Professional Documents

Culture Documents

103 Handling of Flammable Materials

103 Handling of Flammable Materials

Uploaded by

jayadushOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

103 Handling of Flammable Materials

103 Handling of Flammable Materials

Uploaded by

jayadushCopyright:

Available Formats

HSE MANAGEMENT SYSTEM SAFE OPERATING PROCEDURE

Doc. Number Rev. Date Page No

HIGHLY FLAMMABLE LIQUIDS HSE/SOP/103 0 20 Oct 03 1 of 2

1 GENERAL GUIDELINES

All deliveries of HFLs (Highly Flammable Liquids) should be made directly into a store. They must not be off loaded into one

position, and left until later for someone to put them away in the correct store.

Decanting, mixing or sampling should not be carried out in a store. It should be done in the open air or in a separate room

constructed of fire resisting materials or with adequate fire control system.

Funnels should be used to prevent spillage whilst decanting is taking place and drip trays should be used to catch any

spillage that may inadvertently occur.

Any spillage should be soaked up using dry earth, sand or proprietary absorbents.

Metal bins with lids should be provided for any used absorbents to be placed in and these should be emptied regularly and

carefully.

Advice should be sought on the disposal of all used absorbents from the local authority Waste Disposal Officer.

2 EMPTY TANKS AND CONTAINERS

DO NOT CUT ANY EMPTY TANKS, CONTAINERS OR DRUMS. THEY ARE FULL OF GAS AND WILL EXPLODE AND

KILL YOU.

Special care is necessary when demolishing or dismantling disused tanks. By disturbing the tank or heating the residues left

inside, you may cause an explosive concentration of vapors. Before any dismantling work is carried out, advice should be

sought from the HSE Engineer.

Any entry which is to be made into any disused or large tanks should only be made under a Permit to Work system.

3 USE OF HIGHLY FLAMMABLE LIQUIDS

In general, where work involves the use of any HFL inside a room, all electrical power should be turned off. If space heating

is needed, it should be flameproof and incapable of causing the ignition of any vapors given off by the HFL.

Heavy concentrations of HFL vapors should be avoided and dispersed, if necessary, by natural or mechanical ventilation.

Other points which should be considered are:

• Naked flames, welding and heating torches or smoking materials should be prohibited in any area where HFLs are

present.

• Metal bins with lids must be provided for off-cuts, waste or rags. They should be emptied regularly.

• Use a suitable container with a lid for any brushes or scrapers, which require soaking, removing residues of HFLs.

This should be placed in a safe area well away from any possible source of ignition.

4 SPRAYING OF HIGHLY FLAMMABLE LIQUIDS

The use of a gun for spraying highly flammable liquids may introduce airborne explosive mists into the workplace, thereby

creating a hazard both to the user and to other works in the area. New covering materials, such as paints, varnishes and

lacquers, and the techniques for applying them, have been developed and extensive use of spray painting equipment can

now be seen on construction sites.

Points to be noted:

• Identify the material carefully and always follow the manufacturer’s instructions as to preparation, use and

application.

• Always use the correct type of spraying equipment.

• Always use the hygiene and washing facilities provided.

• Do not introduce ignition sources into the working area.

• Do not smoke or use naked flames in the working area.

• Always place warning signs in the approaches to the area where the work is being carried out, in the doorways of the

room where HFLs are being used and use physical barriers, if necessary, to stop any unauthorized persons

approaching the work site.

REVIEWED & APPROVED QA & HSE MANAGER

HSE MANAGEMENT SYSTEM SAFE OPERATING PROCEDURE

Doc. Number Rev. Date Page No

HIGHLY FLAMMABLE LIQUIDS HSE/SOP/103 0 20 Oct 03 2 of 2

5 PETROLEUM BASED ADHESIVES

The requirements for the storage and use of petroleum mixtures are very similar to those necessary for highly flammable

liquids. All references on the previous pages should, therefore, also be applicable to petroleum-based adhesives. The

following notes indicate the additional, special precautions that are required for petroleum-based adhesives.

Dangers can arise from petroleum-based adhesives in poorly ventilated areas, when vapors are allowed to collect in spaces

or areas where they cannot naturally disperse. Vapors from petroleum-based adhesives are flammable, narcotic and toxic,

and will replace the oxygen in the air causing drowsiness, unconsciousness and ultimately death.

