Professional Documents

Culture Documents

3.6 Installation Requirements: 3.6.1 Electrical Work

3.6 Installation Requirements: 3.6.1 Electrical Work

Uploaded by

MICopyright:

Available Formats

You might also like

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- UMGC ACCT326 Technology ProjectDocument14 pagesUMGC ACCT326 Technology ProjectAdje DangNo ratings yet

- Sales SopDocument19 pagesSales SopFelix Mwanduka100% (1)

- Physics of Medical X-Ray Imaging (1) Chapter 10: Figure 10.1. Digital Radiographic System DesignDocument21 pagesPhysics of Medical X-Ray Imaging (1) Chapter 10: Figure 10.1. Digital Radiographic System DesignNguyen Cong HuynhNo ratings yet

- BREEAM Ene 03 External Lighting GuidelinesDocument5 pagesBREEAM Ene 03 External Lighting GuidelinesClifford Juan CorreaNo ratings yet

- Interference of Light & It's Applications (Interferometry)Document24 pagesInterference of Light & It's Applications (Interferometry)Pranav Marathe100% (11)

- Design of A Single Ended Two Stage Opamp Using 90Nm Cmos GPDK TechnologyDocument8 pagesDesign of A Single Ended Two Stage Opamp Using 90Nm Cmos GPDK Technologygill6335100% (1)

- LED Luminaires part 1Document10 pagesLED Luminaires part 1salaitaosama1995No ratings yet

- SSL Version1 Draft 122006Document16 pagesSSL Version1 Draft 122006jorojoroNo ratings yet

- Bright Tomorrow Lighting Competition (L Prize) : Competition Requirements For PAR 38 Halogen Replacement LampsDocument19 pagesBright Tomorrow Lighting Competition (L Prize) : Competition Requirements For PAR 38 Halogen Replacement LampscrennydaneNo ratings yet

- Editedl. Meps and Labelling Programs-1Document33 pagesEditedl. Meps and Labelling Programs-1Helen B. AriasNo ratings yet

- BCA Green Mark Certification For New BuildingsDocument125 pagesBCA Green Mark Certification For New Buildingslwin_oo2435No ratings yet

- 2015 Sec Commercial Chapter 4Document106 pages2015 Sec Commercial Chapter 4Rodel AlmohallasNo ratings yet

- Lighting CalculationDocument13 pagesLighting Calculationmringkel100% (1)

- Lighting Criteria StandardsDocument19 pagesLighting Criteria Standards18926119No ratings yet

- ZCB-Design v3 Energy Modelling GuidelinesDocument14 pagesZCB-Design v3 Energy Modelling Guidelinestijeanlandry7267No ratings yet

- ZERO-Code REFERENCIAS DE EIUDocument16 pagesZERO-Code REFERENCIAS DE EIUDianys RocafuerteNo ratings yet

- CIBSE LG 3 Addendum Visual Environment For Display Screen UseDocument7 pagesCIBSE LG 3 Addendum Visual Environment For Display Screen UseIvano DellaPiccaNo ratings yet

- Complete Submittal-Zoya PDFDocument163 pagesComplete Submittal-Zoya PDFXiPHeR100No ratings yet

- LG3update Lighting Guide 3 Addendum 2001Document7 pagesLG3update Lighting Guide 3 Addendum 2001S E Krishnan IyerNo ratings yet

- PBRS - Resourceful EnergyDocument31 pagesPBRS - Resourceful EnergyMohamed ShiraziNo ratings yet

- LEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYDocument30 pagesLEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYTomaszNo ratings yet

- Dla SDD Memo120412Document52 pagesDla SDD Memo120412omermmkaNo ratings yet

- Preview - CP 24-1999Document5 pagesPreview - CP 24-1999Weijin LeowNo ratings yet

- Information Bulletin 8 PBRS RE R1 Rev3Document4 pagesInformation Bulletin 8 PBRS RE R1 Rev3FarahnaazNo ratings yet

- Quality Reqs Electric Prcocess Heaters S 723Qv2020 12Document12 pagesQuality Reqs Electric Prcocess Heaters S 723Qv2020 12Serge RINAUDONo ratings yet

- 1 Rcny 5000-01Document20 pages1 Rcny 5000-01annaNo ratings yet

- GUIDELINES FOR Certificate of Approval Lamp Latest PDFDocument4 pagesGUIDELINES FOR Certificate of Approval Lamp Latest PDFevonchayNo ratings yet

- Part 1 Solar LED RoadLighting V1a 2023 10aug23Document24 pagesPart 1 Solar LED RoadLighting V1a 2023 10aug23Doughnut Chilli PiNo ratings yet

- DirectDocument6 pagesDirectChandu RavuriNo ratings yet

- 2020 Nec ChangesDocument2 pages2020 Nec ChangesErnesto VillanuevaNo ratings yet

