Professional Documents

Culture Documents

Oxygen/Acetylene Welding and Cutting Works: Safe Operating Procedure

Oxygen/Acetylene Welding and Cutting Works: Safe Operating Procedure

Uploaded by

jayadushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxygen/Acetylene Welding and Cutting Works: Safe Operating Procedure

Oxygen/Acetylene Welding and Cutting Works: Safe Operating Procedure

Uploaded by

jayadushCopyright:

Available Formats

HSE MANAGEMENT SYSTEM SAFE OPERATING PROCEDURE

Doc. Number Rev. Date Page No

OXYGEN/ACETYLENE WELDING AND HSE`/SOP/112 0 17 Nov 03 1 of 1

CUTTING WORKS

Follow these safety tips when using a torch:

• Inspect equipment and ensure it’s in good working condition and free of oil before each use.

• Blow out cylinder valves before attaching regulators.

• Release adjusting screw on regulators before opening cylinder valves.

• Purge oxygen and acetylene lines before lightning the torch.

• Open cylinder valves slowly. Do not stand directly in front of the regulator while opening.

• Light torch with friction lighter or stationary pilot flame.

• Do not use acetylene at pressures higher than 15 psi.

• Light acetylene before opening oxygen valve on torch.

• When lighting torch, point away from persons and combustibles.

• Keep cylinders upright, chained to a support, and always use an appropriate cart to move.

While moving cylinders have the protective collar screwed into place to protect the valves.

• Keep cylinder caps in place when cylinders are not in use.

• Store oxygen cylinders away from cylinders with flammable gases (greater than 20 feet or

separated by a fire barrier at least 5 feet tall)

• Do not allow acetylene gas to come in contact with unalloyed copper. An explosion could result

due to formation of copper acetylide.

• Immediately repair oxygen and acetylene leaks.

• Do not store overnight with pressure on the regulator

• Ensure that flashback arrestors are installed between the regulator and the hose if the torch

does not have one built into its handle.

• Always use a pressure regulator. Use the proper regulator for each gas and pressure range.

• Never force connections that do not fit. Watch out for connectors with faulty seats; get rid of

them.

• Check connections for leaks. Use soapy water or its equivalent. Do not use a flame.

• Remove leaking cylinders from inside storage and notify the supplier.

• Do not tamper with or attempt to repair cylinder valves. Notify the supplier.

• Keep hoses, cables, and other equipment clear of passageways, stairs, ladders, etc.

• When a cylinder is empty, close its valve and tag it “EMPTY” or store in a separate area.

• Replace damaged equipment, including hoses.

• Take steps to prevent sparks from falling through floor cracks, etc. Remove or protect

combustible material in “falling spark” zones.

• Remove combustibles at least 35 feet from hot work. If combustibles cannot be relocated 35

feet from hot work, complete a hot work permit.

• Keep a Class ABC Fire Extinguisher near.

• Before cutting or welding on a “empty” container, be sure it does not contain flammable vapors

or any residues that might burn or give off flammable or toxic vapors.

• Keep flame and hot slag off concrete. Intense heat may cause flying particles of concrete.

• Provide adequate ventilation whenever welding or cutting around cadmium zinc, lead, fluorine

compounds, or other toxic materials.

• Keep sleeves and collars buttoned on clothing.

• Wear gloves and eye protection with the appropriate shade.