Ignition of the vapors by a spark from a tool, by switching a light switch, plug or any other electrical equipment on or off, can

result in a serious explosion.

Points to remember:

• Identify the adhesive carefully and follow the manufacturer’s instructions as to uses and application of the adhesive.

• Open all doors and windows. It is essential that the work area be ventilated as well as it possible.

• Extinguish all flames, pilot lights and heating appliances.

• Do not smoke or allow ignition sources into the work area.

• Use the correct warning notices in areas where petroleum based adhesives are being used. Put up physical barriers,

if necessary, to prevent unauthorized entry.

Where petroleum based adhesives are used and you are concerned about dangerous vapors collecting and possibly causing

a dangerous situation, use sampling equipment to assess the possibility of a hazardous situation occurring.

REVIEWED & APPROVED QA & HSE MANAGER

You might also like

- Acute and Chronic Wounds - Current Management Concepts (PDFDrive)Document1,872 pagesAcute and Chronic Wounds - Current Management Concepts (PDFDrive)Tasha FarahNo ratings yet

- Medical Insurance Policy - FirstFix - Version3Document3 pagesMedical Insurance Policy - FirstFix - Version3marklee torres100% (1)

- Working Safely With Conformal Coatings - A Guide To Safe Working PracticesDocument4 pagesWorking Safely With Conformal Coatings - A Guide To Safe Working PracticesLee HitchensNo ratings yet

- SBS Leaflet PDFDocument2 pagesSBS Leaflet PDFjayadushNo ratings yet

- Pink Panther - Diabetes Management - Chapter 25Document6 pagesPink Panther - Diabetes Management - Chapter 25jennmoyerNo ratings yet

- Dangerous Goods Checklist For Contractors: Explanation CommentDocument1 pageDangerous Goods Checklist For Contractors: Explanation CommentKatlego MoepiNo ratings yet

- 6 - Store InspectionDocument4 pages6 - Store InspectionabdulrehmanNo ratings yet

- Organic SolventsSOPDocument6 pagesOrganic SolventsSOPNikhilesh KumarNo ratings yet

- Lab CHP Sop Entire-2Document66 pagesLab CHP Sop Entire-2Furqan ShabbirNo ratings yet

- Fire & SafetyDocument18 pagesFire & SafetyBalakumar67% (3)

- Final Health and SafetyDocument11 pagesFinal Health and SafetyMalka Melani JayaweeraNo ratings yet

- Freelander 2 BADocument6 pagesFreelander 2 BAJim LiebNo ratings yet

- Dremel CautinDocument28 pagesDremel CautinrcpilotNo ratings yet

- Safe Working With Flammable SubstancesDocument5 pagesSafe Working With Flammable SubstancesTrebor SantosNo ratings yet

- R32 MSDSDocument10 pagesR32 MSDSErinoviar AkilNo ratings yet

- Probler P2 Elite Operation ManualDocument28 pagesProbler P2 Elite Operation ManualPavel KosevNo ratings yet

- 2012-10 - Laboratory Fire SafetyDocument5 pages2012-10 - Laboratory Fire SafetykhavihongNo ratings yet

- General Laboratory RulesDocument1 pageGeneral Laboratory RulesCarmel Anne Trawon TumaponNo ratings yet

- Hamdan Fire Safety - Protection ProcedureDocument8 pagesHamdan Fire Safety - Protection ProcedureAli jafriNo ratings yet

- Blasting Painting WorkDocument4 pagesBlasting Painting WorkHasanuddin HAMIDNo ratings yet

- 091-0541 CobraTig 150XM 254-151 LoResDocument32 pages091-0541 CobraTig 150XM 254-151 LoResAmenAllahRaoudhaBoukerNo ratings yet

- Vogel Zang Stove Kit BK 150 eDocument16 pagesVogel Zang Stove Kit BK 150 eLovely GreenNo ratings yet

- Laboratory Safety GuidelinesDocument36 pagesLaboratory Safety Guidelinesdimuthu manojNo ratings yet

- Smoker InstructionsDocument28 pagesSmoker InstructionsjoelmhinckNo ratings yet

- 3.safe Handling and Storage of ChemicalsDocument3 pages3.safe Handling and Storage of Chemicalsjacobpm2010100% (1)

