Professional Documents

Culture Documents

52-13 Sliding System: Product Description Key Features

52-13 Sliding System: Product Description Key Features

Uploaded by

Philippe MeynardOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

52-13 Sliding System: Product Description Key Features

52-13 Sliding System: Product Description Key Features

Uploaded by

Philippe MeynardCopyright:

Available Formats

52-13 sliding system

product description key features

Designed specifically for hopper, tank and mixer vessel weighing systems, the Zinc plated steel or stainless-steel

52-13 sliding system offers excellent load introduction in an economic package. construction

Available in 2-directional bumper or 3-directional bumper arrangement. In

addition, a variant “T” is available, which allows a tangential orientation. Can be 2-directional or 3-directional

supplied with base plate, lift-off protection, welding plates and fixtures. versions

Especially designed for SB4, SB5, SB6, SB14 and SLB load cells.

Blind-hole load introduction

applications Wide range of capacities from

20kg to 10,000kg

Hopper and tank weighing systems, mixing vessel weighing systems.

Very easy to install

accessories + options No check links needed

Upper welding plate Installation by bolting or welding

Welding fixture W&M certified for 3,000 intervals

Base plate, with jacking bolt

Lift off protection

RoHS

compliant

hardware for beam | 52-15 | www.flintec.com B73-Rev4-GB 52-15-hbe-dat-en-1.0.1

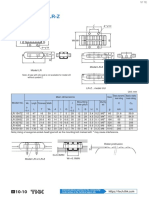

52-13 Dimensions 2-directional bumper and free sliding units (mm)

L6

L7 W4

A accessory welding plate W1

H4

B B T1

W5

basic sliding system

H5 H7

A-A

H3 A Note: T2

Side forces and lift off forces are 2-directional bumper

H1 safe up to E max maximum load cell option lift off protection

capacity.

JS* - Jacking screw (1x)

option base plate with

jacking screw

H2 free sliding

H6

L2 L5

L3 L4

gap 2...3 mm

2-directional bumper with lift

off protection

W1 W2 W3

GS* - Ground stand

B-B

D D* - for bolted version of installation

free sliding with lift off

L1

protection

Load cell type H1 H2 H3 H4 H5 H6 H7 L1 L2 L3 L4 L5 L6 L7 W1 W2 W3 W4 W5 D T1 T2

SB4/SB5-

75 30 90 15 48 27 44 80 125 100 15 56 85 25 68 70 90 100 48 13 M10 M12

5/10/20 kN

SB4/SB5-50 kN 110 50 130 20 65 45 62 105 160 130 9 50 110 30 94 100 120 140 58 16 M16 M20

SB4/SB5-100 kN 135 50 160 25 90 45 88 135 205 160 10 51 135 35 120 130 150 180 68 20 M20 M24

SB6-0.2/0.5/1/2

78 40 90 12 42 36 30 55 115 95 5 46 70 20 54 60 80 80 38 8 M6 M8

kN

SB14-0.5/1/2.5/5

75 35 90 15 43 32 39 80 125 100 - 37 85 25 68 70 90 100 48 13 M10 M12

klb

SLB- 74 35 89 15 42 32 38 80 125 100 - 17 85 25 68 70 90 100 48 13 M10 M12

0.2/0.5/1/2.5/5

klb

Assembly drawings with installation instructions and CAD files for customer’s own application drawings are available on request.

hardware for beam | 52-15 | www.flintec.com B73-Rev4-GB 52-15-hbe-dat-en-1.0.1 2

52-13 Dimensions 3-directional bumper and free sliding units (mm)

L6

L7 W4

A accessory welding plate W1

H4

B W5 B

basic sliding

system

H5 H7

A-A

H3 A Note:

T2

Side force Fr and lift off forces are

option lift off 3-directional bumper

safe up to E max= maximum load cell

H1 capacity. Side force Fa is safe up to 2x protection

E max= 2x maximum load cell capacity.

