Professional Documents

Culture Documents

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Uploaded by

Mohammad KamruzzamanCopyright:

Available Formats

You might also like

- Whirlpool - Organisational Structure and AnalysisDocument20 pagesWhirlpool - Organisational Structure and AnalysisTaposh Sarkar40% (5)

- Lean Manufacturing A Vital Tool To Enhance Productivity in ManufacturingDocument8 pagesLean Manufacturing A Vital Tool To Enhance Productivity in ManufacturingNuriaNo ratings yet

- Ie Department Objective of The DepartmentDocument44 pagesIe Department Objective of The DepartmentDhanaperumal VarulaNo ratings yet

- Production PPC Leader Production SupervisorDocument3 pagesProduction PPC Leader Production SupervisornorlieNo ratings yet

- Production Planning and Material Control ManagerDocument3 pagesProduction Planning and Material Control ManagerRajVardhanNo ratings yet

- Tips For 5S On The Shop FloorDocument5 pagesTips For 5S On The Shop FloorAnonymous v5QjDW2eHxNo ratings yet

- 5 S Information and Training OutlineDocument5 pages5 S Information and Training Outlinekprasad_mlNo ratings yet

- Kirandeep - JIT & LeanDocument22 pagesKirandeep - JIT & LeanAmarjeet Singh RanaNo ratings yet

- Cost and Time Savings of Apparel Industry Through Elimination of Non-Valuated Process in Cutting SectionDocument9 pagesCost and Time Savings of Apparel Industry Through Elimination of Non-Valuated Process in Cutting SectionImranNo ratings yet

- Module 3 - Production ControlDocument55 pagesModule 3 - Production ControlRahul LoharNo ratings yet

- Final Internee Report KAMALDocument129 pagesFinal Internee Report KAMALMd.Kamal HossainNo ratings yet

- Lean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Document35 pagesLean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Vineeta KanwalNo ratings yet

- Application of Lean Manufacturing Tools in Garment IndustryDocument7 pagesApplication of Lean Manufacturing Tools in Garment IndustryVishwanath KrNo ratings yet

- The Correct Way To Implement LeanDocument43 pagesThe Correct Way To Implement LeanHadee SaberNo ratings yet

- Lean Production System (LPS)Document26 pagesLean Production System (LPS)hhmiziNo ratings yet

- Apparel Quality Management: National Institute of Fashion TechnologyDocument13 pagesApparel Quality Management: National Institute of Fashion TechnologyBhaswati PandaNo ratings yet

- Activity BoardDocument3 pagesActivity BoardluxgmNo ratings yet

- Lean Manufacturing: GAYATHRI S (20086306) JAMUNA T (20086310)Document28 pagesLean Manufacturing: GAYATHRI S (20086306) JAMUNA T (20086310)Gayathri SubramanianNo ratings yet

- Tools of Lean MaufacturingDocument22 pagesTools of Lean Maufacturingsahu_dishaNo ratings yet

- Lean Manufacturing in Garment IndustryDocument9 pagesLean Manufacturing in Garment IndustryMathews PJNo ratings yet

- Commissioning A PLC Based Control System Guide in The Automation IndustryDocument4 pagesCommissioning A PLC Based Control System Guide in The Automation IndustryRajuNo ratings yet

- Industrial Engineering PresentationDocument13 pagesIndustrial Engineering PresentationKent RodriguezNo ratings yet

- Industrial Management Unit V: Mrs D Pratibha Associate Professor Anurag Group of InstitutionsDocument53 pagesIndustrial Management Unit V: Mrs D Pratibha Associate Professor Anurag Group of InstitutionsD PRATIBHANo ratings yet

- Industrial Engineering Productivity: Navanendra SinghDocument29 pagesIndustrial Engineering Productivity: Navanendra SinghMritunjay BhartiNo ratings yet

- Line Balancing and WIPDocument17 pagesLine Balancing and WIPTajala MaqsoodNo ratings yet

- Mizan HowladerDocument65 pagesMizan HowladerRejaul Karim Bhuiyan RockyNo ratings yet