- Safe Use Pyrophoric ReagentsDocument9 pagesSafe Use Pyrophoric ReagentsDarius DsouzaNo ratings yet

- Sigma C200a Coaltar Epoxy BaseDocument1 pageSigma C200a Coaltar Epoxy BaseBilal Ghazanfar100% (1)

- 9 C3-Handling-Pyrophoric-Materials-OK-Updated-2021Document3 pages9 C3-Handling-Pyrophoric-Materials-OK-Updated-2021libingms40No ratings yet

- ARA CAR Cutting Torch ProtocolDocument3 pagesARA CAR Cutting Torch Protocoldanik133No ratings yet

- Sds-Evamarine ExteriorDocument6 pagesSds-Evamarine ExteriorSaifuddin FahmiNo ratings yet

- Safety Policies in A Chemical LaboratoryDocument2 pagesSafety Policies in A Chemical Laboratorynieldurante1519No ratings yet

- SOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Document2 pagesSOP Flammable and Combustible Liquids: Doc: AAP/HR/EOHS/SP/FCL/00Neeraj TomerNo ratings yet

- Emergencies and SpillsDocument5 pagesEmergencies and SpillsClement KipyegonNo ratings yet

- Safe Working With Flammable Substances - HSE UK PDFDocument12 pagesSafe Working With Flammable Substances - HSE UK PDFdan antonNo ratings yet

- Lava Heat Italia - Lava Lite Patio Heater - Owners ManualDocument20 pagesLava Heat Italia - Lava Lite Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- Hydrogen Safety OverviewDocument2 pagesHydrogen Safety OverviewgnkameshNo ratings yet

- General Laboratory Safety RulesDocument2 pagesGeneral Laboratory Safety RulesRavintheranNo ratings yet

- TurboDocument126 pagesTurboRomulus GeorgescuNo ratings yet

- Shop Vacuum ProceduresDocument2 pagesShop Vacuum ProceduresRoland von KurnatowskiNo ratings yet

- Construction Fire SafetyDocument10 pagesConstruction Fire SafetyAshish MauryaNo ratings yet

- BUTANE Safety Data Sheet - V6Document10 pagesBUTANE Safety Data Sheet - V6Mohammed NuseirNo ratings yet

- Pit Boss Smoker Owner's ManualDocument32 pagesPit Boss Smoker Owner's Manuallulabell79No ratings yet

- Chemical Storeroom ChecklistDocument5 pagesChemical Storeroom ChecklistEamonn Mc Conway100% (1)

- Manual Dezumidificator TurbionaireDocument108 pagesManual Dezumidificator TurbionairePerfectreviewNo ratings yet

- Fire Prevention ProcedureDocument7 pagesFire Prevention ProcedureEmmanuel TsabolaNo ratings yet

- Turbionaire Senso 12Document108 pagesTurbionaire Senso 12vimannNo ratings yet

- Oxy Fuel CuttingDocument32 pagesOxy Fuel Cuttingvpsimbu86No ratings yet

- Safe Use Pyrophoric ReagentsDocument8 pagesSafe Use Pyrophoric ReagentsGeorgeNo ratings yet

- Flammable Liquids GasesDocument1 pageFlammable Liquids GasesKyaw Kyaw AungNo ratings yet

- Safety While Working On PipelinesDocument6 pagesSafety While Working On PipelinesVaibhav Vithoba Naik0% (1)

- MS Horizontal Series PW Manual Rev 0 12022017 1Document76 pagesMS Horizontal Series PW Manual Rev 0 12022017 1Robert BNo ratings yet

- Flammable Solvents Use SopDocument1 pageFlammable Solvents Use SopciukbescribdNo ratings yet

- Etc Smoke Density AstmDocument8 pagesEtc Smoke Density AstmEngr. Mehadi Hassan NahidNo ratings yet

- General Laboratory Safety PracticesDocument98 pagesGeneral Laboratory Safety PracticesMark Lorenzo NegreNo ratings yet

- Umeguard SX White Cs-651Document12 pagesUmeguard SX White Cs-651Mugilrajan DevarajanNo ratings yet

- Fuel Blending SOP1Document5 pagesFuel Blending SOP1Hendra Andreas Noverman SinagaNo ratings yet

