Professional Documents

Culture Documents

Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During Construction

Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During Construction

Uploaded by

Mahmoud AlwasifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During Construction

Storage of Materials: Engineering Encyclopedia Project Management Managing Materials During Construction

Uploaded by

Mahmoud AlwasifCopyright:

Available Formats

Engineering Encyclopedia Project Management

Managing Materials During Construction

• A Place to Work

In order to have the correct material available when needed, the material must arrive at jobsite, be

inspected and protected, stored where it can be found, issued to the right person, and used where

it was intended. Field material control encompasses the remaining steps from receipt to end use.

The construction warehouse/storage function is responsible for material control from receipt to

issue.

Storage of Materials

With materials representing over 40% of the costs of a typical project the proper handling and

storage can impact the success of the project. The Project Engineer should pay particular

attention to the maintenance and record keeping associated with the storage of materials at the

jobsite. Remember, it is just as important to keep the incorrect material out of the project, as it is

to get the correct material into the project.

Maintenance

The proper maintenance of project materials not only prior to being installed but prior to the on-

stream date are important to assuring the material will function properly when required to do so.

Protective maintenance should be continued after release from warehouse control and when

material or equipment is installed in the final location. Following is a list of items which the

Project Engineer will want to become familiar with.

• Materials should be kept off the ground on pallets, sleepers, dunnage, temporary

concrete slabs, etc.

• Materials should be covered (as required) by tarpaulins, plastic sheets, temporary

shelters, etc. Delicate items such as electronics should be placed in inside dry

storage.

• Machined or metallic surfaces should be protected by rust preventative. The

vendors’ recommendations should be followed.

• Lube oil in machinery should be checked periodically for level and cleanliness.

• Large shafts in rotating equipment should be rotated periodically.

• Instruments and electrical equipment should be stored inside.

• Piping should be capped to keep out dirt and debris and to protect ends.

• Flange surfaces should be protected by wooden discs.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Project Management

Managing Materials During Construction

• Paints and other highly flammable materials should be kept in segregated storage

and at safe distance. Responsible personnel must be clearly designated and

reporting requirements established.

Record Keeping

Job Procedure should cover protective maintenance of materials and equipment at the jobsite from

time of receipt until such materials or equipment are turned over ready for commissioning.

Protection includes protection from weather, environment, physical damage and any other

potential damage or deterioration. Periodic inspections should be made of materials in open

storage.

Accurate records must be kept to record the acceptance and issue of materials from the jobsite

storage area to the jobsite. The loss of almost any item can jeopardize the completion of the

project. Objectives of field material record keeping are:

To know at all times:

• What material has been received at site

• That the materials at the site are properly stored

• When the materials are scheduled for installation

• That the material can be easily retrieved from storage

• That bulk commodity materials are pre-packaged for issue

• That claims are filed promptly for items damaged in shipment or shortages in

shipments

• What shortages and surpluses are ordered and their arrival

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Project Management

Managing Materials During Construction

ISSUES RELATED TO MANAGING PROJECT SURPLUS AND EXCESS MATERIALS

Introduction

A well executed project should have no more than 3% or 4% material surplus or excess at the end

of commissioning. Excessive materials which are surplus or excess are usually an indication of

unsatisfactory material control or significant late changes in the scope of work.

Procedures to Return Surplus Materials

New or good-as-new DC surplus material can be turned in to DC surplus inventory for full credit

by completing Form A-7287 provided the material:

• Is expected to have future use while remaining in new or good-as-new condition

until used; and

• Is not shown on the list “Materials not acceptable for DC surplus inventory”; and

• Consists of items with a line item value greater than $1,000.

Items with a line item value of $1,000 or less are transferred to Dhahran Reclamation Yard for no

credit by use of Form A-112 “Reclamation Receipt."

There are three exceptions to the above limitation of $1,000 or less value. They are:

• Portions of a major assembly which have already been accepted for DC surplus

inventory; or

• Spare parts (with adequate cross-reference data provided by SAPMT) for

engineered items which have already been accepted for DC surplus inventory; or

• Specialized fittings for items which have already been accepted for DC surplus

inventory.