- Productivity Improvement With Kaizen Tool in Garment IndustryDocument6 pagesProductivity Improvement With Kaizen Tool in Garment IndustrySUHRIT BISWASNo ratings yet

- 7 QC Tools: Training Module OnDocument38 pages7 QC Tools: Training Module OnSomnath BanerjeeNo ratings yet

- A Study of Lean Manufacturing Practice With Reference To Indian ManufacturingDocument11 pagesA Study of Lean Manufacturing Practice With Reference To Indian ManufacturingRahul Ramesh PareraoNo ratings yet

- Idle Time Reduction in Machining Processes atDocument29 pagesIdle Time Reduction in Machining Processes atHarsheel PanchasaraNo ratings yet

- Becoming LeanDocument79 pagesBecoming LeanItqan ArchiaNo ratings yet

- 5s in Simba Apparels KenyaDocument19 pages5s in Simba Apparels KenyaPrerna Khatri100% (1)

- Garment Analyzer™: Flexible Predetermined Motion Time SystemDocument30 pagesGarment Analyzer™: Flexible Predetermined Motion Time SystemardinrajaNo ratings yet

- QM Pillar: (Quality Maintenance)Document17 pagesQM Pillar: (Quality Maintenance)G K MohanNo ratings yet

- Capacity, Performance, UlitizationDocument7 pagesCapacity, Performance, Ulitizationaqsa imranNo ratings yet

- Industrial Engineering: What Industrial Engineers Do?Document28 pagesIndustrial Engineering: What Industrial Engineers Do?Ayaan ChakravarthiNo ratings yet

- GSD Management PresentationDocument20 pagesGSD Management PresentationLM MuhammadNo ratings yet

- Wip PDFDocument29 pagesWip PDFEruNo ratings yet

- Role of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilDocument6 pagesRole of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilNatala WillzNo ratings yet

- Chapter 8 The Quality SystemDocument24 pagesChapter 8 The Quality SystemBiraj GhimireNo ratings yet

- Making Workstudy WorkDocument5 pagesMaking Workstudy Workmahavarun3096No ratings yet

- Delux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionDocument4 pagesDelux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionmaulikgadaraNo ratings yet

- Improving Working Conditions and Productivity in The Garment IndustryDocument166 pagesImproving Working Conditions and Productivity in The Garment IndustryAli ArsalanNo ratings yet

- Industrial EngineeringDocument9 pagesIndustrial Engineeringrjrahul25No ratings yet

- Lean Manufacturing Full Seminar Report 123456Document22 pagesLean Manufacturing Full Seminar Report 123456Pradeep Mahil50% (2)

- Improving Sewing Section Efficiency ThroDocument11 pagesImproving Sewing Section Efficiency ThroCBBCV68No ratings yet

- Manufacturing Engineering IDocument4 pagesManufacturing Engineering Iahmish kabbaxe100% (1)

- 5 S Partex GroupDocument127 pages5 S Partex Grouprblrana1No ratings yet

- QC ManagementDocument4 pagesQC ManagementSakib ZamanNo ratings yet

- Garment L-IDocument70 pagesGarment L-Isiyoum negashNo ratings yet

- 7 Common Myths About Manufacturing Management: What Chinese Factory Managers Need To KnowDocument20 pages7 Common Myths About Manufacturing Management: What Chinese Factory Managers Need To KnowraiyanduNo ratings yet

- Lean Production - ReportDocument29 pagesLean Production - ReportAlexanderNo ratings yet

- IEMS Module 2Document17 pagesIEMS Module 2M.José Copons GalloNo ratings yet

- Fulltext01 PDFDocument120 pagesFulltext01 PDFBhushan KambleNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- What Are The Reports Made by IE Department in Garment Factories?Document10 pagesWhat Are The Reports Made by IE Department in Garment Factories?YousufNo ratings yet

- An Application of Six Sigma MethadologyDocument26 pagesAn Application of Six Sigma MethadologyBrijesh PandeyNo ratings yet

