Professional Documents

Culture Documents

General Solder Paste Handling Guidelines - Asia: Reference Bulletin

General Solder Paste Handling Guidelines - Asia: Reference Bulletin

Uploaded by

Mohan BaskaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Solder Paste Handling Guidelines - Asia: Reference Bulletin

General Solder Paste Handling Guidelines - Asia: Reference Bulletin

Uploaded by

Mohan BaskaranCopyright:

Available Formats

REFERENCE BULLETIN

General Solder Paste Handling Guidelines – Asia

INTRODUCTION

Below are the general guidelines to be used for handling ALPHA® Solder Pastes. The product Technical Bulletin (TB)

should always be referred to for verification of any specific recommendations or conditions.

SHIPPING

• ALPHA solder paste products are engineered to be shipped between 0-29°C (32-84°F). Differences in local

packaging suppliers warrant multiple packaging and shipping techniques to maintain this specification.

• Our distributor partners take active responsibility during final transport and delivery to our customers for maintaining

the integrity of Cookson Electronics soldering materials. During shipment, every care should be taken to use

completely frozen gel packs together with solder paste in thermally controlled boxes to maintain paste integrity.

STORAGE

• Long term storage of solder paste is best achieved by refrigeration 0-10°C (32-50°F). The material should be placed

in a storage area designed to maintain this temperature range (refrigerator or cold room) immediately upon receipt.

• Typical no-clean solder paste shelf life is 6 months, water-soluble paste ranges from 3-6 months in a refrigerated

environment. Verify product Technical Bulletin for exceptions. Please note shelf life is determined from the date of

manufacturing.

• Cartridges are best stored vertically, tip down. If stored horizontally, best practice is to turn cartridges 180° once every

week.

• Solder paste should never be stored at room temperature 19-25°C (66-77°F) for prolonged periods of time. Room

temperature stability is intended to provide manufacturing flexibility after storing the product. The typical room

temperature shelf life of unopened paste is 2 weeks. Please refer to the specific TB for any exceptions to this

recommendation.

• Exposure to temperature above 29°C (84°F) will decrease the useful life of paste, meaning shorten its shelf life.

PREPARATION

• Paste should always be used on a First In First Out (FIFO) basis. To maintain optimum performance paste should

not be stored outside the refrigerator any longer than necessary (never more than four (4) days).

• Solder paste should be allowed to reach room temperature, 19-25°C (66-77°F), without forced heating or machine

mixer. We recommend a typical period of 3-4 hours out of refrigeration, depending on packaging size. The specified

viscosity of each paste is based on measurement at 25°C.

• Best practices for solder past printing are to maintain the temperature inside the printer between 22°C – 29°C, 40% -

60% RH. Please consult the product Technical Bulletin for pastes that may operate outside of this window.

USAGE

• For jar packaging, manually stir the solder paste with spatula for 30 – 60 seconds to ensure paste homogeneity.

Rotating/centrifugal force mixing equipment is not recommended. If a rotating/centrifugal force mixing equipment is

used, a maximum time of 1 minute at 300 RPM is recommended.

109 Corporate Blvd., South Plainfield, NJ 07080 , 1-800-367-5460, alpha.cooksonelectronics.com

• Apply an even paste bead on the stencil over the length of the squeegee with a diameter of approximately 12 mm

(1/2”). Replenish when paste bead is <12 mm (1/2”) and replace the material when exceeded stencil life or has been

exposed to high temperatures inside the printer >29°C (84°F). If the solder paste is designed for printing at

temperatures over 29°C, it will be indicated on the technical bulletin.

• Refer to product Technical Bulletin for room temperature stability life.

Unopened Paste Jars

• Unopened paste jars that have been exposed to 25°C (77°F) for 4 days may be returned to the refrigerator to stop

further degradation of the product and can be expected to perform per the product Technical Bulletin..

• Unopened paste jars are stable in room temperature for a maximum of 2 weeks. Room temperature stability is

intended to provide manufacturing flexibility after storing the product. Exceeding 2 weeks of room temperature

storage will compromise the performance of the solder paste during printing. Please refer to the specific TB for any

exceptions to this recommendation.

• If the paste has been at room temperature for two weeks, the paste should be used immediately or dispose of the

paste.

Opened Jars But Unused Paste

• Opened jars may pick up moisture in the solder paste and are subjected to condensation when refrigerated.

• Do not return jars that were already opened to refrigeration.

• If a jar is opened and unused, return the lid to the jar, keep the jar at room temperature, and use the paste within its

two week room temperature shelf life.

Opened Jars and Used Paste

• This refers to paste on stencil.