JS* - Jacking screw (1x)

option base plate with

jacking screw

H2 free sliding

H6

L8 (ca) L2 L5

L3 L4

gap 2...3 mm

3-directional bumper with lift

off protection

W1 W2 W3

GS* - Ground stand

D D* - for bolted version of installation

B-B free sliding with lift off

L1

protection

Load cell type H1 H2 H3 H4 H5 H6 H7 L1 L2 L3 L4 L5 L6 L7 L8 W1 W2 W3 W4 W5 D T1 T2

SB4/SB5-

75 30 90 15 48 27 44 80 125 100 15 56 85 25 67 68 70 90 100 48 13 M10 M12

5/10/20 kN

SB4/SB5-50 kN 110 50 130 20 65 45 62 105 160 130 9 50 110 30 103 94 100 120 140 58 16 M16 M20

SB4/SB5-100 kN 135 50 160 25 90 45 88 135 205 160 10 51 135 35 132 120 130 150 180 68 20 M20 M24

SB6-0.2/0.5/1/2

78 40 90 12 42 36 30 55 115 95 5 46 70 20 ? 54 60 80 80 38 8 M6 M8

kN

SB14-0.5/1/2.5/5

75 35 90 15 43 32 39 80 125 100 - 37 85 25 65 68 70 90 100 48 13 M10 M12

klb

SLB-

0.2/0.5/1/2.5/5 74 35 89 15 42 32 38 80 125 100 - 17 85 25 65 68 70 90 100 48 13 M10 M12

klb

hardware for beam | 52-15 | www.flintec.com B73-Rev4-GB 52-15-hbe-dat-en-1.0.1 3

52-13T Sliding Systems (allows tangential mounting) (mm)

L7

L8 W4

A accessory welding plate W1

H4

T1

- Sliding plate

SP*

B B

basic sliding

H5 system

H7

H3 A A-A

option lift off T2

H1 protection

2-directional bumper

JS* - Jacking screw (1x) option base plate with

jacking screw

H2

H6

L6 L2 L5

L3 L4 2-directional bumper with

GS*- Ground stand lift off protection

Note:

Side forces are safe up to 50% of E max=

W2 W3 50% of maximum load cell capacity. Lift

off forces are safe up to E max= maximum

load cell capacity.

D D* - for bolted version of installation

L1

B-B

Load cell type H1 H2 H3 H4 H5 H6 H7 L1 L2 L3 L4 L5 L6 L7 L8 W1 W2 W3 W4 D T1 T2

SB4/SB5-

85 30 100 15 58 27 44 80 125 100 15 56 49 110 50 68 70 90 100 13 M10 M12

5/10/20 kN

SB4/SB5-50 kN 125 50 150 25 80 45 62 105 160 130 9 50 75 150 75 94 100 120 150 16 M16 M20

SB4/SB5-100 kN 155 50 180 25 110 45 88 135 205 160 10 51 90 180 90 120 130 150 180 20 M20 M24

SB14-0.5/1/2.5/5

85 35 100 15 53 32 39 80 125 100 - 37 49 110 50 68 70 90 100 13 M10 M12

klb

SLB-

0.2/0.5/1/2.5/5 84 35 99 15 52 32 38 80 125 100 - 17 49 110 50 68 70 90 100 13 M10 M12

klb

Remark: Not compatible with 52-13.

hardware for beam | 52-15 | www.flintec.com B73-Rev4-GB 52-15-hbe-dat-en-1.0.1 4

orientation of 2-directional bumper and free sliding units

drawing symbols

2-directional bumper

Free sliding

orientation of 3-directional bumper and free sliding units

drawing symbols

3-directional bumper

Fr

Fa

Fr

free sliding unit

main side load direction main side load direction

tanks with tangentially mounted load cells

drawing symbols

2-directional bumper

free sliding unit

Specifications and dimensions are subject to change without notice.

hardware for beam | 52-15 | www.flintec.com B73-Rev4-GB 52-15-hbe-dat-en-1.0.1 5

You might also like

- Practical Management Science 4th Edition Winston Solutions ManualDocument5 pagesPractical Management Science 4th Edition Winston Solutions ManualLaurenBatesnqkim100% (14)