- LPG Filling Station COP Nov 2007 (11-2008)Document4 pagesLPG Filling Station COP Nov 2007 (11-2008)qaramanNo ratings yet

- Mayor, Royal and Pontifical University of San Francisco Xavier of ChuquisacaDocument4 pagesMayor, Royal and Pontifical University of San Francisco Xavier of ChuquisacaJuan José Tirado BalcasNo ratings yet

- DULUX Diamond Matt Safety SheetDocument8 pagesDULUX Diamond Matt Safety SheetjustinNo ratings yet

- Management of Combustible Gas, Oxygen Displacing Gases and Toxic GasesDocument18 pagesManagement of Combustible Gas, Oxygen Displacing Gases and Toxic GasesFfwms Spain0% (1)

- Assignment of Control TechniquesDocument15 pagesAssignment of Control TechniquesAnanda NairNo ratings yet

- British Council PrintDocument1 pageBritish Council PrintjayadushNo ratings yet

- Nature VS PsychologyDocument4 pagesNature VS PsychologyjayadushNo ratings yet

- Construction Project Management-Sri Lankan ExampleDocument16 pagesConstruction Project Management-Sri Lankan ExamplejayadushNo ratings yet

- MRN 163Document1 pageMRN 163jayadushNo ratings yet

- Central Province - Phy - Marking SchemeDocument18 pagesCentral Province - Phy - Marking SchemejayadushNo ratings yet

- Academic WritersDocument3 pagesAcademic WritersjayadushNo ratings yet

- Parapsychology Relevant To Spirituality and Psychiatry James PandarakalamDocument7 pagesParapsychology Relevant To Spirituality and Psychiatry James PandarakalamjayadushNo ratings yet

- Visakha College Combined Maths 3rd Term Test Paper 2007 Grade 12Document4 pagesVisakha College Combined Maths 3rd Term Test Paper 2007 Grade 12jayadushNo ratings yet

- Applied MarkingDocument14 pagesApplied MarkingjayadushNo ratings yet

- 2020 Vishaka Marking Scheme ChemistryDocument10 pages2020 Vishaka Marking Scheme ChemistryjayadushNo ratings yet

- 404dc6d7-611f-439a-88f6-67842c6d765dDocument28 pages404dc6d7-611f-439a-88f6-67842c6d765djayadushNo ratings yet

- Cracks in Plaster - Masonry Walls - Causes and Repair - Civil Engineering Knowledge BaseDocument3 pagesCracks in Plaster - Masonry Walls - Causes and Repair - Civil Engineering Knowledge BasejayadushNo ratings yet

- Steel PropertiesDocument5 pagesSteel PropertiesjayadushNo ratings yet

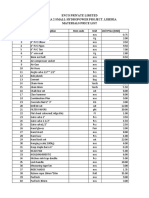

- Price List 2023.12.11 National PVCDocument13 pagesPrice List 2023.12.11 National PVCjayadushNo ratings yet

- Material Price List-LibDocument3 pagesMaterial Price List-LibjayadushNo ratings yet

- Design of RCC Post-Tensioned Flat SlabsDocument6 pagesDesign of RCC Post-Tensioned Flat SlabsjayadushNo ratings yet

- Early Leakage Protection System of LPG (Liquefied Petroleum Gas) Based On Atmega 16 MicrocontrollerDocument12 pagesEarly Leakage Protection System of LPG (Liquefied Petroleum Gas) Based On Atmega 16 MicrocontrollerjayadushNo ratings yet

- A Practical Study of Some Etiological Factors in Theft BehaviorDocument34 pagesA Practical Study of Some Etiological Factors in Theft BehaviorjayadushNo ratings yet

- Wishwa ShakthiyaDocument1 pageWishwa ShakthiyajayadushNo ratings yet

- View Topic - Design Corner Eccentric Footing On Both SideDocument5 pagesView Topic - Design Corner Eccentric Footing On Both SidejayadushNo ratings yet

- Distribution and Supply License No: EL/D/09-006, Lanka Electricity Company (Private) Limited (LECO)Document4 pagesDistribution and Supply License No: EL/D/09-006, Lanka Electricity Company (Private) Limited (LECO)jayadushNo ratings yet

