Professional Documents

Culture Documents

Types of Pile Driving Equipments PDF

Types of Pile Driving Equipments PDF

Uploaded by

nasirjamal330 ratings0% found this document useful (0 votes)

7 views15 pagesOriginal Title

Types of Pile Driving Equipments.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

7 views15 pagesTypes of Pile Driving Equipments PDF

Types of Pile Driving Equipments PDF

Uploaded by

nasirjamal33Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

ei212017 ‘Types of Pile Driving Equipments Applications, Advantages and Details

(© About Us (ttps//theconsructororg/about) | {2 Contact Us (tpss/theconstrucaroraicontacts) |

1. Prvacy Poly (hips ftneconstractorora/pcvacy-2oey)

¥ (https://twittercom/theconstructor2) ¢ (https://www.facebook.com/TheConstructor)

«+ (https://plus.google.com/+TheconstructorOrg)

abe 2, Constructor (neps:streconstcior.org)

ivi Engineering Wome

Building (https://theconstructor.org/building/) How To Guide (https://theconstructor.org/practical-guide/)

Concrete (https://theconstructor.org/concrate/) Construction (https://theconstructor.org/construction/)

Geotechnical (https://theconstructor.org/geotechnical/) Structural (https://theconstructor.org/structural-engg/)

Types of Pile Driving Equipments -Applications, Advantages

and Details

Ae cee

C ie Oring Ha

GO

an

ye anscr WENA)

shouts cmap hanaehaPhaF hana recap

1M (rset cintoetanan Tye Pl Di asp yl Me

Onshbutensekinarrewonarvrogh gancriahglpsrgtuemestn

in popsmtrtrcaninwatesevimatstaapscns Menara

pyrantel oe vera Siler. teas

sce Una

er erases ar

© pmsnscinnsrn!

There are several machines and equipment which are amployed for pile driving during construction, These

machines and tools will be explained in the following sections.

hps:theconstructar orp/geatechnicalpl-criving-equipment-types-uses/17605"2utm_source=pushengage&ulm_medium=pusn_noliicaionautm.ca... 115

ei212017 ‘Types of Pile Driving Equipments Applications, Advantages and Details

comlons.

Lends

ri

Tomplate

Fig.1: Pile Driving Equipment

Fig.2: Pile Driving Equipment

htps:theconstructrorg/geotechricaliple-criving-equipment-types-uses/17605/Putm_source=pushengage&ulm_medium=push_notficaiondutm_ca

28,

ei212017 ‘Types of Pile Driving Equipments Applications, Advantages and Details

neo Soeae

Types of Pile Driving Equipments

+ Ping rigs

+ ling winches

+ Hanging leader

+ Hammer guides

+ Piling hammer

+ Helmet, driving eap, dolly, and packing

Piling Rigs

It composed of a series of leaders, which are consist of tabular element or hard box, placed and fixed on a

crane base as it can be seen from Figure-3.Not only does the leaders support the hammer and the pile but also

{guide them when the pile is forced into the ground.

Fig.3: Plle Driving Rig

The leader can be sloped forward and backward using screw or hydraulic adjustment and attachment at the

base of the equipment as shown in Figure 4 and Figure 5. I is possible to install a series of piles, without

need to move the equipment, through turning around base machine and positioning leaders.

hhps:theconstructr orp/geatechnicalple-criving-equipment-types-uses/17605/2utm_source=pushengage&ulm_medium=pusn_noliicaionauim ca... 3115

ei212017 ‘Types of Pile Driving Equipments “Applications, Advantages and Details

5: Forward Raked Pile

Regarding pile installation in water, pile driving rig can be used to Install piles in water by placing It on pontoon

or leader are fixed on braced frames that mounted on pontaon as shown in Figure-6.

Driver Mounted on Pontoon

htps:theconstructor org/geotechricaliple-criving-equipment-types-uses/17605/2utm_source=pushengage&uim_medium=push_notficationgutm ca... 415

ei212017 ‘Types of Pile Driving Equipments Applications, Advantages and Details

Moreover, It's considerably crucial to pay adequate attention to the position and alignment of the leader since

any disposition would lead to hammer eccentric blows eventually the pile will be either damages or displace

from its original position.

Furthermore, efforts have been made to improve the efficiency of driven pile machine and the Delmag MDT.

(0802, which possess broad range of adjustments with great movement capacity, is compelling exemple,

‘The machine on which Delmag MDY 0801 Is fixed an is @ wheeled hydraulic excavator that it’s rams provided

sideway, forward, and backward sloping leader, in addition to arrange the location of the rig in relation to the

equipment.

