Professional Documents

Culture Documents

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Uploaded by

emraan KhanCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSDS Hygienium Antibacterial Gel DisinfectantDocument9 pagesMSDS Hygienium Antibacterial Gel DisinfectantPetrica DascaluNo ratings yet

- Utilization of Copper Slag in M-Sand As Partial Replacement of Fine AggregateDocument4 pagesUtilization of Copper Slag in M-Sand As Partial Replacement of Fine Aggregateemraan KhanNo ratings yet

- Pick Up Acknowledgement Receipt: Order No. Client DateDocument1 pagePick Up Acknowledgement Receipt: Order No. Client Dateemraan KhanNo ratings yet

- Copper Slag Partially Replaces Fine Aggregate in M 25 Concrete: A Comparative Study of Compressive Strength ResponsesDocument8 pagesCopper Slag Partially Replaces Fine Aggregate in M 25 Concrete: A Comparative Study of Compressive Strength Responsesemraan KhanNo ratings yet

- Natarajaet - Al. 77jDocument8 pagesNatarajaet - Al. 77jemraan KhanNo ratings yet

- Energy Conservation Building Code (ECBC) Compliance and Beyond A Pilot StudyDocument48 pagesEnergy Conservation Building Code (ECBC) Compliance and Beyond A Pilot Studyemraan KhanNo ratings yet

- IBS - MBS - BHIM PNB FAQs - Revised-CompressedDocument13 pagesIBS - MBS - BHIM PNB FAQs - Revised-Compressedemraan KhanNo ratings yet

- Identification of Source Factors of Carbon Dioxide (CO) Emissions in Concreting of Reinforced ConcreteDocument7 pagesIdentification of Source Factors of Carbon Dioxide (CO) Emissions in Concreting of Reinforced Concreteemraan KhanNo ratings yet

- READ - ME (Font Installation) PDFDocument1 pageREAD - ME (Font Installation) PDFemraan KhanNo ratings yet

- Embodied CO Emissions in Building Construction Materials of Hellenic DwellingsDocument9 pagesEmbodied CO Emissions in Building Construction Materials of Hellenic Dwellingsemraan KhanNo ratings yet

- Test ReportsDocument1 pageTest Reportsemraan KhanNo ratings yet

- Syeda Khadija Tul Kubra R.A Pdfbooksfree - PK PDFDocument148 pagesSyeda Khadija Tul Kubra R.A Pdfbooksfree - PK PDFemraan KhanNo ratings yet

- Prefabricated StructureDocument129 pagesPrefabricated Structureemraan Khan100% (1)

- Use of Copper Slag in Concrete: Jagmeet Singh Jaspal Singh Manpreet KaurDocument10 pagesUse of Copper Slag in Concrete: Jagmeet Singh Jaspal Singh Manpreet Kauremraan KhanNo ratings yet

- Nitrating Methyl BenzoateDocument6 pagesNitrating Methyl BenzoateOstap 奧斯塔普67% (3)

- Neenah Filtration PresentationDocument11 pagesNeenah Filtration PresentationSurajPandeyNo ratings yet

- TE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.BDocument13 pagesTE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- POC II Unit 1Document29 pagesPOC II Unit 1adapasivagangaNo ratings yet

- Literature Review - Packaging Storage and Shelf Life AnalysisDocument24 pagesLiterature Review - Packaging Storage and Shelf Life AnalysisDeepak BhanjiNo ratings yet

- High Strength FastenersDocument9 pagesHigh Strength Fastenerssudhiruday31No ratings yet

- 10TH Cbse Science Co-4Document11 pages10TH Cbse Science Co-4manojboa100% (1)

- NNAMDI AZIKIWE UNIVERSITY Past QuestionsDocument7 pagesNNAMDI AZIKIWE UNIVERSITY Past QuestionsIkenna Anthony OkaforNo ratings yet

- Manual PS300-DF00-MT01 EngDocument1 pageManual PS300-DF00-MT01 EngYudi Ananta RangkutiNo ratings yet

- Chemistry - Ch-1 NotesDocument5 pagesChemistry - Ch-1 NoteskomalNo ratings yet

- Worksheet - Melting Point DeterminationDocument4 pagesWorksheet - Melting Point DeterminationSobi SitjarNo ratings yet