Cannibalized/damaged material is turned in to DC surplus inventory for appraised credit provided:

1. Replacement parts are on order or are attached but not affixed; or

2. Repair/replacement of cannibalized/missing parts is undertaken by the user that

wants to return the material.

DC material which is not acceptable for turn-in to DC surplus inventory but is salable is

transferred to the Auction Yard with Form A-8764 “New or Good-as-New Material Disposition”

at appraised value, based on the return obtained on similar material at recent auctions.

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Project Management

Managing Materials During Construction

DC material with a line item value greater than $1,000 that is in new or good-as-new and

unsalable is transferred to Reclamation with Form A-8764 at zero value.

DC material with a line item value greater than $1,000 that is not new or good-as-new and

unsalable is transferred to Reclamation with Form A-112 at zero value.

Material that has been previously issued to users from DC surplus inventory is returned by users

for credit equal to the original issue cost. Users that want to return material to DC surplus

inventory must provide R&DCU with a copy of the original issue document.

Material which is no longer in new or good-as-new condition is not accepted for return but is

transferred to Reclamation with Form A-112 at zero value. Material which has been modified

after issue is rarely accepted for return to DC surplus inventory.

List of material which is specifically excluded from DC surplus inventory include:

• SAMS material

• Air conditioning equipment unless complete with all components; no parts

accepted

• Buildings (unless complete with all components)

• Chemicals and lubricants

• Coated/lined pipe (Surplus at the uncoated pipe price only)

• Construction camp equipment

• Electrical cable (as specified)

• Electric motors less than 10 h.p.

• Ferrous scrap

• Firebrick, insulation, and related cement

• Gas cylinders

• Gaskets

• Lumber, plywood, wallboard

Saudi Aramco DeskTop Standards 9

You might also like

- SITE AND WORKSHOP Notes - Docx-1Document32 pagesSITE AND WORKSHOP Notes - Docx-1Ren100% (5)

- Method of Statement Piping Fab. ErectionDocument22 pagesMethod of Statement Piping Fab. Erectionhasan_676489616100% (1)

- Method of Statement Material Handling, Preservation and StorageDocument8 pagesMethod of Statement Material Handling, Preservation and StoragefazalrehmanNo ratings yet

- Planning For Project Layout ReportDocument11 pagesPlanning For Project Layout ReportAko C Rence100% (2)

- Method Statement Material ManegementDocument10 pagesMethod Statement Material Manegementmangeshshinde124100% (1)

- Fast Retailing (UNIQLO)Document7 pagesFast Retailing (UNIQLO)KAR WAI PHOONNo ratings yet

- Engineering Encyclopedia Project Management Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia Project Management Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Re: Procurement & Material Storage: ProcedureDocument4 pagesRe: Procurement & Material Storage: ProcedureAkash Singh TomarNo ratings yet

- New DOC DocumentDocument5 pagesNew DOC DocumentHazrat AminNo ratings yet

- Aqeel CVDocument4 pagesAqeel CVZameel HarisNo ratings yet

- Method of Statement - Pa SystemDocument15 pagesMethod of Statement - Pa SystemashifNo ratings yet

- Method Statement of Split AC Units InstallationDocument12 pagesMethod Statement of Split AC Units InstallationMomen Ayassrh100% (1)

- Method of Statement MS.01 Clay Tiles Works: Revision HistoryDocument7 pagesMethod of Statement MS.01 Clay Tiles Works: Revision HistoryAhmed MohamedNo ratings yet

- SafetyDocument4 pagesSafetyHazrat AminNo ratings yet

- Equipment and Materials Managementj 1751-2824 2008 00202Document6 pagesEquipment and Materials Managementj 1751-2824 2008 00202iishunasevelinaNo ratings yet

- TKS 4155 Perancangan Pabrik: General Site ConsiderationsDocument35 pagesTKS 4155 Perancangan Pabrik: General Site ConsiderationsDavid BonjolNo ratings yet

- WMS For Installation of Panel BRD & Capacitor BNKDocument9 pagesWMS For Installation of Panel BRD & Capacitor BNKShahed HussainNo ratings yet

