Professional Documents

Culture Documents

AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8

AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8

Uploaded by

symon ellimacOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8

AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8

Uploaded by

symon ellimacCopyright:

Available Formats

Advisory Desk and Codes & Standards

AD 399:

Design of partial penetration butt welds

in accordance with BS EN 1993-1-8

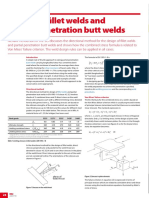

Partial penetration butt welds are covered by Clause 4.7.2, which directs design throat) is less than the preparation, or (b) to conduct weld procedure

the designer to ‘use the method for a deep penetration fillet weld” given in trials to demonstrate what penetration can consistently be achieved. The

clause 4.5.2(3). first approach was encouraged by the 1990 version of BS 5950, where clause

Clause 4.5.2(3) really concerns only the definition of the throat, and leaves 6.6.6.2 specified a reduction of 3 mm for V and bevel welds. Clause 6.9.2 of

the designer unsure of how the design resistance is to be calculated. the 2000 version of BS 5950 specifies no reduction but refers to the depth of

penetration, which may be more or less than the preparation.

Partial penetration welds are considered to be less ductile than full

penetration welds and therefore many design Standards require that they are Design resistance

to be treated in the same way as fillet welds. This is the principle behind the It is recommended the the directional method of clause 4.5.3.2(6) is used

advice in clause 4.7.2. Unless rotation is suitably restrained, eccentricity must when calculating the resistance of a partial penetration butt weld. Assuming

be taken into account when calculating the stress in the weld. Examples of there is no longitudinal stress, the direct stress must be resolved into a

details where eccentricity is introduced in partial penetration butt welds are perpendicular stress on the throat, σ⊥ and a shear stress on the throat,

shown in Figure 4.9 of BS EN 1993-1-8. τ⊥. Expression 4.1 of BS EN 1993-1-8 requires that the combination of

Eccentricity need not be considered if the weld is used as part of a weld perpendicular stresses are verified and also limits the perpendicular stress.

group around the perimeter of a structural hollow section (clause 4.12(3)). With no longitudinal stress on the weld throat, the verifications become:

It is reasonable to assume that there is no eccenticity if the welded element fu 0.9fu

(σ⊥2 + 3τ⊥2)0.5 ≤ and σ⊥ ≤

is part of a member which itself cannot rotate at the joint – for example if a βWγM2 γM2

partial penetration weld is used to connect the flange of a beam to an end

In case (b) of figure 1, assuming the applied force is 2000 N/mm, and the

plate.

throat is 9 mm, the components of force become:

In the numerical example which follows, it is assumed that rotation cannot

σ⊥ = 2000 Cos(33)/9 = 186 N/mm2 and τ⊥ = 2000 Sin(33)/9 = 121 N/mm2

take place.

The combined check of shear and perpendicular stress, with βw = 0.9 for S355

Throat

(taken from Table 4.1) becomes:

The throat of a partial penetration butt weld is the distance from the root to 470

(1862 + 3(121)2)0.5 = 280 N/mm2. The limit is = 418 N/mm2

the external face of the weld, as described in clause 4.5.2(1). Examples are 0.9 × 1.25

shown in figure 1.

0.9 × 470

The perpendicular stress σ⊥ is 186 N/mm2; the limit is

1.25

= 338 N/mm2

Of course, if a standard fillet weld is verified by the same process, using an

angle to the throat of 45°, it can be demonstrated that the resistances are

those quoted in the Blue Book1 for a transverse weld.

a a

33° Reference

1 Steel building design: Design data. In accordance with Eurocodes and UK

a National Annexes (P363). SCI, Reprinted 2015.

(a) (b) (c) Contact: Abdul Malik

Figure 1: Throat (a) of partial penetration welds Tel: 01344636525

Email: advisory@steel-sci.com

Common practice is to either (a) assume the penetration (and hence the

New and revised codes & standards

From BSI Updates June 2016

BRITISH STANDARDS BRITISH STANDARDS NEW WORK STARTED ISO 11666

BS 5427:2016 WITHDRAWN EN ISO 14713-2 Non-destructive testing of welds.