- Operations Manager: - Deliver A Quality Product/service ToDocument23 pagesOperations Manager: - Deliver A Quality Product/service ToakshaynnaikNo ratings yet

- Lean ProductionDocument17 pagesLean ProductionTahir Naeem JattNo ratings yet

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- IE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoDocument3 pagesIE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoSayed Aasim Jawaid100% (1)

- Efeso BSM Dual Brand Lean LabsDocument6 pagesEfeso BSM Dual Brand Lean LabsMohammad KamruzzamanNo ratings yet

- Movement ReportDocument1 pageMovement ReportMohammad KamruzzamanNo ratings yet

- Sample of ForecastingDocument18 pagesSample of ForecastingMohammad KamruzzamanNo ratings yet

- Otp StatusDocument13 pagesOtp StatusMohammad KamruzzamanNo ratings yet

- The Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsDocument7 pagesThe Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsMohammad KamruzzamanNo ratings yet

- Abcd Checklist For Manufacturing ExcellenceDocument24 pagesAbcd Checklist For Manufacturing ExcellenceMohammad KamruzzamanNo ratings yet

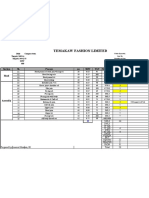

- Temakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPDocument1 pageTemakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPMohammad KamruzzamanNo ratings yet

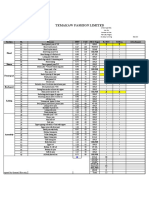

- Temakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Document3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Mohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument2 pagesTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of CUNTIDocument2 pagesTemakaw Fashion LTD: Operation Buletin of CUNTIMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveDocument3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Document4 pagesTemakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Mohammad KamruzzamanNo ratings yet

- Big Data Module 1Document14 pagesBig Data Module 1OK BYENo ratings yet

- Dove Final PresentationDocument20 pagesDove Final PresentationAnshubhi KaroliaNo ratings yet

- MCQs ITB 200 by Virtualine Social Network PDFDocument21 pagesMCQs ITB 200 by Virtualine Social Network PDFkashif14321No ratings yet

- CHAPTER 4 Management Aspect FINALDocument18 pagesCHAPTER 4 Management Aspect FINALPatrick Kyle AgraviadorNo ratings yet

- Oly BMGT L Exit ExamDocument13 pagesOly BMGT L Exit ExamHMichael Abe100% (1)

- Personal Data Breach & Incident Handling ProcedureDocument11 pagesPersonal Data Breach & Incident Handling ProcedureSanda NechiforNo ratings yet

- Options Trading Strategies: A Guide For Beginners: Elvin MirzayevDocument4 pagesOptions Trading Strategies: A Guide For Beginners: Elvin MirzayevJonhmark AniñonNo ratings yet

- Marketing Management Book 1ST Sem MbaDocument271 pagesMarketing Management Book 1ST Sem Mbaamit chavariaNo ratings yet

- Porters Five Force Model in PharmaDocument10 pagesPorters Five Force Model in PharmadishaNo ratings yet

- Chapter-10: 10.0 Employee Relations in BanksDocument11 pagesChapter-10: 10.0 Employee Relations in BanksJitendra YadavNo ratings yet

- Tutorial 5Document2 pagesTutorial 5Yi QiNo ratings yet

- Tugas Kasus Akuntansi Manajemen ABCDocument3 pagesTugas Kasus Akuntansi Manajemen ABCutari yani dewiNo ratings yet

- Assignment of HRMDocument11 pagesAssignment of HRMNirmalNo ratings yet

- A Study of Performance Appraisal System Yahama Motors Sandeep KumarDocument107 pagesA Study of Performance Appraisal System Yahama Motors Sandeep KumarShahzad SaifNo ratings yet

- B3.2 - Cricket Data Analysis - Digital BusinessDocument18 pagesB3.2 - Cricket Data Analysis - Digital BusinessakashNo ratings yet

- Job Description Template - Electrician, Plumber, All AroundDocument2 pagesJob Description Template - Electrician, Plumber, All AroundBINGLHNo ratings yet

