Professional Documents

Culture Documents

Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5

Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5

Uploaded by

SameerChauhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5

Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5

Uploaded by

SameerChauhanCopyright:

Available Formats

www.gatehelp.

com

CHAP 10 MANUFACTURING ENGINEERING PAGE 441

(A) 50.37 (B) 60.37

(C) 70.37 (D) 80.37

MCQ 10.68 In open-die forging, disc of diameter 200 mm and height 60 mm is compressed

without any barreling effect. The final diameter of the disc is 400 mm. The

true strain is

(A) 1.986 (B) 1.686

(C) 1.386 (D) 0.602

MCQ 10.69 The thickness of a metallic sheet is reduced from an initial value of 16 mm

to a final value of 10 mm in one single pass rolling with a pair of cylindrical

rollers each of diameter of 400 mm. The bite angle in degree will be.

(A) 5.936 (B) 7.936

(C) 8.936 (D) 9.936

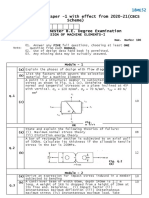

MCQ 10.70 Match the correct combination for following metal working processes.

Processes Associated state of stress

P: Blanking 1. Tension

Q: Stretch Forming 2. Compression

R: Coining 3. Shear

S: Deep Drawing 4. Tension and Compression

5. Tension and Shear

(A) P - 2, Q - 1, R - 3, S - 4

(B) P - 3, Q - 4, R - 1, S - 5

(C) P - 5, Q - 4, R - 3, S - 1

(D) P - 3, Q - 1, R - 2, S - 4

MCQ 10.71 The force requirement in a blanking operation of low carbon steel sheet is

5.0 kN. The thickness of the sheet is ‘t ’ and diameter of the blanked part

is ‘d ’. For the same work material, if the diameter of the blanked part is

increased to 1.5d and thickness is reduced to 0.4t , the new blanking force

in kN is

(A) 3.0 (B) 4.5

(C) 5.0 (D) 8.0

MCQ 10.72 A 200 mm long down sprue has an area of cross-section of 650 mm2 where

the pouring basin meets the down sprue (i.e at the beginning of the down

sprue). A constant head of molten metal is maintained by the pouring basin.

The molten metal flow rate is 6.5 # 105 mm3 /s . Considering the end of

down sprue to be open to atmosphere and an acceleration due to gravity

GATE Previous Year Solved Paper For Mechanical Engineering

Published by: NODIA and COMPANY ISBN: 9788192276250

Visit us at: www.nodia.co.in

You might also like

- Asme B107.1-2002Document26 pagesAsme B107.1-2002PunkR0ckz100% (1)

- Mech 2Document82 pagesMech 2Erwin100% (1)

- Advanced Welding Techniques in Ship ManufacturingDocument15 pagesAdvanced Welding Techniques in Ship Manufacturingmadhan_kumar2000No ratings yet

- Gate Solved Paper - Me: Manufacturing EngineeringDocument72 pagesGate Solved Paper - Me: Manufacturing EngineeringVHemendra NaiduNo ratings yet

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalNo ratings yet

- Metal Forming ME GATE 2020 Previous Year With Ans KeyDocument9 pagesMetal Forming ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- Manufacturing Engineering-4Document1 pageManufacturing Engineering-4SameerChauhanNo ratings yet

- 103 Manufacturing Engineering PDFDocument73 pages103 Manufacturing Engineering PDFSushil Kumar Singh100% (1)

- Manufacturing Engineering-18Document1 pageManufacturing Engineering-18SameerChauhanNo ratings yet

- ME Manufacturing-Engineering PDFDocument73 pagesME Manufacturing-Engineering PDFpankajNo ratings yet

- Objective QuestionsDocument73 pagesObjective QuestionsRajesh ShahNo ratings yet

- ManengDocument88 pagesManengArvind MeenaNo ratings yet

- Manufacturing EngineeringDocument88 pagesManufacturing EngineeringSreevathsaNo ratings yet

- 175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inDocument1 page175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Machine Design: 10 MM 30 MM 94 MpaDocument38 pagesMachine Design: 10 MM 30 MM 94 MpaSreevathsaNo ratings yet

- Manufacturing Engineering-16Document1 pageManufacturing Engineering-16SameerChauhanNo ratings yet

- Manufacturing Engineering-10 PDFDocument1 pageManufacturing Engineering-10 PDFSameerChauhanNo ratings yet

- Sheet Metal Operations ME GATE 2020 Previous Year With Ans KeyDocument4 pagesSheet Metal Operations ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- Production Test PaperDocument9 pagesProduction Test Paperfaheemhaider21No ratings yet

- 3 MM 2 MM: Visit Us At: WWW - Nodia.co - inDocument1 page3 MM 2 MM: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Machine DesignDocument38 pagesMachine DesignBanwari Lal PrajapatNo ratings yet