- DOH Memo For Local Health Departments 12.3.21Document5 pagesDOH Memo For Local Health Departments 12.3.21News10NBCNo ratings yet

- DR - AC Ethical and Legal Issues in Midwifery Practice 2021Document91 pagesDR - AC Ethical and Legal Issues in Midwifery Practice 2021dr.anu RkNo ratings yet

- DB 2 BC 5 D 3Document20 pagesDB 2 BC 5 D 3PJay VegaNo ratings yet

- Chāmpo® Shop Chāmpo Natural Haircare ProductsDocument1 pageChāmpo® Shop Chāmpo Natural Haircare ProductsKirsten NicolsonNo ratings yet

- Bowen TechniqueDocument22 pagesBowen TechniqueizaNo ratings yet

- Anti-Nutritional Factors: G M LochiDocument20 pagesAnti-Nutritional Factors: G M LochiMuhammad NadeemNo ratings yet

- Overhead Crane FamiliarisationDocument16 pagesOverhead Crane Familiarisationmohamed fahsNo ratings yet

- Fake News, Phishing, and Fraud: A Call For Research On Digital Media Literacy Education Beyond The ClassroomDocument8 pagesFake News, Phishing, and Fraud: A Call For Research On Digital Media Literacy Education Beyond The ClassroomqwertzNo ratings yet

- BeclomethasoneDocument2 pagesBeclomethasoneDiane Bonita HerreraNo ratings yet

- Coronavirus (COVID-19) Records PDFDocument2 pagesCoronavirus (COVID-19) Records PDF35130030ksrNo ratings yet

- Struggles of The Bsentrep 1C Students and Their Coping Mechanisms in The New NormalDocument15 pagesStruggles of The Bsentrep 1C Students and Their Coping Mechanisms in The New NormalKathlyn PactorananNo ratings yet

- DRRR Q1 Module 4 08082020 - 5 1Document8 pagesDRRR Q1 Module 4 08082020 - 5 1donabypadida18No ratings yet

- Proceedings of The European Society of AestheticsDocument23 pagesProceedings of The European Society of AestheticsTuuusaNo ratings yet

- Cocoa Butter and Its Alternatives: A Reveiw: Bindu Naik and Vijay KumarDocument11 pagesCocoa Butter and Its Alternatives: A Reveiw: Bindu Naik and Vijay KumarJeyfrey CaleroNo ratings yet

- Id AutismDocument16 pagesId AutismKusmarwaty DrahmaNo ratings yet

- Written Report: Lydia Hall: Care, Cure, Core Nursing TheoryDocument12 pagesWritten Report: Lydia Hall: Care, Cure, Core Nursing TheoryAldrin Limcuando100% (1)

- Indo Petroleum Nurse Grade II AdvertisementDocument4 pagesIndo Petroleum Nurse Grade II AdvertisementjaideepsdNo ratings yet

- Link Company BrochureDocument46 pagesLink Company BrochureDaniel ValeNo ratings yet

- Chapter 7 Food ContaminationDocument29 pagesChapter 7 Food ContaminationMylene NapalanNo ratings yet

- Occupational Stress and Job Burnout Among Nursing Staff Working in Different Hospitals of DelhiDocument81 pagesOccupational Stress and Job Burnout Among Nursing Staff Working in Different Hospitals of DelhiSANJAY KUMARNo ratings yet

- Early Identification and Screening: Definition of Developmental DelayDocument7 pagesEarly Identification and Screening: Definition of Developmental Delayadheena simonNo ratings yet

- Biology ProjectDocument19 pagesBiology ProjectHussain Zohar0% (3)

- Personality AssessmentDocument46 pagesPersonality AssessmentRo An100% (1)

- Managing Conflict and Practicing CivilityDocument9 pagesManaging Conflict and Practicing CivilityAAANo ratings yet

- Defensive PracticeDocument8 pagesDefensive Practicesardar125No ratings yet

- Community Pharmacy Symptoms Diagnosis and Treatment 5Th Edition Edition Paul Rutter Full ChapterDocument67 pagesCommunity Pharmacy Symptoms Diagnosis and Treatment 5Th Edition Edition Paul Rutter Full Chaptermargaret.perez647100% (5)

- FTC 1Document80 pagesFTC 1Alexis Tondo AlmadronesNo ratings yet