- Juken Technology Limited FY2009 Net Profit Soars To S$1,173,000 From S$46,000 in FY2008 - 230210Document3 pagesJuken Technology Limited FY2009 Net Profit Soars To S$1,173,000 From S$46,000 in FY2008 - 230210WeR1 Consultants Pte LtdNo ratings yet

- Mortgage Application Crina (Fillable)Document3 pagesMortgage Application Crina (Fillable)bhupinderNo ratings yet

- Finance Acumen For Non FinanceDocument55 pagesFinance Acumen For Non FinanceHarihar PanigrahiNo ratings yet

- International Financial Managment For OnlineDocument331 pagesInternational Financial Managment For OnlineAmity-elearning75% (4)

- FICO Cash Journal 3Document31 pagesFICO Cash Journal 3biswajit6864No ratings yet

- LESSON Planning A Long Term Content Strategy DECKDocument69 pagesLESSON Planning A Long Term Content Strategy DECKHuy Hoàng PhanNo ratings yet

- CONCEPTUAL FRAMEWORK HandoutDocument6 pagesCONCEPTUAL FRAMEWORK HandoutRuby RomeroNo ratings yet

- Relevant Costs For Decision Making: Illustrative ExampleDocument8 pagesRelevant Costs For Decision Making: Illustrative ExampleKhaled Abo YousefNo ratings yet

- Account Name: Indiabulls Finance Ltd. Bank Name-BANK OF Maharashtra Account No-60463144608 IFSC CODE-MAHB0002256Document3 pagesAccount Name: Indiabulls Finance Ltd. Bank Name-BANK OF Maharashtra Account No-60463144608 IFSC CODE-MAHB0002256chhatria077No ratings yet

- Cost Allocation in GeneralDocument51 pagesCost Allocation in GeneralVaibhav DayalNo ratings yet

- MPS&MRPDocument18 pagesMPS&MRPPrasit SermsiripokaNo ratings yet

- HR Domain Interview QuestionsDocument5 pagesHR Domain Interview QuestionsShubham MohanNo ratings yet

- Corporate Accounting AssignmentDocument6 pagesCorporate Accounting AssignmentKarthikacauraNo ratings yet

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Uploaded by

Mohammad KamruzzamanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Standard Operation Procedure (SOP) : Work Study/ Industrial Engineering - SOP's

Uploaded by

Mohammad KamruzzamanCopyright:

Available Formats

Standard Operation Procedure (SOP)

Work Study/ Industrial Engineering – SOP’s

1. At Style inquiry

Submit Estimated SMV, Outputs and efficiency levels for pre-costing

Analyze and comment on potential of doing the orders inquired.

Attend for the product development meeting and provide proactive input

Attend to do the mock ups for approvals on required construction changes with the evaluation of saving

and benefits

Calculate and submit thread consumption to the merchandising

2. At Production Planning

Submit Estimated SMV, Outputs and efficiency levels for Production planning

Provide proactive input for production scheduling

Check and approve production schedules

Make Line wise details production plan

3. At Pre-production

Testing and preparation for the confirmed orders – Methods, attachments

the samples to submit and comments after receive

Operation bulleting and SMV.

bulleting with Production and technical staff

Attend for line sample

Confirm operation bulleting

Prepare line layouts and discuss and confirm with production and technical staff

manpower allocation for layouts

Prepare skill inventory and requirement for each style

and attend on skill development for style based critical operations (Training in advanced)

Critical path analyses.

Prepare and attend on general skill development plan

fresher training manual

Supervise fresher training and training centre activities

Prepare machine, attachment and manpower requirements based on latest production schedules

Make and follow line feeding plan

Risk analyses before style feeding

4. Line feeding/New style introduction

Attend in new style introduction

Instruct and train workers on correct methods as motion sequence include in desired SMV

for best work place arrangements as method desired on SMV with maintaining a style check list.