- Spaq CoDocument7 pagesSpaq Cofadila mohammedNo ratings yet

- Adhesives: How To Remove Stains From ClothesDocument4 pagesAdhesives: How To Remove Stains From Clothesmercy joy garciaNo ratings yet

- Vitrified Tiles 2Document37 pagesVitrified Tiles 2Drashti KachrolaNo ratings yet

- CBLM Food ProcessingDocument126 pagesCBLM Food ProcessingHazel QuimzonNo ratings yet

- Kidneys Function TestDocument17 pagesKidneys Function TestJustine ChibuyeNo ratings yet

- Laboratory Report in Microbiology and ParasitologyDocument3 pagesLaboratory Report in Microbiology and ParasitologyynaNo ratings yet

- Adv Healthcare Materials - 2023 - Wang - Biodegradable Poly Ester Urethane Acrylate Resins For Digital Light ProcessingDocument13 pagesAdv Healthcare Materials - 2023 - Wang - Biodegradable Poly Ester Urethane Acrylate Resins For Digital Light ProcessingMircavid HeydəroğluNo ratings yet

- Matter Class 9Document1 pageMatter Class 9GauraviNo ratings yet

- PhysicalScience11 Module8 Active Ingredients in Product LabelsDocument16 pagesPhysicalScience11 Module8 Active Ingredients in Product LabelsFRECY MARZAN73% (11)

- SPE 90688 Dilution Strategies For Wax Management and Control For Deepwater Development From A Flow Assurance Perspective: Part - Current Practice and PerspectiveDocument13 pagesSPE 90688 Dilution Strategies For Wax Management and Control For Deepwater Development From A Flow Assurance Perspective: Part - Current Practice and PerspectiveBlackCounterNo ratings yet

- BS 6572Document19 pagesBS 6572Fenner Electromechanical100% (1)

- Investigatory Project Chemistry For Class 12thDocument20 pagesInvestigatory Project Chemistry For Class 12tharpit guptaNo ratings yet

- Omexco Allure Wallpaper Ga - EN Hanging InstructionsDocument1 pageOmexco Allure Wallpaper Ga - EN Hanging InstructionsSocary BedorNo ratings yet

- Duraplate 301 - L - K en PDFDocument4 pagesDuraplate 301 - L - K en PDFtienNo ratings yet

- FTIRDocument79 pagesFTIRshruti shahNo ratings yet

- 4U3S Water SupplyDocument15 pages4U3S Water SupplyKhin Thu Zar HtayNo ratings yet

- Difference Between Sterilization and DisinfectionDocument4 pagesDifference Between Sterilization and Disinfectiontaz_taz3No ratings yet

- Product List - Order SheetDocument2 pagesProduct List - Order SheetRohit PandeyNo ratings yet

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Uploaded by

emraan KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Performance of Copper Slag As Replacement of Fine Aggregate With Different Grades

Uploaded by

emraan KhanCopyright:

Available Formats

Journal of Critical Reviews

ISSN- 2394-5125 Vol 7 , Issue 9, 2020

PERFORMANCE OF COPPER SLAG AS REPLACEMENT OF FINE AGGREGATE WITH

DIFFERENT GRADES

Chadalavada Teja1, Divya Anusha Naidu2, Dr.Dumpa Venkateswarlu3

Department of civil engineeringGodavari Institute of Engineering and Technology (Autonomous), Rajahmundry, AP, India

1,2,3,4,5

Received: 18.03.2020 Revised: 12.04.2020 Accepted: 10.05.2020

Abstract

Copper slag is the waste material that is generated during the manufacturing process of copper. As per the statistics for manufacturing of

one ton copper leads to generation of 2.25 tons of copper slag. Although this material is adopted for different other purposes like land

filling and abbrasive tools preparation, low quality tools and railway ballast materials. Inspite of all these application around the world

only 18 percent of copper slag is used remaining 82% comes under wastage. but if We adopt the same copper slag material as a

replacement of construction material in construction industry as may be full replacement or partial replacement of either cementing

material or fine aggregates it will have a promising future. At the same time the remaining 82 % waste copper slag have the added valve

in construction industry and at the same time land filling problem will get solve.

From past 20 years so many researchers already proved that the the usage of copper slag as a replacement in concrete will possible

due to same granular size of copper likely as of fine aggregate. Not only as fine aggregate replacement, the finely grained copper slag

powder can also be adopted as partial replacement of cementing material to concrete and in the production of cement lime clinkers

There are so many researches are carried around the globe on the usage of copper slag as replacement material, but in India a very

few researches are carried. In this particular thesis mainly looked on to generate specific investigation data on the use of copper slag

as fine aggregate replacement in partial basis.

