Professional Documents

Culture Documents

Bond CFRP

Bond CFRP

Uploaded by

yuva_86Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bond CFRP

Bond CFRP

Uploaded by

yuva_86Copyright:

Available Formats

Investigation of Bond in Concrete Structures Strengthened

with Near Surface Mounted Carbon Fiber Reinforced

Polymer Strips

Tarek Hassan1 and Sami Rizkalla, F.ASCE2

Abstract: Fiber reinforced polymer 共FRP兲 materials are currently produced in different configurations and are widely used for the

strengthening and retrofitting of concrete structures and bridges. Recently, considerable research has been directed to characterize the use

of FRP bars and strips as near surface mounted reinforcement, primarily for strengthening applications. Nevertheless, in-depth under-

standing of the bond mechanism is still a challenging issue. This paper presents both experimental and analytical investigations under-

taken to evaluate bond characteristics of near surface mounted carbon FRP 共CFRP兲 strips. A total of nine concrete beams, strengthened

with near surface mounted CFRP strips were constructed and tested under monotonic static loading. Different embedment lengths were

used to evaluate the development length needed for effective use of near surface mounted CFRP strips. A closed-form analytical solution

is proposed to predict the interfacial shear stresses. The model is validated by comparing the predicted values with test results as well as

nonlinear finite element modeling. A quantitative criterion governing the debonding failure of near surface mounted CFRP strips is

established. The influence of various parameters including internal steel reinforcement ratio, concrete compressive strength, and groove

width is discussed.

DOI: 10.1061/共ASCE兲1090-0268共2003兲7:3共248兲

CE Database subject headings: Bonding; Concrete structures; Beams; Fiber reinforced polymers; Retrofitting.

Introduction damage and would require protective cover, which could interfere

with the presence of floor finishes. Near surface mounted steel

In recent years, fiber reinforced polymer 共FRP兲 composites have bars have been used in Europe since 1947. Asplund 共1949兲 carried

emerged as a potential solution to the problems associated with out tests on concrete beams reinforced with steel bars and others

infrastructures. Resistance to electrochemical corrosion, high reinforced with steel bars grouted into diamond-sawed grooves.

strength-to-weight ratio, and versatility of fabrication have made Test results showed identical behavior for both sets of specimens.

FRP materials attractive to civil engineers. Since 1982, externally Blaschko and Zilch 共1999兲 carried out bond tests on carbon

bonded FRP sheets/strips have been successfully applied to FRP 共CFRP兲 strips inserted inside grooves. Bond tests were con-

strengthen concrete structures 共Meier 1992兲. Although externally ducted on double shear specimens. Test results showed that

bonded FRP reinforcement performed extremely well in practice, strengthening using near surface mounted CFRP strips has a

premature debonding failure was observed and identified by many greater anchoring capacity compared to externally bonded CFRP

researchers 共Saadatmanesh and Ehsani 1989; Sharif et al. 1994; strips. Gentile and Rizkalla 共1999兲 conducted an extensive experi-

Arduini et al. 1997兲. Several details were proposed to avoid this mental program to investigate the feasibility of using near surface

type of failure, which is unacceptable from the point of view of mounted 共GFRP兲 bars for flexural strengthening of timber bridge

structural safety 共Swamy and Mukhopadhyaya 1999兲. stringers. Based on test results, the Tourond Creek bridge con-

Use of near surface mounted FRP rods and strips can preclude structed 39 years ago in Manitoba, Canada, was strengthened

delamination-type failures, frequently observed by using exter- using GFRP bars. The bars were inserted longitudinally in spe-

nally bonded reinforcement. Near surface mounting technique be- cially constructed grooves in the stringers and adhered to the

comes particularly attractive for flexural strengthening in the wood beams with an epoxy resin. Using this technology, the

negative moment regions of slabs and decks, where external re- bridge is capable now to carry the current AASHTO design loads

inforcement would be subjected to mechanical and environmental for less than 15% of the cost estimated to replace the bridge.

Carolin et al. 共2001兲 tested a series of concrete beams

1

Post Doctoral Fellow, Dept. of Civil Engineering, North Carolina strengthened with near surface mounted CFRP strips. Test results

State Univ., Campus Box 7533, Raleigh, NC 27695-7533. demonstrated the effectiveness of the near surface mounting tech-

2

Distinguished Professor, Dept. of Civil Engineering, North Carolina nique compared to the externally bonded technique. Carolin et al.

State Univ., Campus Box 7533, Raleigh, NC 27695-7533. E-mail: recommended replacing the epoxy, used in bonding the strips to

sami_rizkalla@ncsu.edu the surrounding concrete, with cement mortar to improve the

Note. Discussion open until January 1, 2004. Separate discussions

work environment on site.

must be submitted for individual papers. To extend the closing date by

one month, a written request must be filed with the ASCE Managing Nordin et al. 共2001兲 conducted a pilot study on concrete beams

Editor. The manuscript for this paper was submitted for review and pos- strengthened with prestressed near surface mounted CFRP strips.

sible publication on January 8, 2002; approved on May 3, 2002. This Test results showed a substantial increase in cracking and failure

paper is part of the Journal of Composites for Construction, Vol. 7, No. loads for the strengthened specimens. Prestressing the strips did

3, August 1, 2003. ©ASCE, ISSN 1090-0268/2003/3-248 –257/$18.00. not influence the mode of failure. Compared to unstrengthened

248 / JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003

specimens, the prestressed beams had considerably smaller de-

flections at failure.

De Lorenzis and Nanni 共2001兲 investigated the structural per-

formance of simply supported reinforced concrete beams

strengthened with near surface mounted GFRP and CFRP rods.

Both flexural and shear strengthening were examined. Test results

showed that the use of near surface mounted FRP rods is an

effective technique to enhance flexural and shear capacity of re-

inforced concrete beams. The beams strengthened in bending

showed an increase in capacity ranging from 26 to 44% over the

control beam. For the beams strengthened in shear, an increase in

capacity as high as 106% was achieved.

Hassan and Rizkalla 共2002兲 investigated the feasibility of

using different strengthening techniques as well as different types

of FRP for strengthening concrete structures. Large-scale models

of a prestressed concrete bridge were tested to failure. Test results

showed that the efficiency of near surface mounted CFRP strips

was three times that of the externally bonded strips.

Hassan 共2002兲 proposed a general methodology to evaluate the

development length of near surface mounted FRP bars of different

configurations and types of fibers. The influence of the groove Fig. 1. Reinforcement details of test specimens

dimensions, groove spacing, and the limited adhesive cover was

investigated. Hassan and Rizkalla concluded that the tensile

stresses at the concrete-adhesive interface as well as at the FRP- Each beam was strengthened using one CFRP strip inserted into a

adhesive interface are highly dependent on the groove dimensions groove cut at the bottom surface of the beam. The strips, as pro-

and controls the mode of failure of near surface mounted FRP vided by the manufacturer have a nominal width of 50 mm and a

bars. Design charts were provided to establish code specifications total thickness of 1.2 mm. In order to insert the strip within a

for the use of near surface mounted FRP reinforcement. typical concrete cover used for concrete members, the strips were

cut into two halves each, 25 mm wide. Using a concrete saw,

Experimental Program approximately 5 mm wide and 25 mm deep grooves were cut into

the bottom surface of the beams. The grooves were injected with

To evaluate the bond characteristics and load transfer mechanism

epoxy adhesive to provide the necessary bond with the surround-

between near surface mounted CFRP strips and concrete, a total

ing concrete. The strips were carefully placed into the grooves to

of nine simply supported T-beams with a span of 2.5 m and a

ensure that they were completely covered with the epoxy. Instal-

depth of 300 mm were tested. Shear reinforcement consisted of

lation procedures of the strips are illustrated in Fig. 2. Eight dif-

double-legged 10 M steel stirrups, uniformly spaced at 100 mm.