- Treinamento STEC-360A (NC Program) E PDFDocument107 pagesTreinamento STEC-360A (NC Program) E PDFArmando Rivera100% (2)

- KE13N Upload of COPA Offline PlanningDocument6 pagesKE13N Upload of COPA Offline PlanningMOORTHYNo ratings yet

- Gantrex Raillok w20 Steel - LTDocument2 pagesGantrex Raillok w20 Steel - LTOkky PoerwantoNo ratings yet

- Bullivants - PWB Anchor 8 Materials HandlingpdfDocument60 pagesBullivants - PWB Anchor 8 Materials HandlingpdfJill McIntoshNo ratings yet

- Gantrex Raillok w10 Data Sheet ImperialDocument2 pagesGantrex Raillok w10 Data Sheet Imperialjhon jairo arangoNo ratings yet

- Hollo Bolt Desormai Ce PDF 218 Ko 98501 LMOD1Document4 pagesHollo Bolt Desormai Ce PDF 218 Ko 98501 LMOD1Sergey MilovantsevNo ratings yet

- Gantrex Raillok w30 Data Sheet ImperialDocument2 pagesGantrex Raillok w30 Data Sheet ImperialSergio HernandezNo ratings yet

- Hawe Directional Seated Valves Type WN and WHDocument2 pagesHawe Directional Seated Valves Type WN and WHMarek SłowikNo ratings yet

- Fem 9 511Document2 pagesFem 9 511Emilio Jose Andia AbregiNo ratings yet

- Maurey Industries CatalogDocument112 pagesMaurey Industries CatalogGuillaume JaNo ratings yet

- Leidingbeugels StauffDocument161 pagesLeidingbeugels Stauffrxo61263No ratings yet

- LM Guide Separate Type (Radial) Model GSRDocument8 pagesLM Guide Separate Type (Radial) Model GSRtotoNo ratings yet

- 55-20 Mounting RC3Document2 pages55-20 Mounting RC3Hermantoro W. PradanaNo ratings yet

- Weldable Trolley Rail Clip Y7b+3Document2 pagesWeldable Trolley Rail Clip Y7b+3BosNo ratings yet

- Lift-Off Restraints: No Welding - No Drilling - Just ClampingDocument20 pagesLift-Off Restraints: No Welding - No Drilling - Just ClampingRamzi Ben AhmedNo ratings yet

- Lifting Bracket Vdi 3366 Tragzapfen Vdi 3366 Staffa Di Sollevamento Vdi 3366Document19 pagesLifting Bracket Vdi 3366 Tragzapfen Vdi 3366 Staffa Di Sollevamento Vdi 3366fgorinesNo ratings yet

- Gantrex Raillok w15 Steel - LTDocument2 pagesGantrex Raillok w15 Steel - LTOkky PoerwantoNo ratings yet

- HG Series TOPDocument22 pagesHG Series TOPJhon SyalfiandyNo ratings yet

- Uc Ufw 200Document2 pagesUc Ufw 200Xb ZNo ratings yet

- Manual Bard 36.000 BtuDocument8 pagesManual Bard 36.000 BtuEdward Muñoz BNo ratings yet

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- HIWIN Compact Catalogue (English)Document80 pagesHIWIN Compact Catalogue (English)Dobrica PetrovicNo ratings yet

- XCT25L4 Y-CraneDocument16 pagesXCT25L4 Y-CraneDwi Rizki Luqman HakimNo ratings yet

- Technical EC Sheet: T 6055 GB 1 June 05Document17 pagesTechnical EC Sheet: T 6055 GB 1 June 05Fayyaz NadeemNo ratings yet

- LR and LR-Z LRADocument2 pagesLR and LR-Z LRAPerfil DE Aluminio T-slotNo ratings yet

- LEDHDocument6 pagesLEDHretrini2015No ratings yet

- DU Series MCCB CatalogueDocument8 pagesDU Series MCCB Cataloguerobinknit2009No ratings yet