- Energy Efficiency Verification Method PBDS 1-003-C: ScenarioDocument2 pagesEnergy Efficiency Verification Method PBDS 1-003-C: ScenarioQazertNo ratings yet

- Green Mark CriteriaDocument136 pagesGreen Mark CriteriaLim Hai MengNo ratings yet

- For Modelling LEED (Version-1)Document11 pagesFor Modelling LEED (Version-1)Zaw Moe KhineNo ratings yet

- Section 8 Level 2 AuditsDocument32 pagesSection 8 Level 2 AuditsStephanie GregasNo ratings yet

- PIP ELSMC13 Low-Voltage Motor Control Centers - May 2018 PDFDocument24 pagesPIP ELSMC13 Low-Voltage Motor Control Centers - May 2018 PDFist93993No ratings yet

- QS SASO 2663 E Final Draft PDFDocument22 pagesQS SASO 2663 E Final Draft PDFMahjoub AmriNo ratings yet

- Technical Resource ManualDocument16 pagesTechnical Resource ManualpixelnutNo ratings yet

- Oil Containment For Major SubstationDocument46 pagesOil Containment For Major SubstationADsupermanNo ratings yet

- 2013 Peco TarrifDocument15 pages2013 Peco TarrifGary William BrooksNo ratings yet

- BCA GreenMark For Non-Residential Building V3.0Document16 pagesBCA GreenMark For Non-Residential Building V3.0nicklesteohshNo ratings yet

- 630 KV DG SetDocument18 pages630 KV DG SetKEYSTONE INFRA PVT LTDNo ratings yet

- ELEGL02Document26 pagesELEGL02Ariel Anibal AparicioNo ratings yet

- Scope of Works - Project Kayla TOR PSS - Gencorev3-FloatDocument10 pagesScope of Works - Project Kayla TOR PSS - Gencorev3-FloatIzarulhaq AwangNo ratings yet

- SASO 2663:2014: (SASO 2663/2012 Including The Modifications Approved in Saudi Council Board No. ./2014)Document24 pagesSASO 2663:2014: (SASO 2663/2012 Including The Modifications Approved in Saudi Council Board No. ./2014)Mahjoub AmriNo ratings yet

- Rotan OM ApproachDocument173 pagesRotan OM Approach8103 Anshu PatilNo ratings yet

- Volume 1 Chapter 4 JV Verification MethodsDocument8 pagesVolume 1 Chapter 4 JV Verification MethodsMohammad MoazzamiNo ratings yet

- Volume 1 Chapter 10 j6 Artificial Lighting Power PDFDocument18 pagesVolume 1 Chapter 10 j6 Artificial Lighting Power PDFSheand KaseNo ratings yet

- Quality Reqs For Plate and Frame Heat Exchangers API S 749Qv2023 12Document12 pagesQuality Reqs For Plate and Frame Heat Exchangers API S 749Qv2023 12daus nasNo ratings yet

- BS 5225-3Document18 pagesBS 5225-3Avk SanjeevanNo ratings yet

- Quality Requirements For High-Voltage Switchgear and ControlgearDocument11 pagesQuality Requirements For High-Voltage Switchgear and ControlgearErwin MorenoNo ratings yet

- Read More About Project SelectionDocument9 pagesRead More About Project SelectionsaitejairukulapatiNo ratings yet

- QS 2663-2020Document26 pagesQS 2663-2020Ramesh K KarthickNo ratings yet

- Quality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperatureDocument12 pagesQuality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperaturekochicommNo ratings yet

- Griha Criteria No.32 Energy Audit and ValidationDocument13 pagesGriha Criteria No.32 Energy Audit and ValidationrichurichaNo ratings yet

- 091117110542preview - SS 553-2009Document6 pages091117110542preview - SS 553-2009Thanh HuuNo ratings yet

- Carpark Ventilation SpecificationDocument5 pagesCarpark Ventilation SpecificationHo Dac ThanhNo ratings yet

- BREEAM Prisons 2008 Assessor ManualDocument366 pagesBREEAM Prisons 2008 Assessor ManualMarinaNo ratings yet

- Meps TransformersDocument71 pagesMeps TransformersvtechelectricNo ratings yet

- White Paper CAN-ANSI-AHRI 1330-2015Document11 pagesWhite Paper CAN-ANSI-AHRI 1330-2015Allan GomezNo ratings yet

- ATT.2 - Standby Generator Requirement As Per Shell DEPDocument4 pagesATT.2 - Standby Generator Requirement As Per Shell DEPAhmed AdelNo ratings yet

- Guidebook for Utilities-Led Business Models: Way Forward for Rooftop Solar in IndiaFrom EverandGuidebook for Utilities-Led Business Models: Way Forward for Rooftop Solar in IndiaNo ratings yet