ferent embedment lengths of 150, 250, 500, 750, 850, 950, 1,050,

The top flange was reinforced with welded wire fabric 51⫻51

and 1,200 mm were investigated to evaluate the minimum embed-

MW5.6⫻MW5.6. The top reinforcement consisted of two 10 M

ment length required to develop the ultimate force of the strip.

steel bars. The bottom reinforcement consisted of two 10 M steel

The CFRP strips are produced by S&P Clever Reinforcement

bars running along the full length of the beam and two 15 M steel

Company, Switzerland. The strips have a modulus of elasticity of

bars placed at 100 mm from the midspan section of the beam on

150 GPa and an ultimate tensile strength of 2,000 MPa as re-

both sides as shown in Fig. 1. This arrangement of the bottom

ported by the manufacturer. En-Force CFL epoxy adhesive was

reinforcement was selected to identify the location of the flexural

used for bonding the strips to the concrete. The epoxy is produced

failure of the strengthened specimens. The T-section configuration

by Structural Composites, Inc., Waller, Tex. The average com-

was selected to avoid compression failure due to crushing of the

pressive strength of concrete after 28 days was 48 MPa.

concrete. Selection of the specimens’ dimensions was finalized

after testing six pilot specimens to ensure that rupture of near

surface mounted CFRP strips can be achieved if they are bonded Test Setup and Instrumentation

along the full length of the beam.

The beams were tested under a concentrated load applied at mid-

With the maximum moment occurring at the midspan section

span. A closed-loop MTS, 1,000 kN testing machine was used to

of the beam, failure could be due to: 共1兲 debonding of the CFRP

apply the load using stroke control mode. The rate of loading was

strips or 共2兲 rupture of the CFRP strips. Specimens were ad-

1.0 mm/min up to yielding of the internal steel reinforcement,

equately designed to avoid concrete crushing and premature fail-

beyond which the rate was increased to 3.0 mm/min up to failure.

ure due to shear. In case of bond failure, the bond length of the

The instrumentation used to monitor the behavior of the beams

CFRP reinforcement was increased in the subsequent specimens.

during testing is shown in Fig. 3.

In case of flexural failure, the bond length was decreased in the

following specimens. This scheme was applied until an accurate

development length of near surface mounted CFRP strips was

Test Results and Discussion

achieved.

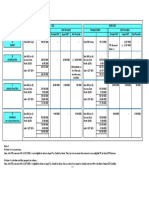

A total of nine concrete beams were tested as given in Table 1.

Strengthening Procedures

The sequence of testing started first by testing specimens B1, B2,

One beam was tested as a control specimen while the other eight B3, and B4 with embedment lengths of 150, 250, 500, and 750

beams were strengthened with near surface mounted CFRP strips. mm, respectively. Based on the results of these tests, Specimens

JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003 / 249

Fig. 3. Instrumentation used for test specimens

sions used in this program is 850 mm. Experimental results for

the test specimens are summarized in Table 1.

Fig. 6 shows the tensile strain in the CFRP strip at ultimate for

different embedment lengths used in this study. The measured

strain values suggest the following three mechanisms as the em-

bedment length increases: 共1兲 For small embedment lengths 共less

Fig. 2. Strengthening procedures

B5 to B8 with embedment lengths ranged from 850 to 1,200 mm

were tested. The load-deflection behavior of the control Specimen

B0 and the eight strengthened specimens is shown in Fig. 4. The

control Specimen B0 failed due to crushing of concrete at a load

level of 52 kN. The figure clearly indicates that using embedment

lengths up to 250 mm provides insignificant improvement in

strength. This is attributed to the early debonding of the CFRP

strips.

A considerable enhancement in strength was observed for em-

bedment lengths greater than 250 mm. Specimens B3 and B4 with

embedment lengths of 500 and 750 mm, respectively, failed also

due to debonding of the CFRP strips. Debonding was observed at

both ends of the strips as well as at midspan. This is attributed to

shear stress concentration at the cutoff point as well as at the

vicinity of flexural cracks. However, final debonding of the CFRP

strips was always controlled by the high shear stress at the strips’

cutoff points. The failure loads for both beams were 60 and 74

kN, respectively. This indicates that full composite action has not

yet been developed and therefore, the measured ultimate load was

increasing with the increase of the embedment length. Beams B5,

B6, B7, and B8 were strengthened using embedment lengths

ranged from 850 to 1,200 mm. The failure of these beams was

due to rupture of the CFRP strips as shown in Fig. 5. The maxi-

mum measured tensile strain in the CFRP strips used for Speci-

mens B5, B6, B7, and B8 was approximately 1.3%. The measured

failure loads for the four beams were almost identical. These re-

sults suggest that the minimum embedment length needed to rup-

Fig. 4. Load-deflection behavior of test specimens

ture the near surface mounted CFRP strips, with the given dimen-

250 / JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003

Table 1. Test Results

Fig. 6. Maximum tensile strain in CFRP strips at failure versus bond

length

the ultimate load carrying capacity of the beams; and 共3兲 ‘‘full

composite mechanism,’’ where the CFRP behaved in a full com-

posite action with beam. For these relatively long embedment

lengths, increasing the embedment length will not provide extra

strength to the retrofitted beam 共Beams B5, B6, B7, and B8兲.

than 250 mm, used for Beams B1 and B2兲 debonding of the

adhesive from the surrounding concrete occurred before yielding Analytical Model

of the internal steel reinforcement without significant develop-

The proposed model is based on the combined shear-bending

ment of the bond. For these small embedment lengths, the failure

model introduced by Malek et al. 共1998兲 for externally bonded

is due to immediate debonding, ‘‘destressed mechanism.’’ The

FRP plates. The model is modified to account for the double

CFRP strips were completely debonded at a very early stage and

bonded area of near surface mounted strips. The model accounts

the beams’ behavior was controlled by the original steel reinforce-

also for the continuous reduction in flexural stiffness due to crack-

ment as before the application of the strengthening scheme. Lin-

ing of the concrete. The derivation of the model is based on the

ear behavior was observed up to cracking, followed by a nonlin-

assumption that shear and bending stresses can be investigated

ear behavior until yielding of the steel reinforcement took place.

separately. Debonding of near surface mounted strips is assumed

After yielding of the steel reinforcement, the increase in the ap-

to occur as a result of high shear stress concentration at cutoff

plied load was negligible until crushing of the concrete occurred.

point. The proposed model accounts only for cases where de-

No significant improvement in strength or stiffness was achieved;

bonding failure is initiated from the strip cutoff points. Other

共2兲 ‘‘bond development mechanism,’’ where the strains at failure

cases where debonding failure is initiated as a result of flexural

are increasing linearly with the increase of the embedment length

cracks or at crack intersections are not considered in the proposed

共Beams B3 and B4兲. For this range of embedment lengths, in-

approach. Considering the equilibrium of an infinitesimal portion

creasing the bond length results in a considerable enhancement in

of the strengthened concrete beam, shown in Fig. 7, the shear

Fig. 5. Rupture of near surface mounted CFRP strips Fig. 7. Infinitesimal portion of test specimen

JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003 / 251

stress along a length of dx can be derived in terms of the incre- and y eff⫽distance from the CFRP strip to the neutral axis of the

mental normal stress in the CFRP strip d f and the thickness of section. The above expression is conditioned by the loading con-

the CFRP strip t f as follows: figuration and can be easily formulated for other load cases as

given in the Appendix. To account for the continuous reduction in

1 d f

⫽ t (1) flexural stiffness due to cracking of concrete, I eff can be expressed

2 dx f as:

冉 冊 冉 冉 冊冊

Assuming linear shear stress-strain relationship for the adhesive

M cr 3 M cr 3

⫽G a ␥ (2) I eff⫽ I g (transformed) ⫹ 1⫺ I cr 共transformed)

Ma Ma

where G a and ␥⫽shear modulus and shear strain of the adhesive,

关 Branson and Trost 1982兴 (12)

respectively.

