Professional Documents

Culture Documents

Properties of Chemical Foamed-Sand Modification Tests For Metro Shield Tunneling Engineering

Properties of Chemical Foamed-Sand Modification Tests For Metro Shield Tunneling Engineering

Uploaded by

Moez SelmiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties of Chemical Foamed-Sand Modification Tests For Metro Shield Tunneling Engineering

Properties of Chemical Foamed-Sand Modification Tests For Metro Shield Tunneling Engineering

Uploaded by

Moez SelmiCopyright:

Available Formats

Geotechnical Special Publication No.

221 © ASCE 2011 48

Properties of Chemical Foamed-sand Modification Tests for Metro

Shield Tunneling Engineering

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

G.G. Qiao1, D.J. Yuan1 and B. Liu2

1

Ph.D, School of Civil Engineering, Beijing Jiaotong University, Beijing, P. R. China; Beijing 100044;

bjqgg@163.com

1

Professor, School of Civil Engineering, Beijing Jiaotong University, Beijing, P. R. China; Beijing

100044; yuandj603@163.com

2

Professor, Department of Civil Engineering, China University of Mining and Technology, Beijing, P.

R. China 100083; dr_boliu@163.com

ABSTRACT: As the most advanced soil improvement technique, foam modifying soil

measures always be taken when the EPB shield tunneling in the water-rich sand and

complex strata. Experimental research on foam-modified fine sand and coarse sand

was carried out using self-developed foam agent, conclusions were drawn that foam

can not only reduce the permeability coefficient and shear strength significantly, but

also it can enhance the fluidity of the sand greatly; If appropriate quantity of bentonite

or clay is injected in the sands, the water-holding capacity and liquidity will be further

enhanced while the permeability coefficient of modified sands will be further reduced.

Combining the experimental results of permeability, direct shear strength and fluidity

of foam-modified sand, the corresponding quantitative indicators were proposed and it

will provide reference for the parameters selection of sand modification in the shield

tunneling construction. And some field experimental results of metro construction are

introduced to show the performance of foam.

INTRODUCTION

The water-rich sand stratum are widely distributed in Guangzhou and Suzhou, shield

tunneling in the complex strata is prone to result in spewing and blocking, it has

frequently induced ground failures and collapse accidents. Tunneling in the poor

fluidity, high water content and high permeability strata often encounter the following

technical problems: The water and sand prone to separation after the stratum is

squeezed and disturbed by the shield, the excavated soil in the chamber can not form a

"plastic fluidity" media, so the dumping problems often appears; the sand in front of the

face consolidates due to water losing, the density of the sand at the bottom of the

chamber is higher because of the sedimentation of sand particles, while the upper

density is relatively lower, so it is difficult for the face pressure to maintain dynamic

balance, and it affects the posture control; because of the large internal friction of the

sand, arch effect is prone to form due to high pressure, it often leads to blocking and the

torque and thrust increasing, and the wearing of the cutter head and the cutter drum is

serious.

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 49

Soil improvement is the most effective way to solve the above problems at present, of

which the chemical foamed-soil is the most advanced method. In the GeoHunan

International Conference 2009, the author et al (Liu B., Li T. & Qiao G. G. 2009)

introduced the microstructures of Guangzhou red clay, and the chemical foamed-clay

modification experimental results were presented. In this paper, the author’s latest

research on the foamed-sand will be introduced.

SOIL MODIFICATION EXPERIMENTS AND RESULTS ANALYSIS

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

More than 100 groups of tests were conducted on the foamed sand, which involve 35

groups of permeability tests, 25 groups of liquidity tests, 40 groups of shear strength

tests, only part of the experimental results are presented in this paper.

Permeability modification experiment

The constant head permeability method is adopted. It was determined that the

permeability coefficient of the adopted experimental fine sand is 2.54×10-3cm/s, and

that of the coarse sand is 1.66×10-2cm/s. All of the permeability coefficients stated in

this paper were adjusted to the standard temperature.

