Professional Documents

Culture Documents

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Uploaded by

Kamrul HasanCopyright:

Available Formats

You might also like

- Process Calculations - 1 MLD - SBRDocument164 pagesProcess Calculations - 1 MLD - SBRRAJ100% (8)

- JAR TEST Lab ReportDocument12 pagesJAR TEST Lab ReportAmirulizwan Azamri29% (7)

- Study of Water Quality at Sungai Mengkibol, Kluang, JohoreDocument12 pagesStudy of Water Quality at Sungai Mengkibol, Kluang, JohoreInahMisumiNo ratings yet

- Lecture - 1 Components of Sewage Collection SystemDocument19 pagesLecture - 1 Components of Sewage Collection SystemDanial Abid100% (1)

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- MARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Document1 pageMARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Oleksandr ShcherbynaNo ratings yet

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- 02.plan de Amplasare PDFDocument1 page02.plan de Amplasare PDFPopa SergiuNo ratings yet

- Preliminary Stowage Plan MV Beautrident - Rev.10.03.2022Document1 pagePreliminary Stowage Plan MV Beautrident - Rev.10.03.2022Oleksandr ShcherbynaNo ratings yet

- To Control Unit OCS, See Circuit Diagram 2081507Document1 pageTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNo ratings yet

- 9971-1120 All eDocument3 pages9971-1120 All emohamad eslamiNo ratings yet

- BWV 1068Document2 pagesBWV 1068Jakub OlszewskiNo ratings yet

- Isha Asbuild Equipment Layout 1 ST Floor - Rev-11Document1 pageIsha Asbuild Equipment Layout 1 ST Floor - Rev-11Harsh ShahNo ratings yet

- Shifting Bottleneck Procedure For Job Shop SchedulingDocument8 pagesShifting Bottleneck Procedure For Job Shop SchedulingJonas OliveiraNo ratings yet

- Wiring Genset Without Box Tier 4B B 13 No 20Document1 pageWiring Genset Without Box Tier 4B B 13 No 20cesar saavedra saavedraNo ratings yet

- Tegy 05 10007 0002 - 4Document1 pageTegy 05 10007 0002 - 4aryo ganda pakpahanNo ratings yet

- Auxiliary SLD MCRDocument1 pageAuxiliary SLD MCRVamsi Manoj0% (1)

- CC TV: To Floor PL-1150 PL-1150Document1 pageCC TV: To Floor PL-1150 PL-1150Anonymous dqH2vXNo ratings yet

- Planos 9978Document34 pagesPlanos 9978Omar50% (2)

- 07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupDocument1 page07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupSami DominguezNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Super Mario Bros USA Overworld Theme in RagtimeDocument2 pagesSuper Mario Bros USA Overworld Theme in RagtimeGloria SequeiraNo ratings yet

- A Thousand Years - Christina Perri From The Twilight SagaDocument6 pagesA Thousand Years - Christina Perri From The Twilight SagaKaterina GalatouNo ratings yet

- Ira6000 8000 Series-CdDocument427 pagesIra6000 8000 Series-Cdluongnam100% (1)

- 05 624000 4800000700 Asb Civ DRG 000015 - 01Document1 page05 624000 4800000700 Asb Civ DRG 000015 - 01Arafat BauntoNo ratings yet

- Baritos UnoDocument2 pagesBaritos UnocarlosNo ratings yet

- Section SK014Document1 pageSection SK014abdul jackilNo ratings yet

- Transceiver: RF AntDocument8 pagesTransceiver: RF AntAnisa SripianaNo ratings yet

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Jacques Champion de Chambonnières - Suite en La - Premier LivreDocument7 pagesJacques Champion de Chambonnières - Suite en La - Premier LivreMinhDuckNo ratings yet

- Circuit-Diagram-MP5 PLAYERDocument1 pageCircuit-Diagram-MP5 PLAYERDevi HihuhNo ratings yet

- Lip SlursDocument2 pagesLip SlursBrady NeeseNo ratings yet

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 pagesFur Elise: Clavierstuck in A Minor - Woo 59LUZNo ratings yet