Assuming linear strain-displacement relationships for the ad- where M cr and M a ⫽cracking and applied moments on a concrete

hesive section, respectively; and I g and I cr⫽gross and cracked moment

of inertia of the transformed strengthened section, respectively.

du dw

␥⫽ ⫹ (3) The corresponding neutral axis depth can be expressed as

冉 冊 冉 冉 冊冊

dz dx

2.5 2.5

M cr M cr

where u and w⫽longitudinal and transverse displacements of the c eff⫽ c g ⫹ 1⫺ c cr

adhesive, respectively. Using Eq. 共1兲, and differentiating with re- Ma Ma

spect to x results in 关 Branson and Trost 1982兴 (13)

d 2 f

dx 2

⫽

2G a d 2 u

⫹ 冉

d 2w

t f dx dz dx 2 冊 (4)

where c g and c cr⫽neutral axis depth for gross and cracked trans-

formed strengthened sections, respectively.

d 2 u/dxdz can be expressed as y eff⫽d f ⫺c eff (14)

d 2u

⫽

d du

dx dz dz dx 冉 冊

d 1

⫽ 共 f ⫺ c 兲 ⫽ 共 f ⫺ c 兲 ⫽

dz ta

1 f c

⫺

ta E f Ec 冉 冊 where d f ⫽depth of near surface mounted strips from compression

fiber.

Rewriting Eq. 共8兲

(5)

where f and c ⫽interfacial strain of the CFRP strip and con-

crete, respectively; E f and E c ⫽modulus of elasticity of the CFRP

strip and concrete, respectively; t a ⫽thickness of the adhesive

d 2 f

dx 2

⫺ 2 f ⫽⫺ 2 n 冉 Pl o y eff Py eff

2I eff

⫹

2I eff

x 冊 (15)

layer; and f and c ⫽normal stress in the CFRP strip and con- The general solution for Eq. 共15兲 can be expressed as

crete, respectively.

From symmetry n Py eff n Pl o y eff

f ⫽C 1 e x ⫹C 2 e ⫺x ⫹ x⫹ (16)

2I eff 2 I eff

d 2w

⫽0 (6) where C 1 and C 2 ⫽constants. The solution represents a character-

dx 2 istic solution for f as

The governing differential equation for the tensile stress in near f characteristic⫽C 1 e x ⫹C 2 e ⫺x (17)

surface mounted CFRP strips can be expressed as

and a particular solution for f as

d 2 f 2G a 2G a

⫺ f ⫽⫺ (7) n Py eff n Pl o y eff

dx 2 t at f E f t at f E c c

f particular⫽ x⫹ (18)

2I eff 2I eff

Rewriting Eq. 共7兲

The shear stress can be expressed as

d 2 f

dx 2

⫺ f ⫽⫺ n c

2 2

(8)

⫽

tf

冋

2 1

C e x ⫺C 2 e ⫺x ⫹

n Py eff

2I eff 册 (19)

where

Constants C 1 and C 2 can evaluated using the following boundary

2G a conditions:

2⫽ (9)

t at f E f

f ⫽0 at x⫽0 (20)

Ef

n⫽ (10) ⫽0 at x⫽L (21)

Ec

where L⫽embedment length of the CFRP strip. Using the above

For simply supported beams subjected to a concentrated load at boundary conditions, the following expressions for C 1 and C 2 are

midspan, the normal stress in concrete c can be evaluated in derived:

terms of the effective moment of inertia, I eff as follows:

⫺n Py eff

Pl o y eff P y eff C 1⫽ 关 1⫹l o e ⫺L 兴 (22)

c⫽ ⫹ x (11) 4 I eff cosh共 L 兲

2I eff 2I eff

where P⫽applied concentrated load; l o ⫽unbonded length of the n Pl o y eff

C 2 ⫽⫺C 1 ⫺ (23)

CFRP strip; x⫽longitudinal coordinate starting from cutoff point; 2I eff

252 / JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003

Fig. 8. Mohr-Coulomb failure criterion

Fig. 9. Mesh dimensions used in finite element analysis

Using practical values for and L, cosh共L兲 is always a very

large number compared to other terms. Therefore, the constant C 1 analysis at the cutoff point. The finite element modeling described

can be ignored. Rewriting Eq. 共19兲, the shear stress can be ex- in this paper was conducted using the ANACAP program 共Version

pressed as 2.1兲. ANACAP is known for its advanced nonlinear capabilities of

冋 册

the concrete material model 共James 1997兲. The ANACAP software

t f n Pl o y eff ⫺x n Py eff employs the classical incremental theory of plasticity that relates

⫽ e ⫹ (24)

2 2I eff 2I eff the increment of plastic strain to the state of stresses and stress

Debonding will occur when the shear stress reaches a maximum increment. Formulation of the yield surfaces, loading, and failure

value, which depends on the concrete properties. surfaces take into account the effect of confinement on the con-

crete behavior. The concrete material is modeled by the smeared

cracking methodology in which progressive cracking is assumed

Failure Criterion to be distributed over an entire element 共Rashid 1968兲. Verifica-

tion of the ANACAP program using independent experimental

Many research studies investigated the bond characteristics of results can be found elsewhere 共Hassan et al. 2000兲.

FRP strips externally bonded to concrete specimens 共Sharif et al.

1994; Quantrill et al. 1996; Arduini et al. 1997兲. Test results

showed that the maximum sustainable interface shear stress Modeling of Test Specimens

ranged between 3.5 to 6 MPa, with failure occurring in the con-

crete in all cases. Consequently, premature debonding of near Two test specimens, B3 and B4, were selected from the experi-

surface mounted CFRP strips is governed by the shear strength of mental program to be modeled using finite element analysis. Fail-

the concrete. Other components of the system such as the epoxy ure of both beams was due to debonding of the near surface

adhesive and the CFRP strips have superior strength and adhesion mounted CFRP strips at cutoff points. Taking advantage of the

properties compared to concrete. Knowing the compressive and symmetry of the specimens, only a quarter of the beams was

tensile strength of concrete, the Mohr-Coulomb line, which is modeled. The concrete, epoxy, and the CFRP strip were modeled

tangential to both Mohr’s circles for pure tension and pure com- using 20-node isoparametric brick elements with a 2⫻2⫻2 re-

pression, can be represented as shown in Fig. 8. All circles tan- duced Gauss integration scheme. Each node has three transla-

gential to the Mohr-Coulomb line represent a critical stress com- tional degrees of freedom. The load was applied as a uniform

bination. The maximum critical shear stress for the pure shear pressure acting on an area of 100⫻150 mm. Several analytical

circle is given by simulations were carried out by varying the size of the elements

around the cutoff point. The influence of the mesh size on the

f ⬘c f ct predicted shear stresses at cutoff point was noticeable. Mesh di-

max⫽ (25) mensions used for Test Specimens B3 and B4 with embedment

f ⬘c ⫹ f ct

lengths of 500 and 750 mm, respectively, are shown in Fig. 9.

