings yet

- PaintsDocument14 pagesPaintsaarthi100No ratings yet

- 4 BromotolueneDocument2 pages4 BromotolueneDaisyfrankieNo ratings yet

- Direct-Thermochemical-Liquefaction Commercialization OverviewDocument28 pagesDirect-Thermochemical-Liquefaction Commercialization OverviewJairoVidalNo ratings yet

- Assessment of Compositional Changes of Carbonated Cement - 2022 - Journal of BuDocument8 pagesAssessment of Compositional Changes of Carbonated Cement - 2022 - Journal of BuAliNo ratings yet

- BDW86S-F - 45cm Dishwasher UC 5.7.13 PDFDocument23 pagesBDW86S-F - 45cm Dishwasher UC 5.7.13 PDFrudiNo ratings yet

- Usp36-Nf31 02 214Document2 pagesUsp36-Nf31 02 214Jersa Mae MaravillaNo ratings yet

- Erkoloc Pro PDB en - KopyaDocument2 pagesErkoloc Pro PDB en - KopyaALEGOZ ALEGOZNo ratings yet

- Calibration Curve: Concentration Absorbance (MG/L) F (X) 0.0374290909x R 0.9996352674 AbsorbanceDocument16 pagesCalibration Curve: Concentration Absorbance (MG/L) F (X) 0.0374290909x R 0.9996352674 Absorbanceprmahajan18No ratings yet

- 636 1237 1 SMDocument7 pages636 1237 1 SMsepvi indahNo ratings yet

- Ch. 7 Control of Microbial GrowthDocument10 pagesCh. 7 Control of Microbial GrowthYousef DosouqiNo ratings yet

- VESTA Exercise SheetsDocument5 pagesVESTA Exercise SheetsMarcos BHNo ratings yet

- Penerbitan Pelangi Sdn. BHD.: Pergerakan Bahan Merentasi Membran PlasmaDocument23 pagesPenerbitan Pelangi Sdn. BHD.: Pergerakan Bahan Merentasi Membran PlasmaZue Zuerra100% (1)

- Happy SubstancesDocument32 pagesHappy Substancesnicka castilloNo ratings yet

- M-I Drilling Fluids Material Safety Data Sheet: Pipelax WDocument4 pagesM-I Drilling Fluids Material Safety Data Sheet: Pipelax WHunterNo ratings yet

- Ws Classification of Matter KeyDocument2 pagesWs Classification of Matter KeyKirryn ParsonNo ratings yet