- BMG Bea08052011Document52 pagesBMG Bea08052011SJNo ratings yet

- XJN 160Document2 pagesXJN 160Xb ZNo ratings yet

- Hydraulic Jacks English Metric E329e-1Document2 pagesHydraulic Jacks English Metric E329e-1wahyusuwahyoNo ratings yet

- V RAIL en Technical Data SheetDocument4 pagesV RAIL en Technical Data Sheetfahmi fsNo ratings yet

- BaoliDocument4 pagesBaoliAsif JavedNo ratings yet

- Simmetrik 6DOF Motion Simulator Platform - Bill of MaterialsDocument3 pagesSimmetrik 6DOF Motion Simulator Platform - Bill of MaterialsAnimatronic sonoroNo ratings yet

- Helipath InstructionsDocument4 pagesHelipath InstructionsRobert Soto100% (1)

- Setft eDocument3 pagesSetft eLandry YoboueNo ratings yet

- Ask Uk PDFDocument8 pagesAsk Uk PDFhepcomotionNo ratings yet

- HDCB 01 Uk PDFDocument4 pagesHDCB 01 Uk PDFhepcomotionNo ratings yet

- Anexo 4 Plano de Válvulas ActualesDocument1 pageAnexo 4 Plano de Válvulas ActualesPablo TorresNo ratings yet

- QW-Series Patines HiwinDocument13 pagesQW-Series Patines HiwinWANKEL25No ratings yet

- Grua Liebherr LR 1750 BMKDocument124 pagesGrua Liebherr LR 1750 BMKcesar alejandro scavoNo ratings yet

- UC ULS 140 DTFV CompressedDocument2 pagesUC ULS 140 DTFV CompressedcooluniuNo ratings yet

- Technical Information ASSET DOC LOC 4899132Document10 pagesTechnical Information ASSET DOC LOC 4899132Zac Francis DaymondNo ratings yet

- Specification Sheet - Neo Modern - CC Toilet - TF2630Document2 pagesSpecification Sheet - Neo Modern - CC Toilet - TF2630Toan Nguyen ThanhNo ratings yet

- Truck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionDocument4 pagesTruck-Mounted Cranes: For Applications With Large Vehicles HB-R Series, The Perfect SolutionRodrigo LealNo ratings yet

- Anbauformular 2014 enDocument1 pageAnbauformular 2014 enMarcelo RojasNo ratings yet

- Installation Instructions For Spring Hangers-2Document1 pageInstallation Instructions For Spring Hangers-2Andrei Ionut UtaNo ratings yet

- Parker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationDocument2 pagesParker Pneumatic LV / EZ Series Lockout Valves: Material Specifications Operating InformationSoriSori2008No ratings yet

- Drawing-Enquiry-Form Parallel Shaft Gearbox: Erhan ZerenDocument1 pageDrawing-Enquiry-Form Parallel Shaft Gearbox: Erhan ZerenayavuzbvsNo ratings yet

- NSK Ball Rail Guide Wall Chart LH SeriesDocument1 pageNSK Ball Rail Guide Wall Chart LH SeriesHenryNo ratings yet

- Blowout Preventers: Invetion Unique Design & Extraordinary CraftsmanshipDocument40 pagesBlowout Preventers: Invetion Unique Design & Extraordinary CraftsmanshipAhmed HajiNo ratings yet

- Extension To The Demag Standard Crane RangeDocument2 pagesExtension To The Demag Standard Crane RangeMAGSTNo ratings yet

- 1 ZCC 100H: Crawler CraneDocument21 pages1 ZCC 100H: Crawler CraneYulianto JoeNo ratings yet

- REMA YA Mini Ratchet Hoist: Only WeighsDocument5 pagesREMA YA Mini Ratchet Hoist: Only WeighsRanaNo ratings yet

- Standard WireropesDocument6 pagesStandard Wireropesmohkal1260No ratings yet

- Metal Building Systems ManualDocument4 pagesMetal Building Systems ManualTrần Tiến0% (1)