where f ⬘c ⫽compressive strength of concrete after 28 days; and Further refinement of the mesh around cutoff points increased the

f ct⫽tensile strength of concrete. Equating the shear strength pro- predicted shear stress by less than 0.5%.

posed in Eq. 共25兲 to the shear stress given in Eq. 共24兲, debonding

loads for near surface mounted CFRP strips can be determined for

Comparison with Finite Element Analysis

this specific loading case and embedment length. Other loading

cases are given in the Appendix. The interfacial shear stress distributions for Specimens B3 and B4

are calculated at two different load levels and compared to those

predicted using finite element analysis. The first selected load

Verification of Analytical Model level was less than the cracking load of the test specimens to

validate the analytical model at the elastic stage. The second se-

The analytical model is verified by comparing the calculated lected load level matched the cracking load at cutoff points for

shear stress from Eq. 共24兲 to that obtained from finite element Specimens B3 and B4. The shear modulus of the epoxy adhesive

JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003 / 253

Fig. 12. Maximum shear stress at cutoff point versus applied load

Fig. 10. Comparison of proposed model to finite element method

before cracking of concrete at cutoff point

was set to 1,230 MPa as reported by the manufacturer. Based on loads for different embedment lengths are also shown in Fig. 12.

a groove width of 5 mm, the thickness of the epoxy adhesive used In general, the predicted loads at the maximum shear stress for

in the analysis was set to 1.9 mm. The results of the finite element each length are in a good agreement with the measured debonding

analysis together with the proposed analytical model are shown in loads. The predicted debonding loads for Specimens B1, B2, B3,

Fig. 10 at the elastic stage. The results, at the onset of cracking and B4 underestimated the measured values by less than 10%.

are shown in Fig. 11. Interfacial shear stress distribution, pre- The proposed model showed good agreement to beams of embed-

dicted using the analytical model is in a good agreement with the ment lengths either at the distressed stage or at the bond devel-

results of the finite element analysis before cracking of the con- opment stage. The midspan section of the test specimen was ana-

crete. At the onset of cracking of the concrete at cutoff points, the lyzed using a strain compatibility approach to predict the flexural

calculated shear stress distribution is deviated from the finite el- behavior up to failure. The stress-strain relationship of the con-

ement results. This behavior is attributed to possible redistribution crete was modeled using a parabolic relationship in compression.

of shear stresses around the cracks. Such a phenomenon is ac- The internal compression force in the concrete was evaluated

counted for in the finite element analysis and not considered in using the stress-block parameters introduced by Collins and

the proposed model. However, the maximum shear stress calcu- Mitchell 共1991兲. The stress-strain behavior of the CFRP reinforce-

lated using the analytical model is in good agreement with the ment was assumed to be linearly elastic up to failure. The average

finite element results. Using the proposed model for the effective tensile stresses in the concrete between the cracks were consid-

transformed moment of inertia showed good agreement in pre- ered in the analysis using an average tensile stress-strain relation-

dicting the maximum interfacial shear stresses at cutoff points. ship for the concrete introduced by Collins and Mitchell 共1991兲.

These tensile stresses are concentrated in a zone of concrete

around the reinforcement called the ‘‘effective embedment zone’’

Comparison with Experimental Results defined by the CEB-FIP 共1978兲. The tensile stresses in the

Debonding loads are predicted using the proposed analytical cracked concrete outside the effective embedment zone are ig-

model in Eqs. 共24兲 and 共25兲 for different embedment lengths of nored in the analysis. The predicted failure load due to the rupture

the CFRP strips as shown in Fig. 12. The measured debonding of the CFRP strip and accounting for the tension stiffening of

concrete is 75 kN. Failure of Specimen B5, with an embedment

length of 850 mm was due to the rupture of the CFRP strip at a

load level of 79 kN, which is 5% higher than the predicted value.

Fig. 12 shows also that the minimum embedment length needed

to rupture the CFRP strips used in this program is greater than

750 mm and less than 850 mm, which coincides with the experi-

mental results.

The development length is highly dependent on the dimen-

sions of the strips, concrete properties, adhesive properties, inter-

nal steel reinforcement ratio, reinforcement configuration, type of

loading, and groove width. The proposed model in Eqs. 共24兲 and

共25兲, can be used to estimate the development length of near

surface mounted strips of any configuration as follows:

1. Use the proposed equations, Eqs. 共24兲 and 共25兲, to determine

the debonding load of the strip for different embedment

lengths as shown in Fig. 13. The resulting curve represents a

failure envelope due to debonding of the strip at cutoff point;

2. Use a cracked section analysis at sections of maximum in-

Fig. 11. Comparison of proposed model to finite element method

duced normal stresses and determine the ultimate load re-

after cracking of concrete at cutoff point

quired to rupture the strip as shown in Fig. 13; and

254 / JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003

Fig. 13. General procedures to calculate development length of near

Fig. 15. Influence of concrete compressive strength

surface mounted strips

3. Determine the development length at the intersection of the neutral axis depth and slightly increases the debonding loads. The

line corresponding to flexural failure of the strip with the analysis indicated that failure loads due to the rupture of the

curve representing debonding failure at cutoff point. CFRP strips were substantially increased with the increase of the

The calculated development length will preclude brittle failure reinforcement ratio. Consequently, the development is increased.

due to debonding of the strips and will ensure full composite Such an increase in the development length is highly pronounced

action between the strip and concrete up to failure. at low steel reinforcement ratios. At the absence of the internal

steel reinforcement ( s ⫽0), doubling the height of the CFRP

strip doubles the failure load due to rupture of the strip. Conse-

Parametric Study quently, the required development length is doubled as shown in

Fig. 14. The higher the internal steel reinforcement ratio, the less

Based on the confidence established in the analytical model, the the contribution of the CFRP reinforcement in increasing the rup-

analysis is extended to investigate the influence of various param- ture load. Therefore, the influence of doubling the height of the

eters, believed to affect the development length of near surface CFRP strip on the development length is significantly reduced for

mounted CFRP strips. The key parameters are identified as the high steel reinforcement ratios as shown in Fig. 14.

internal steel reinforcement ratio, concrete compressive strength, The influence of the concrete compressive strength and the

and groove width. In the following analysis, tension stiffening of groove width is illustrated in Figs. 15 and 16, respectively. The

the concrete was not accounted for to simplify the procedure. Fig. analysis was performed using two different internal steel rein-

14 shows the influence of the internal steel reinforcement ratio on forcement ratios. The first reinforcement ratio was set to 0.57% to

the development of near surface mounted CFRP strips. Two dif- match the steel reinforcement ratio at midspan section of the test

ferent sizes of CFRP strips were considered in the analysis. The specimens. The second reinforcement ratio was set to 1% to simu-

first strip has a height of 25 mm. The strip can be easily inserted late the most commonly used reinforcement ratio in flexural

in typical concrete covers. The height of the second strip is 50 members. The analysis indicated that failure loads due to the rup-

mm and was selected to accommodate typical bridge members ture of the CFRP strips were trivially changed with the variation

normally provided with large concrete covers. The thickness of of either the concrete compressive strength or the groove width.

the CFRP strips was set to 1.2 mm in both cases. In general, However, increasing concrete compressive strength results in a

increasing the internal steel reinforcement ratio shifts down the significant increase in the maximum shear stresses max . Further-

more, increasing the thickness of the adhesive 共by increasing the

Fig. 14. Influence of internal steel reinforcement ratio Fig. 16. Influence of groove width

JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003 / 255

groove width兲 reduces the shear deformation within the adhesive qny eff

layer. Consequently, the interfacial shear stresses are reduced. a⫽⫺ (27)