REVIEWED & APPROVED QA & HSE MANAGER

You might also like

- 2008 Mondeo Owner ManualDocument286 pages2008 Mondeo Owner Manualusa_400486% (7)

- Method Statement For Hot WorkDocument1 pageMethod Statement For Hot WorkDark FantasyNo ratings yet

- SBS Leaflet PDFDocument2 pagesSBS Leaflet PDFjayadushNo ratings yet

- Oisd RP 167 PDFDocument28 pagesOisd RP 167 PDFgirishhodlur100% (1)

- Compressed Gas Safety: Program Objective Purpose and ScopeDocument3 pagesCompressed Gas Safety: Program Objective Purpose and ScopeAjani CherenfantNo ratings yet

- Compressed Gas Cylinders Safety: StorageDocument3 pagesCompressed Gas Cylinders Safety: StorageHebron DawitNo ratings yet

- Safety Meeting Topic: Compressed Gas Safety: Provided By: Hellman & Associates, Inc.,, 303-384-9828Document1 pageSafety Meeting Topic: Compressed Gas Safety: Provided By: Hellman & Associates, Inc.,, 303-384-9828Vikas YamagarNo ratings yet

- Reference 1 PDFDocument10 pagesReference 1 PDFJanicka Palencia AgaNo ratings yet

- User-Manual-25262Compressed Gas Cylinders PowerPointDocument20 pagesUser-Manual-25262Compressed Gas Cylinders PowerPointMohammed NaseeruddinNo ratings yet

- Compressed Gas Cryogenic Liquid Cylinder SafetyDocument5 pagesCompressed Gas Cryogenic Liquid Cylinder SafetyHebron DawitNo ratings yet

- Compressed GasDocument3 pagesCompressed GassherinNo ratings yet

- Oxygen Acetylene Welding & Cutting Equipment: HosesDocument5 pagesOxygen Acetylene Welding & Cutting Equipment: HosesLloyd MontonNo ratings yet

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointInspire KharianNo ratings yet

- Hot Work Safety - OMSDocument52 pagesHot Work Safety - OMSMurthy LaxmanNo ratings yet

- Cutting Torch SafetyDocument1 pageCutting Torch Safetyyasser awadallhNo ratings yet

- Compressed GasesDocument2 pagesCompressed GasesJerome BautistaNo ratings yet

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointRajanbabuNo ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- JJ104 Workshop Technology CHAPTER1 Safety in The Use of OxyDocument2 pagesJJ104 Workshop Technology CHAPTER1 Safety in The Use of OxyAh TiangNo ratings yet

- T 1839 F Welding OperationDocument44 pagesT 1839 F Welding OperationrubelNo ratings yet

- Jenis-Jenis Api NyalaanDocument39 pagesJenis-Jenis Api NyalaanIji XiiNo ratings yet

- Welding - Storage and Handling of Compressed Gas CylindersDocument4 pagesWelding - Storage and Handling of Compressed Gas CylindersDarmendar SinghNo ratings yet

- What Should I Do When Storing Compressed Gas CylindersDocument3 pagesWhat Should I Do When Storing Compressed Gas Cylinderssirsa11No ratings yet

- Compressed Gases: (General Safety Requirements For Storage and Handling)Document36 pagesCompressed Gases: (General Safety Requirements For Storage and Handling)mrsoumenghoshNo ratings yet

- Gas Cylinder Safety SiDocument2 pagesGas Cylinder Safety SisubhashNo ratings yet

- Welding and Cutting SafetyDocument22 pagesWelding and Cutting SafetyyawarhassanNo ratings yet

- Cutting Torch SafetyDocument1 pageCutting Torch SafetyDocholosoNo ratings yet

- Safety Concerns: June, 2019 Batangas Grand TerminalDocument15 pagesSafety Concerns: June, 2019 Batangas Grand TerminalMackoy MarasiganNo ratings yet

- Electric Arc Weldin SafetyDocument5 pagesElectric Arc Weldin SafetynickurfriendNo ratings yet

- Oxy Acetylene SopDocument1 pageOxy Acetylene SopLouise BNo ratings yet

- OxyfuelDocument103 pagesOxyfuelNiranjan khatuaNo ratings yet

- Compressed GasesDocument50 pagesCompressed Gasesandrea santosNo ratings yet

- Safety Sheet - Use of Compressed Hydrogen Gas CylinderDocument2 pagesSafety Sheet - Use of Compressed Hydrogen Gas CylinderManishNo ratings yet