- Method of Statement MS.01 Clay Tiles Works: Revision HistoryDocument6 pagesMethod of Statement MS.01 Clay Tiles Works: Revision HistoryAhmed MohamedNo ratings yet

- Site Layout, Administrative Area and Construction Area-1Document23 pagesSite Layout, Administrative Area and Construction Area-1samuel asanteNo ratings yet

- Materials Management-Final - Participant FileDocument42 pagesMaterials Management-Final - Participant FileAhyaanNo ratings yet

- Good Warehousing Practices (GWP)Document36 pagesGood Warehousing Practices (GWP)erikaoktavianipurba100% (1)

- Warehouse and Inventory ManagementDocument74 pagesWarehouse and Inventory ManagementAna Gianelli D. Villanueva0% (1)

- Method of Statement MS.01 Clay Tiles Works: Revision HistoryDocument6 pagesMethod of Statement MS.01 Clay Tiles Works: Revision HistoryAhmed MohamedNo ratings yet

- Amte 415 - Lesson 6 (New)Document43 pagesAmte 415 - Lesson 6 (New)Joshua Kevin GaleraNo ratings yet

- SC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTDocument20 pagesSC 401 Lecture 03-1 CONSTRUCTION SITE LAYOUTJoseph BaruhiyeNo ratings yet

- Site Works: Ce151P Building Systems Engineering Scege Mapua UniversityDocument33 pagesSite Works: Ce151P Building Systems Engineering Scege Mapua UniversityOmen JettNo ratings yet

- Site LayoutDocument13 pagesSite LayoutAzrulZamriNo ratings yet

- Chapter 1Document12 pagesChapter 1Emmanuel NamkumbeNo ratings yet

- DX SplitDocument29 pagesDX Splitsiva_nagesh_2No ratings yet

- Topic 1: Construction Materials Management and ControlDocument33 pagesTopic 1: Construction Materials Management and Controlumie772003100% (1)

- Commissioning Chilled Water TES Tank Systems: Technical FeatureDocument10 pagesCommissioning Chilled Water TES Tank Systems: Technical FeatureJuan Fernando AriasNo ratings yet

- Chapter ShutdownDocument31 pagesChapter ShutdownhaiqalNo ratings yet

- Mos - Installation of MDB, SMDB & DBDocument25 pagesMos - Installation of MDB, SMDB & DBMohamed shabeebNo ratings yet

- Sec03 - Duties and ResponsibilitiesDocument11 pagesSec03 - Duties and ResponsibilitiesYusufNo ratings yet

- Sagana Narrative Description of Site OrganisationDocument7 pagesSagana Narrative Description of Site OrganisationValerie Rose DiboNo ratings yet

- For PreservationDocument7 pagesFor PreservationnoelNo ratings yet

- Points: A-Plant Location and Site SelectionDocument13 pagesPoints: A-Plant Location and Site SelectionAnnyessienNo ratings yet

- Financial Report: Educ 206 School FinanceDocument20 pagesFinancial Report: Educ 206 School FinanceLibrea LemuelNo ratings yet

- Stores Management Objective & Service: Objective - To Provide The Service To Production or Operating Functions. ServicesDocument72 pagesStores Management Objective & Service: Objective - To Provide The Service To Production or Operating Functions. ServicesShashikant Kari100% (1)

- Msra For False CeilingDocument23 pagesMsra For False Ceilinga63150256No ratings yet

- Aterial Oordination: Material Coordination 67Document3 pagesAterial Oordination: Material Coordination 67COE201No ratings yet

- Metherd Statement For Wiring & Cable-R0Document11 pagesMetherd Statement For Wiring & Cable-R0Ahmad Saqqa100% (1)

- Department of Building Technology KnustDocument37 pagesDepartment of Building Technology Knustjuliusosei40No ratings yet

- Construction Process: Content of ChapterDocument16 pagesConstruction Process: Content of ChapterbhattadivyadevvNo ratings yet

- Site Organization OutlineDocument3 pagesSite Organization OutlinealomartaylorNo ratings yet

- Scope of Works-TSF Ore Rehandling To ROM PadDocument6 pagesScope of Works-TSF Ore Rehandling To ROM Padgeorgesways247No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 01600-1 Materials and EquipmentDocument4 pagesITCC in Riyadh Residential Complex J10-13300 01600-1 Materials and EquipmentuddinnadeemNo ratings yet