2I eff

These phenomena result in a significant increase in debonding

loads and consequently reduce the development length as shown qny eff

in Figs. 15 and 16. b⫽ 共 L ⬘ ⫺2l o 兲 (28)

2I eff

and

Conclusions qny eff qny eff l o

c⫽⫺ ⫹ 共 L ⬘ ⫺l o 兲 (29)

Based on the findings of this investigation, the following conclu- 2 I eff 2I eff

sions can be drawn:

1. The use of near surface mounted CFRP strips is feasible and

Case II. Simply Supported Beam Subjected

effective for strengthening/repair of concrete structures;

to Two Concentrated Loads

2. Use of near surface mounted CFRP strips substantially in-

creases both stiffness and strength of concrete beams. The For a simply supported beam subjected to two equal concentrated

ultimate load carrying capacity of the beams can be in- loads 2P placed symmetrically about the center line of the beam,

creased by as much as 53% for the specimens used in this the induced shear stress can be expressed as

冋 册

program. Groove dimensions of 5 mm wide by 25 mm deep

were adequate to prevent splitting of the epoxy cover; t f n P y eff n Py effl o ⫺x

⫽ ⫹ e (30)

3. The proposed analytical model is capable of predicting the 2 I eff I eff

interfacial shear stress distribution, ultimate load carrying

where t f ⫽thickness of the strip; n⫽defined by Eq. 共10兲;

capacity, and mode of failure of concrete beams strengthened

P⫽concentrated load; l o ⫽unbonded length of the strip;

with near surface mounted CFRP strips. Excellent agreement

⫽defined by Eq. 共9兲; y eff⫽distance from the strip to the neutral

was established between the predicted values using the pro-

axis of the section; and I eff⫽effective moment of inertia of the

posed model and those predicted using finite element analy-

transformed section.

sis;

4. The proposed failure criterion for debonding of near surface

mounted CFRP strips provided sufficient evidence and con-

fidence in predicting debonding loads; Notation

5. Debonding loads increase by increasing the embedment

length of CFRP strips, concrete compressive strength, and/or The following symbols are used in this paper:

groove width; C 1 , C 2 ⫽ parameters in solution of differential equation;

6. Development length of near surface mounted CFRP strips c cr ⫽ neutral axis depth for cracked transformed

increases by increasing the internal steel reinforcement ratio. section;

The development length decreases with the increase of either c eff ⫽ effective neutral axis depth for transformed

the concrete compressive strength and/or the groove width. section;

c g ⫽ neutral axis depth for gross transformed section;

d f ⫽ depth of near surface mounted CFRP strips from

Acknowledgments compression fiber;

E c ⫽ modulus of elasticity of concrete;

The writers wish to acknowledge the support of the Network of E f ⫽ modulus of elasticity of CFRP strips;

Centres of Excellence, ISIS Canada, program of the Government f c⬘ ⫽ compressive strength of concrete after 28 days;

of Canada and the Natural Science and Engineering Research f ct ⫽ tensile strength of concrete;

Council. The writers gratefully acknowledge the support provided G a ⫽ shear modulus of adhesive;

by S&P Clever Reinforcement Company, Switzerland, Structural h ⫽ total height of concrete section;

Composites Inc., for providing the materials used in the test pro- I cr(transformed)

gram. The writers would also like to acknowledge the support ⫽ cracked moment of inertia of transformed

provided by Vector Construction Ltd., Winnipeg, Canada for per- strengthened section;

forming all the strengthening work. Special thanks to M. McVey I eff ⫽ effective moment of inertia of transformed

for his assistance during fabrication and testing of the specimens. strengthened section;

I g(transformed)

⫽ gross moment of inertia of transformed strengthened

Appendix. Shear Stress for Different Loading section;

Configurations L ⫽ embedment length of CFRP strip;

L ⬘ ⫽ total span of simply supported beam;

Case I. Simply Supported Beam Subjected l o ⫽ unbonded length of CFRP strip;

to Uniform Load M a ⫽ applied moment on concrete section;

M cr ⫽ cracking moment of concrete section;

For a simply supported beam of a span L ⬘ , subjected to a uniform n ⫽ defined by Eq. 共10兲;

load q, the induced shear stress can be expressed as P ⫽ applied concentrated load;

tf P cr ⫽ applied concentrated load that causes cracking at

⫽ 关 ax⫹b⫹ce ⫺x 兴 (26) cutoff points;

2

P d ⫽ experimental debonding load;

where P u ⫽ failure load;

256 / JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003

q ⫽ applied uniform load; contrainte 共CEB-FIP兲. 共1978兲. Model code for concrete structures:

ta ⫽ thickness of adhesive layer; CEB-FIP international recommendations, 3rd Ed., Comité Euro-

tf ⫽ thickness of CFRP strip; International du Béton, Paris, 348 p.

u ⫽ longitudinal displacement in adhesive layer; Collins, M., and Mitchell, D. 共1991兲. Prestressed concrete structures,

Prentice-Hall, Englewood Cliffs, New Jersey.

w ⫽ transverse displacement in adhesive layer;

De Lorenzis, L., and Nanni, A. 共2001兲. ‘‘Shear strengthening of rein-

x ⫽ longitudinal coordinate starting from cutoff point

forced concrete beams with near-surface mounted fibre reinforced

of CFRP strip; polymer rods.’’ ACI Struct. J., 98共1兲, 60– 68.

y eff ⫽ distance from CFRP strip to neutral axis; Gentile, C., and Rizkalla, S. 共1999兲. ‘‘Flexural strengthening of timber

␥ ⫽ shear strain in adhesive; beams using FRP.’’ Technical Rep., ISIS Canada, Univ. of Manitoba,

c ⫽ interfacial strain of concrete; Winnipeg, Manitoba, Canada.

f ⫽ interfacial strain of CFRP strips; Hassan, T. 共2002兲. ‘‘Flexural performance and bond characteristics of

u ⫽ strain of near surface mounted CFRP strips at FRP strengthening techniques for concrete structures.’’ PhD thesis,

failure; Univ. of Manitoba, Winnipeg, Man., Canada, 304p.

s ⫽ internal steel reinforcement ratio; Hassan, T., Abdelrahman, A., Tadros, G., and Rizkalla, S. 共2000兲. ‘‘FRP

c ⫽ normal stress in concrete; reinforcing bars for bridge decks.’’ Can. J. Civ. Eng., 27共5兲, 839– 849.

f ⫽ normal stress in CFRP strip; Hassan, T., and Rizkalla, S. 共2002兲. ‘‘Flexural strengthening of pre-

stressed bridge slabs with FRP systems.’’ PCI J., 47, 76 –93.

⫽ interfacial shear stress;

James, R. G. 共1997兲. ANACAP concrete analysis program theory manual,

max ⫽ maximum shear stress at concrete-epoxy Version 2.1, Anatech Corp., San Diego.

interface; and Malek, A., Saadatmanesh, H., and Ehsani, M. 共1998兲. ‘‘Prediction of

⫽ defined by Eq. 共9兲. failure load of R/C beams strengthened with FRP plate due to stress

concentration at the plate end.’’ ACI Struct. J., 95共1兲, 142–152.

Meier, U. 共1992兲. ‘‘Carbon fibre-reinforced polymers: Modern materials

References in bridge engineering.’’ Struct. Eng. Int. (IABSE, Zurich, Switzerland),

2, 7–12.

Arduini, M., Di Tommaso, A., and Nanni, A. 共1997兲. ‘‘Parametric study Nordin, H., Taljsten, B., and Carolin, A. 共2001兲. ‘‘Concrete beams

of beams with externally bonded FRP reinforcement.’’ ACI Struct. J., strengthened with prestressed near surface mounted reinforcement.’’