Explain the SMV, Targets and plan efficiency and Incentive levels to each and every worker

Play a active roll on reducing line feeding losses (Through put time)

Optimum utilization of machine and equipment

Attend for style first bundle meeting

5. At Running Production and day to day

Capacity study of all layout/Operations at two to three days after feeding

SMV revision and confirmation with comparing the capacity after complete the capacity study

Make potential plans after capacity study

1st line layout re-balancing based on actual capacities and as per potential plan

Attend in daily line pocket meeting

Attend on daily line balancing

the bottle necks, technical and quality issues and attend to solve with addressing to the responsible

persons

Interval capacity study and line layout re-balancing once a every two weeks time in first month and

once a month after first month

Plan and attend in Continuous Training of workers

Attend in Continuous method improvements and SMV reductions

Organize and conduct daily efficiency meeting with production staff

Improving individual efficiencies with monitoring and making sure that the efficiency reports are

accurate

Monitor and record individual and line off standard times (lost time) and take necessary actions to

reduce the lost times. Address and discuss with management on off standard times

Achieve the maximum potentials of individuals and sections and maintain the minimum capacity gaps

Achieved planed production targets and line efficiencies

6. Post Production

Style reconciliation of technical (SMV, Efficiency, Production output, Thread consumption, Production

plan, Bottlenecks)

Monitor the style reconciliation of received to ship

Monitor the post costing

7. General

Performance evaluation of workers and factory staff. Do the grading

Introducing and monitoring incentive schemes/Motivation tools

Plan and monitor the skill upgrade program

Management update on latest management concepts, Technology, systems and procedures, methods,

tools and attachments.

Maintain and achieve the targets of key productivity indicators (KPI) and do the comparison with other

industries for management information

Maintain all filing and document systems

Special tasks/Projects assign by management

Attend for management meeting and give proactive input

training and maintain records of achievements

----------------------------

You might also like

- Whirlpool - Organisational Structure and AnalysisDocument20 pagesWhirlpool - Organisational Structure and AnalysisTaposh Sarkar40% (5)

- Lean Manufacturing A Vital Tool To Enhance Productivity in ManufacturingDocument8 pagesLean Manufacturing A Vital Tool To Enhance Productivity in ManufacturingNuriaNo ratings yet

- Ie Department Objective of The DepartmentDocument44 pagesIe Department Objective of The DepartmentDhanaperumal VarulaNo ratings yet

- Production PPC Leader Production SupervisorDocument3 pagesProduction PPC Leader Production SupervisornorlieNo ratings yet

- Production Planning and Material Control ManagerDocument3 pagesProduction Planning and Material Control ManagerRajVardhanNo ratings yet

- Tips For 5S On The Shop FloorDocument5 pagesTips For 5S On The Shop FloorAnonymous v5QjDW2eHxNo ratings yet

- 5 S Information and Training OutlineDocument5 pages5 S Information and Training Outlinekprasad_mlNo ratings yet

- Kirandeep - JIT & LeanDocument22 pagesKirandeep - JIT & LeanAmarjeet Singh RanaNo ratings yet

- Cost and Time Savings of Apparel Industry Through Elimination of Non-Valuated Process in Cutting SectionDocument9 pagesCost and Time Savings of Apparel Industry Through Elimination of Non-Valuated Process in Cutting SectionImranNo ratings yet

- Module 3 - Production ControlDocument55 pagesModule 3 - Production ControlRahul LoharNo ratings yet

- Final Internee Report KAMALDocument129 pagesFinal Internee Report KAMALMd.Kamal HossainNo ratings yet

- Lean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Document35 pagesLean Manufacturing: Presented by Vineeta Kanwal ID No. 44316Vineeta KanwalNo ratings yet

- Application of Lean Manufacturing Tools in Garment IndustryDocument7 pagesApplication of Lean Manufacturing Tools in Garment IndustryVishwanath KrNo ratings yet

- The Correct Way To Implement LeanDocument43 pagesThe Correct Way To Implement LeanHadee SaberNo ratings yet

- Lean Production System (LPS)Document26 pagesLean Production System (LPS)hhmiziNo ratings yet