Permeability Coefficient (cm/s)

-6

6.0x10

Fine sand

Coarse sand

-6

4.0x10

-6

2.0x10

25 30 35

Fine Particle Ratio (%)

FIG.1 Permeability of foam & bentonite modified saturated fine sand & coarse

sand

The experimental result of foam and bentonite improved saturated fine sand and

coarse sand is shown in Fig.1. The data showed in Fig.1 are the permeability coefficient

of 2h later after the sand was improved, the adopted foam concentration C is 3%, and

the foam injection rate (FIR) is 20%. The experimental results show the permeability of

single foam improved sand is 3.85×10-4cm/s, it exceeded the scope of

10-5cm/s~10-6cm/s (S. Queband et al 1998 & Zhang G.J., Liu Y 2005). After the

bentonite is mixed into the sand until the fine particle components reaches 30%, the

permeability coefficient of the improved sand reaches the magnitude of 10-6~10-7, the

modification effect is very good.

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 50

Shear strength modification experiment

The internal friction angle of the unimproved fine sand is 39º, the coarse sand is 43º.

Fig.2 shows that with the increasing of foam agent concentration, the internal friction

angle of the foamed sand reduces gradually, but the decreasing range of the foam

improved coarse sand is lower than that of the fine sand.

38

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

Fine Sand

36

Internal Friction Angle (° )

Coarse Sand

34 FIR=30%

32

30

28

26

1 2 3 4 5

C (%)

FIG.2 Internal friction angle of foamed fine sand and coarse sand vs. C

Fluidity experiment

Fig. 3 showed the slump test pictures. Picture A is the slump of unimproved fine sand,

it shows that the fluidity and water retention are poor, the water and sand prone to

separation. Photo B shows the slump of foam improved fine sand, it proofs that the

fluidity and water retention of the foamed-sand is enhanced greatly, but the slump

value is more than 20cm, it do not meet the requirement upon Zhang’s opinion of

10~15cm (Zhang F. X., Zhu H. H., Fu D. M. 2004). Photo C shows the slump picture of

foam and bentonite modified coarse sand, the improved coarse sand gains a good

"plastic fluidity", and the "plastic fluidity" can maintain a relative long time.

According to the experimental results, Fig.4 and Fig.5 are obtained. Raffaele Vinai

(Raffaele Vinai et. al.) also obtained similar graphics with Fig.5.

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 51

A) Unimproved fine sand B) Foamed fine sand C) Foam & bentonite improved coarse sand

FIG.3 Pictures of slump tests

60

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

50

FIR (%) 40

30

20

10

0 5 10 15 20 25

Sl ( )

FIG.4 Slump statistic of the foamed improved fine sand

60

50 A a

C B

40

FIR (%)

30 C E

b

20

D

10

8 10 12 14 16 18

W (%)

FIG.5 Optimization figure of foam modifying sand

In Fig.5, because of the low soil moisture of zone A, the slump value is small and the

liquidity is poor; zone B obtains large slump values, the foamed-sand is thin; zone C

says the slump is between 10~16cm, the slump value of the foamed sand is ideal; zone

D indicates the slump value of the foamed-sand is small and the liquidity is poor; zone

E expresses the high water content of soil, the sand is saturated or near saturated.

By analyzing the slump experimental results of the foam improved sand, the relative

ideal slump value range of foamed-sand was obtained, and foam injection rate and the

soil water content codetermine the "plastic fluidity" of the foamed-sand. For coarse

sand, the higher the fine ingredients, the better the fluidity of the foamed-sand.

The proposal on "plastic fluidity" of foamed-sand applied in the laboratory

Based on the international and domestic research result, the author put forward the

evaluation criteria proposal on the "plastic fluidity" of foamed sand applied in the lab:

the ideal "plastic fluidity" of foamed sand has to simultaneously meet the following

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 52

criteria: when the "fluidity" of foam modified sand is determined by slump, the slump

value should fall into the scope of 10cm~16cm, when the muck delivery method is

pipeline, a larger slump value of 20cm may be appropriately; the critical of

permeability coefficient of foamed sand should fall into the scope of 10-5~10-6cm/s; the

internal friction angle of foam-sand should reduce more than 8°.