94共5兲, 493–501. Proc., Int. Conf. on FRP Composites in Civil Engineering, Research

Asplund, S. O. 共1949兲. ‘‘Strengthening bridge slabs with grouted rein- Centre for Advanced Technology in Structural Engineering, Dept. of

forcement.’’ ACI Struct. J., 20共4兲, 397– 406. Civil and Structural Engineering, The Hong Kong Polytechnic Univ.,

Blaschko, M., and Zilch, K. 共1999兲. ‘‘Rehabilitation of concrete struc- Hong Kong, 1067–1075.

tures with strips glued into slits.’’ Proc., 12th Int. Conf. on Composite Quantrill, R. J., Hollaway, L. C., and Thorne, A. M. 共1996兲. ‘‘Predictions

Materials, Organization of the Int. Conf. on Composite Materials, of the maximum plate end stresses of FRP strengthened beams. II.’’

Paris, CD-ROM. Mag. Concrete Res., 48共177兲, 343–351.

Branson, D. E., and Trost, H. 共1982兲. ‘‘Unified procedures for predicting Rashid, Y. R. 共1968兲. ‘‘Analysis of prestressed concrete pressure vessels.’’

the deflection and centrodal axis location of partially cracked nonpre- Nucl. Eng. Des., 7共4兲, 334 –344.

stressed and prestressed concrete members.’’ ACI Struct. J., 79共2兲, Saadatmanesh, E., and Ehsani, M. R. 共1989兲. ‘‘Application of fibre-

119–130. composites in civil engineering.’’ Proc., 7th ASCE Structures Con-

Carolin, A. Nordin, M. and Taljsten, B. 共2001兲. ‘‘Concrete beams gress, ASCE, New York, 526 –535.

strengthened with near surface mounted reinforcement of CFRP.’’ Sharif, A., Al-Sulaimani, G. J., Basunbul, I. A., Baluch, M. H., and Gha-

Proc., Int. Conf. on FRP Composites in Civil Engineering, Research leb, B. N. 共1994兲. ‘‘Strengthening of initially loaded reinforced con-

Centre for Advanced Technology in Structural Engineering, Dept. of crete beams using FRP plates.’’ ACI Struct. J., 91共2兲, 160–168.

Civil and Structural Engineering, The Hong Kong Polytechnic Univ., Swamy, R. N., and Mukhopadhyaya, P. 共1999兲. ‘‘Debonding of carbon

Hong Kong, 1059–1066. fibre reinforced polymer plate from concrete beams.’’ Eng. Structs

Comité Euro-International du Béton-Fédération International de la Pré- and Bldgs., 134共11兲, 301–317.

JOURNAL OF COMPOSITES FOR CONSTRUCTION © ASCE / AUGUST 2003 / 257

You might also like

- Behavior of CFRP For Prestressing and Shear Reinforcements of Concrete Highway BridgesDocument10 pagesBehavior of CFRP For Prestressing and Shear Reinforcements of Concrete Highway Bridgesflaco_astrozaNo ratings yet

- Flexural Strength of WoodDocument3 pagesFlexural Strength of WoodAndrea Mae SanchezNo ratings yet

- Bond Mechanism of NSM FRP Bars For Flexural Strengthening of Concrete StructuresDocument39 pagesBond Mechanism of NSM FRP Bars For Flexural Strengthening of Concrete StructuresDoua AbdouNo ratings yet

- Uji Kegagalan Beton PDFDocument8 pagesUji Kegagalan Beton PDFudotemNo ratings yet

- Mechanical and Bond Properties of New Generation of Isorod CFRP Reinforcing Bars For Concrete StructuresDocument23 pagesMechanical and Bond Properties of New Generation of Isorod CFRP Reinforcing Bars For Concrete StructuresAhmed AjelNo ratings yet

- Paper - IJST - HajrasoulihaDocument14 pagesPaper - IJST - HajrasoulihaMehdi KhorasaniNo ratings yet

- An Experimental Study On Kevlar Strengthening of Beam Column ConnectionsDocument9 pagesAn Experimental Study On Kevlar Strengthening of Beam Column ConnectionsMarimuthu KaliyamoorthyNo ratings yet

- Repair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperDocument9 pagesRepair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperD Raul CfNo ratings yet

- Antoniades Etal 2005 Tests On Seis Damaged RC Walls Repaired W FRP PDFDocument12 pagesAntoniades Etal 2005 Tests On Seis Damaged RC Walls Repaired W FRP PDFDiego Andres Palacios OrtegaNo ratings yet

- 1 s2.0 S2090447915001823 MainDocument7 pages1 s2.0 S2090447915001823 Mainjsun19No ratings yet

- Ase10 5 BankDocument12 pagesAse10 5 BankmarkicivanNo ratings yet

- 2013 Punching Shear Strengthening of TwoDocument10 pages2013 Punching Shear Strengthening of TwoMehdi KhorasaniNo ratings yet

- The Open Civil Engineering Journal: Structural Behavior of Strengthened RC Beams in Shear Using CFRP StripsDocument11 pagesThe Open Civil Engineering Journal: Structural Behavior of Strengthened RC Beams in Shear Using CFRP StripsGoitom Teklay GebrekidanNo ratings yet

- A State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPDocument15 pagesA State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPenghrc.2208No ratings yet

- Behavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsDocument16 pagesBehavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsBatisxuta MichaelNo ratings yet

- Strengthening of Beams Using Carbon Fibre Reinforced PolymerDocument7 pagesStrengthening of Beams Using Carbon Fibre Reinforced PolymerAkhilesh B.MNo ratings yet

- Innovative Applicationof FRPsfor Seismic Strengtheningof RCShear WallDocument20 pagesInnovative Applicationof FRPsfor Seismic Strengtheningof RCShear Wall오상진No ratings yet

- Behavior of Axially Loaded Concrete-Filled Circular Fiber-Reinforced Polymer TubesDocument10 pagesBehavior of Axially Loaded Concrete-Filled Circular Fiber-Reinforced Polymer Tubesflaco_astrozaNo ratings yet

- 612 - Aci Structural Journal by Wiryanto DewobrotoDocument168 pages612 - Aci Structural Journal by Wiryanto Dewobrotomavane25No ratings yet

- In Uence of Edge Sharpness On The Strength of Square Concrete Columns Confined With FRP Composite LaminatesDocument11 pagesIn Uence of Edge Sharpness On The Strength of Square Concrete Columns Confined With FRP Composite LaminatesAboalmaaliNo ratings yet

- Bending Behaviour of Mortar Reinforced With FibersDocument12 pagesBending Behaviour of Mortar Reinforced With FibersWilliam CaballeroNo ratings yet

- Bond Behavior of CFRP Strengthened Steel Structures DawoodDocument13 pagesBond Behavior of CFRP Strengthened Steel Structures DawoodmastourNo ratings yet

- Bond Mechanism of Near-Surface-Mounted Fiber-Reinforced Polymer Bars For Flexural Strengthening of Concrete StructuresDocument10 pagesBond Mechanism of Near-Surface-Mounted Fiber-Reinforced Polymer Bars For Flexural Strengthening of Concrete StructuresMishraq ul quraishNo ratings yet

- Finite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewDocument8 pagesFinite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewAfia.S.HameedNo ratings yet

- Experimental Study On Sprayed FRP System For Strengthening Reinforced Concrete BeamsDocument13 pagesExperimental Study On Sprayed FRP System For Strengthening Reinforced Concrete BeamsAmel RADJEFNo ratings yet