- Gas Cylinder SafetyDocument68 pagesGas Cylinder Safetymortadha husainNo ratings yet

- Utsc Section 3 - Laboratory EquipmentDocument5 pagesUtsc Section 3 - Laboratory EquipmentNiel A.No ratings yet

- Compressed Gas Cylinder Safety SOPDocument5 pagesCompressed Gas Cylinder Safety SOPIdris AdeniranNo ratings yet

- CGC SafetyDocument9 pagesCGC SafetySOLY_POP_10No ratings yet

- Compressed Gas Cylinder SafetyDocument7 pagesCompressed Gas Cylinder SafetyJer HomeNo ratings yet

- Welding and Gas CuttingDocument20 pagesWelding and Gas CuttingAtma Prakash SinhaNo ratings yet

- Ar Oxygen Acetyleneuseandsafety 141013030455 Conversion Gate01 PDFDocument36 pagesAr Oxygen Acetyleneuseandsafety 141013030455 Conversion Gate01 PDFSuad BushiNo ratings yet

- Gas Welding ComponentsDocument57 pagesGas Welding ComponentsJoseph Magbanua Dato-onNo ratings yet

- Instruction Manual For Mig Welding Machine: Important Safety Information!!!Document13 pagesInstruction Manual For Mig Welding Machine: Important Safety Information!!!Hoai namNo ratings yet

- Toolbox Talk CylindersDocument1 pageToolbox Talk CylindersAdel SukerNo ratings yet

- Oxy-Acetylene Cutting SafetyDocument31 pagesOxy-Acetylene Cutting SafetyDarby Morgan100% (1)

- Tips On SafetyDocument14 pagesTips On SafetyMani GNo ratings yet

- Safe Storage Handling LPG Gas PDFDocument1 pageSafe Storage Handling LPG Gas PDFAnonymous dSFbLxc9100% (1)

- Safety in Welding and CuttingDocument33 pagesSafety in Welding and CuttingBhavya ShuklaNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- Rog-Hse-Pro-016, Procedure For Transportation of Gas CylindersDocument3 pagesRog-Hse-Pro-016, Procedure For Transportation of Gas CylindersvladNo ratings yet

- Safety GramDocument4 pagesSafety GramsjmpakNo ratings yet

- GN08 Oxy-Fuel Gas Daily Checklist Rev 2 May 2011Document1 pageGN08 Oxy-Fuel Gas Daily Checklist Rev 2 May 2011cuxuanchieuNo ratings yet

- Compressed Gas SafetyDocument26 pagesCompressed Gas SafetyTonyNo ratings yet

- Compressed Gas Cylinder OJTDocument5 pagesCompressed Gas Cylinder OJTMr SinghNo ratings yet

- Asafetyprecautionstorching PDFDocument5 pagesAsafetyprecautionstorching PDFharsh_mankadNo ratings yet

- Gas CylindersDocument3 pagesGas Cylindersnadim haqueNo ratings yet

- Compress Gas SafeyDocument11 pagesCompress Gas SafeyIshmael TettehNo ratings yet

- Oxyacetylene CuttingDocument24 pagesOxyacetylene CuttingTan Chin TeeNo ratings yet

- SOP For Gas CylindersDocument1 pageSOP For Gas CylindersVinod Gupta0% (1)

- Eugene Dorothy Its Not A Laughing Matter PDFDocument155 pagesEugene Dorothy Its Not A Laughing Matter PDFtaibkNo ratings yet

- Sop For Storage, Handling & Use of Gas CylindersDocument8 pagesSop For Storage, Handling & Use of Gas Cylinderssuvojitroy2000No ratings yet

- Compressed Gas SafetyDocument20 pagesCompressed Gas SafetyMd Rafat ArefinNo ratings yet