- Para Elisa PianoDocument4 pagesPara Elisa PianoLUZNo ratings yet

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 pagesFur Elise: Clavierstuck in A Minor - Woo 59marioNo ratings yet

- Msi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aDocument66 pagesMsi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aВладимир МазурNo ratings yet

- 14 621830 4800000771 Hac Ele DRG 300522 - BDocument1 page14 621830 4800000771 Hac Ele DRG 300522 - BAhmed MorsyNo ratings yet

- PHQ519 PCB DiagramDocument9 pagesPHQ519 PCB DiagramncirNo ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- 2021 PISD AttendanceZone MapDocument2 pages2021 PISD AttendanceZone MapAngela Vargas GudiñoNo ratings yet

- Chopin Etude Op.10 No. 4 C Minor"Torrent": Presto (Document8 pagesChopin Etude Op.10 No. 4 C Minor"Torrent": Presto (Justus HellwegNo ratings yet

- RTA System MapDocument2 pagesRTA System MapMorNo ratings yet

- Refer To Building 5 Package: For ConstructionDocument1 pageRefer To Building 5 Package: For ConstructionjanNo ratings yet

- Cimentación: RevisionesDocument1 pageCimentación: Revisionesjose Tello GonzalesNo ratings yet

- Analisi Triadi E Rivolti: Esercizio 2Document2 pagesAnalisi Triadi E Rivolti: Esercizio 2televisioneNo ratings yet

- TPD MS338 PC799Document14 pagesTPD MS338 PC799José SoeiroNo ratings yet

- Zoning Rev1 25-Aug-20Document1 pageZoning Rev1 25-Aug-20ahmed yaqoobNo ratings yet

- Bach Organ SoloDocument5 pagesBach Organ SoloCarmine RiccoNo ratings yet

- UntitledDocument359 pagesUntitledAfan AhmedNo ratings yet

- Mte MBL-9000Document1 pageMte MBL-9000Francisco Sanabria Najera100% (7)

- K710a V2.0 SCH+Document10 pagesK710a V2.0 SCH+coliuntung02No ratings yet

- Arquitectura Rolando Final 2Document1 pageArquitectura Rolando Final 2Jhordan VizalayaNo ratings yet

- 21001-EA-ECD-001-01 - AC Single Line Diagram-SignedDocument4 pages21001-EA-ECD-001-01 - AC Single Line Diagram-SignedRamesh NNo ratings yet

- Schematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Document10 pagesSchematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Riza VirsadaNo ratings yet

- Plano Esquemático Huawei Y320Document9 pagesPlano Esquemático Huawei Y320Gonzalo CastañedaNo ratings yet

- Burgmuller Etude: L'OrageDocument3 pagesBurgmuller Etude: L'Oragealberto loiNo ratings yet

- Tokim-Panompoana: AmpifitiaDocument4 pagesTokim-Panompoana: AmpifitiaHosea RandNo ratings yet

- Simulation & ModellingDocument9 pagesSimulation & ModellinghanidanorazlanNo ratings yet

- Homeostasis: A State of Balance in The BodyDocument9 pagesHomeostasis: A State of Balance in The BodyhanidanorazlanNo ratings yet

- S S S Shopping For Food Hopping For Food Hopping For Food Hopping For FoodDocument6 pagesS S S Shopping For Food Hopping For Food Hopping For Food Hopping For FoodNabil BkimalNo ratings yet

- 鋼琴ver1Document3 pages鋼琴ver1chiochiiooNo ratings yet

- Math Workshop, Grade 3: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade 3: A Framework for Guided Math and Independent PracticeNo ratings yet

- Pelton Turbine Question AnswerDocument8 pagesPelton Turbine Question AnswerKamrul HasanNo ratings yet

- Innovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraDocument51 pagesInnovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraKamrul HasanNo ratings yet

- Nature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Document34 pagesNature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Kamrul HasanNo ratings yet

- How Does Francis Turbine Work ?: Runner - at The Heart of The SystemDocument3 pagesHow Does Francis Turbine Work ?: Runner - at The Heart of The SystemKamrul HasanNo ratings yet