- International Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402Document13 pagesInternational Journal of Research and Innovation : Strengthening of RC Beams Using FRP Sheet 1401-1402ijripublishersNo ratings yet

- Flexural Strengthening of Prestressed Bridge Slabs With FRP SystemsDocument18 pagesFlexural Strengthening of Prestressed Bridge Slabs With FRP SystemsAyman BadrNo ratings yet

- Different CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Document11 pagesDifferent CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Sulaiman Mohsin AbdulAzizNo ratings yet

- Bond STRGDocument8 pagesBond STRGyuva_86No ratings yet

- Paper With Tabatabaei - Composites Part B - 2013Document10 pagesPaper With Tabatabaei - Composites Part B - 2013Mehdi KhorasaniNo ratings yet

- Strengthening of Concrete Slab-Column Connections Using CFRP StripsDocument9 pagesStrengthening of Concrete Slab-Column Connections Using CFRP Stripsvishwanath malalanayakeNo ratings yet

- Finite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyDocument13 pagesFinite Element Modelling of Strengthened Simple Beams Using FRP Techniques: A Parametric StudyRizki Nuursirullah MahibNo ratings yet

- Repair of Pre-Cracked Reinforced Concrete (RC) Beams With Openings Strengthened Using FRP Sheets Under Sustained LoadDocument13 pagesRepair of Pre-Cracked Reinforced Concrete (RC) Beams With Openings Strengthened Using FRP Sheets Under Sustained LoadHaider AliNo ratings yet

- Strengthening of RC Beams With Large Openings in Shear by CFRP Laminates: Experiment and 2D Nonlinear Finite Element AnalysisDocument10 pagesStrengthening of RC Beams With Large Openings in Shear by CFRP Laminates: Experiment and 2D Nonlinear Finite Element AnalysisSoumya GoraiNo ratings yet

- Ductility of Concrete Beams Reinforced With Hybrid FRP RebarsDocument13 pagesDuctility of Concrete Beams Reinforced With Hybrid FRP RebarsMuhammad YounisNo ratings yet

- 612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFDocument168 pages612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFchaval01No ratings yet

- 1 s2.0 S0264127515307747 MainDocument12 pages1 s2.0 S0264127515307747 Mainj.riquelme16No ratings yet

- Experimental Investigation On Flexural Strength of Beam Using CFRPDocument9 pagesExperimental Investigation On Flexural Strength of Beam Using CFRPDharma banothuNo ratings yet

- 2e60 PDFDocument8 pages2e60 PDFSājä Al MallakNo ratings yet

- Journal of King Saud University - Engineering SciencesDocument10 pagesJournal of King Saud University - Engineering SciencescherniNo ratings yet

- Engineering Structures: Jincheng Yang, Morgan Johansson, Mohammad Al-Emrani, Reza HaghaniDocument9 pagesEngineering Structures: Jincheng Yang, Morgan Johansson, Mohammad Al-Emrani, Reza Haghanimohamed ellithyNo ratings yet

- Case Studies in Construction Materials: Thaar S. Al-Gasham, Jasim M. Mhalhal, Sallal R. AbidDocument22 pagesCase Studies in Construction Materials: Thaar S. Al-Gasham, Jasim M. Mhalhal, Sallal R. Abideng. douaaNo ratings yet

- Effect of Bond Surface Area On The Shear Strength of Carbon Fibre Reinforced Polymer (CFRP) Strengthened Reinforced Concrete BeamsDocument9 pagesEffect of Bond Surface Area On The Shear Strength of Carbon Fibre Reinforced Polymer (CFRP) Strengthened Reinforced Concrete BeamsItuknowNo ratings yet

- Fiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionDocument18 pagesFiber-Reinforced Plastic Grid For Reinforced Concrete ConstructionPari PatelNo ratings yet

- Strengthening of RC Beams in Flexure Using Ferrocement: S.U. Khan, S.F.A.Rafeeqi and T. AyubDocument13 pagesStrengthening of RC Beams in Flexure Using Ferrocement: S.U. Khan, S.F.A.Rafeeqi and T. Ayubthomas13711363No ratings yet

- Flexural Response of Reinforced Concrete (RC) Beams Strengthened With Near Surface Mounted (NSM) Fibre Reinforced Polymer (FRP) BarsDocument15 pagesFlexural Response of Reinforced Concrete (RC) Beams Strengthened With Near Surface Mounted (NSM) Fibre Reinforced Polymer (FRP) Barsmohamed ellithyNo ratings yet

- Strengthening of Shear Deficient Reinforced Concrete Beams Retrofitted With Cement-Based CompositesDocument12 pagesStrengthening of Shear Deficient Reinforced Concrete Beams Retrofitted With Cement-Based Compositesalaa hassoonNo ratings yet

- 2017 - Ozbakkaloglu, Togay Fang, Chengfeng Gholampour, Aliakbar - Influence of FRP Anchor Configuration On The BehaviorDocument18 pages2017 - Ozbakkaloglu, Togay Fang, Chengfeng Gholampour, Aliakbar - Influence of FRP Anchor Configuration On The BehaviorTigon Vo NgocNo ratings yet

- Behavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer SheetsDocument20 pagesBehavior of Prestressed Concrete I-Girders Strengthened in Shear With Externally Bonded Fiber-Reinforced-Polymer Sheetsbojana_246941181No ratings yet

- Full Paper Rosen Boom KehoeDocument5 pagesFull Paper Rosen Boom KehoeGermar PorquerinoNo ratings yet

- Efficiency SFR 2003Document10 pagesEfficiency SFR 2003Kemal Tuşat YücelNo ratings yet

- Lowcost Fiber Rope Reinforced Polymer FRRP Confinement of Square Columns With Different Corner RadiiBuildingsDocument24 pagesLowcost Fiber Rope Reinforced Polymer FRRP Confinement of Square Columns With Different Corner RadiiBuildingsAnat RuangrassameeNo ratings yet

- Study The Structural Behaviour of Ferrocement Beam: UNIMAS E-Journal of Civil EngineeringDocument7 pagesStudy The Structural Behaviour of Ferrocement Beam: UNIMAS E-Journal of Civil EngineeringAnonymous xC6bM4x6U6No ratings yet

- FRP Paper PDFDocument6 pagesFRP Paper PDFRikson TandelilinNo ratings yet

- The Use of Wire Mesh-Polyurethane Cement (WM-PUC) Composite To Strengthen RC T-Beams Under ExureDocument15 pagesThe Use of Wire Mesh-Polyurethane Cement (WM-PUC) Composite To Strengthen RC T-Beams Under ExureSivarajSivaNo ratings yet

- CFRP-steel Hybrid Retrofitting of Steel-Concrete Composite StructuresDocument9 pagesCFRP-steel Hybrid Retrofitting of Steel-Concrete Composite StructuresUsha EngineeringNo ratings yet

- Published DeepBeamswithopeningsDocument11 pagesPublished DeepBeamswithopeningsEngmka KimoNo ratings yet

- Flexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemDocument12 pagesFlexural Strengthening of Reinforced Concrete Beam-Column Joints Using Innovative Anchorage SystemmekidesNo ratings yet

- Case Studies in Construction Materials: Ra Fid Saeed AteaDocument8 pagesCase Studies in Construction Materials: Ra Fid Saeed Ateaviewer208No ratings yet

- General Academic Vacancy PositionDocument287 pagesGeneral Academic Vacancy Positionyuva_86No ratings yet

- NIT Patna Bihta CampusDocument16 pagesNIT Patna Bihta Campusyuva_86No ratings yet