- Electric Motorcycle Charging Infrastructure Road Map for IndonesiaFrom EverandElectric Motorcycle Charging Infrastructure Road Map for IndonesiaNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- NC19402 Engineering Report LetterDocument4 pagesNC19402 Engineering Report LetterMINo ratings yet

- Brochure Clean Renewable Energy Brand UpdateDocument2 pagesBrochure Clean Renewable Energy Brand UpdateMINo ratings yet

- 9a 3610 - Ongoing CS ContractDocument19 pages9a 3610 - Ongoing CS ContractMINo ratings yet

- Survey of Grid Forming Inverter Applications Julia MatevosyanDocument18 pagesSurvey of Grid Forming Inverter Applications Julia MatevosyanMINo ratings yet

- 1 NC-019402 Offer LetterDocument18 pages1 NC-019402 Offer LetterMINo ratings yet

- Words - Google SearchDocument1 pageWords - Google SearchMINo ratings yet

- Final ReportDocument22 pagesFinal ReportMINo ratings yet

- Simplesolarfarm 2019Document20 pagesSimplesolarfarm 2019MINo ratings yet

- KB Document 246Document59 pagesKB Document 246MINo ratings yet

- S2022.10.17.Online Stab - en Power System StabilityDocument1 pageS2022.10.17.Online Stab - en Power System StabilityMINo ratings yet

- Hvac Eguide: Instruments and ServicesDocument26 pagesHvac Eguide: Instruments and ServicesMINo ratings yet

- ADLT - DimOnOff SCMS Data SheetDocument4 pagesADLT - DimOnOff SCMS Data SheetMINo ratings yet

- GCN - Energy Storage Microgrid Conference - 20170911Document14 pagesGCN - Energy Storage Microgrid Conference - 20170911MINo ratings yet

- Zen Ecosystems Demand Response Rert Trial Summer 2017 18Document17 pagesZen Ecosystems Demand Response Rert Trial Summer 2017 18MINo ratings yet

- ADLT DimOnOff Topology DiagramDocument1 pageADLT DimOnOff Topology DiagramMINo ratings yet

- Demand Response Trial Test December 2020Document35 pagesDemand Response Trial Test December 2020MINo ratings yet

- Powershop Demand Response Program Final 2020Document9 pagesPowershop Demand Response Program Final 2020MINo ratings yet

- ADLT - DimOnOff G3 Gateway Data SheetDocument3 pagesADLT - DimOnOff G3 Gateway Data SheetMINo ratings yet

- The Dawn of A New Apac Era: Air Conditioning Product RangeDocument11 pagesThe Dawn of A New Apac Era: Air Conditioning Product RangeMI100% (1)

- Tech-Evapac2001 0Document17 pagesTech-Evapac2001 0MINo ratings yet

- ADLT - DimOnOff RME-H2 Node Data SheetDocument3 pagesADLT - DimOnOff RME-H2 Node Data SheetMINo ratings yet

- ADLT DimOnOff OverviewDocument7 pagesADLT DimOnOff OverviewMINo ratings yet

- ADLT - DimOnOff RGBW Controller Data SheetDocument3 pagesADLT - DimOnOff RGBW Controller Data SheetMINo ratings yet

- ADLT - DimOnOff RTM Node Data SheetDocument3 pagesADLT - DimOnOff RTM Node Data SheetMINo ratings yet

- ADLT - DimOnOff RME-H3 Node Data SheetDocument4 pagesADLT - DimOnOff RME-H3 Node Data SheetMINo ratings yet

- ADLT - DimOnOff LNLV Node Data SheetDocument3 pagesADLT - DimOnOff LNLV Node Data SheetMINo ratings yet

- Lorawan AU ChannelsDocument6 pagesLorawan AU ChannelsMINo ratings yet

- LED Parking Garages & ControlsDocument38 pagesLED Parking Garages & ControlsMINo ratings yet

- Beletich Report For IPART On Commercial Lighting - February 2013Document64 pagesBeletich Report For IPART On Commercial Lighting - February 2013MINo ratings yet

- Binomial Approx To NormalDocument8 pagesBinomial Approx To NormalOLUWASEYI OJUOLANo ratings yet

- Alcatel 1660 SMDocument8 pagesAlcatel 1660 SMILiketobWithuNo ratings yet

- Smart Doctors Assistant - An Advanced Appointment Booking System For HospitalsDocument8 pagesSmart Doctors Assistant - An Advanced Appointment Booking System For HospitalsIJAR JOURNALNo ratings yet

- 22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Document1 page22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Ansaf AskyNo ratings yet

- Critical Variables and Constructs in The Context of Project Management: Importance-Performance AnalysisDocument29 pagesCritical Variables and Constructs in The Context of Project Management: Importance-Performance AnalysisAdhi Tol Serpan Seksi 3No ratings yet

