Professional Documents

Culture Documents

Manufacturing Engineering-16

Manufacturing Engineering-16

Uploaded by

SameerChauhanCopyright:

Available Formats

You might also like

- Objective QuestionsDocument73 pagesObjective QuestionsRajesh ShahNo ratings yet

- ME Manufacturing-Engineering PDFDocument73 pagesME Manufacturing-Engineering PDFpankajNo ratings yet

- Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5Document1 pageProcesses Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5SameerChauhanNo ratings yet

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalNo ratings yet

- Gate Solved Paper - Me: Manufacturing EngineeringDocument72 pagesGate Solved Paper - Me: Manufacturing EngineeringVHemendra NaiduNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet

- 103 Manufacturing Engineering PDFDocument73 pages103 Manufacturing Engineering PDFSushil Kumar Singh100% (1)

- Metal Forming ME GATE 2020 Previous Year With Ans KeyDocument9 pagesMetal Forming ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- 114 PDFDocument73 pages114 PDFMonu SharmaNo ratings yet

- Manufacturing Engineering-13Document1 pageManufacturing Engineering-13SameerChauhanNo ratings yet

- Manufacturing Engineering-4Document1 pageManufacturing Engineering-4SameerChauhanNo ratings yet

- Production Test PaperDocument9 pagesProduction Test Paperfaheemhaider21No ratings yet

- Operation Process P. 1. Q. 2. R. 3. S. 4. 5. 6.: Visit Us At: WWW - Nodia.co - inDocument1 pageOperation Process P. 1. Q. 2. R. 3. S. 4. 5. 6.: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- 2022-May ME-322 109Document2 pages2022-May ME-322 109Sidhant SadyalNo ratings yet

- Manufacturing EngineeringDocument88 pagesManufacturing EngineeringSreevathsaNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- Force Power in Metal CuttingDocument7 pagesForce Power in Metal CuttingRavinder AntilNo ratings yet

- 2.2 Force, Power in Metal Cutting Q&A For StudentDocument7 pages2.2 Force, Power in Metal Cutting Q&A For StudentnikhilbathamNo ratings yet

- Reound Hardness TesterDocument3 pagesReound Hardness TesterpoongodiskNo ratings yet

- ManengDocument88 pagesManengArvind MeenaNo ratings yet

- Effect of Heat Treatneb Processes On Ductil Cast Iron Mechanical PropertiesDocument6 pagesEffect of Heat Treatneb Processes On Ductil Cast Iron Mechanical Properties2022353017No ratings yet

- ME204Document2 pagesME204raja93satNo ratings yet

- Modern Machining ProcessesDocument4 pagesModern Machining ProcessesGangadhar TallaNo ratings yet

- 3 MM 2 MM: Visit Us At: WWW - Nodia.co - inDocument1 page3 MM 2 MM: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Manufacturing Engineering-19Document1 pageManufacturing Engineering-19SameerChauhanNo ratings yet

- Qin 2020 J. Phys. Conf. Ser. 1681 012012Document6 pagesQin 2020 J. Phys. Conf. Ser. 1681 012012Taner DemirelNo ratings yet

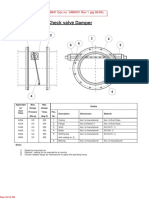

- 2 Check Type Damper Drawing 1555074039Document1 page2 Check Type Damper Drawing 1555074039Gohilakrishnan ThiagarajanNo ratings yet

- Iconn 2022Document16 pagesIconn 2022Mahendra SinghNo ratings yet

- Metal Cutting QuestionsDocument65 pagesMetal Cutting QuestionsPratik DhandeNo ratings yet

- Dongil SteelDocument5 pagesDongil SteelJoseph DixonNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Lathe: by S K MondalDocument70 pagesLathe: by S K MondalAMIT KUMAR PANDEYNo ratings yet

- Manufacturing Engineering-26Document1 pageManufacturing Engineering-26SameerChauhanNo ratings yet