PRACTICAL APPLICATION OF FOAM MODIFYING SAND

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

In the Yushan Park of Suzhou subway line one, shield tunneling in the full-face

saturated fine sand strata, the tunnel depth is 10.7m~11.3m, the groundwater level is

1.5m~2m. The total thrust and cutter torque is higher, and larger surface subsidence is

obtained. The driving parameters are shown in Table 1.

Table 1 Driving parameters in the full-face saturated fine sand strata

Items Parameters

Chamber pressure 0.17~0.19 Mpa

Total thrust 15000~19500kN

Driving speed 4.6~5.5cm/min

Conveyer rotational About 13.2 r/min

speed

Grouting volume 3.0~3.6m3

Grouting pressure 0.40~0.50MPa

Cutter torque 2000~4000kNm

27000

Total Thrust (KN)

24000

21000

18000

No Foam Injected

15000

160 165 170 175 180 185 190 195

Ring Number

FIG.6 Total thrust

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 53

Cutter Torque (kNm)

4000

3500

3000

2500

2000

No Foam Injected

1500

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

160 165 170 175 180 185 190 195

Ring Number

FIG.7 The cutter torque

0

Surface Settlement (mm)

-5

-10

No Foam Injected

-15

Z160 Z165 Z170 Z175 Z180 Z185 z195

Ring Number

FIG.8 Ultimate ground settlement of tunnel axis

After foam agent of 20L/Ring is injected, the situation is improved, Fig.6, Fig.7 and

Fig.8 show that in the case of injected foam, the total thrust, cutter torque and surface

settlement are reduced, and the following construction experiences were achieved:

1) The EPB shield tunnelling in the water rich fine sand strata, the driving speed must

be controlled; neither too fast, nor too slow, downtime should be avoided, particularly

in the higher surface settlement requirement section.

2) The grouting volume and injection pressure should be strictly controlled. In the

higher settlement requirement section, some modified silicate sodium should be

grouted, and the second grouting should be adopted where it is necessary to improve

the filling density, so as to controlling the ground subsidence further.

3) Tunneling in the fine sand strata, shield posture is difficult to control, so the

operator should pay close attention to the horizontal and vertical deviation, to avoid

possible over digging.

4) Strengthening the monitoring of the surface settlement, timely feedback, timely

adjustment, to find the optimal driving parameters.

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 54

CONCLUSIONS

Based on the permeability, fluidity, shear strength test of the foamed fine sand and

coarse sand, the following conclusions are drawn:

1. Foam can significantly reduce the permeability of fine sand and coarse sand, but

for the water-rich sand, the permeability and fluidity of foamed-sand is not satisfied,

bentonite or clay slurry should be injected to increase the percentage of the minute

particles to fill up sand pores, this can both improve the water blocking performance

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

and simultaneously improve the fluidity and water retention, which can effectively

avoid the "spewing" and other accidents.

2. Foam can dramatically reduce the permeability and shear strength of sand,

enabling the internal friction angle reducing more than 8°. And foam can significantly

improve the fluidity of the sand, when injected foam and bentonite slurry, the modified

sand can get a good "plastic fluidity", and this performance can keep even longer.

3. The evaluation criteria proposal on "plastic fluidity" of foamed sand applied in the

lab was put forward: the ideal "plastic fluidity" of foamed sand has to simultaneously

meet the following criteria: when the "fluidity" of foam modified sand is determined by

slump, the slump value should fall into the scope of 10cm~16cm, when the muck

delivery method is pipeline, a larger slump value of 20cm may be appropriately; the

critical of permeability coefficient of foamed-sand should fall into the scope of

10-5~10-6cm/s; the internal friction angle of foamed sand should reduce more than 8°.

4. Field tests showed that the foam can not only reduce the permeability of sand, but

also can effectively reduce the friction, cutter torque, thrust, cutter wear and surface

settlement.

ACKNOWLEDGMENTS

The research is supported by the National Natural Science Foundation of China

(50878015).

REFERENCES

Liu B., Li T. & Qiao G. G. (2009). "SEM Microstructure and Chemical Foamed-soil

Modification Tests for Swelling Red Strata in Subway Shield tunneling

Engineering." Recent advancement in recent soil behavior, In situ test methods, Pile

foundations, and tunneling, ASCE: 20-26.