- Tensores Van GorpDocument17 pagesTensores Van GorpsalematadorNo ratings yet

- 3 AI - Search IIIDocument72 pages3 AI - Search IIIkuramthanushmaNo ratings yet

- Course Name CO Number With Code Co Statement BT LevelDocument43 pagesCourse Name CO Number With Code Co Statement BT LevelPolkam SrinidhiNo ratings yet

- Tips Tricks To Interviewing Virtually 1 YALI NETWORKDocument2 pagesTips Tricks To Interviewing Virtually 1 YALI NETWORKAKOGU J. AKPOCHI J.No ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Carbide Blank InsertDocument7 pagesCarbide Blank InsertSakthi VelNo ratings yet

- DGSDocument11 pagesDGSsridhar kumar singh100% (1)

- Coating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04Document16 pagesCoating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04lemuel bacsaNo ratings yet

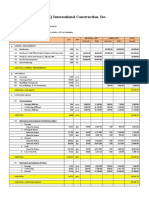

- JQ International Construction, IncDocument2 pagesJQ International Construction, Incyael rodriguez100% (1)

- PROJECT STANDARDS AND SPECIFICATIONS Solid Handling Systems Rev01 PDFDocument10 pagesPROJECT STANDARDS AND SPECIFICATIONS Solid Handling Systems Rev01 PDFVirjil AycochoNo ratings yet

- Introduction of Insulation CoordinationDocument5 pagesIntroduction of Insulation CoordinationTaher El NoamanNo ratings yet

- Backstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsDocument15 pagesBackstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsoliveiralauroNo ratings yet

- Common Service Spares For U-Power and Omega 01012015Document1 pageCommon Service Spares For U-Power and Omega 01012015smartechengineering.infoNo ratings yet

- ML Interview Questions and AnswersDocument25 pagesML Interview Questions and Answerssantoshguddu100% (1)

- BIS3003 - Assessment Brief T3, 2021Document20 pagesBIS3003 - Assessment Brief T3, 2021KushalNo ratings yet

- How To Fix Windows 11 Indexing Is Paused (File Search Not Working)Document36 pagesHow To Fix Windows 11 Indexing Is Paused (File Search Not Working)Mohammed Zahid AnsariNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankWawanNo ratings yet

- Development and Use of Non-Digital or Conventional MaterialsDocument4 pagesDevelopment and Use of Non-Digital or Conventional Materialsorgasazi18No ratings yet

- Aab-e-Kausar by Mufti Ameen PDFDocument306 pagesAab-e-Kausar by Mufti Ameen PDFSamina Kosar96% (26)

- 10 FixedAsset 12 FixedAsset Intro Virtual AssetDocument11 pages10 FixedAsset 12 FixedAsset Intro Virtual AssetCrazy TechNo ratings yet

3.6 Installation Requirements: 3.6.1 Electrical Work

3.6 Installation Requirements: 3.6.1 Electrical Work

Uploaded by

MIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.6 Installation Requirements: 3.6.1 Electrical Work

3.6 Installation Requirements: 3.6.1 Electrical Work

Uploaded by

MICopyright:

Available Formats

any lighting end-user equipment containing mercury must be recycled in accordance with the

recycling requirements of a product stewardship scheme such as ‘Fluorocycle’ or equivalent.33

3.6 Installation requirements

3.6.1 Electrical work

ACPs must ensure that all electrical work involved in the lighting upgrade is performed by

appropriately trained persons and undertaken by or under the supervision of a licensed

electrician.34 This requirement applies even when the lighting upgrade does not require any

wiring work to be conducted or otherwise require an electrician to be present.

3.6.2 Service levels

ACPs must only create ESCs from lighting upgrades that reduce electricity consumption

without reducing service levels (including safety levels) below the pre-upgrade levels.35 For

example, ACPs cannot create ESCs from activities that reduce electricity only by the de-

lamping of a particular area as this would also reduce service levels.

3.7 Performance requirements

ACPs must satisfy the minimum performance requirements for upgrades of building lighting

and upgrades of roads and public spaces (outlined below), to the satisfaction of the Scheme

Administrator. We may publish additional minimum performance requirements for these

upgrades from time to time.

3.7.1 Performance requirements for upgrades of building lighting

For upgrades of building lighting, each space, after implementation of the lighting upgrade

must meet:

q the relevant requirements of AS/NZS 1680 or, where this standard is not applicable,

another benchmark agreed to in advance by the Scheme Administrator

q the requirements of the BCA section F4.4 ‘Artificial lighting’, and

q an Illumination Power Density (IPD) for each space less than or equal to the maximum

IPD allowed under BCA Part J6.

Further information about how BCA requirements apply to the calculation of energy savings

is provided in the Evidence Manual.36

33 Further information about Fluorocycle is available at: www.fluorocycle.org.au/.

34 ESS Rule, cl 9.4.1(d).

35 ESS Rule, cl 5.3(b).

36 The Evidence Manual is available on the ESS website at:

www.ess.nsw.gov.au/Methods_for_calculating_energy_savings/Commercial_Lighting.

