Professional Documents

Culture Documents

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Uploaded by

Rejoy babyCopyright:

Available Formats

You might also like

- Nelson Physics 11 SolutionsDocument14 pagesNelson Physics 11 SolutionsRhea100% (1)

- Energy Loss in Pipe and FittingsDocument10 pagesEnergy Loss in Pipe and FittingsMuhd Fadhil Nazer25% (4)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Planning and Scheduling of SubstructureDocument81 pagesPlanning and Scheduling of SubstructureHnin Wai Mar Aung100% (3)

- Gas Analysis - SECTION6 Interpreting GasDocument10 pagesGas Analysis - SECTION6 Interpreting GasMotorola M Motorola100% (8)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- The Hound of The Baskervilles by Arthur Conan DoyleDocument40 pagesThe Hound of The Baskervilles by Arthur Conan DoyleLisa WardNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS GTAW-SMAW h2Document1 pageWPS GTAW-SMAW h2Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- PQR - 1Document1 pagePQR - 1janardan.sfeNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Report-Welder Qualification TestDocument4 pagesReport-Welder Qualification TestRejoy babyNo ratings yet

- Wqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Document1 pageWqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Rejoy babyNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- ITP For Site Installation of Pipe Rev 1 15.07.10Document4 pagesITP For Site Installation of Pipe Rev 1 15.07.10Rejoy babyNo ratings yet

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanDocument11 pagesDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyNo ratings yet

- Outotec: Danem Engineering Works WLL Doha - QatarDocument4 pagesOutotec: Danem Engineering Works WLL Doha - QatarRejoy babyNo ratings yet

- Danem Engineering Works - WLL: Inspection & Test PlanDocument3 pagesDanem Engineering Works - WLL: Inspection & Test PlanRejoy babyNo ratings yet

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- Consolidated RT TemplateDocument2 pagesConsolidated RT TemplateRejoy babyNo ratings yet

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- QP Specification For Painting & Wrapping of Metal Surfaces PDFDocument89 pagesQP Specification For Painting & Wrapping of Metal Surfaces PDFRejoy babyNo ratings yet

- Painting Spec 7J48N-00-23-17-001Document29 pagesPainting Spec 7J48N-00-23-17-001Rejoy babyNo ratings yet

- ME2403-Power Plant EngineeringDocument5 pagesME2403-Power Plant EngineeringkrishnabrNo ratings yet

- Oil Based Mud ThinnerDocument2 pagesOil Based Mud ThinnerjangriNo ratings yet

- Ma 151 Lecture LT1Document95 pagesMa 151 Lecture LT1ryan_tan_17No ratings yet

- Non Spore Forming Gram Positive Rods: CorynebacteriumDocument6 pagesNon Spore Forming Gram Positive Rods: CorynebacteriumggzgzhhsNo ratings yet

- Stackers-Reclaimers PD WebDocument2 pagesStackers-Reclaimers PD WebharpreetresearchNo ratings yet

- Filmu Nyan2Document61 pagesFilmu Nyan2Nike B. Lavenia BZNo ratings yet

- ASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFDocument41 pagesASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFStorm100% (1)

- Arabiansdances PDFDocument33 pagesArabiansdances PDFDCB100% (2)

- Failure of DescentDocument39 pagesFailure of DescentfahlevyNo ratings yet

- Medications AdministrationDocument9 pagesMedications AdministrationGeylla FaeldoniaNo ratings yet

- 1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFDocument518 pages1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFAlexanderNo ratings yet

- Astm A 865-97Document5 pagesAstm A 865-97Daniel LodiNo ratings yet

- The Ultimate Cancer Proof Diet Prevention and HealingDocument93 pagesThe Ultimate Cancer Proof Diet Prevention and HealingPete pahnNo ratings yet

- Dev and Lap Splice Lengths - ETN-D-1-15Document9 pagesDev and Lap Splice Lengths - ETN-D-1-15erleosNo ratings yet

- 5 Archimedes ١Document4 pages5 Archimedes ١Mohammed Yousif AbdualjabbarNo ratings yet

- FHP ResearchDocument61 pagesFHP ResearchPooja DaveNo ratings yet

- Physics A: Unit: G484: The Newtonian WorldDocument9 pagesPhysics A: Unit: G484: The Newtonian Worldptscribd941No ratings yet