S. Queband, M..sibai and J. - P. Henry. (1998). "Use of Chemical Foam for

Improvements in Drilling by Earth-Pressure Balance Shields in Granular Soils."

Tunneling and Underground Space Technology, Vol.13 (2): 173-180.

Zhang G.J., Liu Y. (2005). "Plastic Technical of Soil in EPB Shield Construction."

Municipal Technical, Vol.23(5): 293-296.

Zhang F. X., Zhu H. H., Fu D. M. (2004). "Shield Tunneling." China Communications

Press, Ver.1

Vinai R. et al., (2008). “Soil conditioning of sand for EPB applications: A laboratory

research.” Tunneling and Underground Space Technology, Vol.23: 308–317.

Tunnel Management, Emerging Technologies, and Innovation

Geotechnical Special Publication No. 221 © ASCE 2011 55

Xu Q.W., Zhu H. H, Liao S. M. (2006). "Model Test Research on Shield Construction

in Sand" Chinese Journal of Underground Space and Engineering, Vol. 2(3):

361~364.

Markus Tuller, Dani Or. (2003). "Hydraulic functions for swelling soils: pore scale

considerations." Journal of Hydrology, Vol.272 (1): 50-71.

Downloaded from ascelibrary.org by University of Birmingham on 06/26/16. Copyright ASCE. For personal use only; all rights reserved.

Tunnel Management, Emerging Technologies, and Innovation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aldi in Australia Case Study AnalysisDocument22 pagesAldi in Australia Case Study AnalysisBIbee NIpanNo ratings yet

- Contemporary Calculus TextbookDocument526 pagesContemporary Calculus TextbookJosé Luis Salazar Espitia100% (2)

- Inferno SummaryDocument4 pagesInferno SummaryAva Barrameda67% (3)

- Thewes2016 - Clogging EvaluationDocument7 pagesThewes2016 - Clogging EvaluationMoez SelmiNo ratings yet

- Professor, Department of Civil Engineering, China University of Mining and Technology, Beijing, P. Assistant Professor, Ph. D StudentDocument7 pagesProfessor, Department of Civil Engineering, China University of Mining and Technology, Beijing, P. Assistant Professor, Ph. D StudentMoez SelmiNo ratings yet

- Soil Conditioning For EPB Shield Tunneling in Argillaceous Siltstone With High Content of Clay Minerals: Case StudyDocument8 pagesSoil Conditioning For EPB Shield Tunneling in Argillaceous Siltstone With High Content of Clay Minerals: Case StudyMoez SelmiNo ratings yet

- Screw Conveyor Device For Laboratory Tests On Conditioned Soil For EPB Tunneling OperationsDocument4 pagesScrew Conveyor Device For Laboratory Tests On Conditioned Soil For EPB Tunneling OperationsMoez SelmiNo ratings yet

- Aggregates From Tunnel Muck Treatments. Properties and Uses: Physicochem. Probl. Miner. Process. 47 (2011) 259-266Document8 pagesAggregates From Tunnel Muck Treatments. Properties and Uses: Physicochem. Probl. Miner. Process. 47 (2011) 259-266Moez SelmiNo ratings yet

- Permeabilité-Peila-clay SoilDocument7 pagesPermeabilité-Peila-clay SoilMoez SelmiNo ratings yet

- Ceramics InternationalDocument6 pagesCeramics InternationalMoez SelmiNo ratings yet

- Peila2014 - Perméabilité-Slump TestDocument6 pagesPeila2014 - Perméabilité-Slump TestMoez SelmiNo ratings yet

- Accepted Manuscript: ApsuscDocument20 pagesAccepted Manuscript: ApsuscMoez SelmiNo ratings yet

- Soil Conditioning of Sand For EPB Applications: A Laboratory ResearchDocument10 pagesSoil Conditioning of Sand For EPB Applications: A Laboratory ResearchMoez SelmiNo ratings yet

- Accepted Manuscript: Chemical Engineering ScienceDocument31 pagesAccepted Manuscript: Chemical Engineering ScienceMoez SelmiNo ratings yet