Finally, not only does the leader operation height can be changed thought leader telescoping but also it could

be folded anto the base while the machine it moved from and to the construction site,

Fig.8: Pile Driver Rig

Piling Winches

‘The prime goal of pling winches is to left the hammer and piles in addition to support tools that responsible for

leader raking and rotation. It functions with pile frames and cifferent powering sources such as hydraulic

power, stream; diesel; or petrol engines, and occasionally electric motors could be applied far powering

htps:theconstructr org/geotechricaliple-criving-equipment-types-uses/17605/Putm_source=pushengage&uim_medium=push_notficatongutm ca... S15

ei212017

hhps:theconstructr orp/geatechnicalpl-crving-equipment-types-uses/17605"2utm_source:

‘Types of Pile Driving Equipments Applications, Advantages and Details

winches,

There are different piling winches with different capacity for instance winches with double or triple drums

possess satisfactory controlling and pile driving speed whereas ene drum winch does not have that advantage.

So, the former type would be favored provided that handing and driving piles with great speed is required

Hanging Leader

Hanging leaders are specifically designed to be hanged from the jib of a crane as shown in Figure-9. A steel

strut, which its length can be varied as per requirements of construction site, provides a stiff connection from

the leader foot to the machine bed frame,

Fig.9: Hanging Leader

Moreover, crane or excavator winch units are utilized to left the hammer and piles using separate drums.

Regarding hammer application, elther drop hammer with friction winch Is considered or it may be operated

using stream or hydraulic power or compressed air which are provided by cifferent units,

Finally, its substantially crucial to practice utmost precaution to hanging leader stifress particularly in the

case of long sloped pile driving since intolerable deformation would lead to eccentric hammer blow and possibly

cause pile fracture

Hammer Guides

‘When itis intended to remove hanging leaders or piling frames completely, rope suspended leaders which are

commonly guided by timber or stee! formwork, would be considered.

In this technique, an independent crane needed to control the pile and establishing the guide and hammer. it

necessary to set and secure the guide properly in order to avoid movements specifically in the during raking

pile installation, This is because serious fatigue stress would generate If the thrust Is not centered properly and

the guide might deteriorate

wushongagesuim_medium=push_noliicaiondutm ca... 6/15

ei212017

‘Types of Pile Driving Equipments Applications, Advantages and Details

Finally, Its required to prevent disproportionate bending stress development in guide and piles because It

leads to undesired results. for example, when heavy hammer is attached to the upper end of 2 long pile wich

Is driven at flat angle of rake, excessive bending stress may be generated at support point in the guide. This

problem might be tackled by providing suitable support for the pile at proper position

rn

Fig.10: Hammer Guided and Rope Suspended Leader for Delmag Diesel Pile Hammer

Piling Hammer

‘There are several factors that greatly influence the decision to choose suitable piling hammer. For example, pile

size and weight, the resistance of the ground which should be overcame in order to obtain specified

penetration, construction site space availability, noise limitation that right be imposed at certain areas, and

availabilty of cranes,

Previously, the combination of a dynamic equation result and extensive experiences were employed to select

piling hammer, but this has changed nowadays and drivability analysis results, which is conducted using

‘computer program based on Smith wave equation, is considered for the piling hammer determination,

{As for input data required for drivabilty analysis, pling hammer producer provided necessary data about

efficiency and energy feature of the piling hammer, It should be bore in mind that pling hammer efficiency is

not a constant and it Is affected by number of factor for example mechanical condition of the hammer and

‘operation temperature.

It shoule be known that the mechanical condition is not influence the efficiency of pling drop hammer. That is

why dynamic pile analysis is carried out and its results would be used to assess the influence of diferent factor

fon the piling hammer efficiency,

‘There are various types of piling hammer with different energy characteristic and each is suitable for specif

construction condition, diferent common types of piling along with their description, application, and

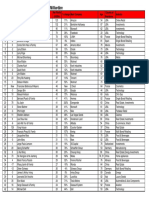

advantages are provided in Table 1:

Table-1: Different types of hammer piling along with their description, application, advantages, and

disadvantages

hps:theconstructr org/geotechricaliple-criving-equipment-types-uses/17605/Putm_source=pushengage&uim_medium=push_notficationgutm ca... 715

ei212017

Drop hammer, Figure 11

ile hammer descri

itis @ forged steel with solid

‘mass ranges from 1000 to

5000Kq, and it i fitted with

lifting eye and lugs for sliding

inthe leaders

Application

Applied to install

test piles

Advantages

Its application

removes the need to

employ steam boiler or

air compressor to

power the hammer, so

itis economical choice

Single acting steam or compressed air hammer, Figure 12

Description

Consist of massive welght

ranges from 2500 to 20000K9

with a cylinder shape, ane the

power source would lift the

hammer to specified height

then the power is cut to drop

the hammer and hit pile

helmet, Maximum hemmer

height 's 1.37m and no higher

1.2m in case of heavy pile

Application

Used for placing

piles with diferent

weights in different

types of soils and

suitable for pile

installation in

marine environment

Double acting pile hammer, Figure 13

Description

Double acting pile hammer is

powered by steam or

compressed and its mass

rages from 90 to 2300K9

Vulcan hammer is an example

of double acting hammer. The

pile is guided by timber frame.