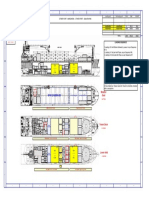

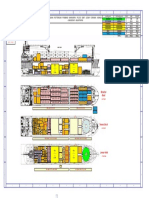

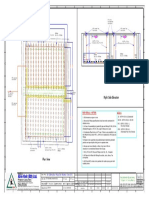

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- Suitability of Pelton, Francis and Kaplan TurbinesDocument2 pagesSuitability of Pelton, Francis and Kaplan TurbinesKamrul HasanNo ratings yet

- About Ice DetailsDocument10 pagesAbout Ice DetailsKamrul HasanNo ratings yet

- How Different Type of Losses Affect in Centrifugal Pump Frictional LossDocument3 pagesHow Different Type of Losses Affect in Centrifugal Pump Frictional LossKamrul HasanNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

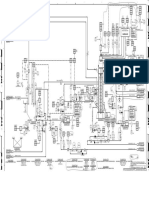

- Alim Knit (BD) LTD.: Process Flow Diagram For EtpDocument1 pageAlim Knit (BD) LTD.: Process Flow Diagram For EtpKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: General NotesDocument1 pageAlim Knit (BD) LTD.: General NotesKamrul HasanNo ratings yet

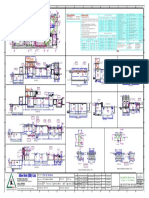

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/dayDocument1 pageAlim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/dayKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- Mechanical Engineering Interview Questions With AnswersDocument25 pagesMechanical Engineering Interview Questions With AnswersKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan & SectionsDocument1 pageAlim Knit (BD) LTD.: Plan & SectionsKamrul HasanNo ratings yet

- Bio-Regen Ammonia RemovalDocument6 pagesBio-Regen Ammonia RemovalMuna AzizNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel990No ratings yet

- MMG Wastewater ManagementDocument376 pagesMMG Wastewater ManagementIndrasis DasNo ratings yet

- Slaughterhouse Wastewater Treatment ManagementDocument23 pagesSlaughterhouse Wastewater Treatment ManagementOc WilliamNo ratings yet

- Jurusan Kesehatan Lingkungan Poltekkes Kemenkes ManadoDocument7 pagesJurusan Kesehatan Lingkungan Poltekkes Kemenkes ManadoNova RizkenNo ratings yet

- Piñon-Colin Et Al. - 2020 - Microplastics in Stormwater Runoff in A Semiarid RDocument30 pagesPiñon-Colin Et Al. - 2020 - Microplastics in Stormwater Runoff in A Semiarid RStephanie Elizabeth Medina PonceNo ratings yet

- Treatment of An Anodizing Waste To Water Quality-Based Effluent LimitsDocument6 pagesTreatment of An Anodizing Waste To Water Quality-Based Effluent LimitsbaneNo ratings yet

- Master Plumber Reviewer: Wastewater TreatmentDocument55 pagesMaster Plumber Reviewer: Wastewater Treatmenthermano balbonNo ratings yet

- Virtual Visit Report ABIDALI MANER 21Document11 pagesVirtual Visit Report ABIDALI MANER 21Abid Maner0% (1)

- Biochemical Oxygen Demand (BOD)Document17 pagesBiochemical Oxygen Demand (BOD)Pinku KhanNo ratings yet

- TDS Terrafloc 7444Document2 pagesTDS Terrafloc 7444Danang HidayatNo ratings yet

- Irjet V6i2264Document4 pagesIrjet V6i2264Broken AngelNo ratings yet

- Solutions For Water PollutionDocument9 pagesSolutions For Water Pollutionvisukonidela100% (1)

- Industrial Wastewater ManagementDocument41 pagesIndustrial Wastewater ManagementAshhad ShafiqueNo ratings yet

- Creating Mini Wastewater Treatment PlantsDocument11 pagesCreating Mini Wastewater Treatment PlantsAnne Maureen MasangcayNo ratings yet

- Mepc 227 64 STP TestingDocument3 pagesMepc 227 64 STP TestingSethu RajNo ratings yet