- 2 67 1587621735 6ijmperdjun20206Document10 pages2 67 1587621735 6ijmperdjun20206TJPRC PublicationsNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Cutting Performance of CBN and Diamond Tools in DryDocument11 pagesCutting Performance of CBN and Diamond Tools in Dryznovak77No ratings yet

- NS2-YR02-P0BAU-140001 Technical Specification - Earthing and Lightning Protection R.0Document46 pagesNS2-YR02-P0BAU-140001 Technical Specification - Earthing and Lightning Protection R.0Quang LuongNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- PDF MEC3102 Tutorial No 1-ASSIGMENT 1Document4 pagesPDF MEC3102 Tutorial No 1-ASSIGMENT 1Beckham ChaileNo ratings yet

- BhattacharyyDocument13 pagesBhattacharyyRenata LisboaNo ratings yet

- 2.1 Theory of Metal Cutting Q&A For StudentDocument8 pages2.1 Theory of Metal Cutting Q&A For Studentnikhilbatham0% (1)

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- A Laser Beam Machining LBM Database For The CuttinDocument10 pagesA Laser Beam Machining LBM Database For The CuttinajaythermalNo ratings yet

- High-Speed Milling Dies and Molds in Their Hardened State: Annals of The CLRP Vol. 46/1/1997Document6 pagesHigh-Speed Milling Dies and Molds in Their Hardened State: Annals of The CLRP Vol. 46/1/1997السيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Guidance For Propeller Blade Welding RepDocument2 pagesGuidance For Propeller Blade Welding RepBharat VermaNo ratings yet

- Production Prepartion ProjectDocument9 pagesProduction Prepartion Projectpiu bangbangNo ratings yet

- 2 1 Theory of Metal Cutting Q A For StudentDocument8 pages2 1 Theory of Metal Cutting Q A For Studentmyidprince100% (2)

- HW 8 Non Traditional Machining Ch26Document2 pagesHW 8 Non Traditional Machining Ch26BobNo ratings yet

- High Carbon Steel Wire PDFDocument4 pagesHigh Carbon Steel Wire PDFChaitanya ShakyaNo ratings yet

- GTP - Acsr WeaselDocument2 pagesGTP - Acsr WeaselBhagawati Prasad SharmaNo ratings yet

- Question Bank Set - 2 PDFDocument69 pagesQuestion Bank Set - 2 PDFsayhigaurav07No ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Manufacturing Engineering-52Document1 pageManufacturing Engineering-52SameerChauhanNo ratings yet

- Manufacturing Engineering-53Document1 pageManufacturing Engineering-53SameerChauhanNo ratings yet

- F D T D T: Visit Us At: WWW - Nodia.co - inDocument1 pageF D T D T: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Processes Associated State of Stress P. 3. Q. 1. R. 2. S. 4Document1 pageProcesses Associated State of Stress P. 3. Q. 1. R. 2. S. 4SameerChauhanNo ratings yet

- Manufacturing Engineering-54Document1 pageManufacturing Engineering-54SameerChauhanNo ratings yet

- Manufacturing Engineering-55Document1 pageManufacturing Engineering-55SameerChauhanNo ratings yet

- Manufacturing Engineering-48Document1 pageManufacturing Engineering-48SameerChauhanNo ratings yet

- Manufacturing Engineering-51Document1 pageManufacturing Engineering-51SameerChauhanNo ratings yet

- For Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inDocument1 pageFor Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Column I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inDocument1 pageColumn I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-45Document1 pageManufacturing Engineering-45SameerChauhanNo ratings yet

- Manufacturing Engineering-40Document1 pageManufacturing Engineering-40SameerChauhanNo ratings yet

- Manufacturing Engineering-46Document1 pageManufacturing Engineering-46SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- ADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inDocument1 pageADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet

- A N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inDocument1 pageA N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- α 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1Document1 pageα 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-38Document1 pageManufacturing Engineering-38SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-28 PDFDocument1 pageManufacturing Engineering-28 PDFSameerChauhanNo ratings yet