- Scope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantDocument3 pagesScope of Work PR 2500366866 - 363-RM1 VRM Int. Repairs & False Air Cor - HPHI - La Union PlantJuancho PaduaNo ratings yet

- 2018-01-27 Architectural Technical SpecsDocument55 pages2018-01-27 Architectural Technical SpecsJake Benliro100% (1)

- Method of Statement - SCS SystemDocument20 pagesMethod of Statement - SCS SystemashifNo ratings yet

- Tcsp12202r0-Material HandlingDocument13 pagesTcsp12202r0-Material HandlingAamir ChaudharyNo ratings yet

- Dr. Najuma Abdul Razack Assistant Professor Department of Chemical Engineering NIT CalicutDocument39 pagesDr. Najuma Abdul Razack Assistant Professor Department of Chemical Engineering NIT CalicutAjeshSurejanNo ratings yet

- Ms 103 EarthworksDocument8 pagesMs 103 EarthworksMaddala Srinivasa Rao100% (1)

- 1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15Document8 pages1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15NirmalKumarSelvarajNo ratings yet

- CH 11 Maintenance and RepairDocument18 pagesCH 11 Maintenance and RepairRiyadh SalehNo ratings yet

- 2 ND Part of PDPEDocument43 pages2 ND Part of PDPEIndresh BharadwajNo ratings yet

- CH 6 Facilities LayoutDocument12 pagesCH 6 Facilities LayoutChernet TeferaNo ratings yet

- Construction EquipmentDocument194 pagesConstruction EquipmentSaud Affan100% (3)

- Testing & Commissioning of CCTV System R0Document15 pagesTesting & Commissioning of CCTV System R0vipinkmlNo ratings yet

- SOP DuctingDocument4 pagesSOP DuctingvoraitcehsNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

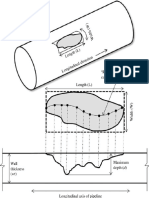

- Dimensions of A Typical Corrosion Defect On PipelineDocument1 pageDimensions of A Typical Corrosion Defect On PipelineMahmoud AlwasifNo ratings yet

- Heat Treatment of Steel: Assessment Performance CriteriaDocument6 pagesHeat Treatment of Steel: Assessment Performance CriteriaMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Failure Analysis ReportDocument1 pageEngineering Encyclopedia: Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Objectives of A Consulting Services Failure Analysis ReportDocument1 pageObjectives of A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Metallic Communications CableDocument45 pagesEngineering Encyclopedia: Metallic Communications CableMahmoud AlwasifNo ratings yet

- Basis For The Recommendations in A Consulting Services Failure Analysis ReportDocument1 pageBasis For The Recommendations in A Consulting Services Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pageEngineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Pages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportDocument1 pagePages: Engineering Encyclopedia Materials & Corrosion Control Failure Analysis ReportMahmoud AlwasifNo ratings yet

- Applying The Recommendations of A Failure Analysis Report To Prevent Future FailuresDocument1 pageApplying The Recommendations of A Failure Analysis Report To Prevent Future FailuresMahmoud AlwasifNo ratings yet

- Engineering Encyclopedia Project Management Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia Project Management Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Procurement Responsibility: Consideration in Successful Materials ProcurementDocument3 pagesProcurement Responsibility: Consideration in Successful Materials ProcurementMahmoud Alwasif100% (1)

- Standard-WPS-AWS-B2-1-1-1-016-94-pdf 16 PDFDocument1 pageStandard-WPS-AWS-B2-1-1-1-016-94-pdf 16 PDFMahmoud AlwasifNo ratings yet

- MT-Procedure 7Document1 pageMT-Procedure 7Mahmoud AlwasifNo ratings yet

- Engineering Encyclopedia: Managing Materials During ConstructionDocument4 pagesEngineering Encyclopedia: Managing Materials During ConstructionMahmoud AlwasifNo ratings yet