- Mixed Liquor Suspended SolidsDocument4 pagesMixed Liquor Suspended SolidsNorizam AyobNo ratings yet

- OK Topic 2 Biological Treatment of WastewaterDocument168 pagesOK Topic 2 Biological Treatment of WastewaterPriyatno JuniantoNo ratings yet

- Brewery Wastewater Treatment Guide: Treat Your Wastewater OnsiteDocument14 pagesBrewery Wastewater Treatment Guide: Treat Your Wastewater OnsiteAA0809No ratings yet

- Pengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDocument7 pagesPengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDwi BintangNo ratings yet

- Sanitation Initiatives of Muntinlupa City by Jet PabiloniaDocument40 pagesSanitation Initiatives of Muntinlupa City by Jet PabiloniaThe Outer Marker100% (1)

- Air Bersih, IPA, Rapid Sand Filter, Design CalculationDocument15 pagesAir Bersih, IPA, Rapid Sand Filter, Design CalculationAndrizal KotoNo ratings yet

- Lab Water 1 ResultsDocument9 pagesLab Water 1 ResultsKhaiiiNo ratings yet

- Water QualityDocument53 pagesWater QualityanonNo ratings yet

- Wastewater TreatmentDocument28 pagesWastewater TreatmentDevie S. IgnacioNo ratings yet

- Advantages of CETPDocument1 pageAdvantages of CETPCharan ReddyNo ratings yet

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Uploaded by

Kamrul HasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Alim Knit (BD) LTD.: Recommended Process & Hydraulic Flow Diagram

Uploaded by

Kamrul HasanCopyright:

Available Formats

1 2 3 4 5 6 7 8

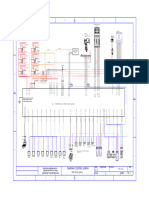

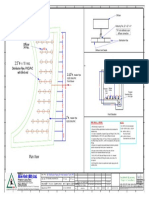

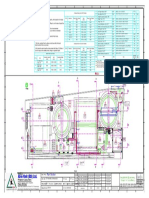

Plant Average Capacity: 45 m3/hr 1. From the jar test of AKBL effluent sample, it is found that the optimum process FM Flow Meter

A Plant Peak Capacity: 50 m3/hr for this dyeing effluent is "appropriate & effective physico-chemical process A

followed by efficient biological process". So, the process has been selected G Gravity Flow

Plant Operating Time: 22 hr/day

accordingly.

Dosing Pump

2. It is to be noted that TDS value of effluent can't be reduced by ETP, eventually DP

TDS will be increased in ETP. So, it is strongly recommended to minimize TDS

within 1500 ppm by optimization of dyeing process. M

Centrifugal Pump

ML Mixed Liquor

B Effluent B

Chemical Solution

Fresh Water

ML

Service Water

Line from WTP FeSO4/ H2SO4 Nutrient 1 Nutrient 2 Poly- Air

G LIME G G PAM G NaOH G G G G

Hydroflock electrolite

Air Air Air Air Air HRT = Hydraulic Retention Time in Hour

G G G G G G G G SOR = Surface Overflow Rate

C Bottom of Tank +6120

Solution Solution Solution Solution Solution Solution Solution Solution

C

Prep. Prep. Prep. Prep. Prep. Prep. Prep. Prep. To

Tank Tank Tank Tank Tank Tank Tank Tank Sludge De-watering

Bottom of Tank +3720 System

Air Service Air Service Air Service Service Service Air Service Air Service

DP DP Service DP DP DP DP

Tank Tank Tank Tank Tank Tank Tank

Tank

D D

LL +3800

Auto pH

Correction

Agitator

(120 ~ 140 rpm)

Agitator

(10 ~ 30 rpm)