Keywords:Copper slag, Compressive Strength, Split Tensile Strength, Flexural Strength, Durability and Weight loss

© 2020 by Advance Scientific Research. This is an open-access article under the CC BY license (http://creativecommons.org/licenses/by/4.0/)

DOI: http://dx.doi.org/10.31838/jcr.07.09.141

INTRODUCTION steady usefulness and considered the impact of super plasticizer

Most of the research project in civil engineering field dealt expansion on the properties of HSC made with copper slag.

with the material altering by replacement of full or partial

basis by industrial waste material and industrial byproducts. Newton a.k (2009 a) researched the impact of utilizing copper

The main replacement in fine aggregate is observed and after slag as a substitution of sand on the properties of superior

the cementing replacement is also mostly observed. New cement (HPC). Eight solid blends were set up with various

results and waste materials are being created by different extents of copper slag running from 0% (for the control blend) to

ventures. Dumping or removal of waste materials causes 100%.

natural and medical issues. Along these lines, reusing of Wei wu et al (2010) researched the mechanical properties of

waste materials is an incredible potential in solid industry. high quality cement fusing copper slag as fine total. The

For a long time, side-effects, for example, fly debris, silica functionality and quality attributes were evaluated through a

smoke and slag were considered as waste materials. progression of tests on six distinctive blending extents at 20%

Concrete arranged with such materials indicated steady copper slag by weight substitution of sand from 0% to

improvement in functionality and strength contrasted with 100%. A high range water diminishing admixture was fused to

typical cement and has been utilized in the development of accomplish satisfactory usefulness.

intensity, synthetic plants and submerged structures. Over

late decades, concentrated research considers have been AIM:

done to investigate all conceivable reuse techniques. The primary point of this exploration work was to research

Development squander, impact heater, steel slag, coal fly powerful substitution of sand and concrete by copper slag in

debris and base debris have been acknowledged in cement and RCC basic components and its applications to

numerous spots as elective totals in bank, streets, asphalts, decrease seismic earth pressure. To accomplish this, a broad

establishment and building development, crude material in examination has been done to research the accompanying

the assembling of conventional Portland concrete brought up utilizing copper slag.

by Teikthyeluin et al (2006).

Copper slag is a modern result material created from the way 1. To locate the ideal extent of copper slag that can be utilized

toward assembling copper. For each ton of copper creation, as a substitution/substitute material for concrete and fine

about 2.2 huge amounts of copper slag is produced. It has total.

been evaluated that roughly 24.6 million tons of slag are 2. To assess compressive and elasticity of copper slag admixed

created from the world copper industry (Gorai et al 2003). solid examples.

Despite the fact that copper slag is broadly utilized in the 3. To research flexural, pivotal compressive and clasping

sand impacting industry and in the assembling of grating quality of copper slag supplanted auxiliary individuals.

apparatuses, the rest of discarded with no further reuse or 4. To research consumption and solidness attributes of copper

recovery. slag admixed concrete.

5. To analyze the chance of utilizing copper slag in opposing

Al-Jabri et al (2009) has examined the presentation of high seismic earth pressure.

quality cement (HSC) made with copper slag as a fine total at

Journal of critical reviews 731

PERFORMANCE OF COPPER SLAG AS REPLACEMENT OF FINE AGGREGATE WITH DIFFERENT GRADES

MATERIALS: low temperature for solidification. The end product is a solid,

A.CEMENT: hard material that goes to the crusher for further processing.

An OPC 43 Grade RASSI concrete was utilized in this Copper slag used in this work was bought from Sterlite

examination. The amount required for this work was surveyed industries (India) ltd, Tuticorin, Tamil Nadu, India.

and the whole amount was bought and put away appropriately in

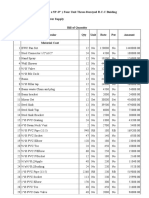

throwing yard. The accompanying tests were directed as per IS Table 4- copper slag sieve analysis observed values

codes.