• Do not remove paste from stencil and mix with unused paste in jar. This will alter the rheology and possibly the

moisture content of the unused paste and, potentially, negatively affect paste performance.

• Failure to follow these guidelines will result in reduced shelf life and diminished product performance and may make

the product unsuitable for use.

• Any used paste on stencil should be put in an empty and clean jar and stored at room temperature..

• Once applied to the stencil, NC and WS pastes are to be consumed within the stencil life, typically 8 hours.

GENERAL

• Always dispose of any unused solder paste in accordance with local environmental legislation.

• Always reference the Technical Bulletin of the specific product before use. Information presented in a product

Technical Bulletin supersedes information contained in this Reference Bulletin.

109 Corporate Blvd., South Plainfield, NJ 07080 , 1-800-367-5460, alpha.cooksonelectronics.com

You might also like

- TAPPI T 564 - Transparent Chart For The Estimation of Defect SizeDocument3 pagesTAPPI T 564 - Transparent Chart For The Estimation of Defect SizeGabriel C.Mendes0% (1)

- Ipc 7527Document3 pagesIpc 7527ram dhuke100% (1)

- Refrigeration PracticalDocument15 pagesRefrigeration PracticalRichardt Loots100% (2)

- Geotab - Price Catalog (Updated May 2022) PDFDocument3 pagesGeotab - Price Catalog (Updated May 2022) PDFAlan TabourianNo ratings yet

- GORE Automotive Vents Exterior Lighting Datasheet ENDocument4 pagesGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangNo ratings yet

- Polymer Film TestingDocument99 pagesPolymer Film Testingchristopher_kephart1No ratings yet

- 852 GBDocument86 pages852 GBomar tleb100% (1)

- A Presentation On Lithium Bromide Absorption Refrigeration SystemDocument15 pagesA Presentation On Lithium Bromide Absorption Refrigeration SystemAyub GNNo ratings yet

- Dupont Zytel: Zytel 73G15Hsl Bk363Document2 pagesDupont Zytel: Zytel 73G15Hsl Bk363Roberto HernandezNo ratings yet

- IPCDocument8 pagesIPCGerald See TohNo ratings yet

- MAXXI 6 Sales Presentation 04-2016Document33 pagesMAXXI 6 Sales Presentation 04-2016Marty SchreckNo ratings yet

- 3-D SPI: More Than Just Defect Detection: Process Optimization by Solder Paste InspectionDocument6 pages3-D SPI: More Than Just Defect Detection: Process Optimization by Solder Paste InspectionShahvez ShahvezNo ratings yet

- Measuring Conformal Coating Adhesion IpcDocument12 pagesMeasuring Conformal Coating Adhesion IpcNguyen Ngoc MinhNo ratings yet

- Cross Cut Kit ManualDocument5 pagesCross Cut Kit ManualYuvaraj Sathish100% (1)

- RoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsDocument3 pagesRoHS Compliant Printed Board Assembly With Guaranteed - Power - Heros ElectronicsHeros ElectronicsNo ratings yet

- I3a CB RPT 62368Document9 pagesI3a CB RPT 62368BillNo ratings yet

- BGA's, LGA's, QFN/DFN's - Oh My, Can Traditional DFM SurviveDocument54 pagesBGA's, LGA's, QFN/DFN's - Oh My, Can Traditional DFM SurvivemrbustaNo ratings yet

- Oryzasil - Company Presentation-2019-12-13Document19 pagesOryzasil - Company Presentation-2019-12-13Jagdish PatelNo ratings yet

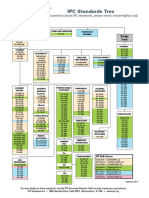

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- Process Capability Report Form06Document8 pagesProcess Capability Report Form06arunradNo ratings yet

- Thesis Report2Document48 pagesThesis Report2Mochammad Rizky DiprasetyaNo ratings yet

- Vp6000-V Brochure enDocument6 pagesVp6000-V Brochure enFarhan AbdurrafiNo ratings yet

- Jep 113 BDocument10 pagesJep 113 BCezaryCezasNo ratings yet

- Jedec Standard: Els ServiçosDocument30 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- Workmanship Standards QE SeminarDocument73 pagesWorkmanship Standards QE SeminarJuanPabloJimenezNo ratings yet

- Ipc 9121a 2022 印制板工艺流程问题解答Document24 pagesIpc 9121a 2022 印制板工艺流程问题解答cdmingNo ratings yet

- Computer-Aided Casting Design and Simulation PDFDocument9 pagesComputer-Aided Casting Design and Simulation PDFmonish KrishnaNo ratings yet