LL +5580

Dyeing Process

Contact Stabilization Tank

E G

FM

G LL +4370

Capacity: 50 m3

E

G

Sample Printing

LL +3310

G

Roughing Filter LL +2000

G LL +3000

G LL +2650

Coagulation Tank G LL +2150 FM G

Flocculation Tank

HRT: 1.2 Min. M FM

HRT: 12 Min. G Ready to

Capacity: 1 m3 LL +1850

Capacity: 10 m3 use for

Discharge

FM M

Coarse Fine

Screen Screen

FGL ±0.0 FGL ±0.0

LL -600

G Filter Feed Tank Filter

LL -860 Feed Pump Iron Multi Activated Post Aeration Tank

Secondary HRT: 24 min. Removing Grade Carbon

Primary Clarifier Neutralization Tank Aeration Tank Capacity: 20 m3 HRT: 1 Hr

F Effluent Collection Channel

ML

G

Capacity: 136 m3

HRT: 2.7 Hr

HRT: 1 Hr

Capacity: 50 m3

HRT: 12 Hr

Capacity: 600 m3 ML

G

Clarifier

HRT: 2.6 Hr

Filter Filter Filter Capacity: 50 m3 F

SOR: 1.29 m/hr Capacity: 128 m3

SOR: 1.0 m/hr

Clear Water Tank

Capacity: 50 m3

Equalization Tank

HRT: 8 Hr

Capacity: 400 m3

1 2

LL +1800 Air Air

G LL +1400

G

Solids Mass Sludge De-watering System

(Re-use) (Screw Press)

G

FGL ±0.0 FGL ±0.0

Blower Blower

Filtrate

To

Equalization Sludge Collection Tank

Tank Capacity: 10 m3

CLIENT:

H

Alim Knit (BD) Ltd.

Project Location:

DWG. TITLE: RECOMMENDED PROCESS & HYDRAULIC FLOW DIAGRAM

DWG. NO.:ETP 50-AKBL-01-P&HFD/R0 SCALE: NTS SHEET: A3

H

C:\Users\Jahid\Pictures\Alim logo.jpg

Kashimpur, Nayapara, Gazipur, Bangladesh.

O : PROJECT: Engr. Jahid Abedin Engr. Shohely Sarker Dr. Tarekh Rasul 05/06/2018

1st Floor, R#12, H#11, Niketan, Gulshan, Dhaka-1212, Bangladesh

Siaam Tower (Level9th 10th), Plot No # 15,117, Mymensingh Mobile: 01882 433 779, 01841 160101, Email: bedc.bd@gmail.com

PROJECT NO.:ETP-04 START DATE: 30/04/2018 REV. DESCRIPTION DRAWN CHECKED APPROVED DATE SIGNATURE WITH SEAL THIS DRAWING AND ALL INFORMATION CONTAINED HERE ON IS THE PROPERTY OF BEDC. MUST NOT BE COPIED OR

Road, Sector #3, Uttara Model Town Dhaka-1230, Bangladesh. REPRODUCED WITHOUT WRITTEN CONSENT.

1 2 3 4 5 6 7 8

You might also like

- Process Calculations - 1 MLD - SBRDocument164 pagesProcess Calculations - 1 MLD - SBRRAJ100% (8)

- JAR TEST Lab ReportDocument12 pagesJAR TEST Lab ReportAmirulizwan Azamri29% (7)

- Study of Water Quality at Sungai Mengkibol, Kluang, JohoreDocument12 pagesStudy of Water Quality at Sungai Mengkibol, Kluang, JohoreInahMisumiNo ratings yet

- Lecture - 1 Components of Sewage Collection SystemDocument19 pagesLecture - 1 Components of Sewage Collection SystemDanial Abid100% (1)

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- MARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Document1 pageMARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Oleksandr ShcherbynaNo ratings yet

- PID Turbcompr Desc1raEtapaDocument1 pagePID Turbcompr Desc1raEtapaJholman SanchezNo ratings yet

- 02.plan de Amplasare PDFDocument1 page02.plan de Amplasare PDFPopa SergiuNo ratings yet

- Preliminary Stowage Plan MV Beautrident - Rev.10.03.2022Document1 pagePreliminary Stowage Plan MV Beautrident - Rev.10.03.2022Oleksandr ShcherbynaNo ratings yet

- To Control Unit OCS, See Circuit Diagram 2081507Document1 pageTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNo ratings yet