Code of practice for the use of BS 5427-1:1996 Zinc coatings. Guidelines and Ultrasonic testing. Acceptance levels

profiled sheet for roof and wall Code of practice for the use of recommendations for the protection Will supersede BS EN ISO 11666:2010

cladding on buildings profiled sheet for roof and wall against corrosion of iron and steel in

Supersedes BS 5427-1:1996 cladding on buildings. Design structures. Hot dip galvanizing

Superseded by BS 5427:2016 Will supersede BS EN ISO 14713-2:2009

BS EN PUBLICATIONS BS EN 1330-7:2005 ISO 5173

Non-destructive testing. Destructive tests on welds in

BS EN ISO 12707:2016

Terminology. Terms used in metallic materials. Bend tests

Non-destructive testing. Magnetic

magnetic particle testing Will supersede BS EN ISO

particle testing. Vocabulary

Superseded by BS EN ISO 12707:2016 5173:2010+A1:2011

Supersedes BS EN 1330-7:2005

NSC

30 July/Aug 16

You might also like

- BR Knauf Ceiling Solutions Mineral Solutions ND MEDocument94 pagesBR Knauf Ceiling Solutions Mineral Solutions ND MEsacdawoodNo ratings yet

- The Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinDocument40 pagesThe Real Science Behind Why The COVID Vaccines Are Destroying Organ Function - Dangers of The Spike ProteinMara Rebeka Herzog100% (7)

- Aisi 1018 Carbon Steel (Uns g10180)Document3 pagesAisi 1018 Carbon Steel (Uns g10180)Naman TanejaNo ratings yet

- NTPCDocument158 pagesNTPCAnand GuptaNo ratings yet

- Architects Illustrated Pocket DictionaryDocument558 pagesArchitects Illustrated Pocket DictionaryFlavia ValNo ratings yet

- Welding QuestnDocument37 pagesWelding QuestnmehdiNo ratings yet

- Technical Lamination SDocument4 pagesTechnical Lamination SAlexander RichardsonNo ratings yet

- Weld Defects CswipDocument10 pagesWeld Defects CswipOLiver RobertNo ratings yet

- Minimum Requirements For The Education, Training, Examination and QualificationDocument41 pagesMinimum Requirements For The Education, Training, Examination and QualificationAntónio PintoNo ratings yet

- Welding and Reinforcement PDFDocument9 pagesWelding and Reinforcement PDFScottBuchholzNo ratings yet

- M. N. Dastur: 8S Company (P) LTD, KolkataDocument151 pagesM. N. Dastur: 8S Company (P) LTD, KolkataHari SankarNo ratings yet

- Welding Requirements Csa A233 Design Concrete StructuresDocument2 pagesWelding Requirements Csa A233 Design Concrete StructureshoustonhimselfNo ratings yet

- Welding Processes in Shipbuilding Industry C. G. PolitisDocument119 pagesWelding Processes in Shipbuilding Industry C. G. PolitisNvlArchNo ratings yet

- Basic Welding Symbols PDFDocument6 pagesBasic Welding Symbols PDFEarl HarbertNo ratings yet

- Defects Lack of Side Wall FusionDocument4 pagesDefects Lack of Side Wall Fusionguru_terexNo ratings yet

- Shearing Force & Bending Moment DiagramDocument17 pagesShearing Force & Bending Moment DiagramdearsaswatNo ratings yet

- 4.0 Destructive TestingDocument81 pages4.0 Destructive Testingfinhay100% (1)

- 3.04 - Basic of Weld DesignDocument74 pages3.04 - Basic of Weld DesignGunGun554No ratings yet

- Advantages of Welded JointsDocument7 pagesAdvantages of Welded JointsNeil RubsNo ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- ECCS PublicationsDocument2 pagesECCS PublicationsKoh Wei SangNo ratings yet

- 3.3.3-Fillet Weld Design 9th Mar 21Document40 pages3.3.3-Fillet Weld Design 9th Mar 21Vivek kmNo ratings yet

- Astm A194-A194m-13 PDFDocument12 pagesAstm A194-A194m-13 PDFjhonnyNo ratings yet

- Welding Engineering: M.Tech. DegreeDocument16 pagesWelding Engineering: M.Tech. DegreerubilNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocument3 pagesSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030No ratings yet

- Use Caution When Specifying "Seal Welds": Design FileDocument4 pagesUse Caution When Specifying "Seal Welds": Design FilePrabhat K KarnaNo ratings yet