8 IPART Commercial Lighting Energy Savings Formula Method Guide V3.4

Building lighting upgrades where AS/NZS 1680 applies must achieve the relevant

requirements of AS/NZS 1680. These may include, but are not limited to, the requirements

related:

q maintained illuminance accounting for lumen depreciation

q control of glare, and

q uniformity of illuminance.

Further information about each of these requirements can be found in AS/NZS 1680.

In addition, AS/NZS 1680 includes specific requirements for a range of lighting upgrades. At

a minimum, ACPs must satisfy the requirements related to:

q Correlated Colour Temperature37 and matching existing lighting

q Colour Rendering Index38 in order to accurately portray colour

q glare, in order to avoid ‘disability glare’ and ‘discomfort glare’

q reflectance off surfaces, and

q daylight effects.

Compliance with the relevant requirements may be checked at the time of audit, so it is

advisable to involve the person responsible for providing the lighting solution and upgrade

in:

q assessing how these requirements apply to the lighting upgrade, and

q ensuring that the lighting upgrade satisfies the requirements.

Other benchmarks where AS/NZS 1680 does not apply

Where the lighting upgrade is outside the scope of AS/NZS 1680, ACPs may apply to the

Scheme Administrator to use another performance benchmark. The application must include:

q the nature of the lighting upgrade

q why AS/NZS 1680 does not apply

q what benchmark or alternative standard is proposed to ensure service levels are

appropriate, and

q how each space will meet, as a minimum, the requirements of BCA Section F4.4, ‘Artificial

lighting’.

Compliance with the performance requirements of the agreed benchmark may be checked at

the time of audit, so it is advisable to prepare the application in consultation with the person

responsible for providing the lighting solution and upgrade.

37 Correlated Colour Temperature is a measurement of the apparent colour of the light source.

38 Colour Rendering Index is a measurement of how accurately a light source can portray the colour of an object

in comparison to an ideal light source such as an incandescent lamp.

Commercial Lighting Energy Savings Formula Method Guide V3.4 IPART 9

You might also like

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- UMGC ACCT326 Technology ProjectDocument14 pagesUMGC ACCT326 Technology ProjectAdje DangNo ratings yet

- Sales SopDocument19 pagesSales SopFelix Mwanduka100% (1)

- Physics of Medical X-Ray Imaging (1) Chapter 10: Figure 10.1. Digital Radiographic System DesignDocument21 pagesPhysics of Medical X-Ray Imaging (1) Chapter 10: Figure 10.1. Digital Radiographic System DesignNguyen Cong HuynhNo ratings yet

- BREEAM Ene 03 External Lighting GuidelinesDocument5 pagesBREEAM Ene 03 External Lighting GuidelinesClifford Juan CorreaNo ratings yet

- Interference of Light & It's Applications (Interferometry)Document24 pagesInterference of Light & It's Applications (Interferometry)Pranav Marathe100% (11)

- Design of A Single Ended Two Stage Opamp Using 90Nm Cmos GPDK TechnologyDocument8 pagesDesign of A Single Ended Two Stage Opamp Using 90Nm Cmos GPDK Technologygill6335100% (1)

- LED Luminaires part 1Document10 pagesLED Luminaires part 1salaitaosama1995No ratings yet

- SSL Version1 Draft 122006Document16 pagesSSL Version1 Draft 122006jorojoroNo ratings yet

- Bright Tomorrow Lighting Competition (L Prize) : Competition Requirements For PAR 38 Halogen Replacement LampsDocument19 pagesBright Tomorrow Lighting Competition (L Prize) : Competition Requirements For PAR 38 Halogen Replacement LampscrennydaneNo ratings yet

- Editedl. Meps and Labelling Programs-1Document33 pagesEditedl. Meps and Labelling Programs-1Helen B. AriasNo ratings yet

- BCA Green Mark Certification For New BuildingsDocument125 pagesBCA Green Mark Certification For New Buildingslwin_oo2435No ratings yet

- 2015 Sec Commercial Chapter 4Document106 pages2015 Sec Commercial Chapter 4Rodel AlmohallasNo ratings yet

- Lighting CalculationDocument13 pagesLighting Calculationmringkel100% (1)

- Lighting Criteria StandardsDocument19 pagesLighting Criteria Standards18926119No ratings yet

- ZCB-Design v3 Energy Modelling GuidelinesDocument14 pagesZCB-Design v3 Energy Modelling Guidelinestijeanlandry7267No ratings yet

- ZERO-Code REFERENCIAS DE EIUDocument16 pagesZERO-Code REFERENCIAS DE EIUDianys RocafuerteNo ratings yet

- CIBSE LG 3 Addendum Visual Environment For Display Screen UseDocument7 pagesCIBSE LG 3 Addendum Visual Environment For Display Screen UseIvano DellaPiccaNo ratings yet