- Ultimate Guide: Plumbing, 4th Updated EditionFrom EverandUltimate Guide: Plumbing, 4th Updated EditionRating: 4 out of 5 stars4/5 (1)

- Construction Project Management-Sri Lankan ExampleDocument16 pagesConstruction Project Management-Sri Lankan ExamplejayadushNo ratings yet

- Nature VS PsychologyDocument4 pagesNature VS PsychologyjayadushNo ratings yet

- British Council PrintDocument1 pageBritish Council PrintjayadushNo ratings yet

- MRN 163Document1 pageMRN 163jayadushNo ratings yet

- Visakha College Combined Maths 3rd Term Test Paper 2007 Grade 12Document4 pagesVisakha College Combined Maths 3rd Term Test Paper 2007 Grade 12jayadushNo ratings yet

- Parapsychology Relevant To Spirituality and Psychiatry James PandarakalamDocument7 pagesParapsychology Relevant To Spirituality and Psychiatry James PandarakalamjayadushNo ratings yet

- Academic WritersDocument3 pagesAcademic WritersjayadushNo ratings yet

- 2020 Vishaka Marking Scheme ChemistryDocument10 pages2020 Vishaka Marking Scheme ChemistryjayadushNo ratings yet

- Applied MarkingDocument14 pagesApplied MarkingjayadushNo ratings yet

- Central Province - Phy - Marking SchemeDocument18 pagesCentral Province - Phy - Marking SchemejayadushNo ratings yet

- 404dc6d7-611f-439a-88f6-67842c6d765dDocument28 pages404dc6d7-611f-439a-88f6-67842c6d765djayadushNo ratings yet

- Price List 2023.12.11 National PVCDocument13 pagesPrice List 2023.12.11 National PVCjayadushNo ratings yet

- Design of RCC Post-Tensioned Flat SlabsDocument6 pagesDesign of RCC Post-Tensioned Flat SlabsjayadushNo ratings yet

- Steel PropertiesDocument5 pagesSteel PropertiesjayadushNo ratings yet

- Cracks in Plaster - Masonry Walls - Causes and Repair - Civil Engineering Knowledge BaseDocument3 pagesCracks in Plaster - Masonry Walls - Causes and Repair - Civil Engineering Knowledge BasejayadushNo ratings yet

- A Practical Study of Some Etiological Factors in Theft BehaviorDocument34 pagesA Practical Study of Some Etiological Factors in Theft BehaviorjayadushNo ratings yet

- View Topic - Design Corner Eccentric Footing On Both SideDocument5 pagesView Topic - Design Corner Eccentric Footing On Both SidejayadushNo ratings yet

- Material Price List-LibDocument3 pagesMaterial Price List-LibjayadushNo ratings yet

- Wishwa ShakthiyaDocument1 pageWishwa ShakthiyajayadushNo ratings yet

- Early Leakage Protection System of LPG (Liquefied Petroleum Gas) Based On Atmega 16 MicrocontrollerDocument12 pagesEarly Leakage Protection System of LPG (Liquefied Petroleum Gas) Based On Atmega 16 MicrocontrollerjayadushNo ratings yet

- Distribution and Supply License No: EL/D/09-006, Lanka Electricity Company (Private) Limited (LECO)Document4 pagesDistribution and Supply License No: EL/D/09-006, Lanka Electricity Company (Private) Limited (LECO)jayadushNo ratings yet

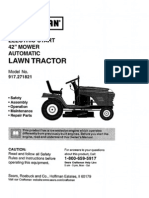

- Mower ManualDocument60 pagesMower Manualhydroxogyn1100% (2)

- Bioenergy and BiofuelsDocument14 pagesBioenergy and BiofuelsA S M Younus Bhuiyan SabbirNo ratings yet

- 159 LoaderDocument1 page159 LoaderAnjum AkramNo ratings yet

- AGUNG SETIYAWAN - File NewDocument13 pagesAGUNG SETIYAWAN - File NewSantri NdesaNo ratings yet