- 04-ANNEXURE-01-ECBC 2017 (Mandatory Requirements) - For Electrical ConsultantDocument18 pages04-ANNEXURE-01-ECBC 2017 (Mandatory Requirements) - For Electrical Consultantyuva_86No ratings yet

- 03-GRIHA V-2019 Design Guideline On ENERGY EFFICIENCY - For Electrical ConsultantDocument16 pages03-GRIHA V-2019 Design Guideline On ENERGY EFFICIENCY - For Electrical Consultantyuva_86No ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabyuva_86No ratings yet

- 02-GRIHA V-2019 Design Guideline On SUSTAINABLE ARCHITECTURE - For ArchitectDocument20 pages02-GRIHA V-2019 Design Guideline On SUSTAINABLE ARCHITECTURE - For Architectyuva_86No ratings yet

- 01-GRIHA V-2019 Design Guideline On SITE PLANNING - For URCDocument11 pages01-GRIHA V-2019 Design Guideline On SITE PLANNING - For URCyuva_86No ratings yet

- Matrix Multi Attributes BMTPCDocument37 pagesMatrix Multi Attributes BMTPCyuva_86No ratings yet

- Bond STRGDocument8 pagesBond STRGyuva_86No ratings yet

- Code Model Cfrp-IDocument1 pageCode Model Cfrp-Iyuva_86No ratings yet

- Bridge Retrofit CFRPDocument9 pagesBridge Retrofit CFRPyuva_86No ratings yet

- 01 Tender Highlights DSIIDCDocument3 pages01 Tender Highlights DSIIDCyuva_86No ratings yet

- Nitcivilnew PDFDocument257 pagesNitcivilnew PDFyuva_86No ratings yet

- ECO CELL PresentationDocument12 pagesECO CELL Presentationyuva_86No ratings yet

- Smart City, Amaravati: Detailed Report On The Scope of Smart City For ConstructionDocument45 pagesSmart City, Amaravati: Detailed Report On The Scope of Smart City For Constructionyuva_86No ratings yet

- Page001to133 PDFDocument133 pagesPage001to133 PDFyuva_86No ratings yet

- Basf Masterseal Below Grade 5500 TdsDocument2 pagesBasf Masterseal Below Grade 5500 Tdsyuva_86No ratings yet

- RILEM General Brochure-June 21stDocument2 pagesRILEM General Brochure-June 21styuva_86No ratings yet

- Page001to133 PDFDocument133 pagesPage001to133 PDFyuva_86No ratings yet

- URC Corporate PresentationDocument143 pagesURC Corporate Presentationyuva_86100% (1)

- SEZ Non Sez: Transaction ChartDocument1 pageSEZ Non Sez: Transaction Chartyuva_86No ratings yet

- 1 WMM Mix DesignDocument24 pages1 WMM Mix Designyuva_86No ratings yet

- Construction Safety Management Csm21Document96 pagesConstruction Safety Management Csm21yuva_86No ratings yet

- BDM Example 11 - 2020 02 PDFDocument15 pagesBDM Example 11 - 2020 02 PDFManuel Alejandro ForeroNo ratings yet

- Dizayn 500mmDocument8 pagesDizayn 500mmsafak ışıkNo ratings yet

- 002.analysis and Design of Beams (USD)Document8 pages002.analysis and Design of Beams (USD)Apple AterradoNo ratings yet

- Bending TestDocument10 pagesBending TestIqmal DaniealNo ratings yet

- The Use of Basalt Aggregates in Concrete Mixes in Jordan: Hamadallah Mohammad Al-BaijatDocument8 pagesThe Use of Basalt Aggregates in Concrete Mixes in Jordan: Hamadallah Mohammad Al-Baijatyrdgcgf5664No ratings yet

- Modulus of Rupture in Bending of Electrode Graphite: Standard Test Method ForDocument3 pagesModulus of Rupture in Bending of Electrode Graphite: Standard Test Method Formohammed ;arasnehNo ratings yet

- Project PresentationDocument39 pagesProject PresentationSajjad Qadir BalochNo ratings yet

- Tristan Larson Flexural Analysis of Reinforced Concrete Beams WorkshopDocument16 pagesTristan Larson Flexural Analysis of Reinforced Concrete Beams WorkshopSalam AbdulNo ratings yet

- Carbon Fibre Retrofitting BeamDocument8 pagesCarbon Fibre Retrofitting BeamMukul DasNo ratings yet

- C 203 - 99 - QziwmwDocument6 pagesC 203 - 99 - QziwmwElvis Lionel FLORES ROCANo ratings yet

- Experimental Investigation of Concrete Breakout Strength of Anchor in Tension Within Fiber Reinforced ConcreteDocument63 pagesExperimental Investigation of Concrete Breakout Strength of Anchor in Tension Within Fiber Reinforced ConcreteMaurício FerreiraNo ratings yet

- Monolithic "Unibody" Light-Frame Structures: An Integrated Solution For Multi-Hazard Mitigation and Building Energy EnhancementDocument14 pagesMonolithic "Unibody" Light-Frame Structures: An Integrated Solution For Multi-Hazard Mitigation and Building Energy Enhancementvrb126No ratings yet

- Effective Length Concepts For Flexural Member DesignDocument4 pagesEffective Length Concepts For Flexural Member DesignInternational Journal of Innovative Science and Research Technology100% (1)

- Characterization of Aegle Marmelos Fiber Reinforced CompositesDocument17 pagesCharacterization of Aegle Marmelos Fiber Reinforced CompositesDino SinghNo ratings yet

- Construction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosDocument7 pagesConstruction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosAhmad MuhammadNo ratings yet

- Resources: The Potential Use of Oyster Shell Waste in New Value-Added By-ProductDocument15 pagesResources: The Potential Use of Oyster Shell Waste in New Value-Added By-ProductValerie LicuananNo ratings yet

- Experiment No. 9 Flexural Strength of Concrete: Name: Anthony Alexander E. de Los Reyes RatingDocument4 pagesExperiment No. 9 Flexural Strength of Concrete: Name: Anthony Alexander E. de Los Reyes RatingDe Los Reyes AndreyNo ratings yet

- Astm C1399 - 103Document6 pagesAstm C1399 - 103ricardoNo ratings yet

- Is 516 Part 1 Section 1Document19 pagesIs 516 Part 1 Section 1devendra choudhary80% (5)

- Course OutlineDocument1 pageCourse OutlineTyn MaturanNo ratings yet

- ASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsDocument1 pageASTM D 790 - 17 Standard Test Methods For Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating MaterialsGustavoNo ratings yet

- Bending Test LAB 1Document10 pagesBending Test LAB 1Iqmal Danieal100% (1)

- Astm C 615-2018Document2 pagesAstm C 615-2018Mohammed AliNo ratings yet

- Reinforced Concrete DesignDocument20 pagesReinforced Concrete DesignIvan Miranda AbadejosNo ratings yet

- A Review On Partial Replacement of Coarse Aggregate With Coconut Shell in The ConcreteDocument11 pagesA Review On Partial Replacement of Coarse Aggregate With Coconut Shell in The ConcreteGelo LibanNo ratings yet

- 10.1007@978 981 13 6019 03 PDFDocument17 pages10.1007@978 981 13 6019 03 PDFkkonthenetNo ratings yet

- AASHTO T97 (2018) - Flexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Document8 pagesAASHTO T97 (2018) - Flexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Ernesto Oscar VidelaNo ratings yet

- 3 Flexural CFRPDocument110 pages3 Flexural CFRPMohammed SohelNo ratings yet

- Can Bamboo Replace Steel As ReinforcemenDocument6 pagesCan Bamboo Replace Steel As ReinforcemenTesfayeNo ratings yet