- Yoshikawa 2015Document16 pagesYoshikawa 2015Moez SelmiNo ratings yet

- Ortiz TapiaDocument5 pagesOrtiz TapiaMoez SelmiNo ratings yet

- AUTHORITY TO SELL - Literal - 10022023Document3 pagesAUTHORITY TO SELL - Literal - 10022023MICHAEL SALINASNo ratings yet

- VikingsDocument21 pagesVikingsSusan MilliganNo ratings yet

- MaleficentDocument7 pagesMaleficentbagasNo ratings yet

- Fall 2012 - BIOL 115 - Essential BiologyDocument3 pagesFall 2012 - BIOL 115 - Essential BiologycreativelyinspiredNo ratings yet

- A Conversation With Elie WieselDocument1 pageA Conversation With Elie Wieselapi-263138429No ratings yet

- Evaluating WebsitesDocument2 pagesEvaluating Websitesapi-322361374No ratings yet

- Welcome To Anderson Workone. Your Career Starts HereDocument28 pagesWelcome To Anderson Workone. Your Career Starts HereHilary TerryNo ratings yet

- 26 Broaching - Principles, Systems and ApplicationsDocument16 pages26 Broaching - Principles, Systems and ApplicationsPRASAD326100% (2)

- Sepak TakrawDocument39 pagesSepak TakrawRandy Gasalao100% (2)

- Lesson 10Document28 pagesLesson 10Tirusameer YarlagaddaNo ratings yet

- Life Orientation September 2023 EngDocument9 pagesLife Orientation September 2023 EngmadzhutatakalaniNo ratings yet

- Grounds For ObjectionsDocument4 pagesGrounds For ObjectionsKath100% (2)

- Eldon Riggs Hugie, Esq. Honored As A Professional of The Year For Five Consecutive Years by Strathmore's Who's Who Worldwide PublicationDocument2 pagesEldon Riggs Hugie, Esq. Honored As A Professional of The Year For Five Consecutive Years by Strathmore's Who's Who Worldwide PublicationPR.comNo ratings yet

- Final Exam Form 1Document12 pagesFinal Exam Form 1ILANGGO KANANNo ratings yet

- Coral Hobbyist MagazineDocument48 pagesCoral Hobbyist MagazineSal EmbNo ratings yet

- How Can Positive Attitude Change Our LifeDocument19 pagesHow Can Positive Attitude Change Our LifeAmir Noor100% (1)

- Dear Admissions Committee Chat GPT - 1Document1 pageDear Admissions Committee Chat GPT - 1Ganesh PolinaNo ratings yet

- Flipkart Case StudyDocument9 pagesFlipkart Case StudyHarshini ReddyNo ratings yet

- Lesson 7Document20 pagesLesson 7rj libayNo ratings yet

- Letter Rejecting Paul Angulo's Reimbursement ClaimDocument4 pagesLetter Rejecting Paul Angulo's Reimbursement ClaimThe Press-Enterprise / pressenterprise.comNo ratings yet

- Soal UAS Bahasa Inggris Kelas 4 SD Semester 1 (Ganjil) Dan Kunci Jawaban (WWW - Bimbelbrilian.com) - DikonversiDocument7 pagesSoal UAS Bahasa Inggris Kelas 4 SD Semester 1 (Ganjil) Dan Kunci Jawaban (WWW - Bimbelbrilian.com) - Dikonversiramdhan09shinNo ratings yet

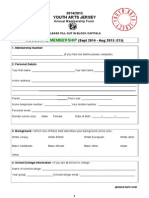

- Youth Arts Jersey - MembershipDocument2 pagesYouth Arts Jersey - MembershipSteve HaighNo ratings yet

- David Copeland-Jackson IndictmentDocument12 pagesDavid Copeland-Jackson IndictmentWashington ExaminerNo ratings yet

- YavorskyDocument544 pagesYavorskyFilipe PadilhaNo ratings yet

- AnsDocument5 pagesAnsSravani RaoNo ratings yet

- Guide JCT 2005 Design Built Rev 2009Document44 pagesGuide JCT 2005 Design Built Rev 2009seanbeagNo ratings yet

- Oppositional Inference: Northwesternuniversity, IncDocument3 pagesOppositional Inference: Northwesternuniversity, IncDanica CumlatNo ratings yet