- 175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inDocument1 page175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Solution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveDocument1 pageSolution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveSameerChauhanNo ratings yet

- Manufacturing Engineering-31 PDFDocument1 pageManufacturing Engineering-31 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-29 PDFDocument1 pageManufacturing Engineering-29 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-34Document1 pageManufacturing Engineering-34SameerChauhanNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet

Manufacturing Engineering-16

Manufacturing Engineering-16

Uploaded by

SameerChauhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Engineering-16

Manufacturing Engineering-16

Uploaded by

SameerChauhanCopyright:

Available Formats

www.gatehelp.

com

PAGE 442 MANUFACTURING ENGINEERING CHAP 10

of 10 4 mm/s2 , the area of the down sprue in mm2 at its end (avoiding

aspiration effect) should be

(A) 650.0 (B) 350.0

(C) 290.7 (D) 190.0

MCQ 10.73 Match the most suitable manufacturing processes for the following parts.

Parts Manufacturing Process

P. Computer chip 1. Electrochemical Machining

Q. Metal forming dies and molds 2. Ultrasonic Machining

R. Turbine blade 3. Electrodischarge Machining

S. Glass 4. Photochemical Machining

(A) P - 4, Q - 3, R - 1, S - 2

(B) P - 4, Q - 3, R - 2, S - 1

(C) P - 3, Q - 1, R - 4, S - 2

(D) P - 1, Q - 2, R - 4, S - 3

• Common Data For Q. 74 and Q.75

A low carbon steel bar of 147 mm diameter with a length of 630 mm is being

turned with uncoated carbide insert. The observed tool lives are 24 min

and 12 min for cutting velocities of 90 m/min and 120 m/ min. respectively.

The feed and depth of cut are 0.2 mm/rev and 2 mm respectively. Use the

unmachined diameter to calculate the cutting velocity.

GATE Previous Year Solved Paper For Mechanical Engineering

Published by: NODIA and COMPANY ISBN: 9788192276250

Visit us at: www.nodia.co.in

You might also like

- Objective QuestionsDocument73 pagesObjective QuestionsRajesh ShahNo ratings yet

- ME Manufacturing-Engineering PDFDocument73 pagesME Manufacturing-Engineering PDFpankajNo ratings yet

- Processes Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5Document1 pageProcesses Associated State of Stress P: 1. Q: 2. R: 3. S: 4. 5SameerChauhanNo ratings yet

- Manufacturing EngineeringDocument72 pagesManufacturing EngineeringAnirban PalNo ratings yet

- Gate Solved Paper - Me: Manufacturing EngineeringDocument72 pagesGate Solved Paper - Me: Manufacturing EngineeringVHemendra NaiduNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet

- 103 Manufacturing Engineering PDFDocument73 pages103 Manufacturing Engineering PDFSushil Kumar Singh100% (1)

- Metal Forming ME GATE 2020 Previous Year With Ans KeyDocument9 pagesMetal Forming ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- 114 PDFDocument73 pages114 PDFMonu SharmaNo ratings yet

- Manufacturing Engineering-13Document1 pageManufacturing Engineering-13SameerChauhanNo ratings yet

- Manufacturing Engineering-4Document1 pageManufacturing Engineering-4SameerChauhanNo ratings yet

- Production Test PaperDocument9 pagesProduction Test Paperfaheemhaider21No ratings yet

- Operation Process P. 1. Q. 2. R. 3. S. 4. 5. 6.: Visit Us At: WWW - Nodia.co - inDocument1 pageOperation Process P. 1. Q. 2. R. 3. S. 4. 5. 6.: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- 2022-May ME-322 109Document2 pages2022-May ME-322 109Sidhant SadyalNo ratings yet

- Manufacturing EngineeringDocument88 pagesManufacturing EngineeringSreevathsaNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- Force Power in Metal CuttingDocument7 pagesForce Power in Metal CuttingRavinder AntilNo ratings yet