- MBB C 750 SPR-SPL-Mounting StudiesDocument1 pageMBB C 750 SPR-SPL-Mounting StudiesAdam KrasowskiNo ratings yet

- SH Flyer Generationen enDocument2 pagesSH Flyer Generationen enyayaNo ratings yet

- Yoshitake AL-140Document2 pagesYoshitake AL-140WidyaNo ratings yet

- Group 9 - SuspensionDocument84 pagesGroup 9 - SuspensionANDREI26No ratings yet

- Simulado 7 AnoDocument6 pagesSimulado 7 AnoAnny LimaNo ratings yet

- Manual de Usuario Dacia Sandero (2011) (238 Páginas) 3Document2 pagesManual de Usuario Dacia Sandero (2011) (238 Páginas) 3Ignacio VillarNo ratings yet

- Kinco-KW User ManualDocument110 pagesKinco-KW User ManualleandroNo ratings yet

- The Revised Final RG 7 10th June 2023Document27 pagesThe Revised Final RG 7 10th June 2023Xain RanaNo ratings yet

- Corporate - Communication - Final ExamDocument15 pagesCorporate - Communication - Final ExamtawfikNo ratings yet

- Blood and Marrow Transplant Quality Management PlanDocument47 pagesBlood and Marrow Transplant Quality Management PlansumathiNo ratings yet

- Introduction To Relational ModelDocument55 pagesIntroduction To Relational ModelHimanshiNo ratings yet

- TF-FT With KidsDocument8 pagesTF-FT With KidsKeren MalchiNo ratings yet

- Department of Education Region Xi, Philippine College of Technology Garden Park Village, Bajada, Davao CityDocument4 pagesDepartment of Education Region Xi, Philippine College of Technology Garden Park Village, Bajada, Davao CityKynneza UniqueNo ratings yet

- Railway EngineeringDocument34 pagesRailway EngineeringCavery Chug100% (1)

- New Microsoft Word DocumentDocument19 pagesNew Microsoft Word DocumentŤhåýğųŢjNo ratings yet

- Item Analysis All Subjects-2013Document26 pagesItem Analysis All Subjects-2013acerblancaNo ratings yet

- The Deep Web and Marianas WebDocument2 pagesThe Deep Web and Marianas Webulysses araoNo ratings yet

- (Advice) The Nine Principles That Broke My Internet:smartphone:reddit Addiction For GoodDocument9 pages(Advice) The Nine Principles That Broke My Internet:smartphone:reddit Addiction For Goodfeowfeow100% (1)

- What's New in Strand7 R3Document96 pagesWhat's New in Strand7 R3TECNICONo ratings yet

- Siyal 2015Document15 pagesSiyal 2015KOHOLE WENCESLASNo ratings yet

- Harmonic PDFDocument38 pagesHarmonic PDFkaihaniNo ratings yet

- Sea Urchin FertilizationDocument9 pagesSea Urchin FertilizationRudra RudraNo ratings yet

- Module-3 Metal CastingDocument100 pagesModule-3 Metal CastingAbdul KhadarNo ratings yet

- Cambridge IGCSE: PHYSICS 0625/62Document12 pagesCambridge IGCSE: PHYSICS 0625/62AdilNo ratings yet

- Thesis Statement About Costa RicaDocument6 pagesThesis Statement About Costa Ricabdfhnsgld100% (2)

- EEE 231 - Lecture 9 PDFDocument9 pagesEEE 231 - Lecture 9 PDFMahfuj EmonNo ratings yet

- Romance OracleDocument108 pagesRomance Oraclericky bernadoNo ratings yet

- Tadano Faun HK 60Document13 pagesTadano Faun HK 60Abdallah GomaaNo ratings yet

- 7 KTPDocument19 pages7 KTPФаина АбиловаNo ratings yet

- Annex B - (Draft) Annual Accomplishment Report TemplateDocument1 pageAnnex B - (Draft) Annual Accomplishment Report TemplateBarangay LGRCNo ratings yet

- (Paper) - Portal Frame PierDocument23 pages(Paper) - Portal Frame PierShaileshRastogiNo ratings yet