- Complete Submittal-Zoya PDFDocument163 pagesComplete Submittal-Zoya PDFXiPHeR100No ratings yet

- LG3update Lighting Guide 3 Addendum 2001Document7 pagesLG3update Lighting Guide 3 Addendum 2001S E Krishnan IyerNo ratings yet

- PBRS - Resourceful EnergyDocument31 pagesPBRS - Resourceful EnergyMohamed ShiraziNo ratings yet

- LEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYDocument30 pagesLEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYTomaszNo ratings yet

- Dla SDD Memo120412Document52 pagesDla SDD Memo120412omermmkaNo ratings yet

- Preview - CP 24-1999Document5 pagesPreview - CP 24-1999Weijin LeowNo ratings yet

- Information Bulletin 8 PBRS RE R1 Rev3Document4 pagesInformation Bulletin 8 PBRS RE R1 Rev3FarahnaazNo ratings yet

- Quality Reqs Electric Prcocess Heaters S 723Qv2020 12Document12 pagesQuality Reqs Electric Prcocess Heaters S 723Qv2020 12Serge RINAUDONo ratings yet

- 1 Rcny 5000-01Document20 pages1 Rcny 5000-01annaNo ratings yet

- GUIDELINES FOR Certificate of Approval Lamp Latest PDFDocument4 pagesGUIDELINES FOR Certificate of Approval Lamp Latest PDFevonchayNo ratings yet

- Part 1 Solar LED RoadLighting V1a 2023 10aug23Document24 pagesPart 1 Solar LED RoadLighting V1a 2023 10aug23Doughnut Chilli PiNo ratings yet

- DirectDocument6 pagesDirectChandu RavuriNo ratings yet

- 2020 Nec ChangesDocument2 pages2020 Nec ChangesErnesto VillanuevaNo ratings yet

- Energy Efficiency Verification Method PBDS 1-003-C: ScenarioDocument2 pagesEnergy Efficiency Verification Method PBDS 1-003-C: ScenarioQazertNo ratings yet

- Green Mark CriteriaDocument136 pagesGreen Mark CriteriaLim Hai MengNo ratings yet

- For Modelling LEED (Version-1)Document11 pagesFor Modelling LEED (Version-1)Zaw Moe KhineNo ratings yet

- Section 8 Level 2 AuditsDocument32 pagesSection 8 Level 2 AuditsStephanie GregasNo ratings yet

- PIP ELSMC13 Low-Voltage Motor Control Centers - May 2018 PDFDocument24 pagesPIP ELSMC13 Low-Voltage Motor Control Centers - May 2018 PDFist93993No ratings yet

- QS SASO 2663 E Final Draft PDFDocument22 pagesQS SASO 2663 E Final Draft PDFMahjoub AmriNo ratings yet

- Technical Resource ManualDocument16 pagesTechnical Resource ManualpixelnutNo ratings yet

- Oil Containment For Major SubstationDocument46 pagesOil Containment For Major SubstationADsupermanNo ratings yet

- 2013 Peco TarrifDocument15 pages2013 Peco TarrifGary William BrooksNo ratings yet

- BCA GreenMark For Non-Residential Building V3.0Document16 pagesBCA GreenMark For Non-Residential Building V3.0nicklesteohshNo ratings yet

- 630 KV DG SetDocument18 pages630 KV DG SetKEYSTONE INFRA PVT LTDNo ratings yet

- ELEGL02Document26 pagesELEGL02Ariel Anibal AparicioNo ratings yet

- Scope of Works - Project Kayla TOR PSS - Gencorev3-FloatDocument10 pagesScope of Works - Project Kayla TOR PSS - Gencorev3-FloatIzarulhaq AwangNo ratings yet

- SASO 2663:2014: (SASO 2663/2012 Including The Modifications Approved in Saudi Council Board No. ./2014)Document24 pagesSASO 2663:2014: (SASO 2663/2012 Including The Modifications Approved in Saudi Council Board No. ./2014)Mahjoub AmriNo ratings yet

- Rotan OM ApproachDocument173 pagesRotan OM Approach8103 Anshu PatilNo ratings yet

- Volume 1 Chapter 4 JV Verification MethodsDocument8 pagesVolume 1 Chapter 4 JV Verification MethodsMohammad MoazzamiNo ratings yet

- Volume 1 Chapter 10 j6 Artificial Lighting Power PDFDocument18 pagesVolume 1 Chapter 10 j6 Artificial Lighting Power PDFSheand KaseNo ratings yet

- Quality Reqs For Plate and Frame Heat Exchangers API S 749Qv2023 12Document12 pagesQuality Reqs For Plate and Frame Heat Exchangers API S 749Qv2023 12daus nasNo ratings yet