- MF & SMO 14th SEP 2022 WTMDocument60 pagesMF & SMO 14th SEP 2022 WTMDeepak KumarNo ratings yet

- Design SCCDocument14 pagesDesign SCCdhruvNo ratings yet

- SDocument16 pagesSKumar KoteNo ratings yet

- Sheet Metal Operation Figures and Q A For StudentsDocument15 pagesSheet Metal Operation Figures and Q A For StudentsRavinder Antil75% (4)

- R K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDocument214 pagesR K Konodia Civil Gate Previous Year - by EasyEngineering - Net 1 PDFDaante VermaNo ratings yet

- Machine DataDocument38 pagesMachine DataEr Mahavir MiyatraNo ratings yet

- Forming E BookDocument22 pagesForming E BookunitybeginsathomeNo ratings yet

- Machine DesignDocument38 pagesMachine Designdeepti412No ratings yet

- Emm 302 Solid and Structural Mechanics 1Document4 pagesEmm 302 Solid and Structural Mechanics 1anniemusyimiNo ratings yet

- Sethu Institute of Technology: Part A (1 Mark)Document15 pagesSethu Institute of Technology: Part A (1 Mark)Deepak KumarNo ratings yet

- Machine Design Questions PDFDocument5 pagesMachine Design Questions PDFrajibNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet

- Zsteel Design Practice Problems With Ans KeyDocument4 pagesZsteel Design Practice Problems With Ans Keyjj012586No ratings yet

- MCQDocument43 pagesMCQBansal RajNeesh67% (6)

- TYPE A - Real Time Quiz End Semester Examination - ME331Document7 pagesTYPE A - Real Time Quiz End Semester Examination - ME331Selvi RNo ratings yet

- Manufacturing Engineering-13Document1 pageManufacturing Engineering-13SameerChauhanNo ratings yet

- Week 4 Assignment 4 Full Marks 16Document3 pagesWeek 4 Assignment 4 Full Marks 16amin alzuraiki0% (1)

- Material Properties and Metal FormingDocument5 pagesMaterial Properties and Metal FormingSaikat BanerjeeNo ratings yet

- Taller No 2 Resistencia I 2013BDocument4 pagesTaller No 2 Resistencia I 2013BAsep Bin UjangNo ratings yet

- Previous Years GATE Questions Sub: Production Technology (Welding)Document12 pagesPrevious Years GATE Questions Sub: Production Technology (Welding)KAUSTUB CHAUHANNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- EsdDocument3 pagesEsdHrishikesh BhavsarNo ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Model Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationDocument10 pagesModel Question Paper - 1 With Effect From 2020-21 (CBCS Scheme) Fifth Semester B.E. Degree ExaminationSharath KotegarNo ratings yet

- Assignment 6 QuestionDocument4 pagesAssignment 6 Questionamin alzuraikiNo ratings yet

- QP FinalDocument2 pagesQP Finalpadmagayathri39No ratings yet

- Calculation of Moments and Shear: Input DataDocument3 pagesCalculation of Moments and Shear: Input DataARSENo ratings yet

- Gujarat Technological UniversityDocument4 pagesGujarat Technological Universitythe grayNo ratings yet

- Btech Me 6 Sem Machine Design Kme602 2022Document3 pagesBtech Me 6 Sem Machine Design Kme602 2022thunderstorm8853No ratings yet

- Manufacturing Engineering-28 PDFDocument1 pageManufacturing Engineering-28 PDFSameerChauhanNo ratings yet

- Distribution, Transmission Systems and Design-QuestionsDocument7 pagesDistribution, Transmission Systems and Design-QuestionsRaimundoNo ratings yet

- List-I (Equipment) List-II (Process) P. 1. Q. 2. R. 3. S. 4. 5Document1 pageList-I (Equipment) List-II (Process) P. 1. Q. 2. R. 3. S. 4. 5SameerChauhanNo ratings yet

- MOM OU Old Question PaperDocument2 pagesMOM OU Old Question PaperAmmineni Syam PrasadNo ratings yet

- Exam Sheet MetalDocument19 pagesExam Sheet MetalIbraheem SabryNo ratings yet

- MME291 TermFinalQues 09-15Document20 pagesMME291 TermFinalQues 09-15behind mirrorNo ratings yet

- 10 Welded JointsDocument20 pages10 Welded JointsROHAN PILLAINo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Processes Associated State of Stress P. 3. Q. 1. R. 2. S. 4Document1 pageProcesses Associated State of Stress P. 3. Q. 1. R. 2. S. 4SameerChauhanNo ratings yet

- F D T D T: Visit Us At: WWW - Nodia.co - inDocument1 pageF D T D T: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-54Document1 pageManufacturing Engineering-54SameerChauhanNo ratings yet

- Manufacturing Engineering-45Document1 pageManufacturing Engineering-45SameerChauhanNo ratings yet