- Apparel Quality Management: National Institute of Fashion TechnologyDocument13 pagesApparel Quality Management: National Institute of Fashion TechnologyBhaswati PandaNo ratings yet

- Activity BoardDocument3 pagesActivity BoardluxgmNo ratings yet

- Lean Manufacturing: GAYATHRI S (20086306) JAMUNA T (20086310)Document28 pagesLean Manufacturing: GAYATHRI S (20086306) JAMUNA T (20086310)Gayathri SubramanianNo ratings yet

- Tools of Lean MaufacturingDocument22 pagesTools of Lean Maufacturingsahu_dishaNo ratings yet

- Lean Manufacturing in Garment IndustryDocument9 pagesLean Manufacturing in Garment IndustryMathews PJNo ratings yet

- Commissioning A PLC Based Control System Guide in The Automation IndustryDocument4 pagesCommissioning A PLC Based Control System Guide in The Automation IndustryRajuNo ratings yet

- Industrial Engineering PresentationDocument13 pagesIndustrial Engineering PresentationKent RodriguezNo ratings yet

- Industrial Management Unit V: Mrs D Pratibha Associate Professor Anurag Group of InstitutionsDocument53 pagesIndustrial Management Unit V: Mrs D Pratibha Associate Professor Anurag Group of InstitutionsD PRATIBHANo ratings yet

- Industrial Engineering Productivity: Navanendra SinghDocument29 pagesIndustrial Engineering Productivity: Navanendra SinghMritunjay BhartiNo ratings yet

- Line Balancing and WIPDocument17 pagesLine Balancing and WIPTajala MaqsoodNo ratings yet

- Mizan HowladerDocument65 pagesMizan HowladerRejaul Karim Bhuiyan RockyNo ratings yet

- Productivity Improvement With Kaizen Tool in Garment IndustryDocument6 pagesProductivity Improvement With Kaizen Tool in Garment IndustrySUHRIT BISWASNo ratings yet

- 7 QC Tools: Training Module OnDocument38 pages7 QC Tools: Training Module OnSomnath BanerjeeNo ratings yet

- A Study of Lean Manufacturing Practice With Reference To Indian ManufacturingDocument11 pagesA Study of Lean Manufacturing Practice With Reference To Indian ManufacturingRahul Ramesh PareraoNo ratings yet

- Idle Time Reduction in Machining Processes atDocument29 pagesIdle Time Reduction in Machining Processes atHarsheel PanchasaraNo ratings yet

- Becoming LeanDocument79 pagesBecoming LeanItqan ArchiaNo ratings yet

- 5s in Simba Apparels KenyaDocument19 pages5s in Simba Apparels KenyaPrerna Khatri100% (1)

- Garment Analyzer™: Flexible Predetermined Motion Time SystemDocument30 pagesGarment Analyzer™: Flexible Predetermined Motion Time SystemardinrajaNo ratings yet

- QM Pillar: (Quality Maintenance)Document17 pagesQM Pillar: (Quality Maintenance)G K MohanNo ratings yet

- Capacity, Performance, UlitizationDocument7 pagesCapacity, Performance, Ulitizationaqsa imranNo ratings yet

- Industrial Engineering: What Industrial Engineers Do?Document28 pagesIndustrial Engineering: What Industrial Engineers Do?Ayaan ChakravarthiNo ratings yet

- GSD Management PresentationDocument20 pagesGSD Management PresentationLM MuhammadNo ratings yet

- Wip PDFDocument29 pagesWip PDFEruNo ratings yet

- Role of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilDocument6 pagesRole of IT in Lean Manufacturing: A Brief Scenario: G T Padmane, M T Sohel, P D PatilNatala WillzNo ratings yet

- Chapter 8 The Quality SystemDocument24 pagesChapter 8 The Quality SystemBiraj GhimireNo ratings yet

- Making Workstudy WorkDocument5 pagesMaking Workstudy Workmahavarun3096No ratings yet

- Delux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionDocument4 pagesDelux Bearings Pvt. LTD.: Why Why Analysis For In-House RejectionmaulikgadaraNo ratings yet