- Technical Lamination SDocument4 pagesTechnical Lamination SirmakNo ratings yet

- Miller - 2010 Welding Heavy Structural Steel SucessfulyyDocument15 pagesMiller - 2010 Welding Heavy Structural Steel SucessfulyyLleiLleiNo ratings yet

- Weld SysmbolDocument17 pagesWeld SysmbolBashu PoudelNo ratings yet

- Welding Metallurgy,: Flux Core Arc WeldingDocument28 pagesWelding Metallurgy,: Flux Core Arc WeldingAhmed El MorsyNo ratings yet

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDocument2 pagesSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNo ratings yet

- Specification No: LMB-COI-TRG-001 Rev No. R0 Page ofDocument16 pagesSpecification No: LMB-COI-TRG-001 Rev No. R0 Page ofApoorv MathurNo ratings yet

- ShajuDocument49 pagesShajuArunprasad MurugesanNo ratings yet

- Lack of Fusion PDFDocument6 pagesLack of Fusion PDFDhinesh GnanadhasNo ratings yet

- IRSM-28-12 Final DraftDocument43 pagesIRSM-28-12 Final DraftShiv PandeyNo ratings yet

- Analysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsDocument13 pagesAnalysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsLiu YangtzeNo ratings yet

- En 1993 1 12 2007 PDFDocument11 pagesEn 1993 1 12 2007 PDFRajan SteeveNo ratings yet

- Great Minds of Carbon Equivalent - 1 PDFDocument3 pagesGreat Minds of Carbon Equivalent - 1 PDFSiva SubramaniNo ratings yet

- Fillet Weld and Partial Penetration Butt WeldDocument3 pagesFillet Weld and Partial Penetration Butt Weldsusan87No ratings yet

- Welding Inspection: Welding Symbols Course Reference WIS 5Document52 pagesWelding Inspection: Welding Symbols Course Reference WIS 5Joerge Ryan MaramotNo ratings yet

- Welding TWIDocument16 pagesWelding TWIEngr Arfan Ali DhamrahoNo ratings yet

- HD Bolts BS - 7419Document5 pagesHD Bolts BS - 7419Deana White100% (1)

- Modular Expansion Joints For Road Bridges: August 2019Document65 pagesModular Expansion Joints For Road Bridges: August 2019Marko ZgbNo ratings yet

- European Steel Standards PDFDocument2 pagesEuropean Steel Standards PDFMeikaNo ratings yet

- A Review of Factors Affecting Toughness in Welded Steels PDFDocument23 pagesA Review of Factors Affecting Toughness in Welded Steels PDFsurendarNo ratings yet

- Anchor Calculation - Case 2Document10 pagesAnchor Calculation - Case 2MdShahbazAhmedNo ratings yet

- Quiz FundiciónDocument5 pagesQuiz FundiciónJeankCantorNo ratings yet

- Equipment Qualification in Operational Nuclear Power PlantsDocument126 pagesEquipment Qualification in Operational Nuclear Power PlantsAnonymous l2sT4aENo ratings yet

- Documentation of Welding Procedure TestDocument5 pagesDocumentation of Welding Procedure Testrty2No ratings yet

- Hilti-Fischer Anchor BoltDocument2 pagesHilti-Fischer Anchor Boltpavitrakedar100% (1)

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 pagesDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNo ratings yet

- Deflections PortalsDocument9 pagesDeflections PortalsJim SpsNo ratings yet

- Cmjf?i?l-?i: Technical Supply Conditions FOR Threaded Steel FastenersDocument25 pagesCmjf?i?l-?i: Technical Supply Conditions FOR Threaded Steel FastenersrajupetalokeshNo ratings yet

- 1144 Twi Diploma in Welding Engineering July 2019Document1 page1144 Twi Diploma in Welding Engineering July 2019Tauqeer SalimNo ratings yet

- SHS WeldingDocument44 pagesSHS Weldingamarkhamhgnl100% (1)

- CKKolom 1Document5 pagesCKKolom 1Hans 't Hart100% (1)

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentKhalid PerwezNo ratings yet

- HSS DesignManual 1Document170 pagesHSS DesignManual 1hassankhoshsiarNo ratings yet

- Domex Welding PDFDocument16 pagesDomex Welding PDFAgourame Abderrahmane100% (1)

- New and Revised Codes & StandardsDocument1 pageNew and Revised Codes & StandardsJianhua WuNo ratings yet