- 9971-1120 All eDocument3 pages9971-1120 All emohamad eslamiNo ratings yet

- BWV 1068Document2 pagesBWV 1068Jakub OlszewskiNo ratings yet

- Isha Asbuild Equipment Layout 1 ST Floor - Rev-11Document1 pageIsha Asbuild Equipment Layout 1 ST Floor - Rev-11Harsh ShahNo ratings yet

- Shifting Bottleneck Procedure For Job Shop SchedulingDocument8 pagesShifting Bottleneck Procedure For Job Shop SchedulingJonas OliveiraNo ratings yet

- Wiring Genset Without Box Tier 4B B 13 No 20Document1 pageWiring Genset Without Box Tier 4B B 13 No 20cesar saavedra saavedraNo ratings yet

- Tegy 05 10007 0002 - 4Document1 pageTegy 05 10007 0002 - 4aryo ganda pakpahanNo ratings yet

- Auxiliary SLD MCRDocument1 pageAuxiliary SLD MCRVamsi Manoj0% (1)

- CC TV: To Floor PL-1150 PL-1150Document1 pageCC TV: To Floor PL-1150 PL-1150Anonymous dqH2vXNo ratings yet

- Planos 9978Document34 pagesPlanos 9978Omar50% (2)

- 07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupDocument1 page07-H-501 - Diagrama de Sistema Hvac - 1 - Hvac System Diagram Rev.5 MarkupSami DominguezNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Super Mario Bros USA Overworld Theme in RagtimeDocument2 pagesSuper Mario Bros USA Overworld Theme in RagtimeGloria SequeiraNo ratings yet

- A Thousand Years - Christina Perri From The Twilight SagaDocument6 pagesA Thousand Years - Christina Perri From The Twilight SagaKaterina GalatouNo ratings yet

- Ira6000 8000 Series-CdDocument427 pagesIra6000 8000 Series-Cdluongnam100% (1)

- 05 624000 4800000700 Asb Civ DRG 000015 - 01Document1 page05 624000 4800000700 Asb Civ DRG 000015 - 01Arafat BauntoNo ratings yet

- Baritos UnoDocument2 pagesBaritos UnocarlosNo ratings yet

- Section SK014Document1 pageSection SK014abdul jackilNo ratings yet

- Transceiver: RF AntDocument8 pagesTransceiver: RF AntAnisa SripianaNo ratings yet

- Coo 4Document1 pageCoo 4Jok PrasNo ratings yet

- Jacques Champion de Chambonnières - Suite en La - Premier LivreDocument7 pagesJacques Champion de Chambonnières - Suite en La - Premier LivreMinhDuckNo ratings yet

- Circuit-Diagram-MP5 PLAYERDocument1 pageCircuit-Diagram-MP5 PLAYERDevi HihuhNo ratings yet

- Lip SlursDocument2 pagesLip SlursBrady NeeseNo ratings yet

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 pagesFur Elise: Clavierstuck in A Minor - Woo 59LUZNo ratings yet

- Para Elisa PianoDocument4 pagesPara Elisa PianoLUZNo ratings yet

- Fur Elise: Clavierstuck in A Minor - Woo 59Document4 pagesFur Elise: Clavierstuck in A Minor - Woo 59marioNo ratings yet

- Msi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aDocument66 pagesMsi Gs63 7re Stealth Pro Ms-16k4 Ms-17b4 0aВладимир МазурNo ratings yet

- 14 621830 4800000771 Hac Ele DRG 300522 - BDocument1 page14 621830 4800000771 Hac Ele DRG 300522 - BAhmed MorsyNo ratings yet

- PHQ519 PCB DiagramDocument9 pagesPHQ519 PCB DiagramncirNo ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- 2021 PISD AttendanceZone MapDocument2 pages2021 PISD AttendanceZone MapAngela Vargas GudiñoNo ratings yet

- Chopin Etude Op.10 No. 4 C Minor"Torrent": Presto (Document8 pagesChopin Etude Op.10 No. 4 C Minor"Torrent": Presto (Justus HellwegNo ratings yet