- Manufacturing Engineering-53Document1 pageManufacturing Engineering-53SameerChauhanNo ratings yet

- Manufacturing Engineering-52Document1 pageManufacturing Engineering-52SameerChauhanNo ratings yet

- Manufacturing Engineering-55Document1 pageManufacturing Engineering-55SameerChauhanNo ratings yet

- For Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inDocument1 pageFor Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-46Document1 pageManufacturing Engineering-46SameerChauhanNo ratings yet

- Column I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inDocument1 pageColumn I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-51Document1 pageManufacturing Engineering-51SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- A N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inDocument1 pageA N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-48Document1 pageManufacturing Engineering-48SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- α 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1Document1 pageα 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1SameerChauhanNo ratings yet

- ADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inDocument1 pageADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet

- Manufacturing Engineering-38Document1 pageManufacturing Engineering-38SameerChauhanNo ratings yet

- 175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inDocument1 page175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-40Document1 pageManufacturing Engineering-40SameerChauhanNo ratings yet

- Solution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveDocument1 pageSolution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveSameerChauhanNo ratings yet

- Manufacturing Engineering-31 PDFDocument1 pageManufacturing Engineering-31 PDFSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-34Document1 pageManufacturing Engineering-34SameerChauhanNo ratings yet

- Manufacturing Engineering-29 PDFDocument1 pageManufacturing Engineering-29 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-28 PDFDocument1 pageManufacturing Engineering-28 PDFSameerChauhanNo ratings yet

- Mechanical Working of MetalsDocument76 pagesMechanical Working of MetalsPradip GuptaNo ratings yet

- Primary Shaping ProcessDocument51 pagesPrimary Shaping ProcessHar Quin50% (2)

- Katalog Elevator Lift #Rev1Document19 pagesKatalog Elevator Lift #Rev1Wataru Ardhy MizunoNo ratings yet

- ch08 - Metal CastingDocument108 pagesch08 - Metal Castingarju antonyNo ratings yet

- How To Repair A Plastic BumperDocument2 pagesHow To Repair A Plastic BumperJen AkersNo ratings yet

- Runners and GatesDocument35 pagesRunners and Gatesbjdavies2010100% (2)

- The Line Boring MachineDocument22 pagesThe Line Boring MachineJinky L. LavegaNo ratings yet

- Auto Clips and Fasteners 2014.original PDFDocument1 pageAuto Clips and Fasteners 2014.original PDFdletica_1No ratings yet

- Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Document2 pagesWelding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Erick HoganNo ratings yet

- Wharf LadderDocument11 pagesWharf LadderAnandNo ratings yet

- Bolt Design and Embedment Length CheckDocument6 pagesBolt Design and Embedment Length CheckHarish M PNo ratings yet

- Lindapter Type f3 DatasheetDocument1 pageLindapter Type f3 DatasheetTarun SharmaNo ratings yet

- Port DrawingsDocument6 pagesPort DrawingsAbobrinhaestrgadaNo ratings yet

- Drawing Auto Cleaner Caster WheelDocument3 pagesDrawing Auto Cleaner Caster Wheelera chaolongNo ratings yet

- BS en ISO 5457 Drawing Sheet SizesDocument2 pagesBS en ISO 5457 Drawing Sheet SizesSai CharanNo ratings yet

- Production Engineering by SKMondalDocument201 pagesProduction Engineering by SKMondalavimam129100% (3)

- US5457886Document9 pagesUS5457886aungkyawzoreNo ratings yet

- Company Profile SCMA 2023Document12 pagesCompany Profile SCMA 2023Herman BrandonNo ratings yet

- 3.2 S-MS, S-MD Z en - AutoperforantesDocument52 pages3.2 S-MS, S-MD Z en - AutoperforantescanocarloNo ratings yet

- Astm F 2329Document5 pagesAstm F 2329haharameshNo ratings yet

- Lecture Cad CamDocument84 pagesLecture Cad Camismail_69No ratings yet

- Manufacturing Engineering: Basics of Manufacturing EngineeringDocument3 pagesManufacturing Engineering: Basics of Manufacturing EngineeringPrincess GinezNo ratings yet

- ME3493_Manufacturing TechnologyDocument10 pagesME3493_Manufacturing TechnologySriram SrinivasanNo ratings yet

- Bolt Torque Specifications: Maintenance MinuteDocument2 pagesBolt Torque Specifications: Maintenance MinuteJamil AlsalemNo ratings yet

- Adapter SleeveDocument7 pagesAdapter SleeveAdrian GarciaNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- National Pipe Thread Chart OPT P PDFDocument1 pageNational Pipe Thread Chart OPT P PDFRoselio MayoNo ratings yet

- Fixture (Tool) - Wikipedia, The Free EncyclopediaDocument4 pagesFixture (Tool) - Wikipedia, The Free Encyclopediaचन्दनप्रसादNo ratings yet