Diesel pile hammer, Figure 14

Description

hps:theconstructr orp/geatechnicalipl-criving-equipment-types-uses/17605"2utm_source:

Application

Applied to instal

sheet piles and

suitable for

providing rapid

succession of blows.

Itcan be used to

demolish rocks for

extracting piles

Application

Advantages

Drop height and

frequency of each drop

can be controlled by

operator,

Advantag

Its specifically

designed to impart

numerous blows at

short time. 300 blows

per minute for

lightweight hammer

and 100 blow/ minute

for heavyweight

hammer

Advantages

1ushengageS.uim_medium=push_notticaiondum ca.

‘Types of Pile Driving Equipments Applications, Advantages and Details

isadvantages

‘The height of hammer

Gropping cannot be

controlled property at

project site, and itis

possible to use

substantial dropping

when driving becomes

tough and hence the pile

Gamage is possible

Disadvantages

Pile fracture is possible is

the specified hammer

height is exceeded

Disadvantages

It is needs maintenance

and lubrication

Disadvantages

ans.

ei212017 ‘Types of Pile Driving Equipments Applications, Advantages and Details

It is powered through self-

Ignition of compressed fuel

and air mixture. There are

various types of such hammer

with cifferent weights ranges

from 4500 to 15000Kq. Lastly,

tis considerably reliable type

of hammer and different pile

types such as sheet pile,

batter pile, and H-beams,

It properly drives

pile in soft soll

coneition

Hydraulic operated hammer, Figure 15

Description Application

Hydraulic hammer is

manufactured in different anc

large sizes ranges from

‘moderate loading to heavy

loading, Hydraulic fluid raises Tt suteble for pling

the pile and then release itto in land and in water

fall freely on the pile in toa depth of

‘addition to have power 1000m

activated downstroke. Nat only

can hammer be operated

‘manually but also

automatically,

It is economical and

self-contained. Tt

provides sustained

blow which more

efficient that ordinary

blows

Advantages

It creates less noise

and vibration

compared with diesel

hammer and it does

not release fumes

1t might damage precast

conerete pile when strong

layer come up while

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Covid Testing FormDocument3 pagesCovid Testing Formnasirjamal3350% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Universiti Malaysia Sabah Teaching Hospital: Cold Water Supply SystemDocument99 pagesUniversiti Malaysia Sabah Teaching Hospital: Cold Water Supply Systemnasirjamal33No ratings yet

- Tutorial For BeginnersDocument3 pagesTutorial For Beginnersnasirjamal33No ratings yet

- Specs MECHANICAL-ORIGINALDocument99 pagesSpecs MECHANICAL-ORIGINALnasirjamal33No ratings yet

- Method Jointing StatementDocument6 pagesMethod Jointing Statementnasirjamal33No ratings yet

- B-I-M PRESENTATION - LatestDocument15 pagesB-I-M PRESENTATION - Latestnasirjamal33No ratings yet

- Types of Ties Used in Building Construction, Their Design and Uses PDFDocument6 pagesTypes of Ties Used in Building Construction, Their Design and Uses PDFnasirjamal33No ratings yet

- What Is A Plinth Beam - Its Purpose, Applications and Construction PDFDocument3 pagesWhat Is A Plinth Beam - Its Purpose, Applications and Construction PDFnasirjamal33No ratings yet

- BIM TECH PRESENTATION - LatetsDocument20 pagesBIM TECH PRESENTATION - Latetsnasirjamal33No ratings yet

- Buku Kontrak PDFDocument94 pagesBuku Kontrak PDFnasirjamal33No ratings yet

- ARCHI-Types of Floor ScreedsDocument2 pagesARCHI-Types of Floor Screedsnasirjamal33No ratings yet

- What Is A Plinth Beam - Its Purpose, Applications and Construction PDFDocument3 pagesWhat Is A Plinth Beam - Its Purpose, Applications and Construction PDFnasirjamal33No ratings yet

- Hurun Global Rich List 2018 - Alle 2.694 MilliardäreDocument60 pagesHurun Global Rich List 2018 - Alle 2.694 Milliardärenasirjamal33No ratings yet

- LAU Chi-Hing 2006Document120 pagesLAU Chi-Hing 2006Budi Purnomo STNo ratings yet

- PLUMBING-How To Determine Suitable Pipe Sizes For Water Distribution in Buildings - PDFDocument8 pagesPLUMBING-How To Determine Suitable Pipe Sizes For Water Distribution in Buildings - PDFnasirjamal33No ratings yet