- Mercruiser Alarms and Fault Codes: Alarm # Fault PWR Limit DescriptionDocument1 pageMercruiser Alarms and Fault Codes: Alarm # Fault PWR Limit DescriptionJason WilliamNo ratings yet

- C675Fd01 IMPCO Spectrum PartsDocument281 pagesC675Fd01 IMPCO Spectrum Partsulsh1954No ratings yet

- Astm D43 2014Document7 pagesAstm D43 2014Engineering TasblockNo ratings yet

- Installation & Parts Manual: MS-Series Spherical Two-Case MetersDocument40 pagesInstallation & Parts Manual: MS-Series Spherical Two-Case MeterslataNo ratings yet

- Códigos de Deficiencias y Referencia Normativa 17Document68 pagesCódigos de Deficiencias y Referencia Normativa 17Wilson Bautista P100% (1)

- SPE-193038-MS Pioneering Rigless Perforating, Clean-Up Operation, Well Testing With MPLT and Bottom Hole Sampling in Remote PlatformDocument8 pagesSPE-193038-MS Pioneering Rigless Perforating, Clean-Up Operation, Well Testing With MPLT and Bottom Hole Sampling in Remote PlatformTheNourEldenNo ratings yet

- List Candidate (Indonesia) 2020Document1 pageList Candidate (Indonesia) 2020Wiro FirefighterNo ratings yet

- Material Handling & TransportDocument23 pagesMaterial Handling & TransportKhadeejaNo ratings yet

- Headline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationDocument3 pagesHeadline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationIonut-alexandru IordacheNo ratings yet

- Kia Sedona Grand Carnival Owner's ManualDocument593 pagesKia Sedona Grand Carnival Owner's Manualraza514No ratings yet

- Presentation On Hydrotreating Process: Presented byDocument16 pagesPresentation On Hydrotreating Process: Presented bySantoso WijayaNo ratings yet

- Coal and Petroleum - Class 8 - NCERT Exercise Questions - PANTOMATHDocument2 pagesCoal and Petroleum - Class 8 - NCERT Exercise Questions - PANTOMATHsourav9823No ratings yet

- Lecture 2 - 102MAE ThermofluidsDocument21 pagesLecture 2 - 102MAE ThermofluidsNafiz Uddin NihalNo ratings yet

- Unit 1: Automotive IndustriesDocument3 pagesUnit 1: Automotive IndustriesMohamed NadjibNo ratings yet

- What Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsDocument8 pagesWhat Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsSherwin Delfin CincoNo ratings yet

- First Five Machine ProblemsDocument4 pagesFirst Five Machine ProblemsGerald GavinaNo ratings yet

- Boiler Uptake Fire and Exhaust Gas Economiser FireDocument2 pagesBoiler Uptake Fire and Exhaust Gas Economiser FireAVINASH ANAND RAO100% (1)

- F3 - WES (OIC & MGT) Additional Questions On SafetyDocument5 pagesF3 - WES (OIC & MGT) Additional Questions On SafetyCHERRY ANN OLAJAYNo ratings yet

- Power Wave R500: Operator's ManualDocument42 pagesPower Wave R500: Operator's ManualJohan ZraghozNo ratings yet

- 03 ASTM E2412-04 Vfur7493Document22 pages03 ASTM E2412-04 Vfur7493Denis AudreyNo ratings yet

- MINOTAUR Petrol Station SystemsDocument40 pagesMINOTAUR Petrol Station Systemstruckman1000No ratings yet

- J1510 - 201705-Lubricants For Two-Stroke-Cycle Gasoline EnginesDocument4 pagesJ1510 - 201705-Lubricants For Two-Stroke-Cycle Gasoline EnginesJicheng PiaoNo ratings yet

- Aniline Point Lab ReportDocument2 pagesAniline Point Lab ReportJoos Monkeyfied89% (9)