• specific gravity (Le – Chatelier flask) (IS: 1727-1967)

• Standard consistency (IS: 4031 – 1988 Part 4)

• Initial setting time (IS: 4031 – 1988 Part 5)

• final setting time (IS: 4031 – 1988 Part 5)

Table 1 -Tests on cement

Table 5- copper slag physical properties observed

FINE AGGREGATE:

The clean Godavari river sand adopted for the fine aggregate

testing purpose as per IS: 2386- 1968 (III). The below test

are carried,

▪ Specific gravity test

▪ Sieve Analysis and Fineness Modulus test

▪ Water absorption test

Table 2- Fine aggregate test results

Figure 1-copper slag sample

Table 6 Chemical properties of copper slag

C.COARSE AGGREGATE

In this thesis the locally available Rajahmundry quarry gravel

metal of size 20 mm and down, was adopted and the below

tets carried for selction of those aggregates.

• Specific gravity test (IS: 2386-1968 Part 3)

• Bulk density test (IS: 2386-1968 Part 3)

• Sieve analysis and Fineness modulus test (IS: 2386-1968

Part 3)

• Crushing value test (IS: 2386 – 1968 Part 4)

MIX DESIGN:

Table 3- Tests on coarse aggregate The blend extent picked for this examination is 1: 1.66: 3.76 with

Water/Cement proportion of 0.45 appeared in Table 4.8. M20

concrete was utilized. These fundamental blend extents were

changed in utilizing copper slag as a halfway trade for sand and

concrete. Absolutely twelve solid blends were set up with various

extents of copper slag extending from 0% (for control blend) to

. 60% with sand named as CC, S10, S20, S30, S40, S50 and S60 (Six

blends), 5% to 20% with concrete named as C05, C10, C15 and

COPPER SLAG: C20 (Four blends) and one joined blend named as CMB (One

Copper slag is a by-product material produced from the blend). Every blend contains three examples.

process of manufacturing copper. As the copper settles down

in the smelter, it has a higher density, impurities stay in the

top layer and then are transported to a water basin with a

Journal of critical reviews 732

PERFORMANCE OF COPPER SLAG AS REPLACEMENT OF FINE AGGREGATE WITH DIFFERENT GRADES

Table 7- WEIGHT AS PER MIX DESIGN Table 10- compressive strength of mortar cubes

NUMBER OF SPECIMENS:

The number of specimens cast for this research was given in

Table 4.9.

For Sand Replacement

Table 8- NUMBER OF SAMPLES Compressive strength test on concrete cubes:

The effect of copper slag substitution as a fine aggregate on

the strength of concrete is given in Table 6.2, which presents

the average 7 and 28 day cube compressive strength of

concrete. A total number of 42 mortar specimens were cast

and tested shown in Figure 6.1. The unconfined compressive

strength values of concrete mixtures with different

proportions of copper slag tested at 7 and 28 days are also

plotted in Figure 6.2.

Table 11- Compressive strength test on concrete specimens

For corrosion studies :

Table 9-NUMBER OF TEST SAMPLES

TESTRESULTS AND DISCUSSION:

The below tests were conducted on concrete specimens

which are prepared by partial replacement of fine aggregate

with copper slag. Figure 2 Compressive strength of concrete cubes

Compressive strength test on mortar and concrete specimens

• Split tensile test on concrete cylinders of size 150mm

diameter and 300mm height.

• Flexural strength test on concrete beam specimens of size

750 x 150 x 150mm.

• Flexural behaviour of RCC beams of size 1500mm length

and 150mm x 150mm cross section.

• Buckling characteristics of RCC long columns of size

1900mm length and 150mm x 150mm cross section.

Compressive Strength Test:

Compressive strength test on:

The measured compressive strength values are presented

Figure 3 Load Vs deflection diagram of S40 concrete

specimens

Journal of critical reviews 733

PERFORMANCE OF COPPER SLAG AS REPLACEMENT OF FINE AGGREGATE WITH DIFFERENT GRADES

Split Tensile Strength Test on Concrete Cylinders:

Split tensile strength is defined as a method of determining

the tensile strength of concrete using a cylinder which splits

across the vertical diameter. The effect of copper slag

substitution as a fine aggregate on split tensile strength of

concrete is given in Table 6.3.

Table 12- Split tensile strength test on cylinders

Figure 6 Load vs deflection ofS40 beam

Flexural Strength Test on Concrete Beams:

The size of beam specimens cast for flexure test was 750

x150 x 150mm as per IS 456: 2000. The beam specimens

were fabricated and tested with and without copper slag

addition in concrete for normal conditions. 18 numbers of Figure 7 Load vs deflection ofS60 beam

concrete beam specimens were cast with replacement of 0%,

20%, 40%, 60%, 80% and 100%. The flexural strength of

concrete was calculated using the following formula and the

results are given in Table 6.4.