- En 1993-1-8Document69 pagesEn 1993-1-8atiNo ratings yet

- Design Appendix For Structural Steel DesignDocument36 pagesDesign Appendix For Structural Steel DesignridzwanNo ratings yet

- Design of Connetiomn Chankara AryaDocument21 pagesDesign of Connetiomn Chankara AryaMohamed AbdNo ratings yet

- AD 430 - Wind Load On Unclad Frames, May 2019Document1 pageAD 430 - Wind Load On Unclad Frames, May 2019symon ellimac100% (1)

- AD 348 - Bolt Resistance Tables in The Eurocode Blue BookDocument1 pageAD 348 - Bolt Resistance Tables in The Eurocode Blue Booksymon ellimacNo ratings yet

- AD 434 - Validity Rules For Hollow Section Joints, October 2019Document1 pageAD 434 - Validity Rules For Hollow Section Joints, October 2019symon ellimacNo ratings yet

- AD 424 - Shear Stud Length, November 2018Document1 pageAD 424 - Shear Stud Length, November 2018symon ellimacNo ratings yet

- AD 439 - Transverse Reinforcement in Composite Beams, April 2020Document2 pagesAD 439 - Transverse Reinforcement in Composite Beams, April 2020symon ellimacNo ratings yet

- AD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019Document1 pageAD 435 - Beams Supporting Precast Planks - Checks in The Temporary Condition, November 2019symon ellimacNo ratings yet

- AD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019Document1 pageAD 428 - Draft Guidance - Lateral and Torsional Vibration of Half-Through Truss Footbridges, March 2019symon ellimacNo ratings yet

- AD 436 - Section Classification of A Flat Plate, January 2020Document1 pageAD 436 - Section Classification of A Flat Plate, January 2020symon ellimacNo ratings yet

- AD 450 - Resistance of Composite Slabs To Concentrated Loads, October 2020Document1 pageAD 450 - Resistance of Composite Slabs To Concentrated Loads, October 2020symon ellimacNo ratings yet

- AD 431 - Column Web Panel Strengthening, June 2019Document1 pageAD 431 - Column Web Panel Strengthening, June 2019symon ellimacNo ratings yet

- AD 453 - Accumulated Deviations in Erected Steelwork, November 2020Document1 pageAD 453 - Accumulated Deviations in Erected Steelwork, November 2020symon ellimacNo ratings yet

- AD 429 - Slip Factors For Alkali-Zinc Silicate Paint, April 2019Document1 pageAD 429 - Slip Factors For Alkali-Zinc Silicate Paint, April 2019symon ellimacNo ratings yet

- AD 433 - Dynamic Modulus of Concrete For Floor Vibration Analysis, September 2019Document1 pageAD 433 - Dynamic Modulus of Concrete For Floor Vibration Analysis, September 2019symon ellimacNo ratings yet

- AD 448 - Support To Profiled Steel Decking, September 2020Document1 pageAD 448 - Support To Profiled Steel Decking, September 2020symon ellimacNo ratings yet

- AD 427 - Typographical Error in P419, February 2019Document1 pageAD 427 - Typographical Error in P419, February 2019symon ellimacNo ratings yet

- AD 440 - Fire Design of External Steelwork, May 2020Document1 pageAD 440 - Fire Design of External Steelwork, May 2020symon ellimacNo ratings yet

- AD 400 - The Degree of Shear Connection in Composite Beams and SCI P405, September 2016Document1 pageAD 400 - The Degree of Shear Connection in Composite Beams and SCI P405, September 2016symon ellimacNo ratings yet

- New and Revised Codes & Standards: AD 425: AD 426Document1 pageNew and Revised Codes & Standards: AD 425: AD 426symon ellimacNo ratings yet

- AD 415 - Vertical Tying of Columns and Column Splices, February 2018Document1 pageAD 415 - Vertical Tying of Columns and Column Splices, February 2018symon ellimacNo ratings yet

- AD 418 - Web-Post Buckling in Composite Beams With Rectangular and Elongated Web Openings, May 2018Document2 pagesAD 418 - Web-Post Buckling in Composite Beams With Rectangular and Elongated Web Openings, May 2018symon ellimacNo ratings yet

- AD 407 - Section Classification, May 2017Document1 pageAD 407 - Section Classification, May 2017symon ellimacNo ratings yet