- A MODIFIED PENG-ROBINSON EQUATION OF STATE FOR - ELV - 20519 - FTP PDFDocument12 pagesA MODIFIED PENG-ROBINSON EQUATION OF STATE FOR - ELV - 20519 - FTP PDFLuiz Roberto TerronNo ratings yet

- Recipe Name: Yield/Servings: 1 Quantity Unit Ingredients Market Price Price Per Qty UnitDocument3 pagesRecipe Name: Yield/Servings: 1 Quantity Unit Ingredients Market Price Price Per Qty UnitQueenie AmoraNo ratings yet

- C O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FDocument201 pagesC O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FharshiniNo ratings yet

- Supra 2019 Final Design ReportDocument12 pagesSupra 2019 Final Design ReportRishit1840030No ratings yet

- Karina Nayyar - Senior Tester 8+ Years ExperiencedDocument2 pagesKarina Nayyar - Senior Tester 8+ Years ExperiencedSanam BindraNo ratings yet

- Amsafe Seatbelt Airbag: First-Responder Reference GuideDocument10 pagesAmsafe Seatbelt Airbag: First-Responder Reference GuideAngel MogrovejoNo ratings yet

- AravindDocument6 pagesAravindyuvi7003No ratings yet

- North East Ds2022Document6 pagesNorth East Ds2022Marlon MccarthyNo ratings yet

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Uploaded by

Rejoy babyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Procedure Qualification Record (PQR) : Filler Metals AWS Specification AWS Classification

Uploaded by

Rejoy babyCopyright:

Available Formats

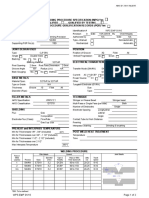

PROCEDURE QUALIFICATION RECORD (PQR)

IDENTIFICATION

Company Name QUALITY FABRICATORS CO.WLL

PQR No. QFAB-PQR-02

POSITION

Revision 00

Position of 3G Fillet N/A

Date 04-8-2015 Groove

Supporting WPS QFAB-pWPS-02 Vertical Dow

Revision 00 Progression n

Up √

Date 02-8-2015

Welding Process SMAW

Type Manual Machine Semi Auto

POSTWELD HEAT TREATMENT

JOINT DESIGN USED

Heating Method N/A

Type Single Double N/A

Backing Yes No Temperature Rise Rate N/A

Backing Material None Bead Thickness : 16mmSoak Temperature N/A

Root Gap 2.5 ± 0.5 Root Face 1.5±0.5

Holding Time N/A

Groove Angle 60°± 10° Radius (J-U) N/A

Temperature Fall Rate N/A

Back Gouging: No Method None

Other N/A

PREHEAT

BASE METALS

Preheat Temp., Min Ambient (27°C)

Material Spec. EN10025 Group 1 to Group 1

Material Grade S 275JR /Heat no-F653870 Inter pass Temp., Min N/A

Thickness 16mm Inter pass Temp., Max 210 °C

Dia (Pipe) N/A

FILLER METALS ELECTRICAL CHARACTERISTICS

AWS A 5.1 Transfer Mode (SMAW)

Specification

AWS E-7018 Short Circuiting N/A Globular

N/A

Classification Spray N/A Pulsed N/A

Current

AC N/A DCEP DECN

Other None

Tungsten Electrode N/A

Size N/A Type N/A

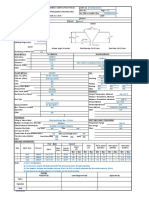

PROCEDURE QUALIFICATION RECORD (PQR)

TECHNIQUE

SHIELDING

Stringer Bead Weave Bead

Flux N/A

Multi-pass Single Pass

Electrode-Flux (Class) N/A

Number of Electrodes Single

Gas N/A

Electrode Spacing

Composition N/A

Longitudinal N/A Lateral N/A Angle N/A

Flow Rate N/A Contact Tube to Work

N/A

Gas Cup Size N/A Distance

Peening None

Wire Brushing &

Inter pass Cleaning

Grinding

WELDING PROCEDURE

Pass or Process Filler Metals Current Volts Travel Sp. Remarks

Layer(s) Class Dia. Type & Amps or Wire mm/min

Polarity Feed Speed

1 SMAW E-7018 2.5 DCEP 70-90 65 65 Preheat Temp:

2 SMAW E-7018 2.5 DCEP 80-100 80 80 Ambient (27°C)

3 SMAW E-7018 3.2 DCEP 90-115 80 80

4 SMAW E-7018 3.2 DCEP 70-90 80 80 Inter pass

5 SMAW E-7018 3.2 DCEP 70-90 80 80 Temp.Max:210°C

Joint Details

T = 16mm, R = 2.5 ± 0.5mm, F= 1.5 ±0.5mm, a 60°± 10°.