F= (M/I)*Y

Figure 4 Flexural failure of S100 concrete beam Figure 8 Load vs deflection ofConcrete beam of various

proportions

Table 13- Flexural strength test results on concrete beams

Table 14-copper slag replaced with sand

CONCLUSION:

Based on the investigations, the following conclusions were

drawn.

• The utilisation of copper slag in concrete provides

additional environmental as well as technical benefits

for all related industries. Partial replacement of copper

slag in fine aggregate and cement reduces the cost of

making concrete.

• Replacement of copper slag (100% replacement with

sand) increases the self weight of concrete specimens to

the maximum of 15-18%.

• The initial and final setting time of copper slag admixed

Figure 5 Load vs deflection of concrete beam concrete is higher than control concrete.

Journal of critical reviews 734

PERFORMANCE OF COPPER SLAG AS REPLACEMENT OF FINE AGGREGATE WITH DIFFERENT GRADES

• Water absorption of copper slag was 0.16% compared • Copper slag can be effectively replaced in making

with 1.25% for sand. Therefore, the workability of bricks, hollow blocks and pavement blocks

concrete increases significantly with the increase of • Since copper slag has higher shear strength value it

copper slag content in concrete mixes. This was can be used for soil stabilization.

attributed to the low water absorption and glassy • Copper slag can be replaced along with fly ash, silica

surface of copper slag. fume and granulated blast furnace slag in concrete and

• The results of compressive, split tensile strength test RCC members which can be tested for mechanical

have indicated that the strength of concrete increases performances.

with respect to the percentage of copper slag added by

the weight of fine aggregate up to 40% (S40). Further REFERENCES

additions of copper slag caused reduction in strength 1. Akihiko, Y. and Takashi, Y. “Study of utilisation of

due to an increase of free water content in the mix. copper slag as fine aggregate for concrete”, Ashikaya

• There was more than 60% improvement in the flexural Kogyo DaigakuKenkyuShuroku, Vol. 23, pp. 79-85,

strength of concrete beams with 40% (S40) copper slag 1996.

replacement for sand. The flexural strength of beams

were increased up to 60% (S60) replacement, when 2. Al-Jabri, K. and Makoto Hisada. “Copper slag as sand

compared to control mixes. After that the strength was replacement for high performance concrete”, Cement &

suddenly decreased to 12% for S80 mixes and 22% for Concrete Composites, Vol. 31,P.P483- 488, 2009.

S100 mixes. The reason for reduction in strength was, 3. ASTM C-1202-09--Standard test method for electrical

the low absorption properties ofcopper slag can leave indication of concrete’s ability to resist chloride ion

excess water in concrete, which can cause excessive penetration: Annual Book of ASTM standards

bleeding at higher copper slag content. (Philadelphia).

• There is an increase of 28.67% of ultimate load carrying 4. Awad Al-Karni, and AbdulhafizAlshenawy, “Modeling of

capacity was achieved for flexure beams, when copper Stress-Strain Curves of Drained Triaxial Test on Sand”,

slag replaced with 40% of sand. The stiffness of S40 American Journal of Applied Sciences, Vol. 3, No. 11, pp.

beams was increased to 33.34% at yield load and 2108-2113, 2006

17.83% at ultimate load compared to control mixes. 5. Ayano, T., Kuramoto, O. and Sakata, K. “Concrete with

• The surface water absorption of concrete was reduced copper slag as fine aggregate”, Jounal of Society

with up to 40% copper slag replacement for sand. The Material Science Japan, Vol. 49, No. 10, pp. 1097-1102,

volume of permeable voids decreased with the 2000.

replacement of up to 40% copper slag. Therefore it can 6. Caijun Shi, and Jueshi Qian, “High performance

be concluded that, copper slag, in the range of 40–50%, cementing materials from industrial slags — a review”

could potentially replace sand in concrete mixtures. Resources, Conservation and Recycling, Vol. 29, pp.

• Utilisation of copper slag as Portland cement 195-207, 2000.

replacement in concrete and as a cement raw material 7. IS : 1727 – 1967, “Indian Standard methods of test for

has the dual benefit of eliminating the costs of disposal pozzolanic materials”, Bureauo of Indian standards,

and lowering the cost of the concrete. New Delhi.