- Ipc Policies and Procedures Cis General Module Rev 2 4-2016Document47 pagesIpc Policies and Procedures Cis General Module Rev 2 4-2016kddjjdi100% (1)

- IPC TM 650 Solder Ball TestDocument3 pagesIPC TM 650 Solder Ball TestJonas Ricafrente MojicaNo ratings yet

- Surface Texture Measurement Fundamentals For Metrology Center Open HouseDocument54 pagesSurface Texture Measurement Fundamentals For Metrology Center Open HouseSushant VashisthaNo ratings yet

- Nasa STD 8739 2 PDFDocument84 pagesNasa STD 8739 2 PDFRanjitha BNo ratings yet

- The Institute For: Introduction To Surface Mount AssemblyDocument246 pagesThe Institute For: Introduction To Surface Mount AssemblyryanNo ratings yet

- Jis C 8715-1 - 2018, EngDocument35 pagesJis C 8715-1 - 2018, Eng7620383tlNo ratings yet

- Iso 2859-2Document26 pagesIso 2859-2Amr Mohamed ElbhrawyNo ratings yet

- Iso News 23e PDFDocument5 pagesIso News 23e PDFThảo PhạmNo ratings yet

- COPQ, CEPQ and CRPQ Measurements To TYSGDocument38 pagesCOPQ, CEPQ and CRPQ Measurements To TYSGNguyễn Tiến DũngNo ratings yet

- Software Test Report: Appendix To The PPA ReportDocument4 pagesSoftware Test Report: Appendix To The PPA ReportJuliaNo ratings yet

- Fin 0519 Veri-Q PREP M16 16TU-CV19 InsertsDocument2 pagesFin 0519 Veri-Q PREP M16 16TU-CV19 Insertscass100% (1)

- Pentapharm Brochure (En) 3.17.14Document12 pagesPentapharm Brochure (En) 3.17.14imakantisNo ratings yet

- Regulation EU 10 - 2011 Update 10-11-2016Document26 pagesRegulation EU 10 - 2011 Update 10-11-2016BasvanLeeuwenNo ratings yet

- Modelo A3 ReportDocument1 pageModelo A3 ReportFrancis ParedesNo ratings yet

- V3I2IJERTV3IS21239Document5 pagesV3I2IJERTV3IS21239erwindNo ratings yet

- Best Practices FactoryDocument207 pagesBest Practices FactorysmtdrkdNo ratings yet

- ANPQP 2.1 - ChangesDocument25 pagesANPQP 2.1 - ChangeskoalaboiNo ratings yet

- Acw 0219Document2 pagesAcw 0219anna_malai078351No ratings yet

- Transcutol HP - : Technical Data SheetDocument3 pagesTranscutol HP - : Technical Data SheetAnonymous kmUdNuIGNo ratings yet

- Lean SpreadsheetDocument13 pagesLean Spreadsheetqais bakrNo ratings yet

- VDADocument20 pagesVDASting GonsalisNo ratings yet

- LDPE C2923 - Con AditivosDocument1 pageLDPE C2923 - Con Aditivosedinson100% (1)

- Guia LabDocument39 pagesGuia LabNaty Johanna Alfaro ParadaNo ratings yet

- Castrol Rustilo DW 902Document2 pagesCastrol Rustilo DW 902vivekpattni0% (1)

- Soldering Iron Calibration Best Practices Dec 2020Document5 pagesSoldering Iron Calibration Best Practices Dec 2020Tyler BarbareeNo ratings yet

- Groupe Renault - CSR V2020Document7 pagesGroupe Renault - CSR V2020OBSC PerfectionNo ratings yet

- RK2670 Series Withstand Voltage Tester ManualDocument42 pagesRK2670 Series Withstand Voltage Tester Manuallab.emea100% (1)

- ISO/TS 22163: Railway Applications - Quality Management System - Business Management System Requirements For Rail OrganizationsDocument2 pagesISO/TS 22163: Railway Applications - Quality Management System - Business Management System Requirements For Rail OrganizationsRagul VinothNo ratings yet

- More Value For Your Machine.: Elettromandrini Cambio Utensile Manuale Manual Tool Change ElectrospindlesDocument5 pagesMore Value For Your Machine.: Elettromandrini Cambio Utensile Manuale Manual Tool Change ElectrospindlesM. MUBASHARNo ratings yet

- IATF1 6949- 2016 英文版 main std PDFDocument62 pagesIATF1 6949- 2016 英文版 main std PDFpunitg_2No ratings yet