- RTA System MapDocument2 pagesRTA System MapMorNo ratings yet

- Refer To Building 5 Package: For ConstructionDocument1 pageRefer To Building 5 Package: For ConstructionjanNo ratings yet

- Cimentación: RevisionesDocument1 pageCimentación: Revisionesjose Tello GonzalesNo ratings yet

- Analisi Triadi E Rivolti: Esercizio 2Document2 pagesAnalisi Triadi E Rivolti: Esercizio 2televisioneNo ratings yet

- TPD MS338 PC799Document14 pagesTPD MS338 PC799José SoeiroNo ratings yet

- Zoning Rev1 25-Aug-20Document1 pageZoning Rev1 25-Aug-20ahmed yaqoobNo ratings yet

- Bach Organ SoloDocument5 pagesBach Organ SoloCarmine RiccoNo ratings yet

- UntitledDocument359 pagesUntitledAfan AhmedNo ratings yet

- Mte MBL-9000Document1 pageMte MBL-9000Francisco Sanabria Najera100% (7)

- K710a V2.0 SCH+Document10 pagesK710a V2.0 SCH+coliuntung02No ratings yet

- Arquitectura Rolando Final 2Document1 pageArquitectura Rolando Final 2Jhordan VizalayaNo ratings yet

- 21001-EA-ECD-001-01 - AC Single Line Diagram-SignedDocument4 pages21001-EA-ECD-001-01 - AC Single Line Diagram-SignedRamesh NNo ratings yet

- Schematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Document10 pagesSchematic Diagram of P300 - 4800105M301 - P3 - V1 - 20130123Riza VirsadaNo ratings yet

- Plano Esquemático Huawei Y320Document9 pagesPlano Esquemático Huawei Y320Gonzalo CastañedaNo ratings yet

- Burgmuller Etude: L'OrageDocument3 pagesBurgmuller Etude: L'Oragealberto loiNo ratings yet

- Tokim-Panompoana: AmpifitiaDocument4 pagesTokim-Panompoana: AmpifitiaHosea RandNo ratings yet

- Simulation & ModellingDocument9 pagesSimulation & ModellinghanidanorazlanNo ratings yet

- Homeostasis: A State of Balance in The BodyDocument9 pagesHomeostasis: A State of Balance in The BodyhanidanorazlanNo ratings yet

- S S S Shopping For Food Hopping For Food Hopping For Food Hopping For FoodDocument6 pagesS S S Shopping For Food Hopping For Food Hopping For Food Hopping For FoodNabil BkimalNo ratings yet

- 鋼琴ver1Document3 pages鋼琴ver1chiochiiooNo ratings yet

- Math Workshop, Grade 3: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade 3: A Framework for Guided Math and Independent PracticeNo ratings yet

- Pelton Turbine Question AnswerDocument8 pagesPelton Turbine Question AnswerKamrul HasanNo ratings yet

- Innovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraDocument51 pagesInnovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraKamrul HasanNo ratings yet

- Nature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Document34 pagesNature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Kamrul HasanNo ratings yet

- How Does Francis Turbine Work ?: Runner - at The Heart of The SystemDocument3 pagesHow Does Francis Turbine Work ?: Runner - at The Heart of The SystemKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- Suitability of Pelton, Francis and Kaplan TurbinesDocument2 pagesSuitability of Pelton, Francis and Kaplan TurbinesKamrul HasanNo ratings yet

- About Ice DetailsDocument10 pagesAbout Ice DetailsKamrul HasanNo ratings yet

- How Different Type of Losses Affect in Centrifugal Pump Frictional LossDocument3 pagesHow Different Type of Losses Affect in Centrifugal Pump Frictional LossKamrul HasanNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Process Flow Diagram For EtpDocument1 pageAlim Knit (BD) LTD.: Process Flow Diagram For EtpKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: General NotesDocument1 pageAlim Knit (BD) LTD.: General NotesKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/dayDocument1 pageAlim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/dayKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- Mechanical Engineering Interview Questions With AnswersDocument25 pagesMechanical Engineering Interview Questions With AnswersKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan & SectionsDocument1 pageAlim Knit (BD) LTD.: Plan & SectionsKamrul HasanNo ratings yet