• When copper slag replaced with cement, addition of 8. IS 2386 : Part 3 : “Methods of Test for Aggregates for

hydrated lime by 1.5% to the weight of cement gives Concrete Part 3, 1963.

improvement in the rate of strength gain. S-type 9. IS 4031: Part 4: “Methods for physical test for hydraulic

hydrated lime was used as activator for pozzolanic cements”, Bureau of Indian standards, New Delhi, 1988.

reaction to improve the strength gain in copper slag 10. IS 516:1959, “Method of Test for Strength of Concrete”,

admixed concrete. Reaffirmed 2004, Bureau of Indian standards, New

• The maximum compressive, split tensile strength was Delhi.

achieved at 15% (C15) replacement to the weight of

cement. There is an increase of compressive strength

was achieved around 15.13% compared to control

mixes. But, this is 26% lower than S40 specimens.

Similarly, for split tensile strength test, the strength was

increased to 15.23% for C15 specimens compared to

control mixes, whereas this is 10% lower than S40

specimens.

• It was observed that, the copper slag replacement for

sand is more effective than cement.

• For cement replacement, ultimate load carrying

capacity of copper slag admixed RCC beams has

increased to 25% with that of control specimens.

• There is an increase of 14.47% of compressive strength

in combination mixes (CMB) compared to control mix.

The compressive strength improvement is slighltly

lesser than S40 and C15 specimens but greater than

C05 and C10 specimens.

SCOPE FOR FUTURE WORKS

• This research was intended to examine the influence

of copper slag additions in concrete and RCC elements

for M20 mixes. The same word can be extended to

higher grades of concrete mixes with varing

water/cement ratio

Journal of critical reviews 735

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MSDS Hygienium Antibacterial Gel DisinfectantDocument9 pagesMSDS Hygienium Antibacterial Gel DisinfectantPetrica DascaluNo ratings yet

- Utilization of Copper Slag in M-Sand As Partial Replacement of Fine AggregateDocument4 pagesUtilization of Copper Slag in M-Sand As Partial Replacement of Fine Aggregateemraan KhanNo ratings yet

- Pick Up Acknowledgement Receipt: Order No. Client DateDocument1 pagePick Up Acknowledgement Receipt: Order No. Client Dateemraan KhanNo ratings yet

- Copper Slag Partially Replaces Fine Aggregate in M 25 Concrete: A Comparative Study of Compressive Strength ResponsesDocument8 pagesCopper Slag Partially Replaces Fine Aggregate in M 25 Concrete: A Comparative Study of Compressive Strength Responsesemraan KhanNo ratings yet

- Natarajaet - Al. 77jDocument8 pagesNatarajaet - Al. 77jemraan KhanNo ratings yet

- Energy Conservation Building Code (ECBC) Compliance and Beyond A Pilot StudyDocument48 pagesEnergy Conservation Building Code (ECBC) Compliance and Beyond A Pilot Studyemraan KhanNo ratings yet

- IBS - MBS - BHIM PNB FAQs - Revised-CompressedDocument13 pagesIBS - MBS - BHIM PNB FAQs - Revised-Compressedemraan KhanNo ratings yet

- Identification of Source Factors of Carbon Dioxide (CO) Emissions in Concreting of Reinforced ConcreteDocument7 pagesIdentification of Source Factors of Carbon Dioxide (CO) Emissions in Concreting of Reinforced Concreteemraan KhanNo ratings yet

- READ - ME (Font Installation) PDFDocument1 pageREAD - ME (Font Installation) PDFemraan KhanNo ratings yet

- Embodied CO Emissions in Building Construction Materials of Hellenic DwellingsDocument9 pagesEmbodied CO Emissions in Building Construction Materials of Hellenic Dwellingsemraan KhanNo ratings yet

- Test ReportsDocument1 pageTest Reportsemraan KhanNo ratings yet

- Syeda Khadija Tul Kubra R.A Pdfbooksfree - PK PDFDocument148 pagesSyeda Khadija Tul Kubra R.A Pdfbooksfree - PK PDFemraan KhanNo ratings yet

- Prefabricated StructureDocument129 pagesPrefabricated Structureemraan Khan100% (1)