- 2.2 Force, Power in Metal Cutting Q&A For StudentDocument7 pages2.2 Force, Power in Metal Cutting Q&A For StudentnikhilbathamNo ratings yet

- Reound Hardness TesterDocument3 pagesReound Hardness TesterpoongodiskNo ratings yet

- ManengDocument88 pagesManengArvind MeenaNo ratings yet

- Effect of Heat Treatneb Processes On Ductil Cast Iron Mechanical PropertiesDocument6 pagesEffect of Heat Treatneb Processes On Ductil Cast Iron Mechanical Properties2022353017No ratings yet

- ME204Document2 pagesME204raja93satNo ratings yet

- Modern Machining ProcessesDocument4 pagesModern Machining ProcessesGangadhar TallaNo ratings yet

- 3 MM 2 MM: Visit Us At: WWW - Nodia.co - inDocument1 page3 MM 2 MM: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- Compre 15-16 Sem1 With Soln (Charsichoco)Document4 pagesCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghNo ratings yet

- Manufacturing Engineering-19Document1 pageManufacturing Engineering-19SameerChauhanNo ratings yet

- Qin 2020 J. Phys. Conf. Ser. 1681 012012Document6 pagesQin 2020 J. Phys. Conf. Ser. 1681 012012Taner DemirelNo ratings yet

- 2 Check Type Damper Drawing 1555074039Document1 page2 Check Type Damper Drawing 1555074039Gohilakrishnan ThiagarajanNo ratings yet

- Iconn 2022Document16 pagesIconn 2022Mahendra SinghNo ratings yet

- Metal Cutting QuestionsDocument65 pagesMetal Cutting QuestionsPratik DhandeNo ratings yet

- Dongil SteelDocument5 pagesDongil SteelJoseph DixonNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Lathe: by S K MondalDocument70 pagesLathe: by S K MondalAMIT KUMAR PANDEYNo ratings yet

- Manufacturing Engineering-26Document1 pageManufacturing Engineering-26SameerChauhanNo ratings yet

- 2 67 1587621735 6ijmperdjun20206Document10 pages2 67 1587621735 6ijmperdjun20206TJPRC PublicationsNo ratings yet

- 2022-Dec ME-312 53Document2 pages2022-Dec ME-312 53Aakash TiwariNo ratings yet

- Cutting Performance of CBN and Diamond Tools in DryDocument11 pagesCutting Performance of CBN and Diamond Tools in Dryznovak77No ratings yet

- NS2-YR02-P0BAU-140001 Technical Specification - Earthing and Lightning Protection R.0Document46 pagesNS2-YR02-P0BAU-140001 Technical Specification - Earthing and Lightning Protection R.0Quang LuongNo ratings yet

- Question Bank (PPII)Document7 pagesQuestion Bank (PPII)Udaiyar BarathadhithyaNo ratings yet

- PDF MEC3102 Tutorial No 1-ASSIGMENT 1Document4 pagesPDF MEC3102 Tutorial No 1-ASSIGMENT 1Beckham ChaileNo ratings yet

- BhattacharyyDocument13 pagesBhattacharyyRenata LisboaNo ratings yet

- 2.1 Theory of Metal Cutting Q&A For StudentDocument8 pages2.1 Theory of Metal Cutting Q&A For Studentnikhilbatham0% (1)

- Final Exam Key AnswerDocument6 pagesFinal Exam Key Answergirma worku100% (1)

- A Laser Beam Machining LBM Database For The CuttinDocument10 pagesA Laser Beam Machining LBM Database For The CuttinajaythermalNo ratings yet

- High-Speed Milling Dies and Molds in Their Hardened State: Annals of The CLRP Vol. 46/1/1997Document6 pagesHigh-Speed Milling Dies and Molds in Their Hardened State: Annals of The CLRP Vol. 46/1/1997السيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Guidance For Propeller Blade Welding RepDocument2 pagesGuidance For Propeller Blade Welding RepBharat VermaNo ratings yet