- Improving Working Conditions and Productivity in The Garment IndustryDocument166 pagesImproving Working Conditions and Productivity in The Garment IndustryAli ArsalanNo ratings yet

- Industrial EngineeringDocument9 pagesIndustrial Engineeringrjrahul25No ratings yet

- Lean Manufacturing Full Seminar Report 123456Document22 pagesLean Manufacturing Full Seminar Report 123456Pradeep Mahil50% (2)

- Improving Sewing Section Efficiency ThroDocument11 pagesImproving Sewing Section Efficiency ThroCBBCV68No ratings yet

- Manufacturing Engineering IDocument4 pagesManufacturing Engineering Iahmish kabbaxe100% (1)

- 5 S Partex GroupDocument127 pages5 S Partex Grouprblrana1No ratings yet

- QC ManagementDocument4 pagesQC ManagementSakib ZamanNo ratings yet

- Garment L-IDocument70 pagesGarment L-Isiyoum negashNo ratings yet

- 7 Common Myths About Manufacturing Management: What Chinese Factory Managers Need To KnowDocument20 pages7 Common Myths About Manufacturing Management: What Chinese Factory Managers Need To KnowraiyanduNo ratings yet

- Lean Production - ReportDocument29 pagesLean Production - ReportAlexanderNo ratings yet

- IEMS Module 2Document17 pagesIEMS Module 2M.José Copons GalloNo ratings yet

- Fulltext01 PDFDocument120 pagesFulltext01 PDFBhushan KambleNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- What Are The Reports Made by IE Department in Garment Factories?Document10 pagesWhat Are The Reports Made by IE Department in Garment Factories?YousufNo ratings yet

- An Application of Six Sigma MethadologyDocument26 pagesAn Application of Six Sigma MethadologyBrijesh PandeyNo ratings yet

- Operations Manager: - Deliver A Quality Product/service ToDocument23 pagesOperations Manager: - Deliver A Quality Product/service ToakshaynnaikNo ratings yet

- Lean ProductionDocument17 pagesLean ProductionTahir Naeem JattNo ratings yet

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- IE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoDocument3 pagesIE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoSayed Aasim Jawaid100% (1)

- Efeso BSM Dual Brand Lean LabsDocument6 pagesEfeso BSM Dual Brand Lean LabsMohammad KamruzzamanNo ratings yet

- Movement ReportDocument1 pageMovement ReportMohammad KamruzzamanNo ratings yet

- Sample of ForecastingDocument18 pagesSample of ForecastingMohammad KamruzzamanNo ratings yet

- Otp StatusDocument13 pagesOtp StatusMohammad KamruzzamanNo ratings yet

- The Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsDocument7 pagesThe Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsMohammad KamruzzamanNo ratings yet

- Abcd Checklist For Manufacturing ExcellenceDocument24 pagesAbcd Checklist For Manufacturing ExcellenceMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPDocument1 pageTemakaw Fashion Limited: Style Cangaro Teen Target (100%) Target (50%) 75 SMV MPMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process Sec SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C R.Man AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Document3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man 1 1Mohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentDocument1 pageTemakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument2 pagesTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of CUNTIDocument2 pagesTemakaw Fashion LTD: Operation Buletin of CUNTIMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksDocument1 pageTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanNo ratings yet

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveDocument3 pagesTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveMohammad KamruzzamanNo ratings yet

- Temakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Document4 pagesTemakaw Fashion LTD: Operation Buletin of Cura Target (100 %) 76 Target (55 %) 41 SMV 44.22 MP 56Mohammad KamruzzamanNo ratings yet

- Big Data Module 1Document14 pagesBig Data Module 1OK BYENo ratings yet

- Dove Final PresentationDocument20 pagesDove Final PresentationAnshubhi KaroliaNo ratings yet

- MCQs ITB 200 by Virtualine Social Network PDFDocument21 pagesMCQs ITB 200 by Virtualine Social Network PDFkashif14321No ratings yet

- CHAPTER 4 Management Aspect FINALDocument18 pagesCHAPTER 4 Management Aspect FINALPatrick Kyle AgraviadorNo ratings yet