- BS 5225-3Document18 pagesBS 5225-3Avk SanjeevanNo ratings yet

- Quality Requirements For High-Voltage Switchgear and ControlgearDocument11 pagesQuality Requirements For High-Voltage Switchgear and ControlgearErwin MorenoNo ratings yet

- Read More About Project SelectionDocument9 pagesRead More About Project SelectionsaitejairukulapatiNo ratings yet

- QS 2663-2020Document26 pagesQS 2663-2020Ramesh K KarthickNo ratings yet

- Quality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperatureDocument12 pagesQuality Requirements For Field Instruments - Electronic Transmitters - Pressure, Differential Pressure and TemperaturekochicommNo ratings yet

- Griha Criteria No.32 Energy Audit and ValidationDocument13 pagesGriha Criteria No.32 Energy Audit and ValidationrichurichaNo ratings yet

- 091117110542preview - SS 553-2009Document6 pages091117110542preview - SS 553-2009Thanh HuuNo ratings yet

- Carpark Ventilation SpecificationDocument5 pagesCarpark Ventilation SpecificationHo Dac ThanhNo ratings yet

- BREEAM Prisons 2008 Assessor ManualDocument366 pagesBREEAM Prisons 2008 Assessor ManualMarinaNo ratings yet

- Meps TransformersDocument71 pagesMeps TransformersvtechelectricNo ratings yet

- White Paper CAN-ANSI-AHRI 1330-2015Document11 pagesWhite Paper CAN-ANSI-AHRI 1330-2015Allan GomezNo ratings yet

- ATT.2 - Standby Generator Requirement As Per Shell DEPDocument4 pagesATT.2 - Standby Generator Requirement As Per Shell DEPAhmed AdelNo ratings yet

- Guidebook for Utilities-Led Business Models: Way Forward for Rooftop Solar in IndiaFrom EverandGuidebook for Utilities-Led Business Models: Way Forward for Rooftop Solar in IndiaNo ratings yet

- Electric Motorcycle Charging Infrastructure Road Map for IndonesiaFrom EverandElectric Motorcycle Charging Infrastructure Road Map for IndonesiaNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- NC19402 Engineering Report LetterDocument4 pagesNC19402 Engineering Report LetterMINo ratings yet

- Brochure Clean Renewable Energy Brand UpdateDocument2 pagesBrochure Clean Renewable Energy Brand UpdateMINo ratings yet

- 9a 3610 - Ongoing CS ContractDocument19 pages9a 3610 - Ongoing CS ContractMINo ratings yet

- Survey of Grid Forming Inverter Applications Julia MatevosyanDocument18 pagesSurvey of Grid Forming Inverter Applications Julia MatevosyanMINo ratings yet

- 1 NC-019402 Offer LetterDocument18 pages1 NC-019402 Offer LetterMINo ratings yet

- Words - Google SearchDocument1 pageWords - Google SearchMINo ratings yet

- Final ReportDocument22 pagesFinal ReportMINo ratings yet

- Simplesolarfarm 2019Document20 pagesSimplesolarfarm 2019MINo ratings yet

- KB Document 246Document59 pagesKB Document 246MINo ratings yet

- S2022.10.17.Online Stab - en Power System StabilityDocument1 pageS2022.10.17.Online Stab - en Power System StabilityMINo ratings yet

- Hvac Eguide: Instruments and ServicesDocument26 pagesHvac Eguide: Instruments and ServicesMINo ratings yet

- ADLT - DimOnOff SCMS Data SheetDocument4 pagesADLT - DimOnOff SCMS Data SheetMINo ratings yet

- GCN - Energy Storage Microgrid Conference - 20170911Document14 pagesGCN - Energy Storage Microgrid Conference - 20170911MINo ratings yet

- Zen Ecosystems Demand Response Rert Trial Summer 2017 18Document17 pagesZen Ecosystems Demand Response Rert Trial Summer 2017 18MINo ratings yet

- ADLT DimOnOff Topology DiagramDocument1 pageADLT DimOnOff Topology DiagramMINo ratings yet

- Demand Response Trial Test December 2020Document35 pagesDemand Response Trial Test December 2020MINo ratings yet

- Powershop Demand Response Program Final 2020Document9 pagesPowershop Demand Response Program Final 2020MINo ratings yet

- ADLT - DimOnOff G3 Gateway Data SheetDocument3 pagesADLT - DimOnOff G3 Gateway Data SheetMINo ratings yet

- The Dawn of A New Apac Era: Air Conditioning Product RangeDocument11 pagesThe Dawn of A New Apac Era: Air Conditioning Product RangeMI100% (1)

- Tech-Evapac2001 0Document17 pagesTech-Evapac2001 0MINo ratings yet

- ADLT - DimOnOff RME-H2 Node Data SheetDocument3 pagesADLT - DimOnOff RME-H2 Node Data SheetMINo ratings yet