- Bio-Regen Ammonia RemovalDocument6 pagesBio-Regen Ammonia RemovalMuna AzizNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel990No ratings yet

- MMG Wastewater ManagementDocument376 pagesMMG Wastewater ManagementIndrasis DasNo ratings yet

- Slaughterhouse Wastewater Treatment ManagementDocument23 pagesSlaughterhouse Wastewater Treatment ManagementOc WilliamNo ratings yet

- Jurusan Kesehatan Lingkungan Poltekkes Kemenkes ManadoDocument7 pagesJurusan Kesehatan Lingkungan Poltekkes Kemenkes ManadoNova RizkenNo ratings yet

- Piñon-Colin Et Al. - 2020 - Microplastics in Stormwater Runoff in A Semiarid RDocument30 pagesPiñon-Colin Et Al. - 2020 - Microplastics in Stormwater Runoff in A Semiarid RStephanie Elizabeth Medina PonceNo ratings yet

- Treatment of An Anodizing Waste To Water Quality-Based Effluent LimitsDocument6 pagesTreatment of An Anodizing Waste To Water Quality-Based Effluent LimitsbaneNo ratings yet

- Master Plumber Reviewer: Wastewater TreatmentDocument55 pagesMaster Plumber Reviewer: Wastewater Treatmenthermano balbonNo ratings yet

- Virtual Visit Report ABIDALI MANER 21Document11 pagesVirtual Visit Report ABIDALI MANER 21Abid Maner0% (1)

- Biochemical Oxygen Demand (BOD)Document17 pagesBiochemical Oxygen Demand (BOD)Pinku KhanNo ratings yet

- TDS Terrafloc 7444Document2 pagesTDS Terrafloc 7444Danang HidayatNo ratings yet

- Irjet V6i2264Document4 pagesIrjet V6i2264Broken AngelNo ratings yet

- Solutions For Water PollutionDocument9 pagesSolutions For Water Pollutionvisukonidela100% (1)

- Industrial Wastewater ManagementDocument41 pagesIndustrial Wastewater ManagementAshhad ShafiqueNo ratings yet

- Creating Mini Wastewater Treatment PlantsDocument11 pagesCreating Mini Wastewater Treatment PlantsAnne Maureen MasangcayNo ratings yet

- Mepc 227 64 STP TestingDocument3 pagesMepc 227 64 STP TestingSethu RajNo ratings yet

- Mixed Liquor Suspended SolidsDocument4 pagesMixed Liquor Suspended SolidsNorizam AyobNo ratings yet

- OK Topic 2 Biological Treatment of WastewaterDocument168 pagesOK Topic 2 Biological Treatment of WastewaterPriyatno JuniantoNo ratings yet

- Brewery Wastewater Treatment Guide: Treat Your Wastewater OnsiteDocument14 pagesBrewery Wastewater Treatment Guide: Treat Your Wastewater OnsiteAA0809No ratings yet

- Pengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDocument7 pagesPengaruh Tekanan Transmembran Dan Konsentrasi Chemical Limbah Laundry Dengan Membran Ultrafiltrasi AliranDwi BintangNo ratings yet

- Sanitation Initiatives of Muntinlupa City by Jet PabiloniaDocument40 pagesSanitation Initiatives of Muntinlupa City by Jet PabiloniaThe Outer Marker100% (1)

- Air Bersih, IPA, Rapid Sand Filter, Design CalculationDocument15 pagesAir Bersih, IPA, Rapid Sand Filter, Design CalculationAndrizal KotoNo ratings yet

- Lab Water 1 ResultsDocument9 pagesLab Water 1 ResultsKhaiiiNo ratings yet

- Water QualityDocument53 pagesWater QualityanonNo ratings yet

- Wastewater TreatmentDocument28 pagesWastewater TreatmentDevie S. IgnacioNo ratings yet

- Advantages of CETPDocument1 pageAdvantages of CETPCharan ReddyNo ratings yet