- Standard-WPS-AWS-B2-1-1-1-016-94-pdf 8 PDFDocument1 pageStandard-WPS-AWS-B2-1-1-1-016-94-pdf 8 PDFMahmoud AlwasifNo ratings yet

- MT-Procedure 8Document1 pageMT-Procedure 8Mahmoud AlwasifNo ratings yet

- Demand Management, S & OP: Firdauf Achmad Dhewata, ST, MTDocument18 pagesDemand Management, S & OP: Firdauf Achmad Dhewata, ST, MTMaya SariNo ratings yet

- Module 4 InventoryDocument14 pagesModule 4 InventoryKim JisooNo ratings yet

- AIS Chapter 4 Revenue CycleDocument6 pagesAIS Chapter 4 Revenue CycleKate Alvarez100% (1)

- Mohamed Adel Resume CMA p1-2Document3 pagesMohamed Adel Resume CMA p1-2saiporgNo ratings yet

- Gon Bops 30th Anniversary CatalogDocument8 pagesGon Bops 30th Anniversary Catalogvxla100% (1)

- Abcm 1250 Thermal Cutting CopingDocument3 pagesAbcm 1250 Thermal Cutting CopingJose Luis AtaullucoNo ratings yet

- Cost of Good Sold StatementDocument10 pagesCost of Good Sold Statementumar jilaniNo ratings yet

- 06 Inventories and Long-Lived AssetsDocument40 pages06 Inventories and Long-Lived AssetsVan Le HaNo ratings yet

- Bacostmx-3tay2021-Quiz 1Document10 pagesBacostmx-3tay2021-Quiz 1Marjorie Nepomuceno100% (1)

- Acct 203 - CH 6 DqsDocument2 pagesAcct 203 - CH 6 Dqsapi-340301334100% (1)

- Export Processing (Proof of Concept)Document17 pagesExport Processing (Proof of Concept)Geo PerezNo ratings yet

- Assignment Dec 5Document5 pagesAssignment Dec 5Veronica BaileyNo ratings yet

- Inventory Management and Risk PoolingDocument15 pagesInventory Management and Risk PoolingsttamimNo ratings yet

- Partnership FormationDocument3 pagesPartnership Formationmiss independent100% (1)

- Production Planning & ControlDocument2 pagesProduction Planning & ControlJobin AbrahamNo ratings yet

- Chapter 11-Expanded Analysis: Multiple ChoiceDocument17 pagesChapter 11-Expanded Analysis: Multiple ChoiceAsma JamshaidNo ratings yet

- Solved The Following Selected Information Is Presented For Okanagan Corporation ForDocument1 pageSolved The Following Selected Information Is Presented For Okanagan Corporation ForAnbu jaromiaNo ratings yet

- InventryDocument32 pagesInventryjaszuNo ratings yet

- B 1. An Equivalent Unit of Material or Conversion Cost Is Equal ToDocument4 pagesB 1. An Equivalent Unit of Material or Conversion Cost Is Equal ToKATHRYN CLAUDETTE RESENTENo ratings yet

- LAN Based Assessment and Billing System For CamilingDocument2 pagesLAN Based Assessment and Billing System For CamilingBlessie MercadoNo ratings yet

- 05 - Quiz - 1 LOgisticsDocument2 pages05 - Quiz - 1 LOgisticsRobin LusabioNo ratings yet

- Financial Statements As A Management ToolDocument20 pagesFinancial Statements As A Management TooldavidimolaNo ratings yet

- List of SAP MM Transaction CodesDocument3 pagesList of SAP MM Transaction Codesroshan_krNo ratings yet

- Tandon Committee PresentationDocument13 pagesTandon Committee PresentationNitharshini Kannan0% (1)

- Ril Inventory MGMTDocument54 pagesRil Inventory MGMTanimesh88No ratings yet

- Chapter 8 Quiz Answer KeyDocument3 pagesChapter 8 Quiz Answer KeySarah Marie LaytonNo ratings yet

- 8567Document9 pages8567SyedNo ratings yet

- Job OrderDocument7 pagesJob OrderShannon Mojica100% (2)

- Chapter One Accounting For Inventories DefinitionDocument14 pagesChapter One Accounting For Inventories Definitionseneshaw tibebuNo ratings yet