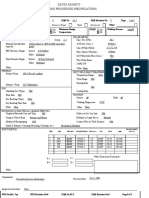

PROCEDURE QUALIFICATION RECORD (PQR)

TEST RESULT

TENSILE TEST

Specimen No Width (mm) Thickness (mm) Area(mm²) Ultimate tensile Ultimate Unit Character of failure

load,N Stress, N/mm² and location

TT-1 20.5 15.63 321.04 160.6 500 PM

TT-1 20.22 15.63 316.04 163.3 517 PM

GUIDED BEND TEST

Specimen No Type of bend Result Remark

Side bend 1 side Passed

Side bend 2 side Passed

Side bend 3 side Passed

Side bend 4 Side Passed

VISUAL INSPECTION

Appearance Undercut Piping Porosity Convexity

Acceptable Less than 1 mm Absent N/A

Test Date 02/08/2015 Report No QFAB/WPS/WV/02

Witnessed By SENTHIL.L

NON DESTRUCTIVE EXAMINATION

RT Report No JR-15-712-OP-RPT-01 Result Acceptable Remarks

UT Report No N/A Result N/A Remarks

FILLET WELD TEST RESULT

Minimum size multiple pass N/A Maximum size single pass N/A

Macroetch Macro etch

1 2 3 1 2 3

All weld-metal tension test Tensile strength ,PSI Yield point / strength , PSI Elongation in 2 in, %

N/A N/A N/A N/A

OTHER TEST

Charpy V Notch Impact Test

Notch Specimen ID Specimen Temp °C Absorbed Energy , Joules

Location Size mm A B C Average

N/A N/A N/A N/A N/A N/A N/A N/A

Laboratory Report No Laboratory test No. Welder No

Emirates industrial MA150238P AD-M-3226 JERRY LORDONE / W01

laboratory L.L.C

Manufacturer Verification Company

Quality Fabricators Company W.L.L Industrial Support Services Co

Name

Signature

Date

You might also like

- Nelson Physics 11 SolutionsDocument14 pagesNelson Physics 11 SolutionsRhea100% (1)

- Energy Loss in Pipe and FittingsDocument10 pagesEnergy Loss in Pipe and FittingsMuhd Fadhil Nazer25% (4)

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Planning and Scheduling of SubstructureDocument81 pagesPlanning and Scheduling of SubstructureHnin Wai Mar Aung100% (3)

- Gas Analysis - SECTION6 Interpreting GasDocument10 pagesGas Analysis - SECTION6 Interpreting GasMotorola M Motorola100% (8)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- 07.4 111 FW ML PF WPS 20mm ENGDocument1 page07.4 111 FW ML PF WPS 20mm ENGViktorNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- The Hound of The Baskervilles by Arthur Conan DoyleDocument40 pagesThe Hound of The Baskervilles by Arthur Conan DoyleLisa WardNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- QC E7018 CJP B-L1a OverheadDocument1 pageQC E7018 CJP B-L1a Overheadwmajordan13No ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocument1 pageWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document2 pagesAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS GTAW-SMAW h2Document1 pageWPS GTAW-SMAW h2Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- P WPS Smaw Ceym 001 021Document1 pageP WPS Smaw Ceym 001 021juan carlos garavitoNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Document1 pageQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13No ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- WPS Astm - A 53Document2 pagesWPS Astm - A 53S. K. M. ShujonNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- PQR - 1Document1 pagePQR - 1janardan.sfeNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Report-Welder Qualification TestDocument4 pagesReport-Welder Qualification TestRejoy babyNo ratings yet

- Wqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Document1 pageWqt-1-13-W-1-3g-Smaw-Alclad-Aws D1.1Rejoy babyNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rejoy babyNo ratings yet

- ITP For Site Installation of Pipe Rev 1 15.07.10Document4 pagesITP For Site Installation of Pipe Rev 1 15.07.10Rejoy babyNo ratings yet

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Danem Engineering Works - WLL.: Quality Control & Inspection Test PlanDocument11 pagesDanem Engineering Works - WLL.: Quality Control & Inspection Test PlanRejoy babyNo ratings yet

- Outotec: Danem Engineering Works WLL Doha - QatarDocument4 pagesOutotec: Danem Engineering Works WLL Doha - QatarRejoy babyNo ratings yet