- Use of Copper Slag in Concrete: Jagmeet Singh Jaspal Singh Manpreet KaurDocument10 pagesUse of Copper Slag in Concrete: Jagmeet Singh Jaspal Singh Manpreet Kauremraan KhanNo ratings yet

- Nitrating Methyl BenzoateDocument6 pagesNitrating Methyl BenzoateOstap 奧斯塔普67% (3)

- Neenah Filtration PresentationDocument11 pagesNeenah Filtration PresentationSurajPandeyNo ratings yet

- TE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.BDocument13 pagesTE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- POC II Unit 1Document29 pagesPOC II Unit 1adapasivagangaNo ratings yet

- Literature Review - Packaging Storage and Shelf Life AnalysisDocument24 pagesLiterature Review - Packaging Storage and Shelf Life AnalysisDeepak BhanjiNo ratings yet

- High Strength FastenersDocument9 pagesHigh Strength Fastenerssudhiruday31No ratings yet

- 10TH Cbse Science Co-4Document11 pages10TH Cbse Science Co-4manojboa100% (1)

- NNAMDI AZIKIWE UNIVERSITY Past QuestionsDocument7 pagesNNAMDI AZIKIWE UNIVERSITY Past QuestionsIkenna Anthony OkaforNo ratings yet

- Manual PS300-DF00-MT01 EngDocument1 pageManual PS300-DF00-MT01 EngYudi Ananta RangkutiNo ratings yet

- Chemistry - Ch-1 NotesDocument5 pagesChemistry - Ch-1 NoteskomalNo ratings yet

- Worksheet - Melting Point DeterminationDocument4 pagesWorksheet - Melting Point DeterminationSobi SitjarNo ratings yet

- Spaq CoDocument7 pagesSpaq Cofadila mohammedNo ratings yet

- Adhesives: How To Remove Stains From ClothesDocument4 pagesAdhesives: How To Remove Stains From Clothesmercy joy garciaNo ratings yet

- Vitrified Tiles 2Document37 pagesVitrified Tiles 2Drashti KachrolaNo ratings yet

- CBLM Food ProcessingDocument126 pagesCBLM Food ProcessingHazel QuimzonNo ratings yet

- Kidneys Function TestDocument17 pagesKidneys Function TestJustine ChibuyeNo ratings yet

- Laboratory Report in Microbiology and ParasitologyDocument3 pagesLaboratory Report in Microbiology and ParasitologyynaNo ratings yet

- Adv Healthcare Materials - 2023 - Wang - Biodegradable Poly Ester Urethane Acrylate Resins For Digital Light ProcessingDocument13 pagesAdv Healthcare Materials - 2023 - Wang - Biodegradable Poly Ester Urethane Acrylate Resins For Digital Light ProcessingMircavid HeydəroğluNo ratings yet

- Matter Class 9Document1 pageMatter Class 9GauraviNo ratings yet

- PhysicalScience11 Module8 Active Ingredients in Product LabelsDocument16 pagesPhysicalScience11 Module8 Active Ingredients in Product LabelsFRECY MARZAN73% (11)

- SPE 90688 Dilution Strategies For Wax Management and Control For Deepwater Development From A Flow Assurance Perspective: Part - Current Practice and PerspectiveDocument13 pagesSPE 90688 Dilution Strategies For Wax Management and Control For Deepwater Development From A Flow Assurance Perspective: Part - Current Practice and PerspectiveBlackCounterNo ratings yet

- BS 6572Document19 pagesBS 6572Fenner Electromechanical100% (1)

- Investigatory Project Chemistry For Class 12thDocument20 pagesInvestigatory Project Chemistry For Class 12tharpit guptaNo ratings yet

- Omexco Allure Wallpaper Ga - EN Hanging InstructionsDocument1 pageOmexco Allure Wallpaper Ga - EN Hanging InstructionsSocary BedorNo ratings yet

- Duraplate 301 - L - K en PDFDocument4 pagesDuraplate 301 - L - K en PDFtienNo ratings yet

- FTIRDocument79 pagesFTIRshruti shahNo ratings yet

- 4U3S Water SupplyDocument15 pages4U3S Water SupplyKhin Thu Zar HtayNo ratings yet

- Difference Between Sterilization and DisinfectionDocument4 pagesDifference Between Sterilization and Disinfectiontaz_taz3No ratings yet

- Product List - Order SheetDocument2 pagesProduct List - Order SheetRohit PandeyNo ratings yet