- ADLT DimOnOff OverviewDocument7 pagesADLT DimOnOff OverviewMINo ratings yet

- ADLT - DimOnOff RGBW Controller Data SheetDocument3 pagesADLT - DimOnOff RGBW Controller Data SheetMINo ratings yet

- ADLT - DimOnOff RTM Node Data SheetDocument3 pagesADLT - DimOnOff RTM Node Data SheetMINo ratings yet

- ADLT - DimOnOff RME-H3 Node Data SheetDocument4 pagesADLT - DimOnOff RME-H3 Node Data SheetMINo ratings yet

- ADLT - DimOnOff LNLV Node Data SheetDocument3 pagesADLT - DimOnOff LNLV Node Data SheetMINo ratings yet

- Lorawan AU ChannelsDocument6 pagesLorawan AU ChannelsMINo ratings yet

- LED Parking Garages & ControlsDocument38 pagesLED Parking Garages & ControlsMINo ratings yet

- Beletich Report For IPART On Commercial Lighting - February 2013Document64 pagesBeletich Report For IPART On Commercial Lighting - February 2013MINo ratings yet

- Binomial Approx To NormalDocument8 pagesBinomial Approx To NormalOLUWASEYI OJUOLANo ratings yet

- Alcatel 1660 SMDocument8 pagesAlcatel 1660 SMILiketobWithuNo ratings yet

- Smart Doctors Assistant - An Advanced Appointment Booking System For HospitalsDocument8 pagesSmart Doctors Assistant - An Advanced Appointment Booking System For HospitalsIJAR JOURNALNo ratings yet

- 22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Document1 page22-NFXP-RLIC-QGC-RLC-TML-00793 - Potable Water Hydrotest Package For EPC Camp 2Ansaf AskyNo ratings yet

- Critical Variables and Constructs in The Context of Project Management: Importance-Performance AnalysisDocument29 pagesCritical Variables and Constructs in The Context of Project Management: Importance-Performance AnalysisAdhi Tol Serpan Seksi 3No ratings yet

- Tensores Van GorpDocument17 pagesTensores Van GorpsalematadorNo ratings yet

- 3 AI - Search IIIDocument72 pages3 AI - Search IIIkuramthanushmaNo ratings yet

- Course Name CO Number With Code Co Statement BT LevelDocument43 pagesCourse Name CO Number With Code Co Statement BT LevelPolkam SrinidhiNo ratings yet

- Tips Tricks To Interviewing Virtually 1 YALI NETWORKDocument2 pagesTips Tricks To Interviewing Virtually 1 YALI NETWORKAKOGU J. AKPOCHI J.No ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Carbide Blank InsertDocument7 pagesCarbide Blank InsertSakthi VelNo ratings yet

- DGSDocument11 pagesDGSsridhar kumar singh100% (1)

- Coating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04Document16 pagesCoating Procedure: For External Protection of Steel Pipelines Using Fusion Bond Epoxy (F.B.E) PTJ-COAT-F.B.E-04lemuel bacsaNo ratings yet

- JQ International Construction, IncDocument2 pagesJQ International Construction, Incyael rodriguez100% (1)

- PROJECT STANDARDS AND SPECIFICATIONS Solid Handling Systems Rev01 PDFDocument10 pagesPROJECT STANDARDS AND SPECIFICATIONS Solid Handling Systems Rev01 PDFVirjil AycochoNo ratings yet

- Introduction of Insulation CoordinationDocument5 pagesIntroduction of Insulation CoordinationTaher El NoamanNo ratings yet

- Backstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsDocument15 pagesBackstop To Prevent Reversal of Inclined Conveyor and Vertical Bucket ElevatorsoliveiralauroNo ratings yet

- Common Service Spares For U-Power and Omega 01012015Document1 pageCommon Service Spares For U-Power and Omega 01012015smartechengineering.infoNo ratings yet

- ML Interview Questions and AnswersDocument25 pagesML Interview Questions and Answerssantoshguddu100% (1)

- BIS3003 - Assessment Brief T3, 2021Document20 pagesBIS3003 - Assessment Brief T3, 2021KushalNo ratings yet

- How To Fix Windows 11 Indexing Is Paused (File Search Not Working)Document36 pagesHow To Fix Windows 11 Indexing Is Paused (File Search Not Working)Mohammed Zahid AnsariNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankWawanNo ratings yet

- Development and Use of Non-Digital or Conventional MaterialsDocument4 pagesDevelopment and Use of Non-Digital or Conventional Materialsorgasazi18No ratings yet

- Aab-e-Kausar by Mufti Ameen PDFDocument306 pagesAab-e-Kausar by Mufti Ameen PDFSamina Kosar96% (26)

- 10 FixedAsset 12 FixedAsset Intro Virtual AssetDocument11 pages10 FixedAsset 12 FixedAsset Intro Virtual AssetCrazy TechNo ratings yet