- Danem Engineering Works - WLL: Inspection & Test PlanDocument3 pagesDanem Engineering Works - WLL: Inspection & Test PlanRejoy babyNo ratings yet

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- Consolidated RT TemplateDocument2 pagesConsolidated RT TemplateRejoy babyNo ratings yet

- Painting Procedure 4288 Danem 28-04-13Document24 pagesPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- QP Specification For Painting & Wrapping of Metal Surfaces PDFDocument89 pagesQP Specification For Painting & Wrapping of Metal Surfaces PDFRejoy babyNo ratings yet

- Painting Spec 7J48N-00-23-17-001Document29 pagesPainting Spec 7J48N-00-23-17-001Rejoy babyNo ratings yet

- ME2403-Power Plant EngineeringDocument5 pagesME2403-Power Plant EngineeringkrishnabrNo ratings yet

- Oil Based Mud ThinnerDocument2 pagesOil Based Mud ThinnerjangriNo ratings yet

- Ma 151 Lecture LT1Document95 pagesMa 151 Lecture LT1ryan_tan_17No ratings yet

- Non Spore Forming Gram Positive Rods: CorynebacteriumDocument6 pagesNon Spore Forming Gram Positive Rods: CorynebacteriumggzgzhhsNo ratings yet

- Stackers-Reclaimers PD WebDocument2 pagesStackers-Reclaimers PD WebharpreetresearchNo ratings yet

- Filmu Nyan2Document61 pagesFilmu Nyan2Nike B. Lavenia BZNo ratings yet

- ASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFDocument41 pagesASUG QM Session 1 QM 101 Introduction To SAP Quality Management Module PDFStorm100% (1)

- Arabiansdances PDFDocument33 pagesArabiansdances PDFDCB100% (2)

- Failure of DescentDocument39 pagesFailure of DescentfahlevyNo ratings yet

- Medications AdministrationDocument9 pagesMedications AdministrationGeylla FaeldoniaNo ratings yet

- 1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFDocument518 pages1992 - Pavese - Modern Gas-Based Temperature and Pressure Measurements PDFAlexanderNo ratings yet

- Astm A 865-97Document5 pagesAstm A 865-97Daniel LodiNo ratings yet

- The Ultimate Cancer Proof Diet Prevention and HealingDocument93 pagesThe Ultimate Cancer Proof Diet Prevention and HealingPete pahnNo ratings yet

- Dev and Lap Splice Lengths - ETN-D-1-15Document9 pagesDev and Lap Splice Lengths - ETN-D-1-15erleosNo ratings yet

- 5 Archimedes ١Document4 pages5 Archimedes ١Mohammed Yousif AbdualjabbarNo ratings yet

- FHP ResearchDocument61 pagesFHP ResearchPooja DaveNo ratings yet

- Physics A: Unit: G484: The Newtonian WorldDocument9 pagesPhysics A: Unit: G484: The Newtonian Worldptscribd941No ratings yet

- A MODIFIED PENG-ROBINSON EQUATION OF STATE FOR - ELV - 20519 - FTP PDFDocument12 pagesA MODIFIED PENG-ROBINSON EQUATION OF STATE FOR - ELV - 20519 - FTP PDFLuiz Roberto TerronNo ratings yet

- Recipe Name: Yield/Servings: 1 Quantity Unit Ingredients Market Price Price Per Qty UnitDocument3 pagesRecipe Name: Yield/Servings: 1 Quantity Unit Ingredients Market Price Price Per Qty UnitQueenie AmoraNo ratings yet

- C O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FDocument201 pagesC O / C - S,, Y V: /Itdversions/19.3.0.1/Itdstart - Aspx?Svc 3F50C3C0-1874-400E-Af3A-5036E 79Dec9FharshiniNo ratings yet

- Supra 2019 Final Design ReportDocument12 pagesSupra 2019 Final Design ReportRishit1840030No ratings yet

- Karina Nayyar - Senior Tester 8+ Years ExperiencedDocument2 pagesKarina Nayyar - Senior Tester 8+ Years ExperiencedSanam BindraNo ratings yet

- Amsafe Seatbelt Airbag: First-Responder Reference GuideDocument10 pagesAmsafe Seatbelt Airbag: First-Responder Reference GuideAngel MogrovejoNo ratings yet

- AravindDocument6 pagesAravindyuvi7003No ratings yet

- North East Ds2022Document6 pagesNorth East Ds2022Marlon MccarthyNo ratings yet