- Production Prepartion ProjectDocument9 pagesProduction Prepartion Projectpiu bangbangNo ratings yet

- 2 1 Theory of Metal Cutting Q A For StudentDocument8 pages2 1 Theory of Metal Cutting Q A For Studentmyidprince100% (2)

- HW 8 Non Traditional Machining Ch26Document2 pagesHW 8 Non Traditional Machining Ch26BobNo ratings yet

- High Carbon Steel Wire PDFDocument4 pagesHigh Carbon Steel Wire PDFChaitanya ShakyaNo ratings yet

- GTP - Acsr WeaselDocument2 pagesGTP - Acsr WeaselBhagawati Prasad SharmaNo ratings yet

- Question Bank Set - 2 PDFDocument69 pagesQuestion Bank Set - 2 PDFsayhigaurav07No ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Manufacturing Engineering-52Document1 pageManufacturing Engineering-52SameerChauhanNo ratings yet

- Manufacturing Engineering-53Document1 pageManufacturing Engineering-53SameerChauhanNo ratings yet

- F D T D T: Visit Us At: WWW - Nodia.co - inDocument1 pageF D T D T: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Processes Associated State of Stress P. 3. Q. 1. R. 2. S. 4Document1 pageProcesses Associated State of Stress P. 3. Q. 1. R. 2. S. 4SameerChauhanNo ratings yet

- Manufacturing Engineering-54Document1 pageManufacturing Engineering-54SameerChauhanNo ratings yet

- Manufacturing Engineering-55Document1 pageManufacturing Engineering-55SameerChauhanNo ratings yet

- Manufacturing Engineering-48Document1 pageManufacturing Engineering-48SameerChauhanNo ratings yet

- Manufacturing Engineering-51Document1 pageManufacturing Engineering-51SameerChauhanNo ratings yet

- For Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inDocument1 pageFor Metal: Atomic Weight Valency The Metal Removal Rate: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Column I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inDocument1 pageColumn I Column II P. 4. Q. 1. R. 2. S. 3.: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Manufacturing Engineering-45Document1 pageManufacturing Engineering-45SameerChauhanNo ratings yet

- Manufacturing Engineering-40Document1 pageManufacturing Engineering-40SameerChauhanNo ratings yet

- Manufacturing Engineering-46Document1 pageManufacturing Engineering-46SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- ADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inDocument1 pageADE Δ θ DE x x θ x x Z d x: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet

- A N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inDocument1 pageA N B N VT A VT B VT: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- α 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1Document1 pageα 12c t t φ r r α α t φ φ: Machining process Mechanism of material removal P. 2. Q. 3. R. 4. S. 1SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-38Document1 pageManufacturing Engineering-38SameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Visit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringDocument1 pageVisit Us At: WWW - Nodia.co - In: GATE Previous Year Solved Paper For Mechanical EngineeringSameerChauhanNo ratings yet

- Manufacturing Engineering-28 PDFDocument1 pageManufacturing Engineering-28 PDFSameerChauhanNo ratings yet

- 175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inDocument1 page175 MM 200 MM 200 MM 10 MM 10 / Ms : Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Solution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveDocument1 pageSolution: Metal Forming Process Types of Stress 1. S. Compressive 2. P. Tensile 3. Q. Shear 4. R. Tensile and CompressiveSameerChauhanNo ratings yet

- Manufacturing Engineering-31 PDFDocument1 pageManufacturing Engineering-31 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-29 PDFDocument1 pageManufacturing Engineering-29 PDFSameerChauhanNo ratings yet

- Manufacturing Engineering-34Document1 pageManufacturing Engineering-34SameerChauhanNo ratings yet

- Manufacturing Engineering-30 PDFDocument1 pageManufacturing Engineering-30 PDFSameerChauhanNo ratings yet