- Oly BMGT L Exit ExamDocument13 pagesOly BMGT L Exit ExamHMichael Abe100% (1)

- Personal Data Breach & Incident Handling ProcedureDocument11 pagesPersonal Data Breach & Incident Handling ProcedureSanda NechiforNo ratings yet

- Options Trading Strategies: A Guide For Beginners: Elvin MirzayevDocument4 pagesOptions Trading Strategies: A Guide For Beginners: Elvin MirzayevJonhmark AniñonNo ratings yet

- Marketing Management Book 1ST Sem MbaDocument271 pagesMarketing Management Book 1ST Sem Mbaamit chavariaNo ratings yet

- Porters Five Force Model in PharmaDocument10 pagesPorters Five Force Model in PharmadishaNo ratings yet

- Chapter-10: 10.0 Employee Relations in BanksDocument11 pagesChapter-10: 10.0 Employee Relations in BanksJitendra YadavNo ratings yet

- Tutorial 5Document2 pagesTutorial 5Yi QiNo ratings yet

- Tugas Kasus Akuntansi Manajemen ABCDocument3 pagesTugas Kasus Akuntansi Manajemen ABCutari yani dewiNo ratings yet

- Assignment of HRMDocument11 pagesAssignment of HRMNirmalNo ratings yet

- A Study of Performance Appraisal System Yahama Motors Sandeep KumarDocument107 pagesA Study of Performance Appraisal System Yahama Motors Sandeep KumarShahzad SaifNo ratings yet

- B3.2 - Cricket Data Analysis - Digital BusinessDocument18 pagesB3.2 - Cricket Data Analysis - Digital BusinessakashNo ratings yet

- Job Description Template - Electrician, Plumber, All AroundDocument2 pagesJob Description Template - Electrician, Plumber, All AroundBINGLHNo ratings yet

- Juken Technology Limited FY2009 Net Profit Soars To S$1,173,000 From S$46,000 in FY2008 - 230210Document3 pagesJuken Technology Limited FY2009 Net Profit Soars To S$1,173,000 From S$46,000 in FY2008 - 230210WeR1 Consultants Pte LtdNo ratings yet

- Mortgage Application Crina (Fillable)Document3 pagesMortgage Application Crina (Fillable)bhupinderNo ratings yet

- Finance Acumen For Non FinanceDocument55 pagesFinance Acumen For Non FinanceHarihar PanigrahiNo ratings yet

- International Financial Managment For OnlineDocument331 pagesInternational Financial Managment For OnlineAmity-elearning75% (4)

- FICO Cash Journal 3Document31 pagesFICO Cash Journal 3biswajit6864No ratings yet

- LESSON Planning A Long Term Content Strategy DECKDocument69 pagesLESSON Planning A Long Term Content Strategy DECKHuy Hoàng PhanNo ratings yet

- CONCEPTUAL FRAMEWORK HandoutDocument6 pagesCONCEPTUAL FRAMEWORK HandoutRuby RomeroNo ratings yet

- Relevant Costs For Decision Making: Illustrative ExampleDocument8 pagesRelevant Costs For Decision Making: Illustrative ExampleKhaled Abo YousefNo ratings yet

- Account Name: Indiabulls Finance Ltd. Bank Name-BANK OF Maharashtra Account No-60463144608 IFSC CODE-MAHB0002256Document3 pagesAccount Name: Indiabulls Finance Ltd. Bank Name-BANK OF Maharashtra Account No-60463144608 IFSC CODE-MAHB0002256chhatria077No ratings yet

- Cost Allocation in GeneralDocument51 pagesCost Allocation in GeneralVaibhav DayalNo ratings yet

- MPS&MRPDocument18 pagesMPS&MRPPrasit SermsiripokaNo ratings yet

- HR Domain Interview QuestionsDocument5 pagesHR Domain Interview QuestionsShubham MohanNo ratings yet

- Corporate Accounting AssignmentDocument6 pagesCorporate Accounting AssignmentKarthikacauraNo ratings yet