- Installation GC1 Gunning Castables - Conventional PDFDocument2 pagesInstallation GC1 Gunning Castables - Conventional PDFLuis PullasNo ratings yet

- Installation CC1 Conventional Castables - StandardDocument3 pagesInstallation CC1 Conventional Castables - Standardheinz wieduwiltNo ratings yet

- Aim Paste Handling Guideline Revnf1Document2 pagesAim Paste Handling Guideline Revnf1ravi.youNo ratings yet

- Refrigerent LaboratoryDocument18 pagesRefrigerent LaboratoryKRG KickFlashNo ratings yet

- 0526 US Inlet Cooling (ASME)Document10 pages0526 US Inlet Cooling (ASME)Dimkovski Sase KazakNo ratings yet

- Ex Works PlanetsWater 'Full' AWG Direct Wholesale Factory Price List 2013Document9 pagesEx Works PlanetsWater 'Full' AWG Direct Wholesale Factory Price List 2013Oglas OglasiNo ratings yet

- Chapter 6 THE SECOND LAW OF THERMODYNAMICS5704685Document29 pagesChapter 6 THE SECOND LAW OF THERMODYNAMICS5704685bensonNo ratings yet

- Development of CO2 Liquefaction Cycles For CO2 SequestratioDocument13 pagesDevelopment of CO2 Liquefaction Cycles For CO2 SequestratioFelipe Di Napoli GarciaNo ratings yet

- Perishable Supply ChainDocument11 pagesPerishable Supply ChainConnected dotphNo ratings yet

- Compressor Technicalspecification: Huangshi Donper Electrical Appliance Co., Ltd. 2016.6Document9 pagesCompressor Technicalspecification: Huangshi Donper Electrical Appliance Co., Ltd. 2016.6phuongtn1991No ratings yet

- Nami Tech Co.,Ltd.: Provision Ref. PlantDocument9 pagesNami Tech Co.,Ltd.: Provision Ref. PlantTamNo ratings yet

- Shock Frosters - GFN: WWW - Guentner.deDocument61 pagesShock Frosters - GFN: WWW - Guentner.deIskandar FirdausNo ratings yet

- AHRI 740 1998 Corrected TablesDocument21 pagesAHRI 740 1998 Corrected TablesBernardo LeorNo ratings yet

- Cascade Refrigeration System (Report)Document8 pagesCascade Refrigeration System (Report)THE PUBGTV100% (1)

- S-000-5710-056 - 0 Systemezation ProcedureDocument28 pagesS-000-5710-056 - 0 Systemezation ProcedureMahadevan Mahalingam100% (4)

- Flamingo ChillersDocument1 pageFlamingo Chillerssaurabhkumar0664No ratings yet

- Importance of Solenoid ValvesDocument16 pagesImportance of Solenoid ValvesRahul PatilNo ratings yet

- MCQQQQQQQQQDocument7 pagesMCQQQQQQQQQNaveen PrabhuNo ratings yet

- Solved Problems Ref SystemDocument5 pagesSolved Problems Ref SystemArchie Gil DelamidaNo ratings yet

- Starlette Plus: The Small Range of Refrigeration DryersDocument4 pagesStarlette Plus: The Small Range of Refrigeration DryersJas SumNo ratings yet

- Script:-.Air Condition ScriptDocument11 pagesScript:-.Air Condition Scriptaimri_cochinNo ratings yet

- Refrigeration - Test - Rig Lab ManualDocument6 pagesRefrigeration - Test - Rig Lab ManualSandeep SainiNo ratings yet

- Cooling TowersDocument57 pagesCooling TowerspreanandNo ratings yet

- Course OutlineDocument14 pagesCourse OutlineTony SparkNo ratings yet

- Food TransportationDocument3 pagesFood TransportationShovonNo ratings yet

- Study of Airflow Patterns in Spiral Blast Freezers On Energy Utilization Efficiency and Freezing Quality.Document13 pagesStudy of Airflow Patterns in Spiral Blast Freezers On Energy Utilization Efficiency and Freezing Quality.Kalejaiye AdedayoNo ratings yet

- Thumb Rule Ac TonnageDocument3 pagesThumb Rule Ac TonnageKuldeep VermaNo ratings yet

- Coolpack ManualDocument14 pagesCoolpack ManualAKHIL100% (3)

- IGC Document 147-13-E Revision of Doc 147-08-EDocument75 pagesIGC Document 147-13-E Revision of Doc 147-08-Elutfirashid87No ratings yet

- ASHRAE Standard ListDocument2 pagesASHRAE Standard ListRahul DeshmukhNo ratings yet