- AD 406 - Transient Response Factors in Vibration Analysis of Staircases, April 2017Document1 pageAD 406 - Transient Response Factors in Vibration Analysis of Staircases, April 2017symon ellimacNo ratings yet

- AD 417 - Resistance of Sections To Combined Shear and Bending, April 2018Document1 pageAD 417 - Resistance of Sections To Combined Shear and Bending, April 2018symon ellimacNo ratings yet

- Waste Collectors in Sri LankaDocument32 pagesWaste Collectors in Sri Lankasameera jayalathNo ratings yet

- Цацулин CQC Mag 2001-06 J - eng PDFDocument1 pageЦацулин CQC Mag 2001-06 J - eng PDFBudo MediaNo ratings yet

- Pollitt & Shaorshadze (2011) - The Role of Behavioural Economics in Energy and Climate Policy PDFDocument31 pagesPollitt & Shaorshadze (2011) - The Role of Behavioural Economics in Energy and Climate Policy PDFRoz KrakraNo ratings yet

- Post-Hearing Brief - SDCIDocument11 pagesPost-Hearing Brief - SDCIThe UrbanistNo ratings yet

- Siwertell Road-Mobile Unloaders Original 32998Document4 pagesSiwertell Road-Mobile Unloaders Original 32998Gospodin RajkovićNo ratings yet

- Feedforward Neural Networks in Depth, Part 1 - Forward and Backward Propagations - I, Deep LearningDocument11 pagesFeedforward Neural Networks in Depth, Part 1 - Forward and Backward Propagations - I, Deep LearningVikash KumarNo ratings yet

- Section 5 - E&A Drawings PDFDocument1,288 pagesSection 5 - E&A Drawings PDFAndrii PodgornyiNo ratings yet

- INFLATIONDocument24 pagesINFLATIONLovely Bordaje dela FuenteNo ratings yet

- Elements of Mechanism by Doughtie and James PDFDocument1 pageElements of Mechanism by Doughtie and James PDFChristian M. CalinayaNo ratings yet

- Unit 4 Travel and Holidays: Pre IeltsDocument21 pagesUnit 4 Travel and Holidays: Pre IeltsQuoc Tan HuynhNo ratings yet

- Steel Grades 2 PDFDocument2 pagesSteel Grades 2 PDFcanakyuz0% (1)

- Dolch PhrasesDocument10 pagesDolch PhrasesCharlie Manahan TemonNo ratings yet

- Sat Iii: Saturation Diving SystemDocument2 pagesSat Iii: Saturation Diving SystemJahel LootiNo ratings yet

- Kiwi Automation Company Aurora Shows Off Its Palletizing RobotDocument3 pagesKiwi Automation Company Aurora Shows Off Its Palletizing RobotPrimanedyNo ratings yet

- Thesis On Wind Power PlantDocument6 pagesThesis On Wind Power PlantPaperWritingServicesBestEvansville100% (2)

- Mike Meyers Comptia A Guide To Managing and Troubleshooting Pcs 4th Edition Meyers Test BankDocument35 pagesMike Meyers Comptia A Guide To Managing and Troubleshooting Pcs 4th Edition Meyers Test Bankamoeboid.amvis.uiem100% (27)

- Janma Vighatika GrahaDocument5 pagesJanma Vighatika Grahatimsmith1081574No ratings yet

- Bondship BookDocument252 pagesBondship Bookmehrdad_5233No ratings yet

- FAI Free Flight Team Selection Process History NotebookDocument176 pagesFAI Free Flight Team Selection Process History NotebookRussell HartillNo ratings yet

- CH 08Document97 pagesCH 08albakili775514617No ratings yet

- Civil Works CW05 R1 (Submission Drawings 16.03.22)Document1 pageCivil Works CW05 R1 (Submission Drawings 16.03.22)Joel AganNo ratings yet

- 2N60 PDFDocument7 pages2N60 PDFFady HachemNo ratings yet

- MEO Class 1 ProjectDocument2 pagesMEO Class 1 ProjectAshish Ranjan0% (1)

- KGVK BrouchureDocument4 pagesKGVK Brouchuregurjit20No ratings yet

- Turbine Presentation, NGDocument46 pagesTurbine Presentation, NGNitesh GargNo ratings yet

- Iveco EUROCARGO RANGEDocument3 pagesIveco EUROCARGO RANGEChe VarianNo ratings yet